This is the amazing collaboration with Esther Perbandt through the Worth Partnership Project. The collection ¨To The Moon“ was presented at Mercedez Benz Fashion Week Berlin where we showcased 3D forms of molded leather. This was a successful and didactic collaboration but the most amazing part of it was working with a professional such as Esther.

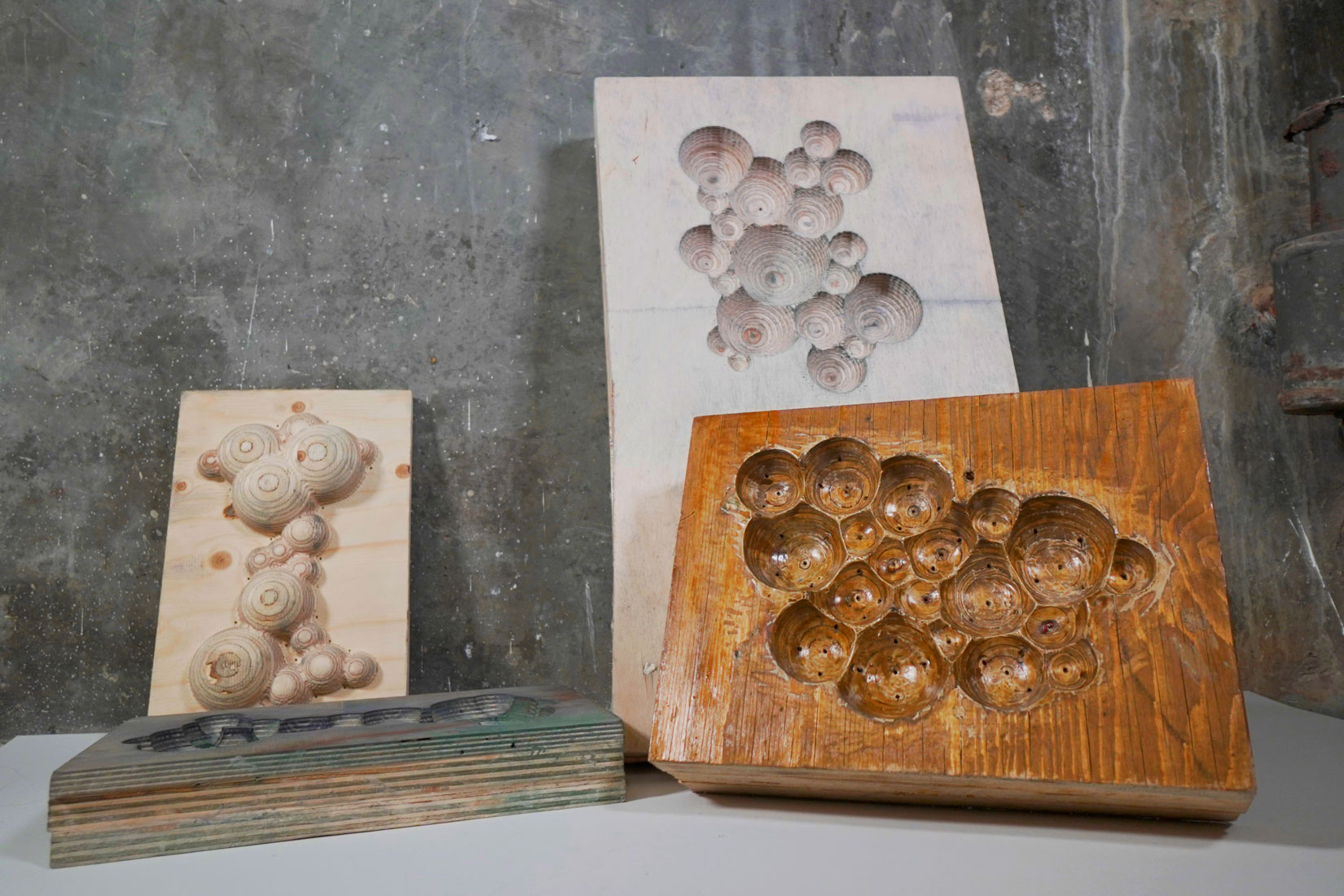

This technique of ¨cuir bouilli¨ in French dates back to the Middle ages for making armor, helmets and other objects for the military and for other functional uses. Leather was considered to be the ¨plastic¨ of the days. It is a traditional craft that due to the petroleum based economy and the automation and mass production is being used less and less and it is a perfect topic for Fab Textiles mission of rescuing traditional craft techniques through new technologies and digital fabrication. Mastering the material was not an easy job!

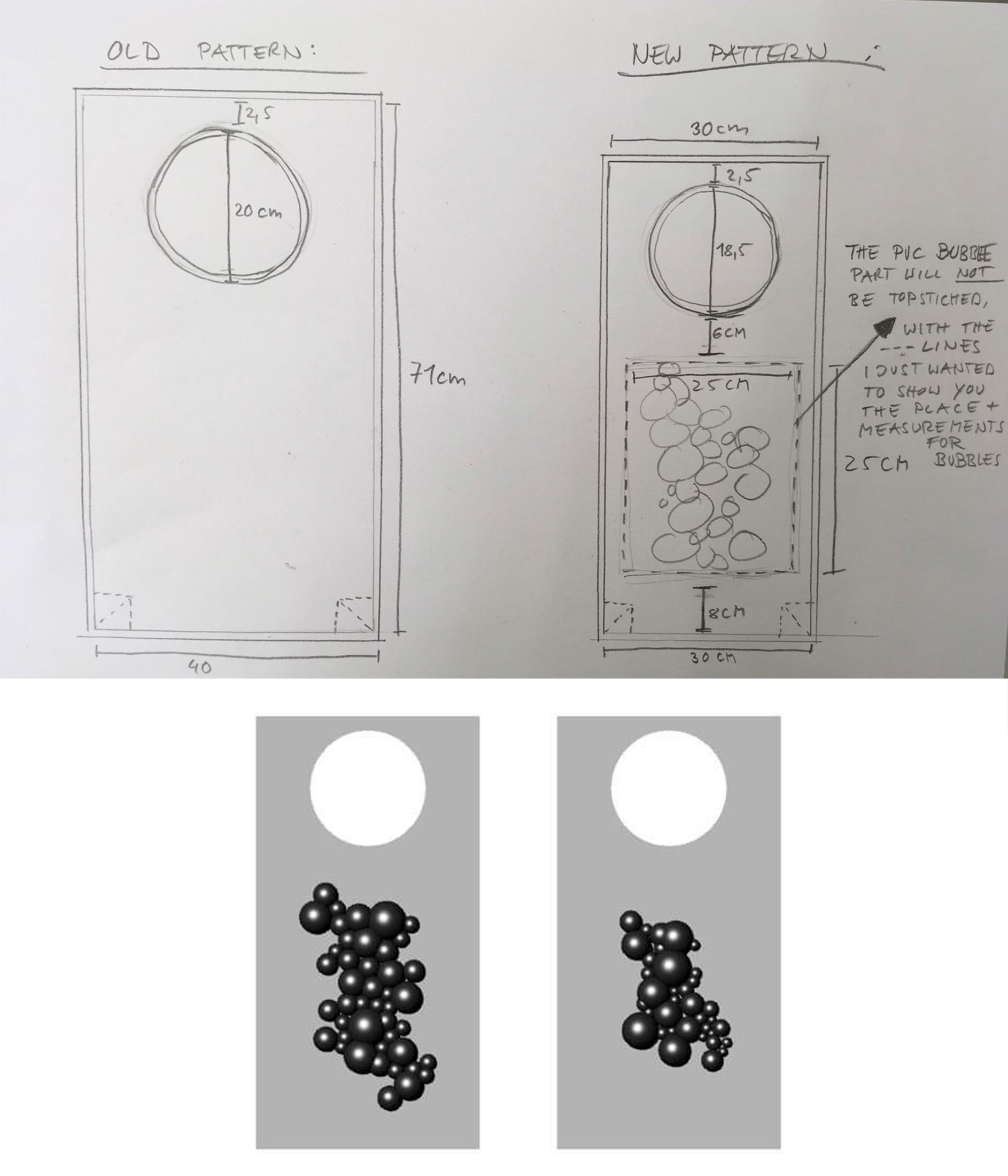

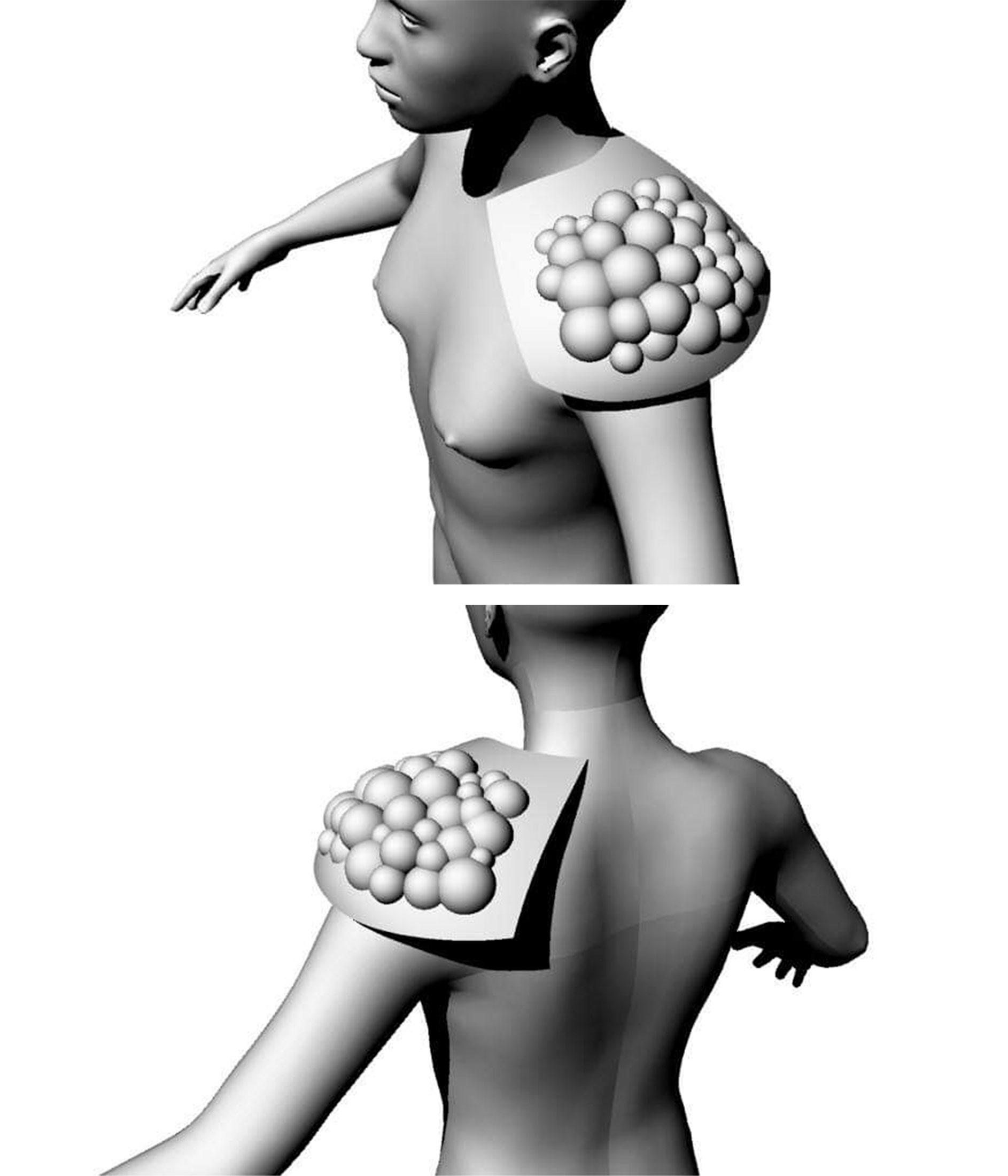

Our collaboration with fashion designers is actually facilitating them to ¨ make their dreams come true ¨. The workflow is quite direct, we receive drawings and sketches and we digitize them through 3D modeling later on digital fabrication.

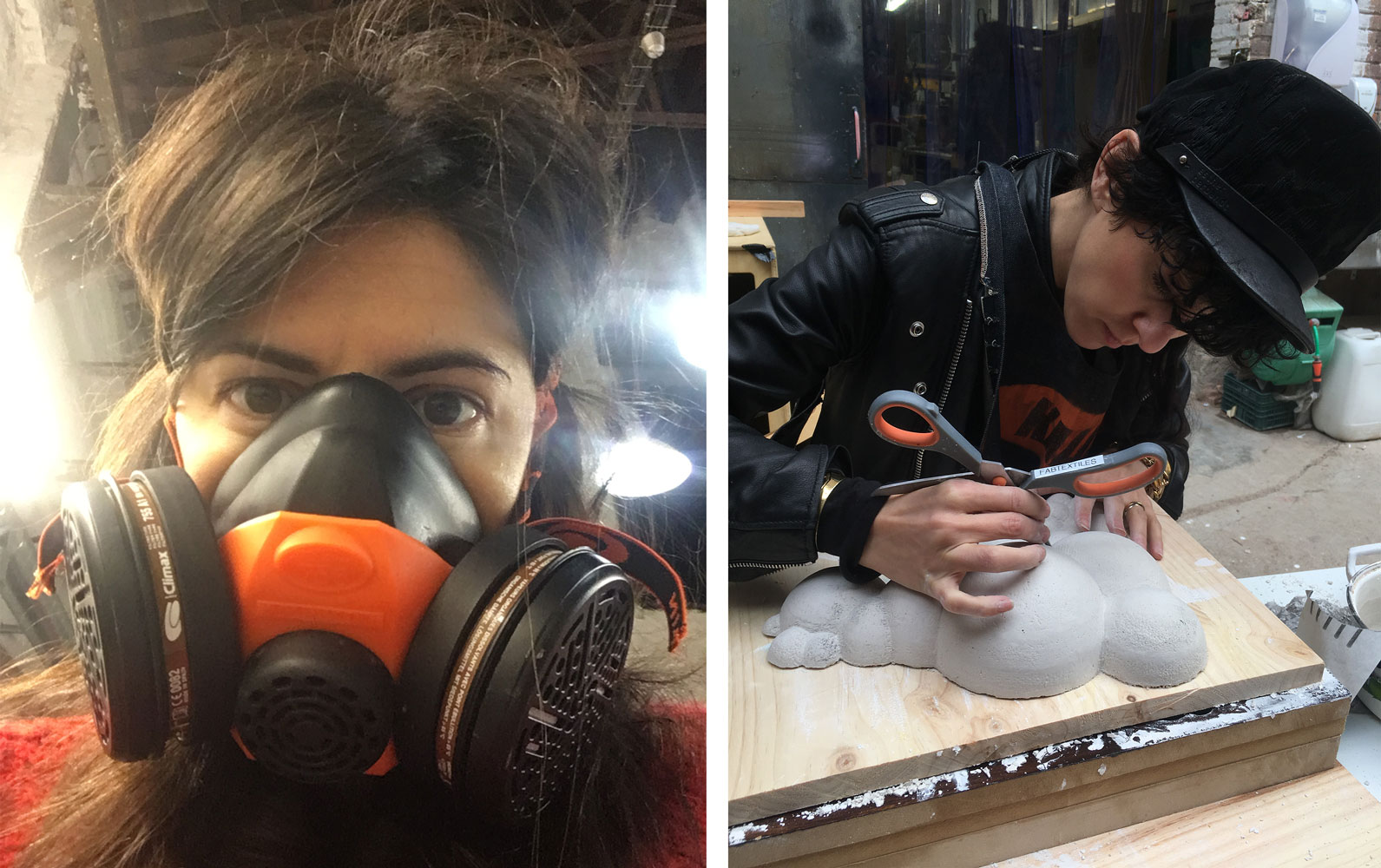

Esther´s proposal initially was to 3D mold recycled PVC from a local Berlin provider she was in contact with. As a circular design idea and converting very low cost waste to up-cycled luxury the project was very promising and coherent. The problem is that PVC is a nasty material and when heated emits hazardous gases that contaminate the environment but also put your own health into risk. Due to the instability of the material and the fact that it should not be heated we concluded that it was inappropriate to work with this technique at the Fab Lab and we changed the project to molding leather technique.We wrote and email to MIT Health and Safety department and they answer was:

MIT's industrial hygiene specialist; he does advise dealing with softening PVC as a hazardous process. 1. PVC plastic start to decompose when the temperature reaches 140 °C, with melting temperature starting around 160 °C. It will release a variety of toxic gases/vapors and odor based on ingredients. 2. They should definitely think about air exchange in the room (probably around 6Ach or more) for controlling the odor 3. They also should think about an local exhaust ventilation which is connected to the house exhaust system. Using fume hoods, canopy hoods, exhausted enclosures and other types of ventilations is recommended. 4. In lack of in-house ventilation, another option is to use the carbon/HEPA filtered fume extractors which adsorb the toxic gases and fumes and don’t need the exhaust drop in building. Check Air Exhaust 5. Using good lab practices in lab/shop work is required like using lab coat, eye protection(goggles) and lab gloves. 6. If they can’t provide enough ventilation in place, they should use respirators with combo cartridge for particles and both organic/inorganic vapors (acid mists). Check Air Purifying Respirators

Initial Research on Recycled PVC heat forming

As complementary accessories to the collection we continue with the organic shapes and use 3d printing for rapid prototyping. The 3D printed pieces where used for metal casting.

Video(https://youtu.be/Szp0HRvj074)

Project Team : Anastasia Pistofidou Nicolas Olmos, Internship at FabTextiles Lab Fanni Huszár, Internship at FabTextiles Lab Photo Credits: Worth Project Team & Fab Lab Barcelona Team