Textiles Academy Bootcamp was an intensive 40h course that took place at IaaC Fab Lab Barcelona with 25 participants from US, Canada, France, Germany, Argentina, Italy, Holland, Chile, Sweden, Greece, England, India and with 20 more participants in the fashion of distributed online education, joining remotely from Wellington, Santiago de Chile, Amsterdam, Seoul, Kamp Lintfort, Leon, Madrid, Lima, Limerick.

Participants from all over the world gathered in Fab Lab Barcelona to attend the bootcamp, it was great to see many friends and to meet new people, all sharing the same excitement for the week-long journey about to start! In Germany, the group at Fab Lab Kamp-Lintfort, mentored by Adriana Cabrera, also a Fab Academy alumni, participated to all week’s activities producing many tests for all the hands-on and three projects.

In Germany, the group at Fab Lab Kamp-Lintfort, mentored by Adriana Cabrera, also a Fab Academy alumni, participated to all week’s activities producing many tests for all the hands-on and three projects.

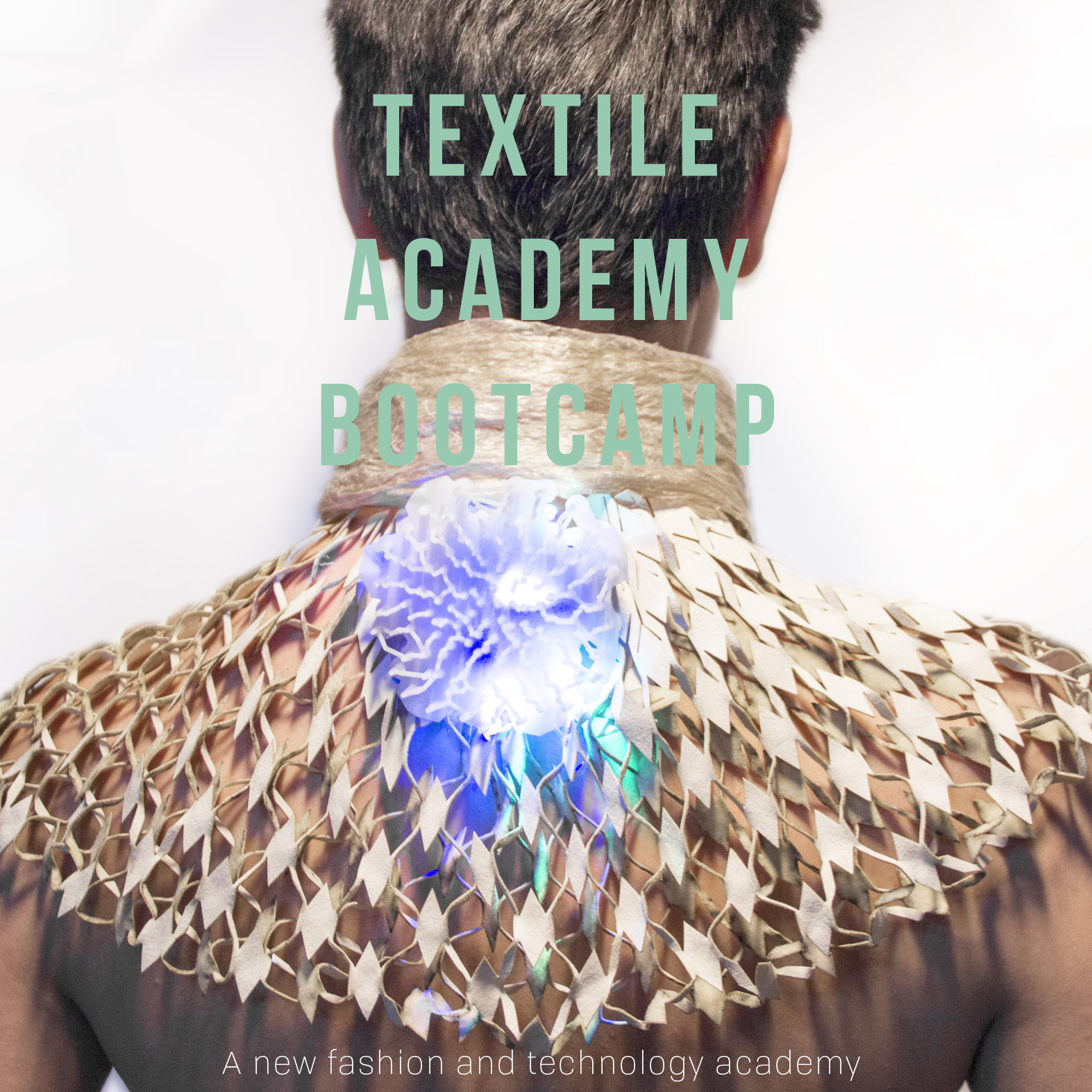

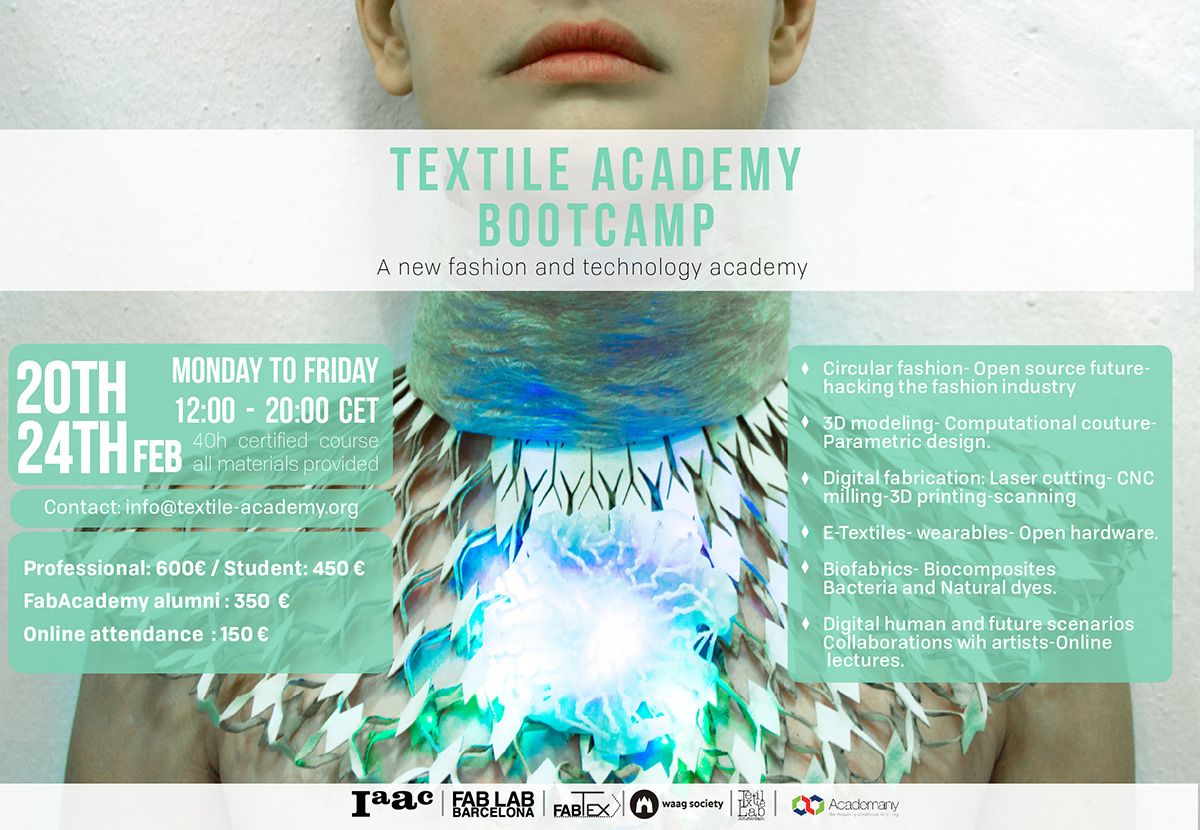

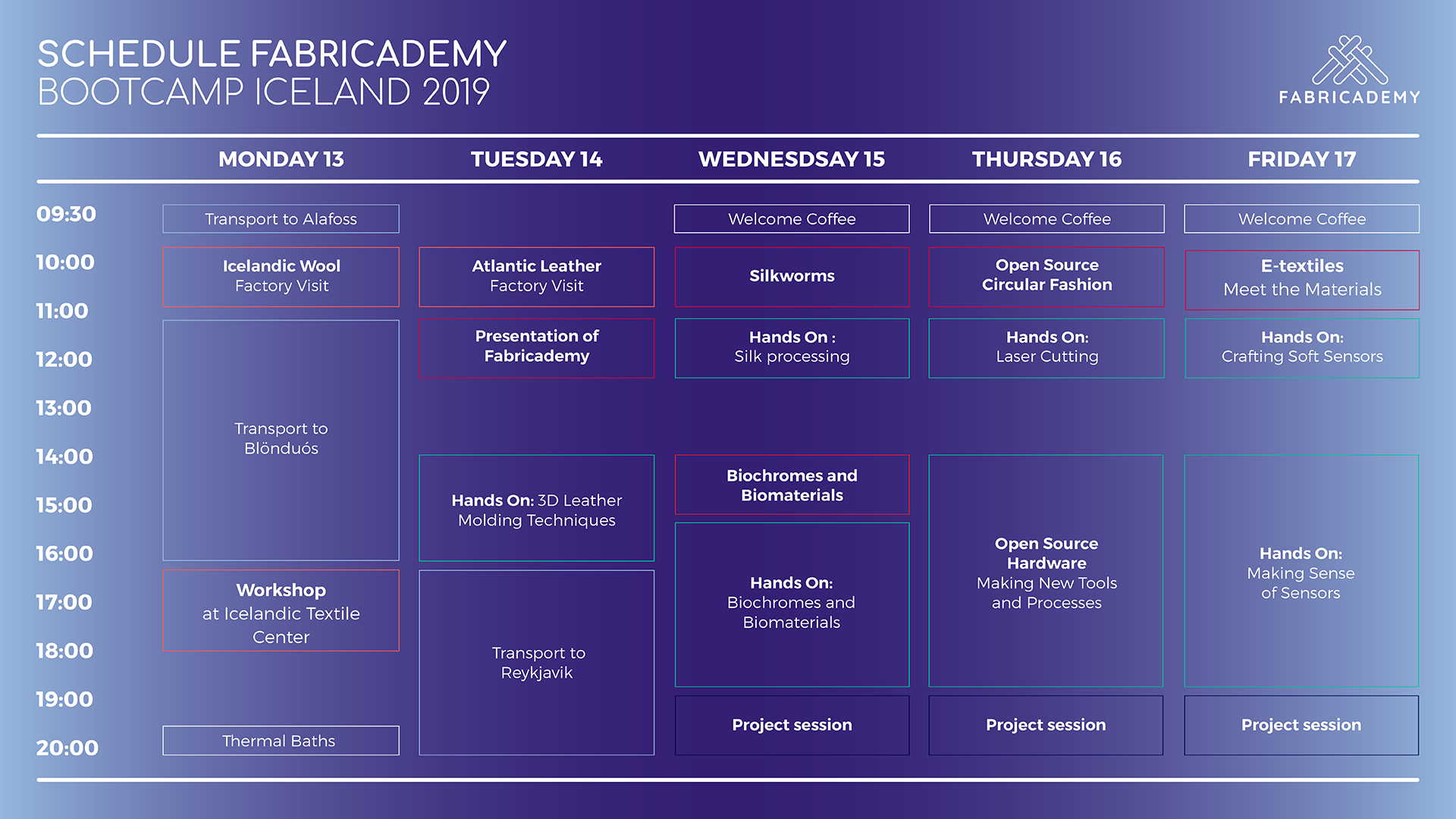

The Textile Academy Bootcamp was the kick off and a pilot course to test the forthcoming Fabricademy, a new textile academy that will run in multiple places all over the world simultaneously, starting mid September 2017.

Missed it? Don’t worry! We decided to publish this short summary to keep everybody who is interested in the Textile Academy updated.

Introducing the Fabricademy program to the network and brainstorming on what are the requirements in infrastructure and skills in order to be able to run the Fabricademy.

Introducing the Fabricademy program to the network and brainstorming on what are the requirements in infrastructure and skills in order to be able to run the Fabricademy.

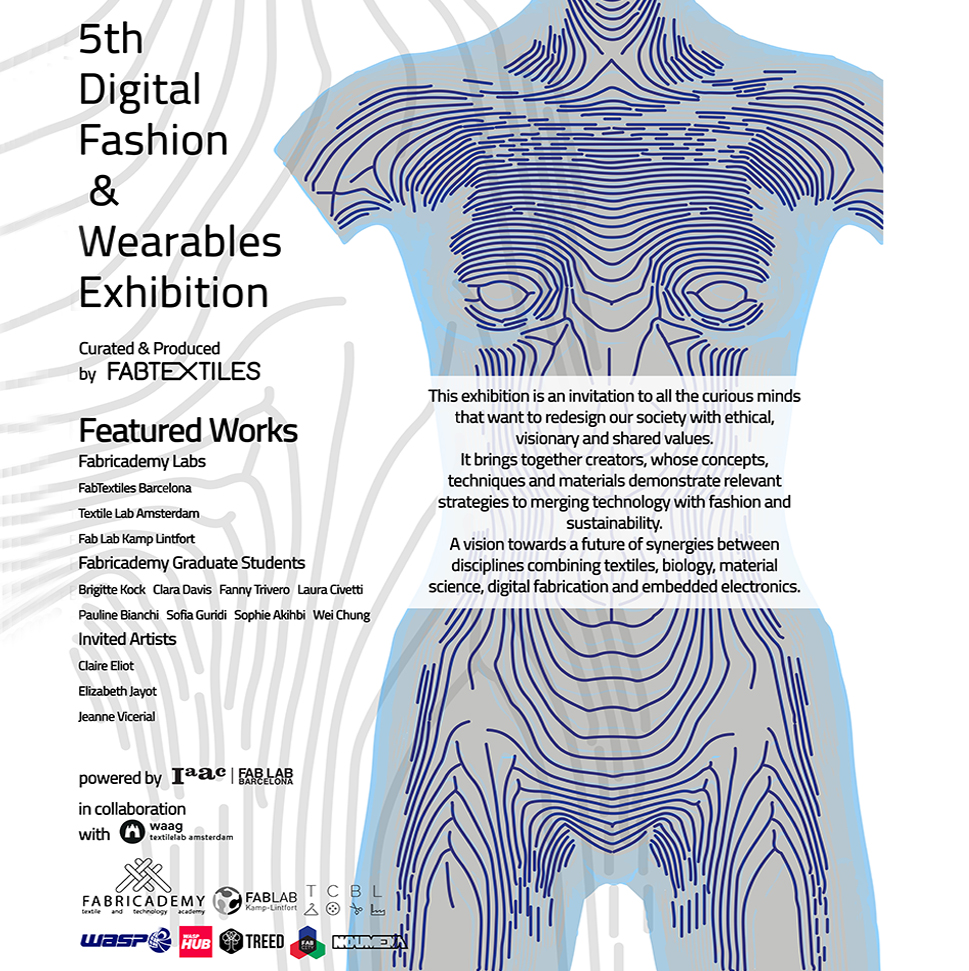

Fabricademy, a new textile academy is will be functioning on the same principles and infrastructure of the global Fab Lab network, but focused on new alternative materials, processes and techniques related to textiles, wearables and soft fabrication. The class will be launched in September 2017, with a top level faculty and an extensive program of 13 weeks, followed by two months of individual project development. Many labs around the world have already expressed interest in participating to this program and we will be opening soon students applications. The course is planned to be carried out all over the world, and the bootcamp is already showing that we will be able to involve everybody interested no matter in which continent they are based.

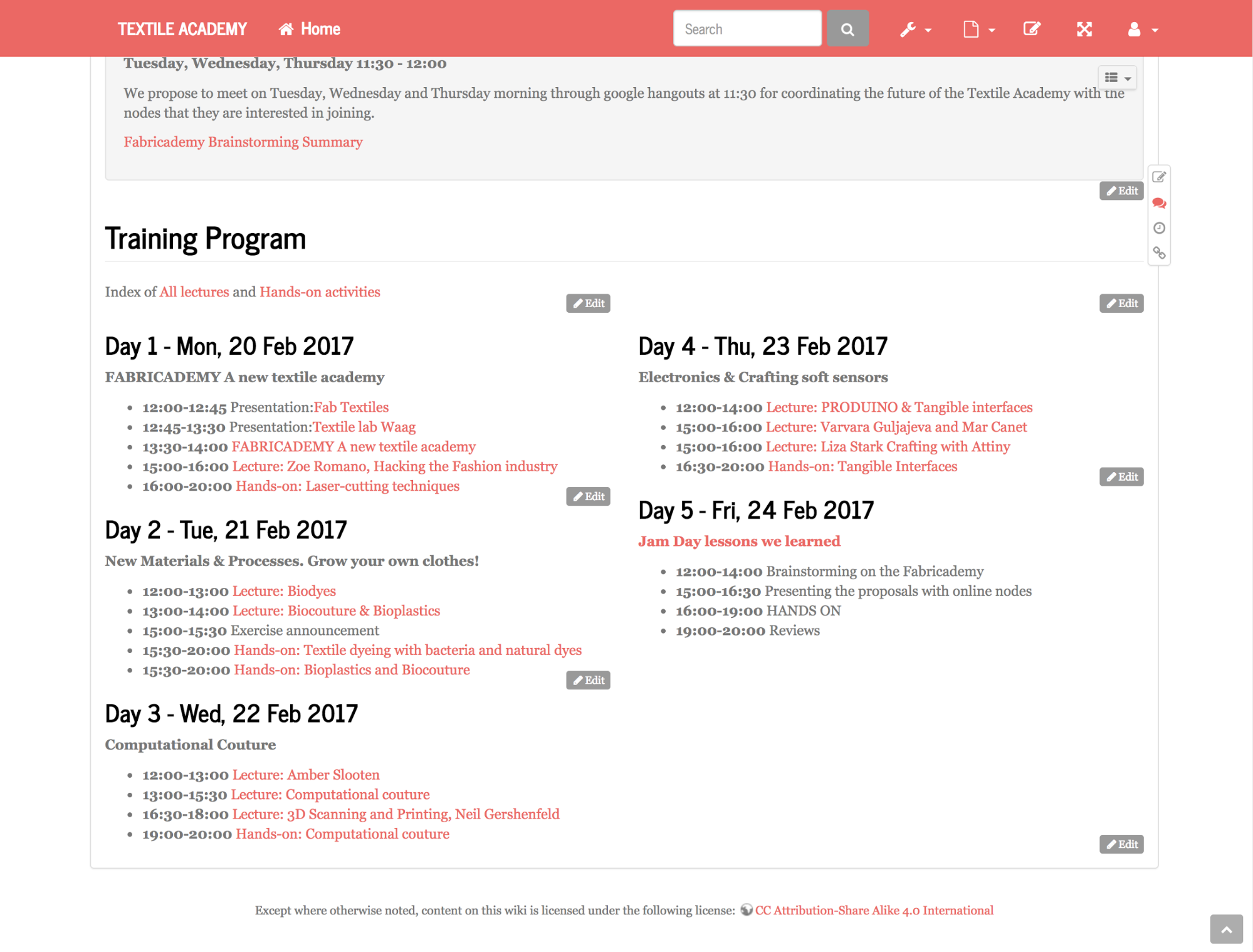

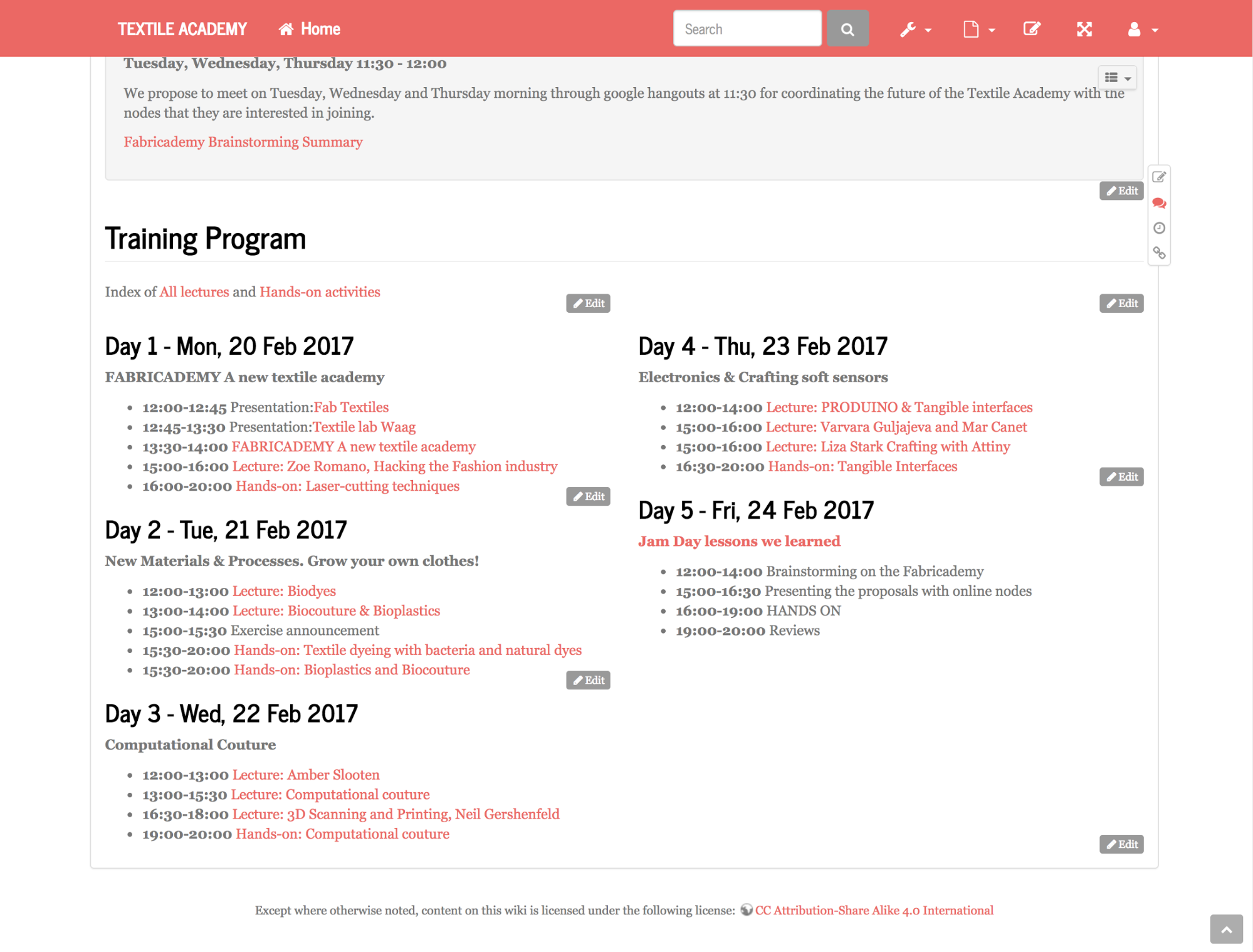

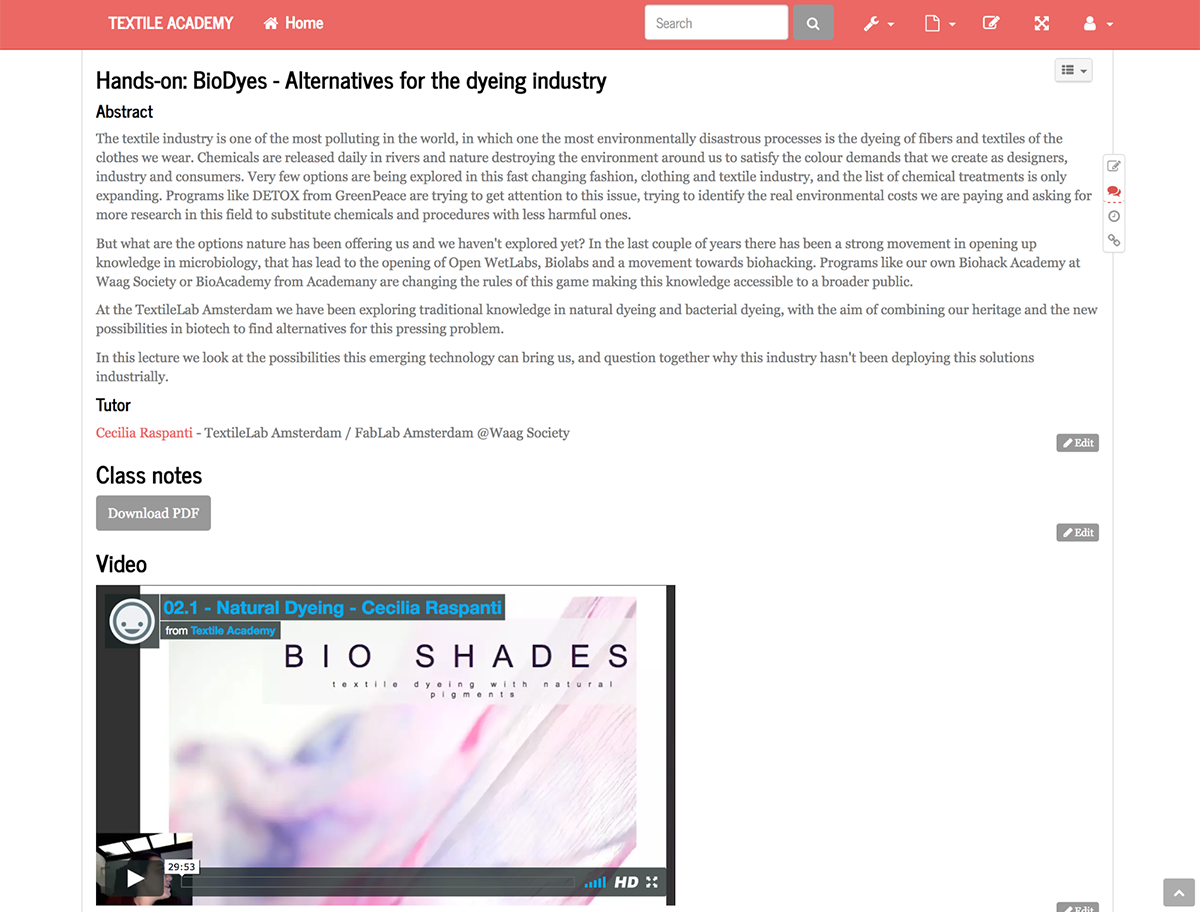

OUR WIKI ! All the content, videos and teaching materials produced during the bootcamp has been edited and collected on the Textile Academy Wiki, the basis for the Fabricademy syllabus, accessible to all the Bootcamp participants.We’ll be updating constantly this repository with new materials, expanding the classes and adding useful resources such as glossaries, recipes and much more…keep an eye on it and feel free to send us suggestions and interesting material to be added to our growing repository!

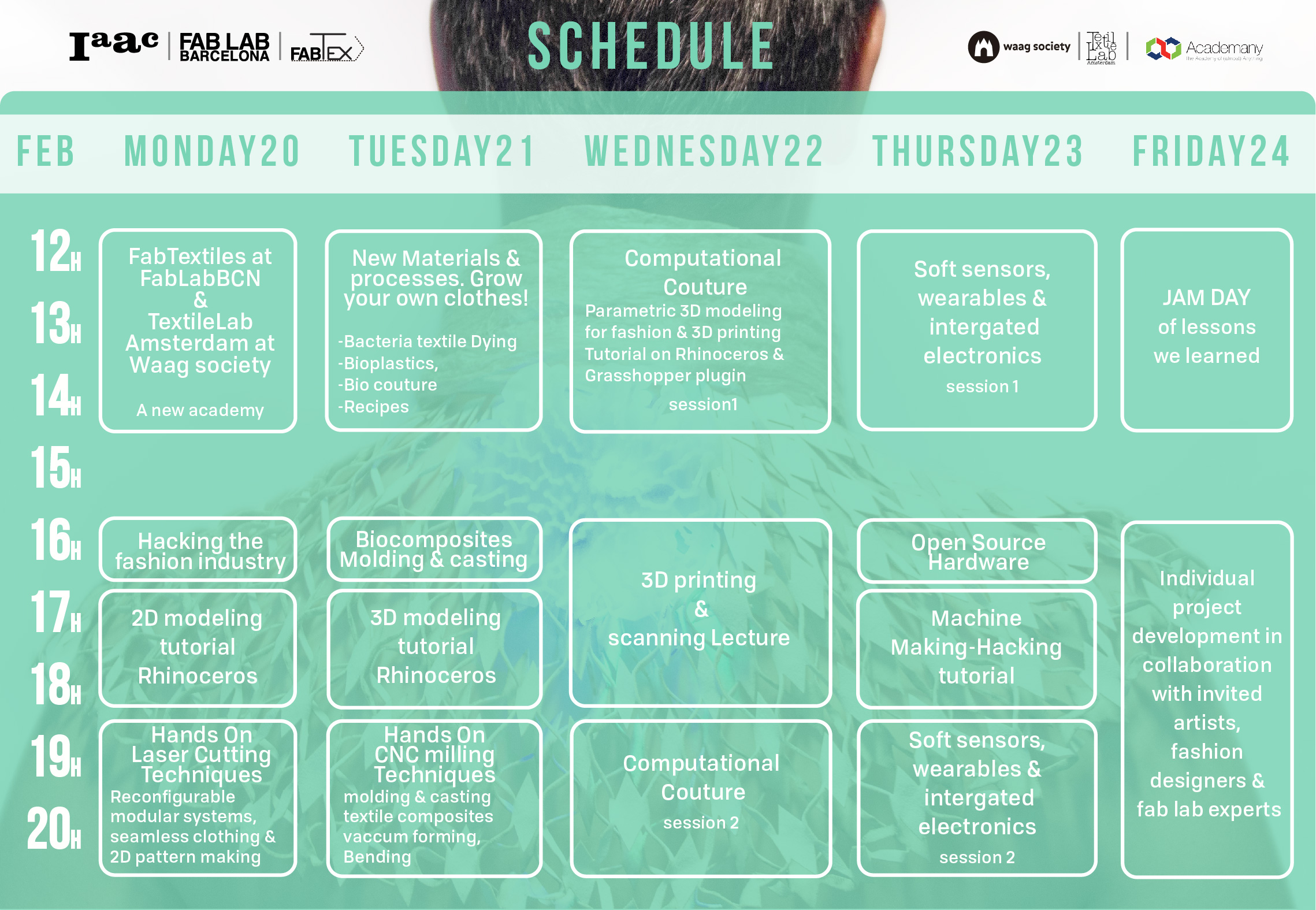

Day 1 – Hacking the fashion industry-seamless clothes

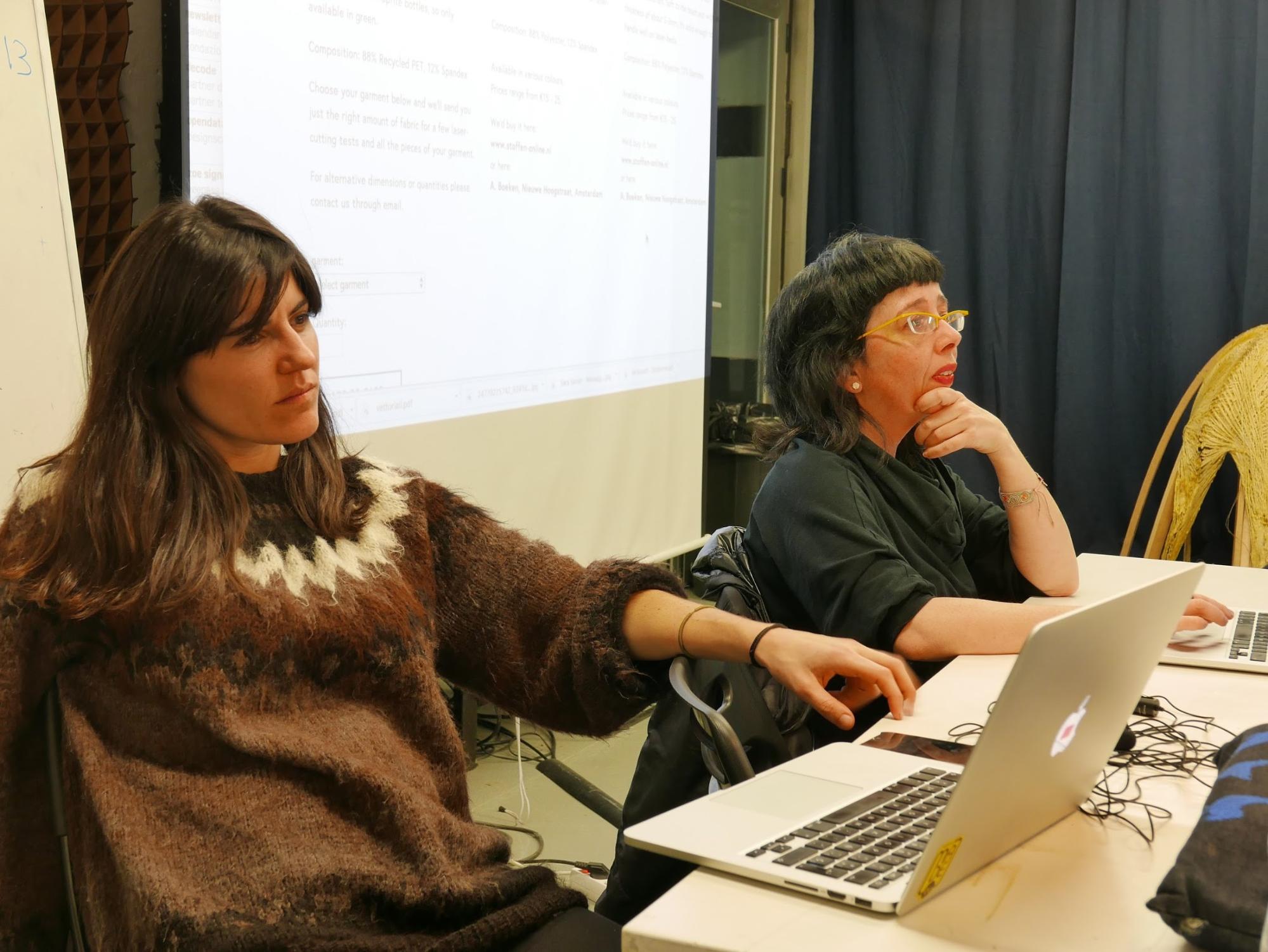

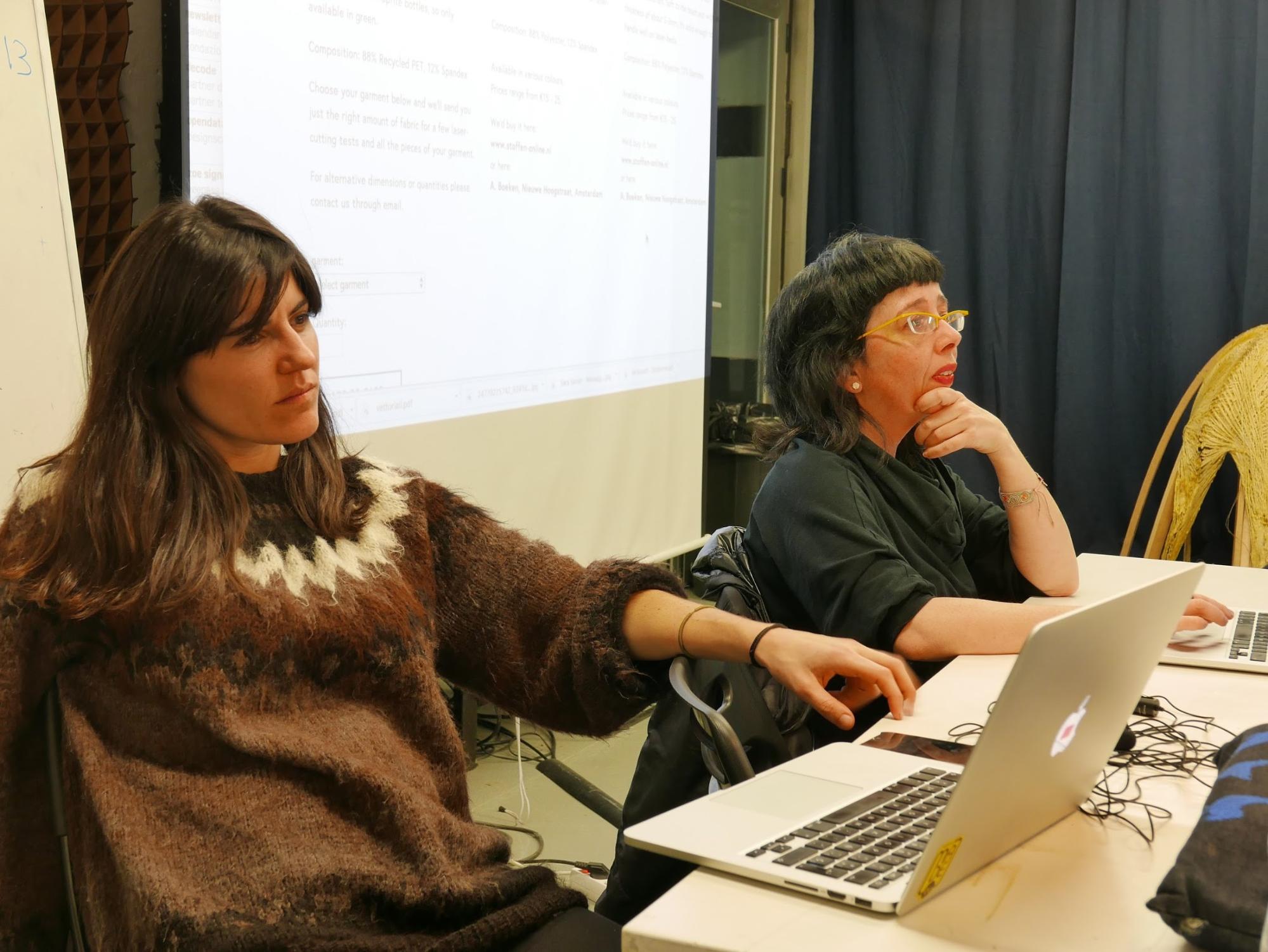

To start the day we did a round of introductions from the local participants, the Bootcamp staff and remote sites. The aim of the first day was to define the context in which we are going to work, the reasons behind this forthcoming and explorative textile movement in Fab Labs and other typologies of innovation labs.Anastasia Pistofidou presented the Fab Textiles project and Cecilia Raspanti showed her work at the Textile Lab Amsterdam and on the TCBL EU project. Anastasia and Zoe discussing about open source economic models in the textile and clothing industry

Anastasia and Zoe discussing about open source economic models in the textile and clothing industry

Zoe Romano, founder of the wemake.cc makerspace and expert in circular fashion, followed with her lecture on “Hacking the fashion industry”, where she presented her work describing a new approach in the design and production of clothing using networks, hacked and open hardware machines, open source softwares. Zoe gave a comprehensive overview about open source branding and gave many examples of open designs that can be realised by anyone in an accordingly equipped lab.

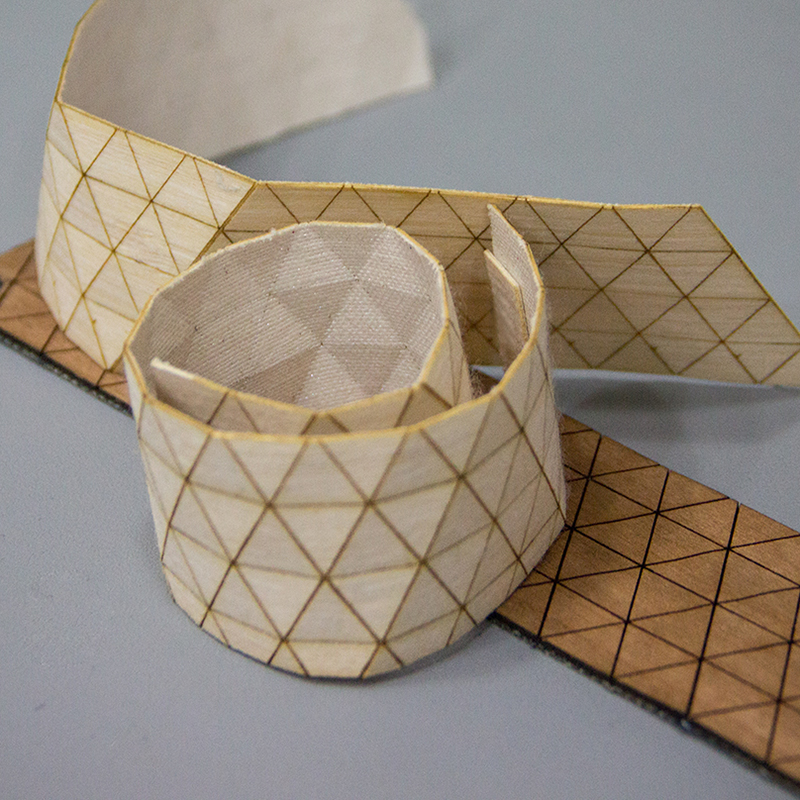

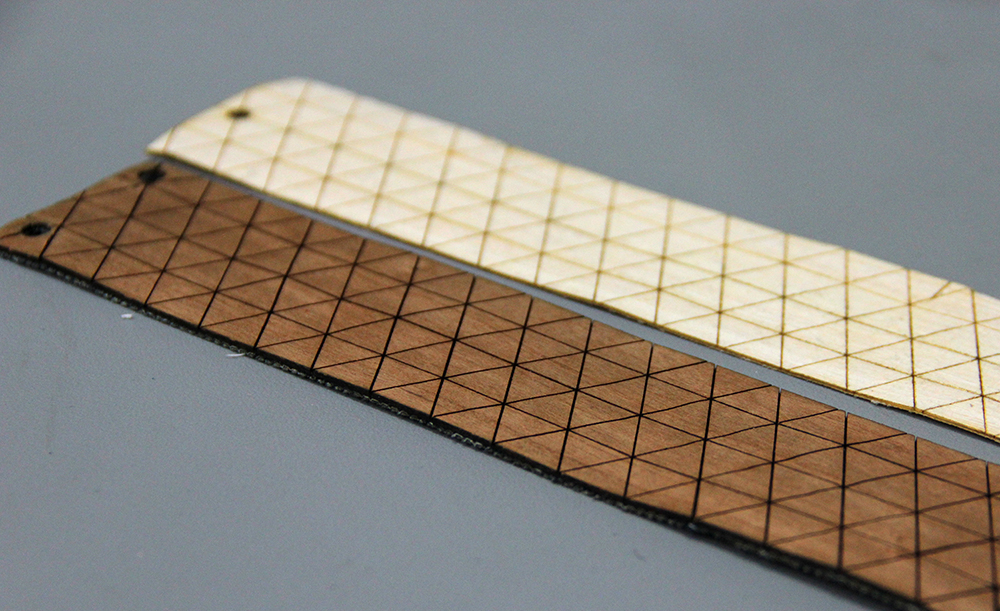

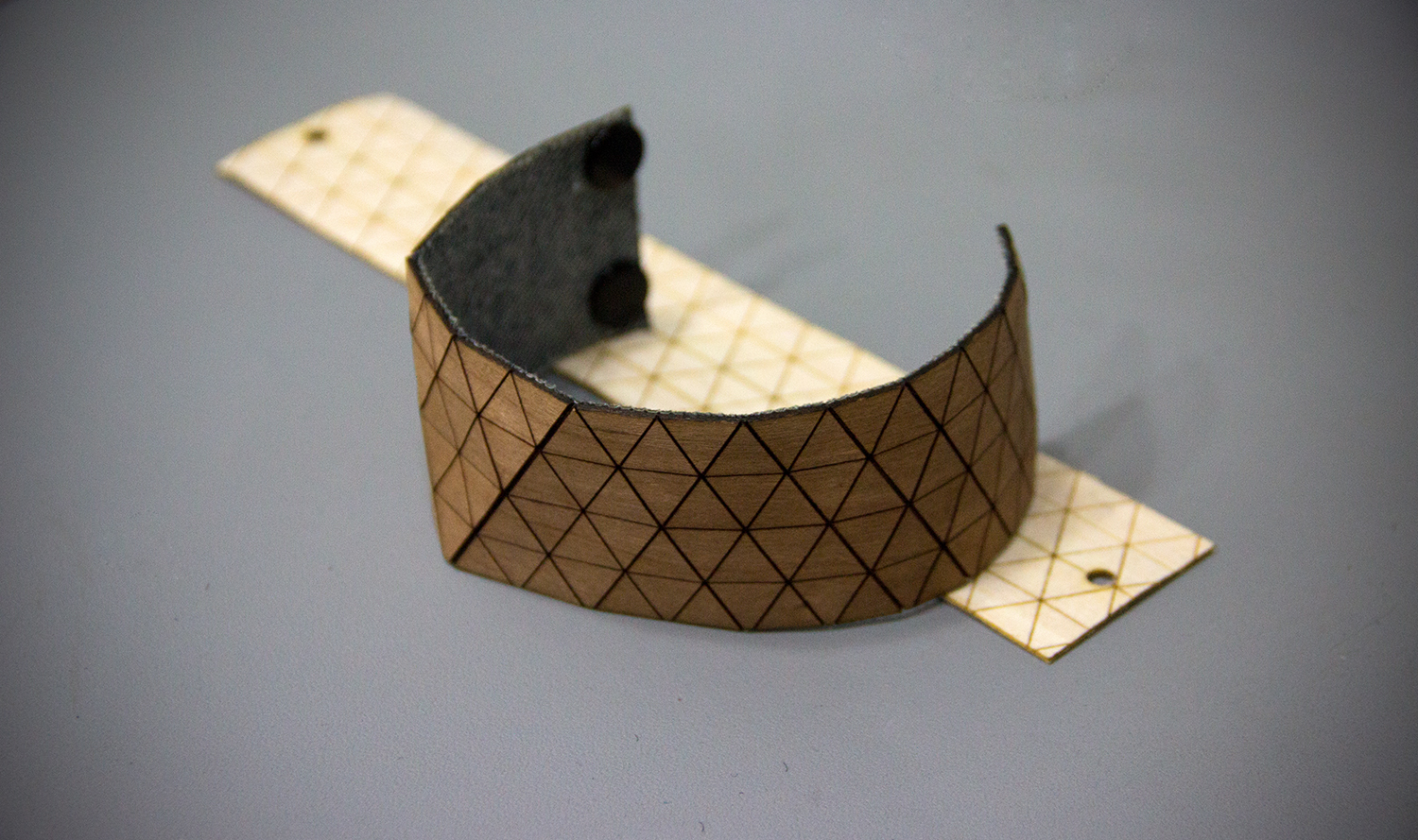

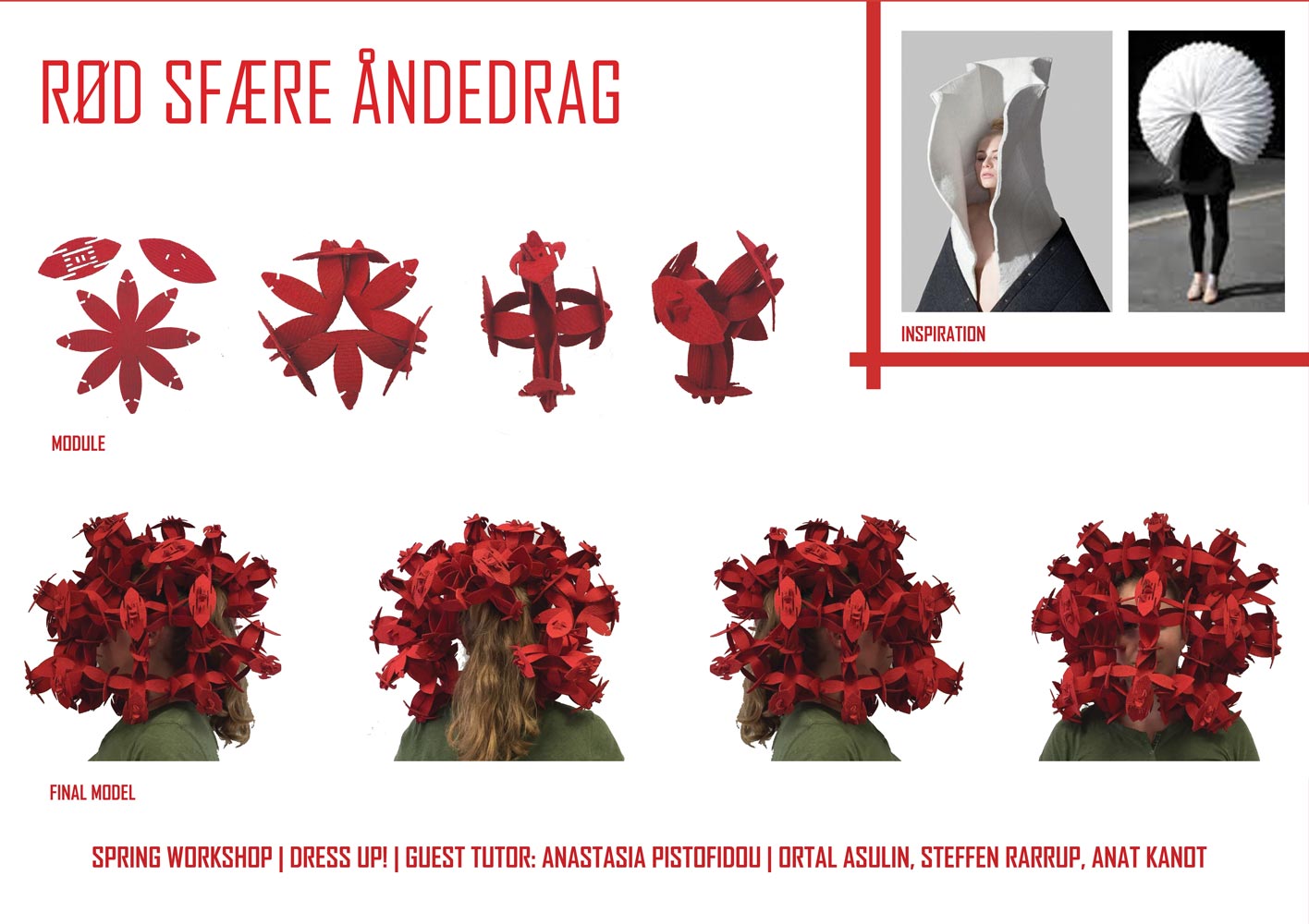

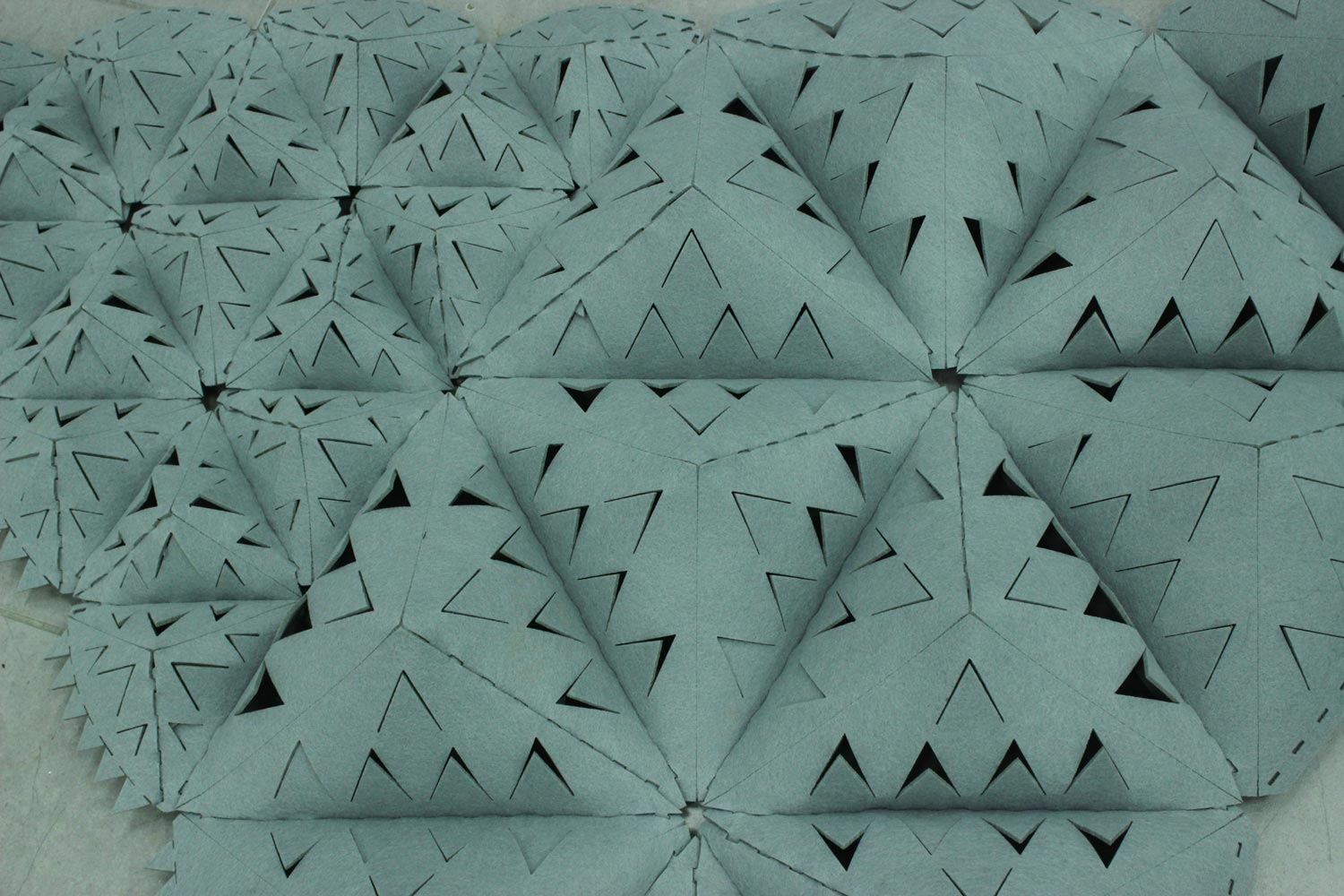

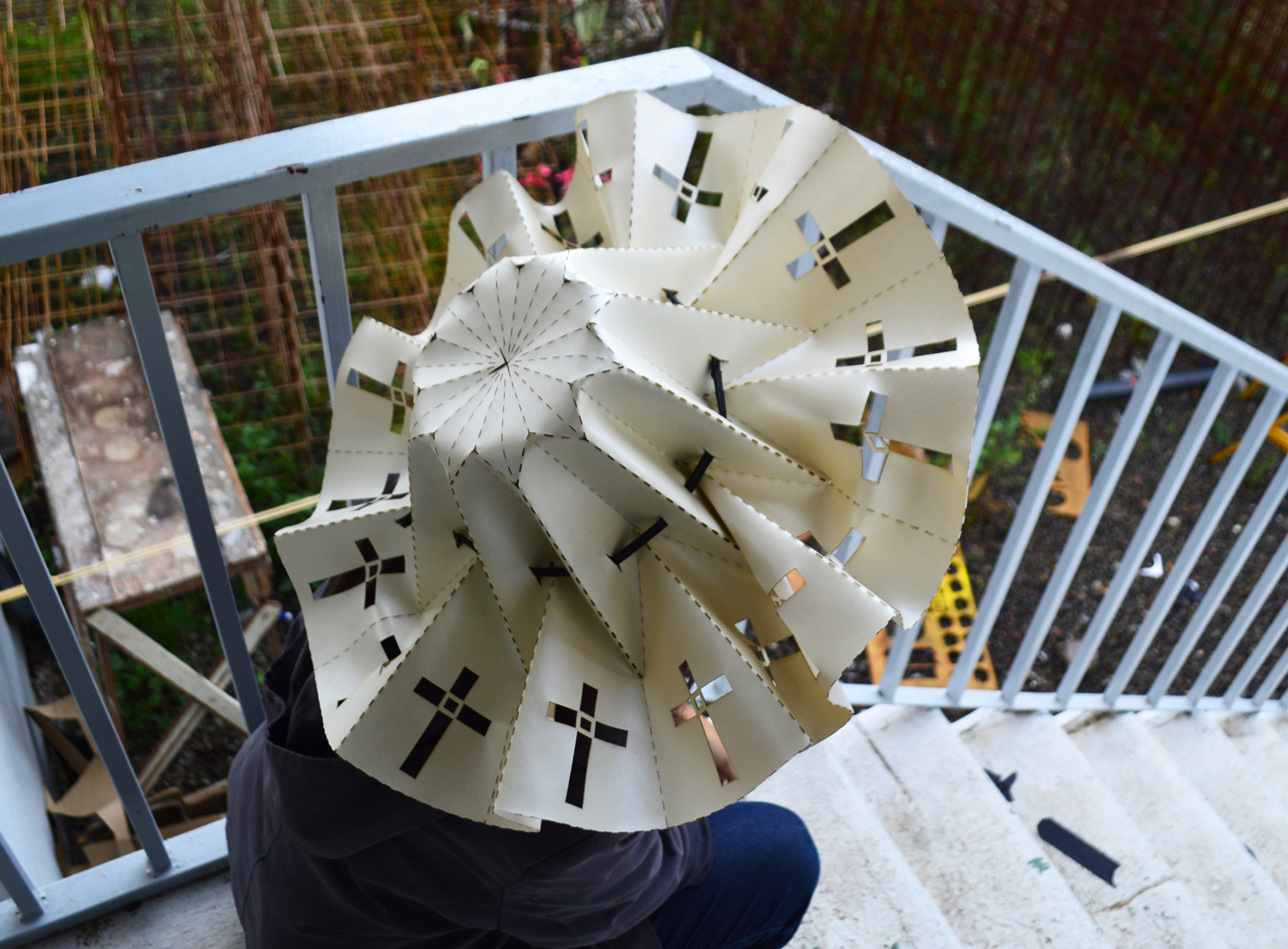

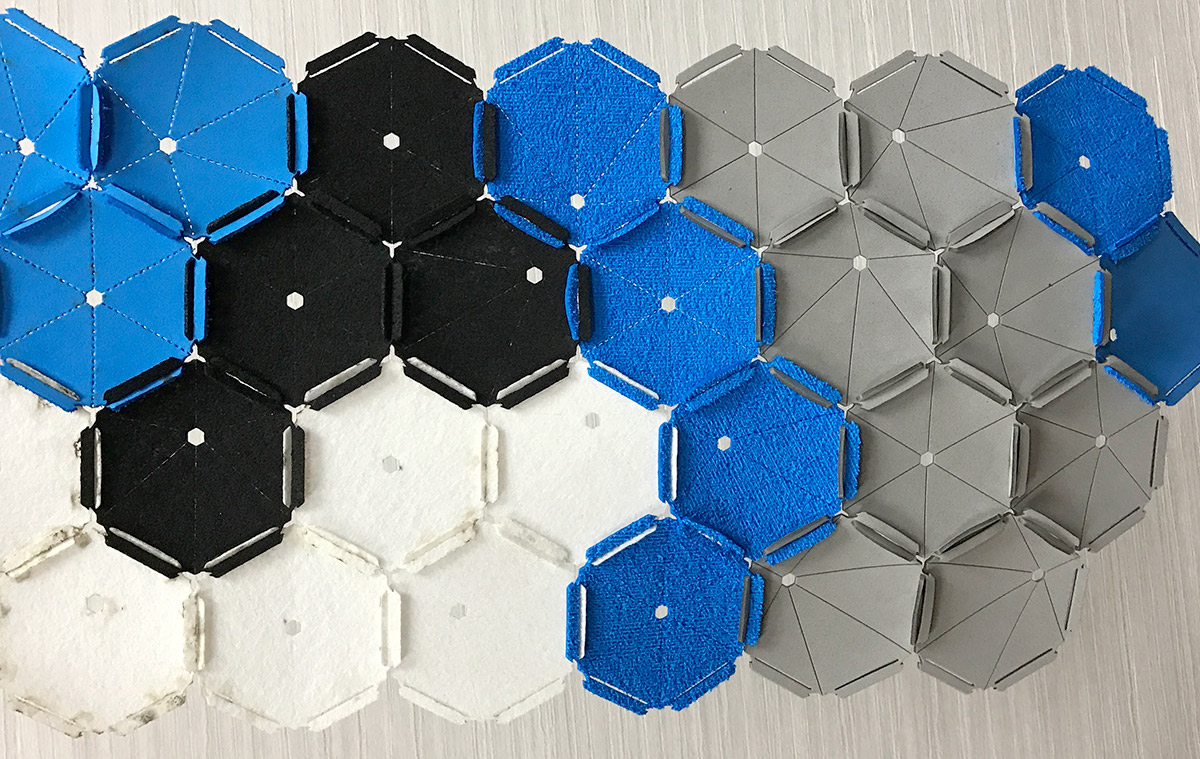

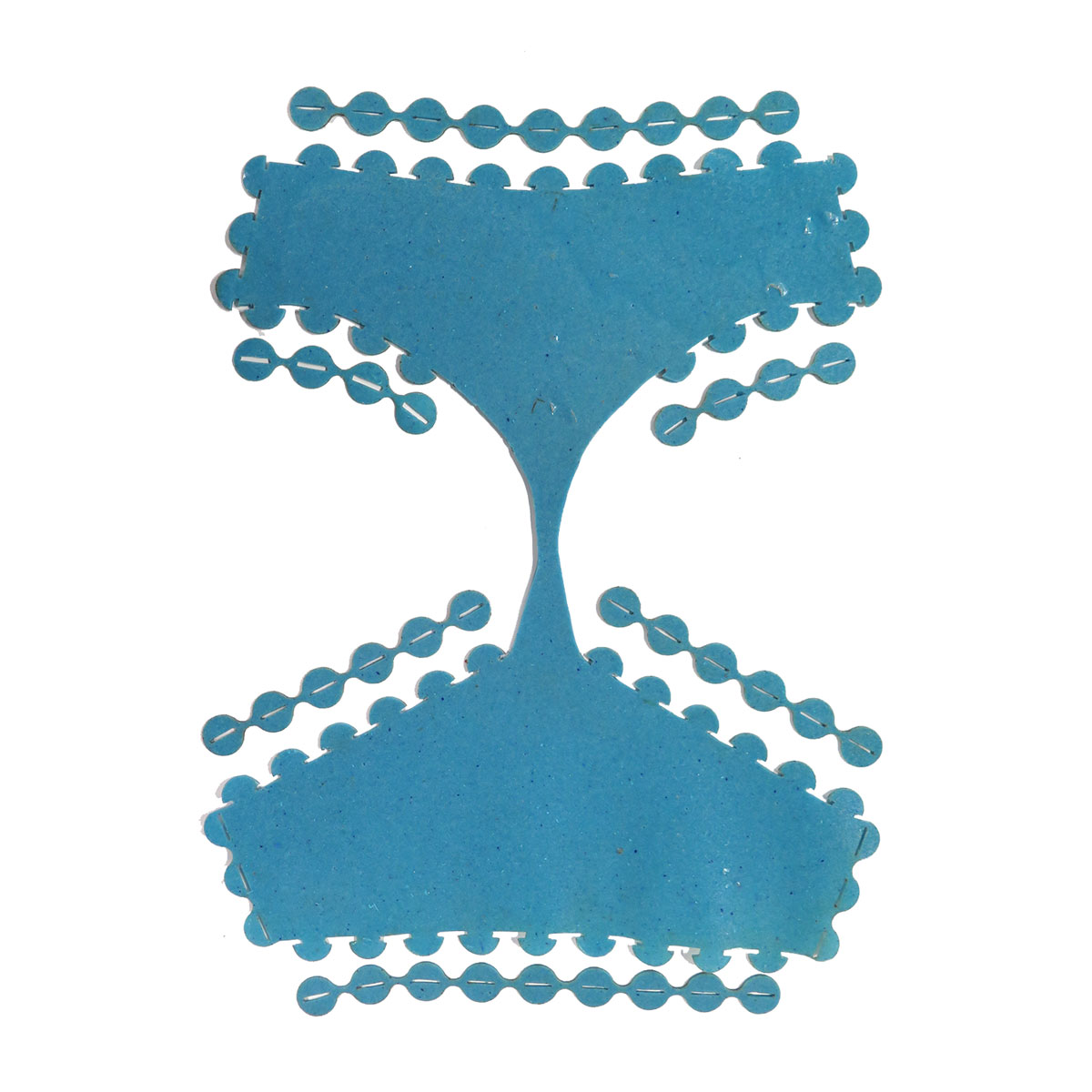

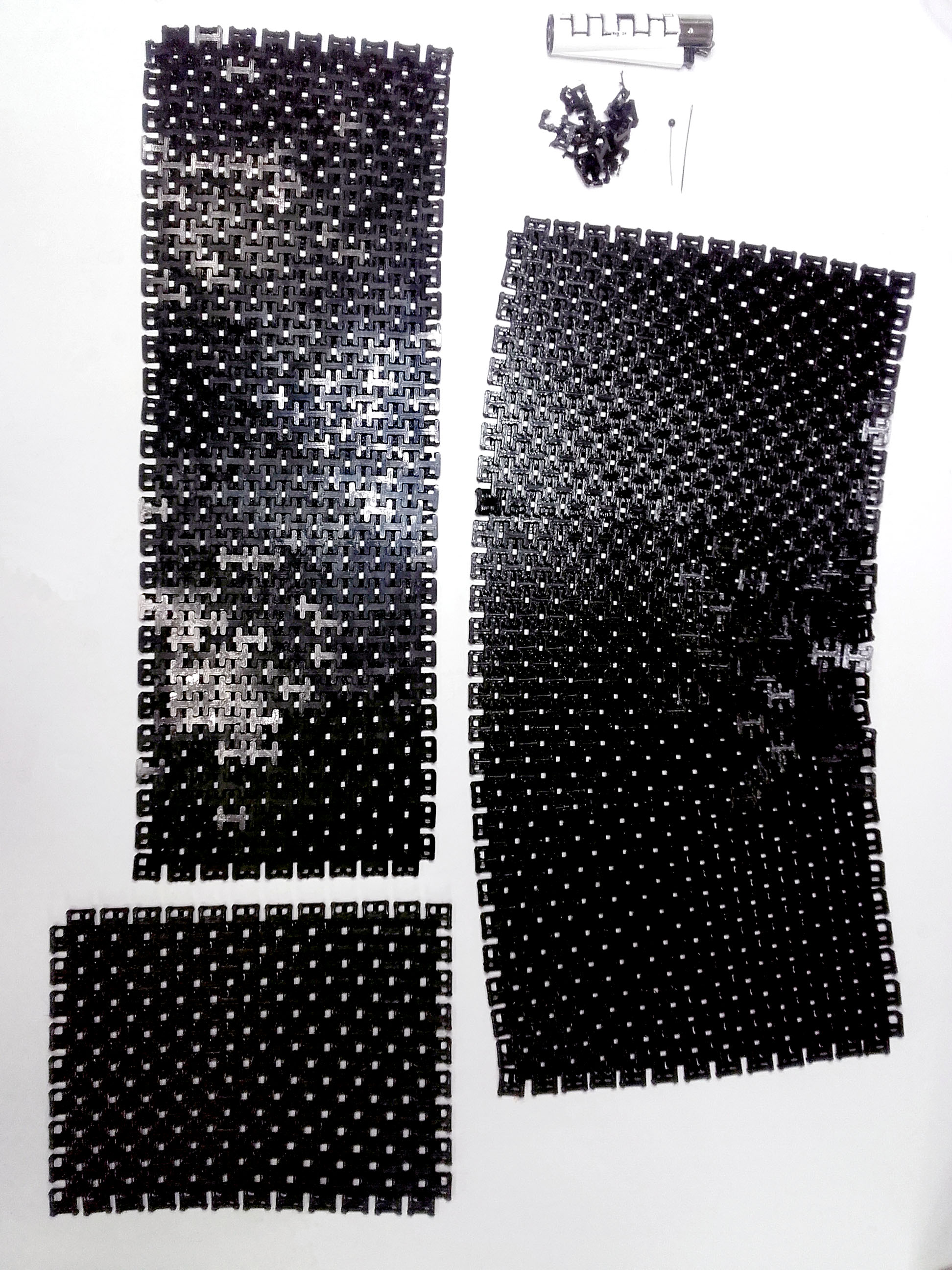

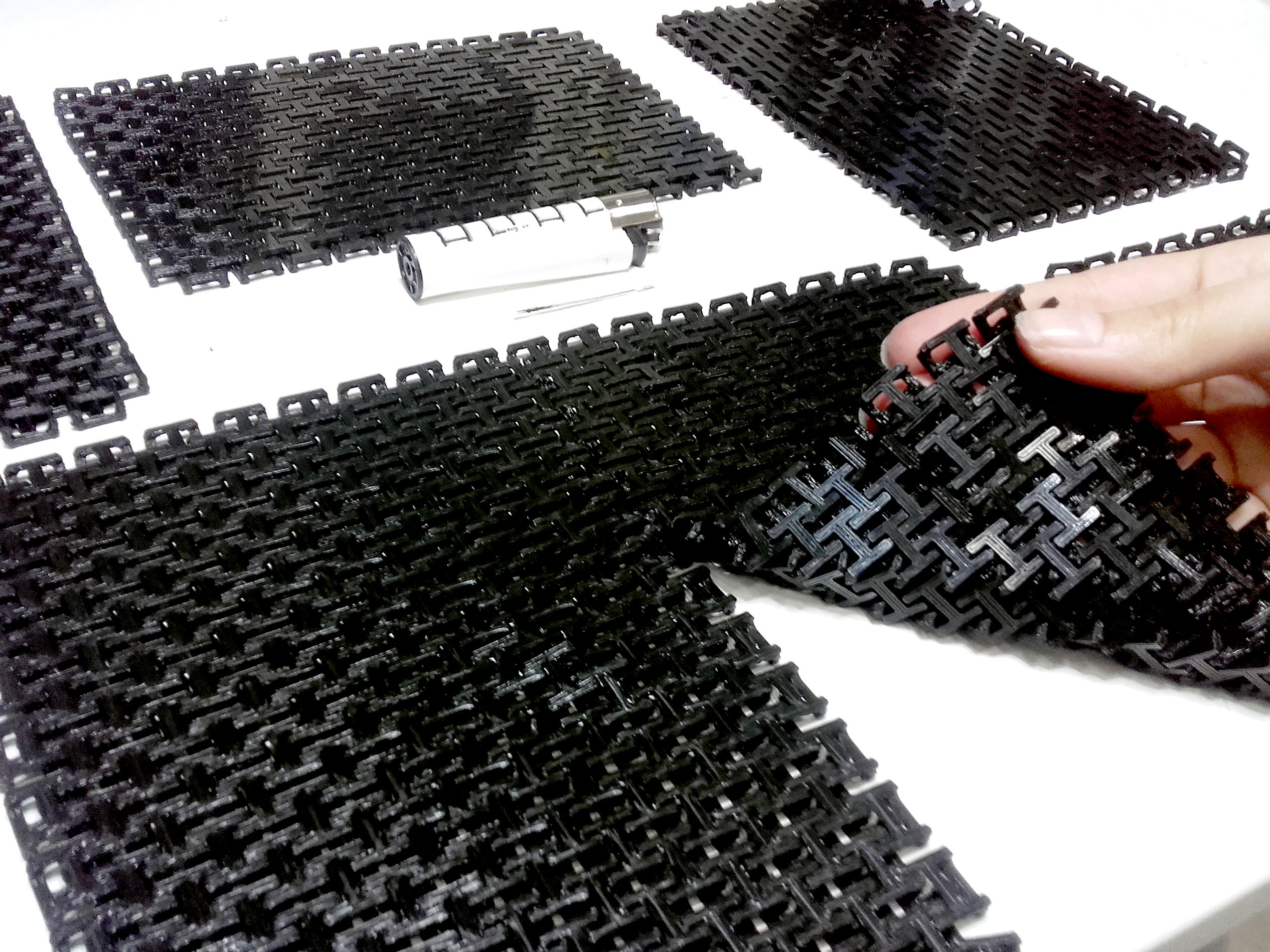

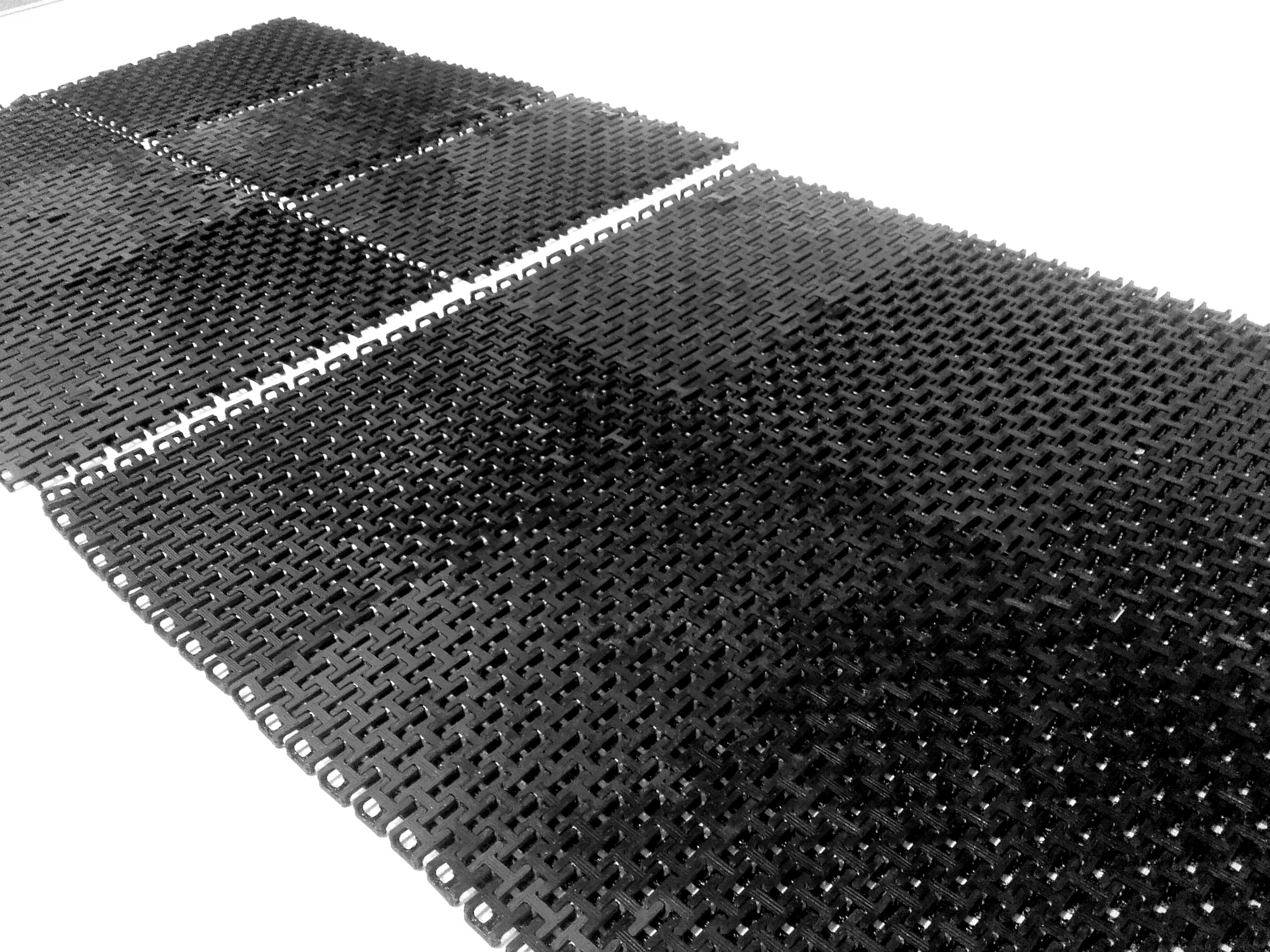

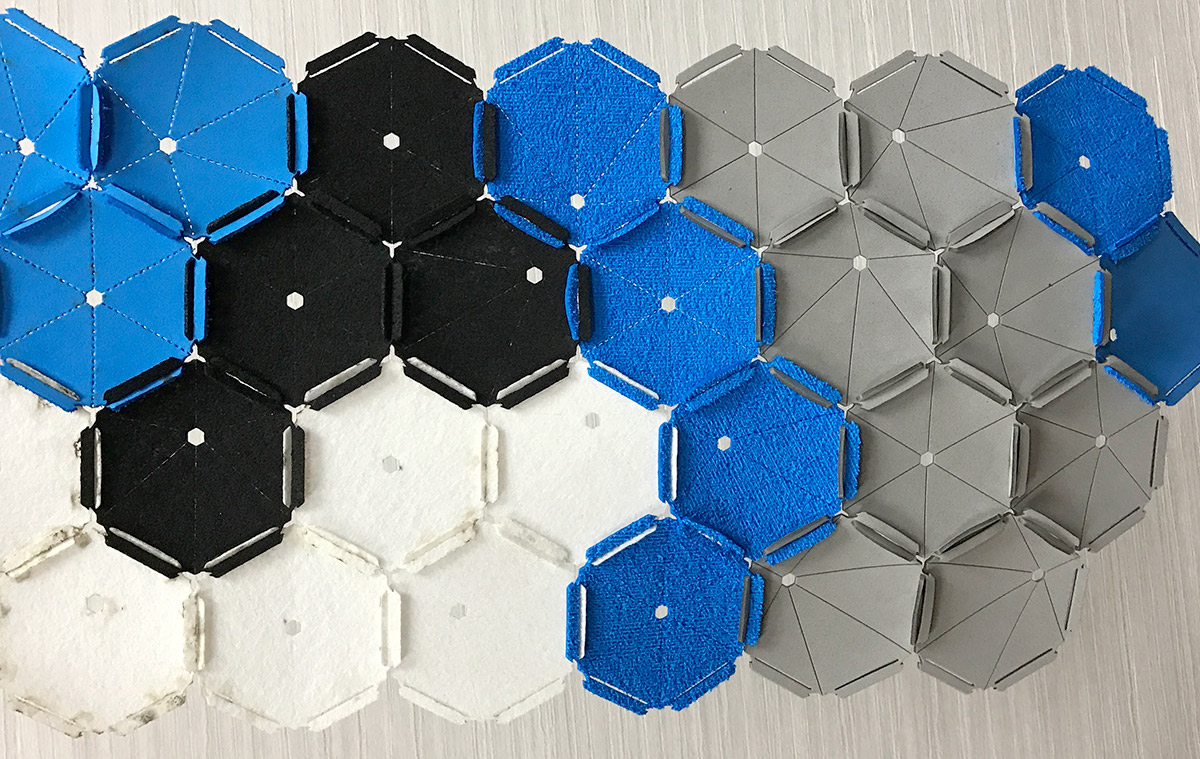

For the Hands-On sessions this day was focused on exploring laser cutting techniques. Anastasia introduced the topic with a tutorial for an effective and safe use of the laser for cutting and engraving fabrics. The objective of the hands on section was to create seamless clothing & reconfigurable modular systems, using any 2D or 3D software to create patterns ready for cutting. Participants were challenged to design and test a modular connection for a pattern in order to assemble textiles in 3D shapes. Lots of interesting projects started to take shape from the different groups all over the world in their research on laser cut inter-laceable patterns. Exploring first interlocking tests. Curious? Take a peak in the exciting outcomes on the JAM day photos!

Exploring first interlocking tests. Curious? Take a peak in the exciting outcomes on the JAM day photos! Viki Fernandez seamless patterns, Brazil

Viki Fernandez seamless patterns, Brazil

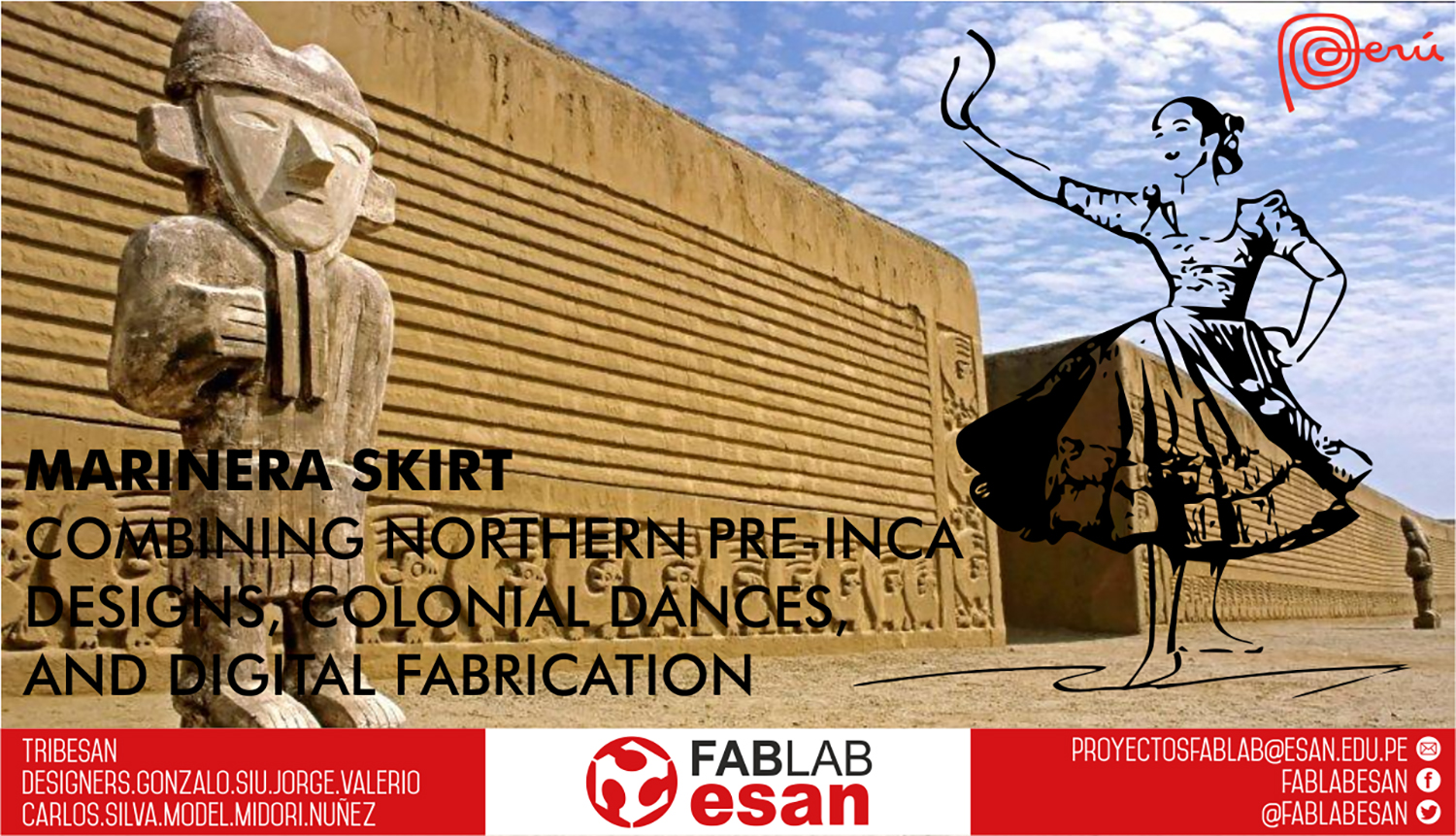

In Peru, the Fab Lab ESAN group showed mastery of seamless design producing lots of examples with different materials.

In Peru, the Fab Lab ESAN group showed mastery of seamless design producing lots of examples with different materials.

Ana de Lara from Santiago de Chile, a member of the opentextiles.org project, produced this beautiful skirt seamless pattern and right, other possibilities combining laser cutting and weaving

Ana de Lara from Santiago de Chile, a member of the opentextiles.org project, produced this beautiful skirt seamless pattern and right, other possibilities combining laser cutting and weaving

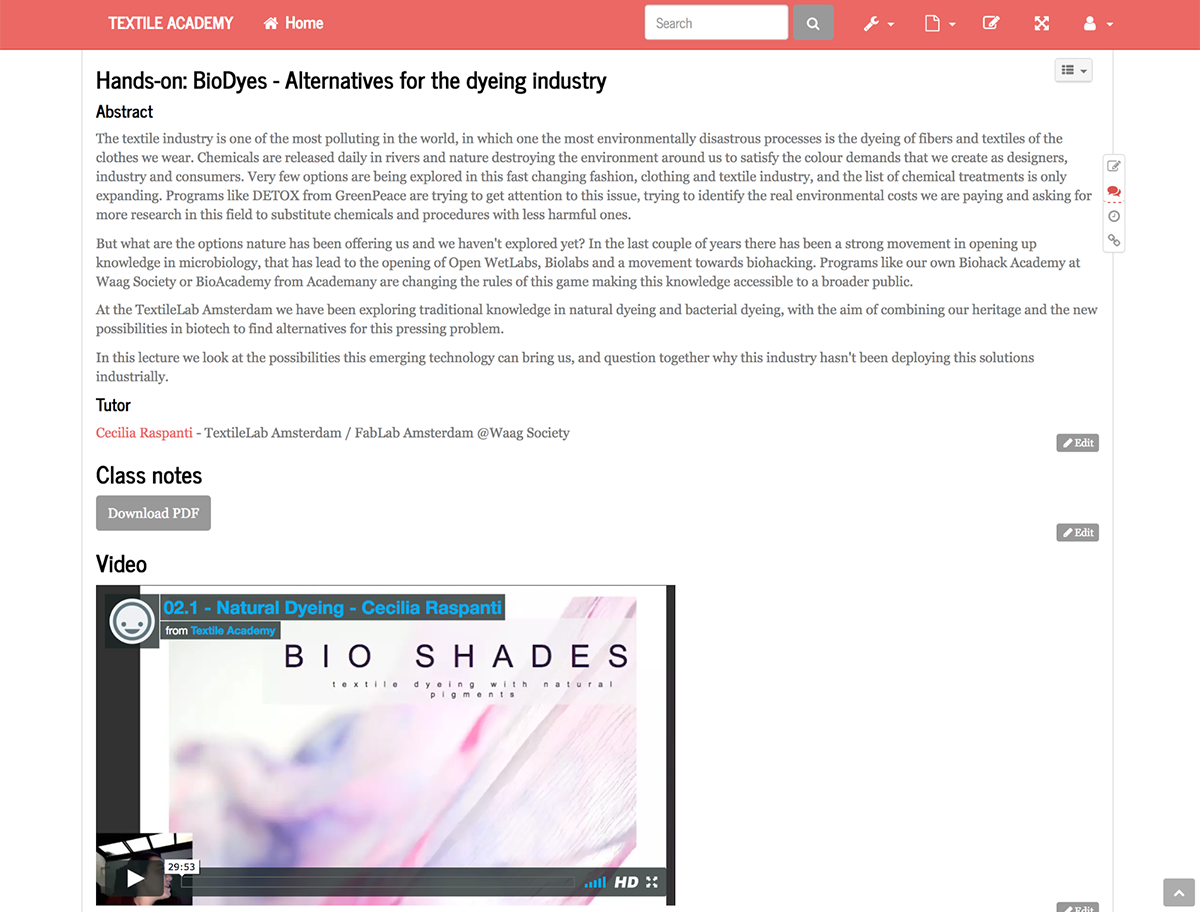

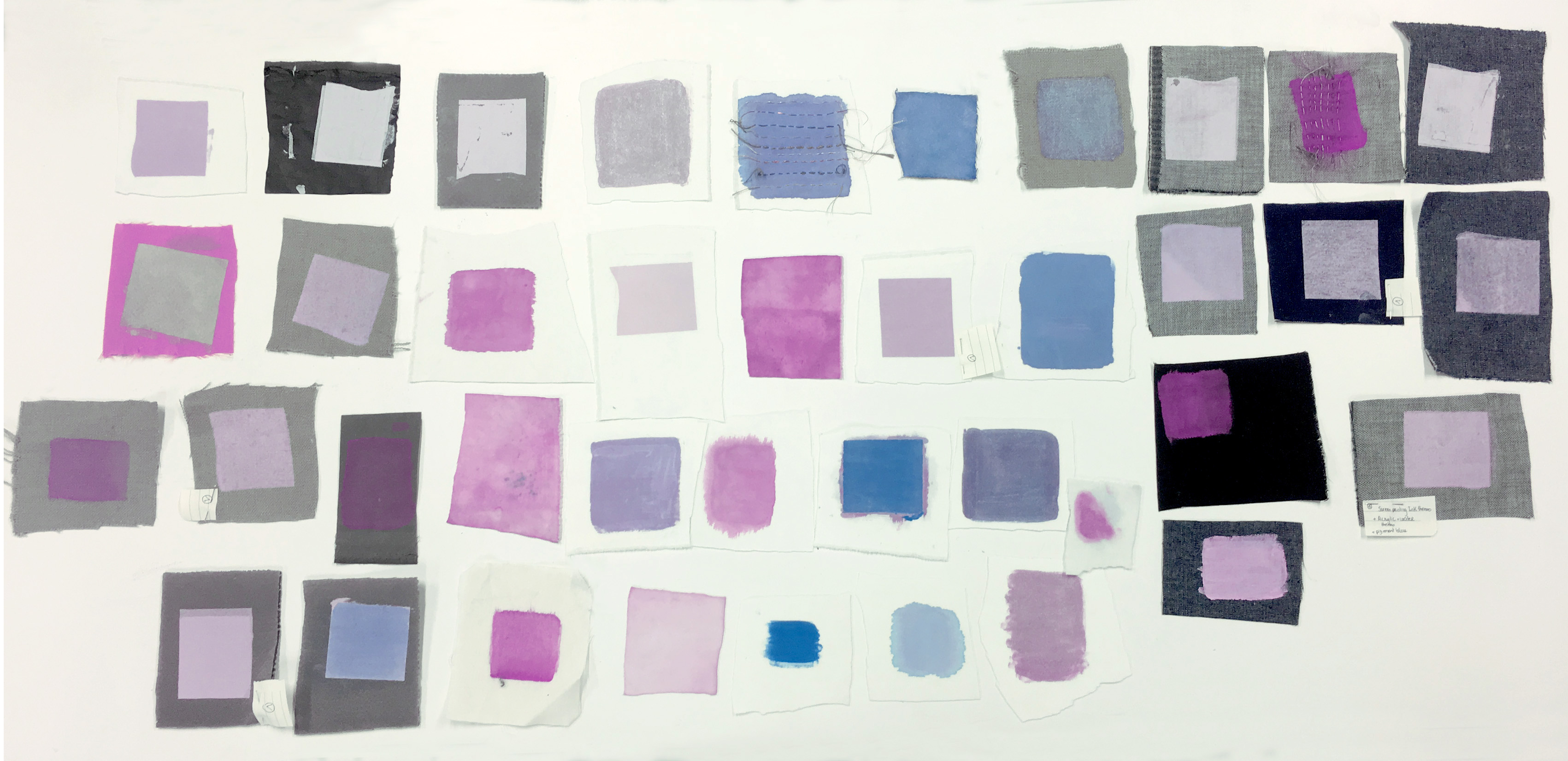

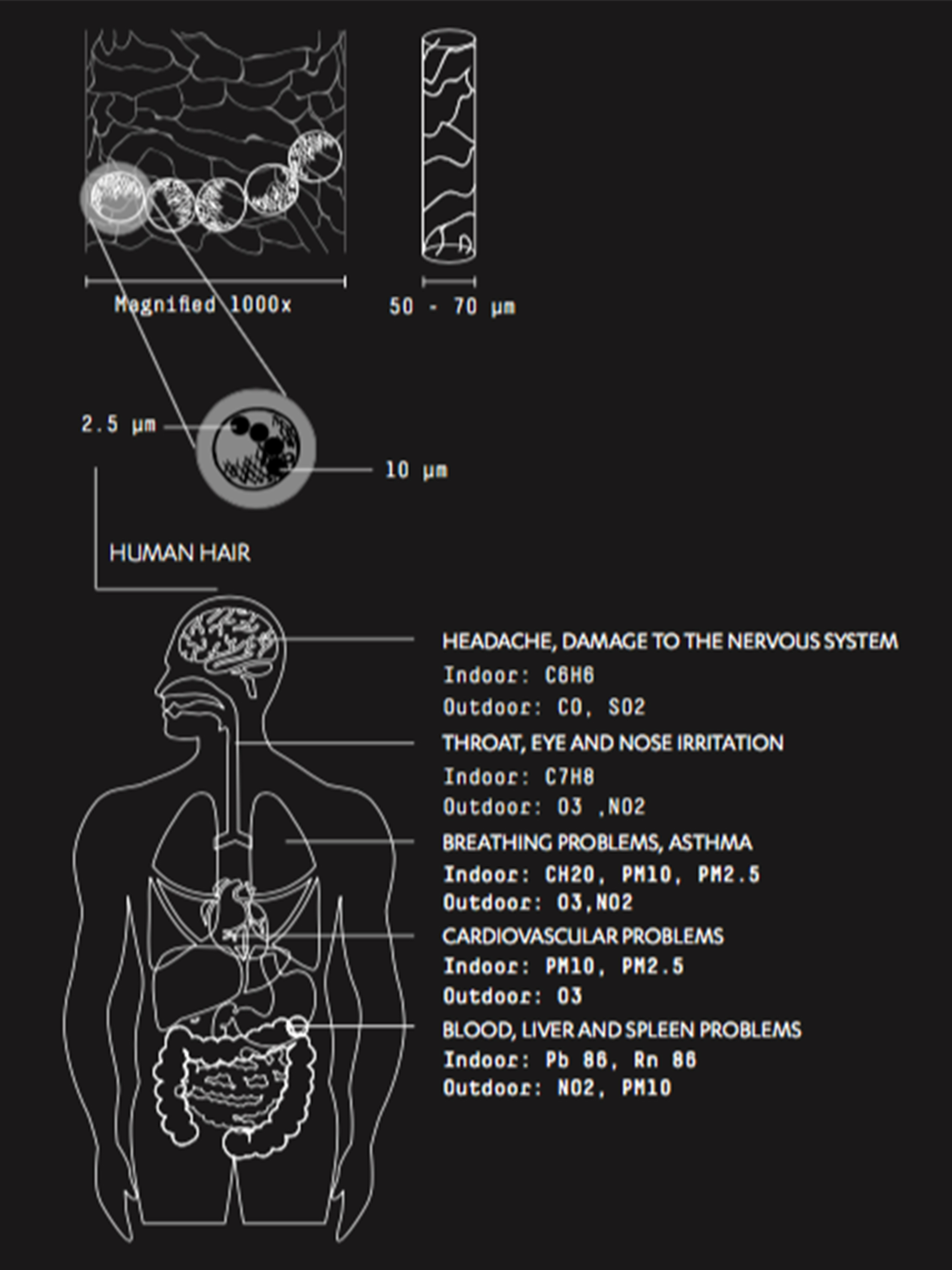

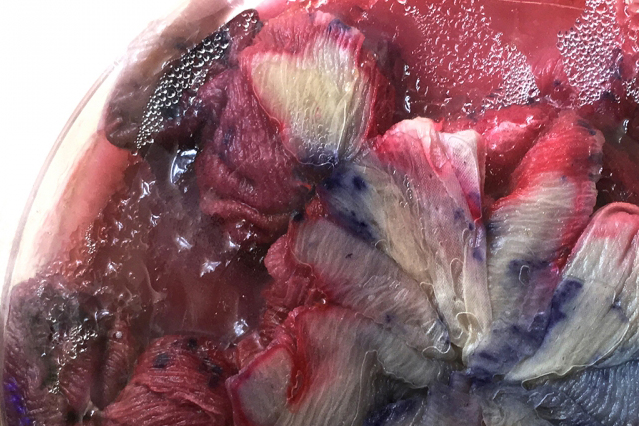

Day 2- – New materials, alternatives processes

The goal for this second day was to learn how to work with new material and processes aimed at growing your own clothes. While this might sound sci-fi, Anastasia and Cecilia guided the participants in this innovative topic with their lectures on Bio-Couture, Bio-Plastics and Bio Dyes. Participants and mentors joining the lecture were really impressed by the projects shown and the global issues related to the use of traditional materials and processes, that have a huge impact on the environment and labour conditions in developing countries. The textile industry, second most polluting industry on earth, often tries to hide the environmental impact of certain chemicals used to process materials and textiles. Fabricademy aims also to explore more friendly and relevant alternatives around these issues, highlighting research paths of the ones driving these innovative future materials and processes.

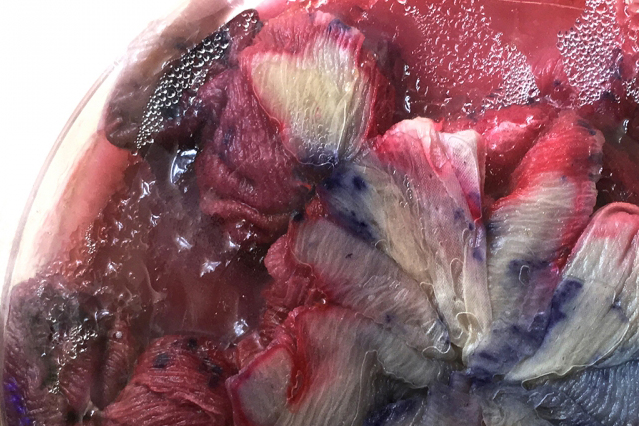

On the technical side the two sessions started a very interesting recipe exchange, for creating and mixing materials, for dyeing with natural ingredients and growing vegan leather. All these materials are being collected and will be part of the Fabricademy online resources. What made this day really great were the hands-on sessions! The local workgroups and all the labs connected remotely started experimenting with the materials covered in the lectures, a meter of kombucha leather, grown for the last two months, was unrolled and cut into pieces to be molded into shape and a rainbow of colors populated the room showing the participant’s bio-dyeing skills.

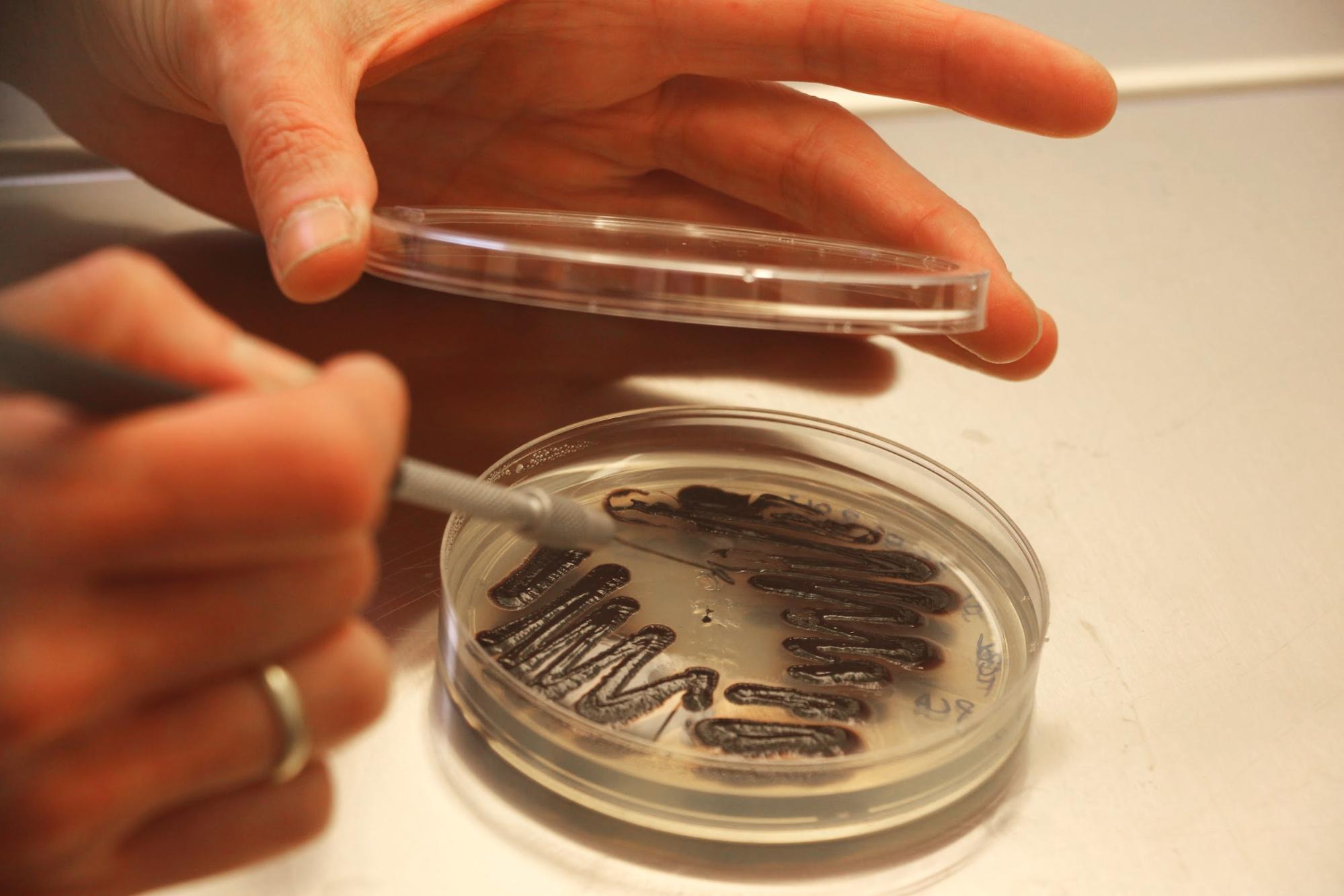

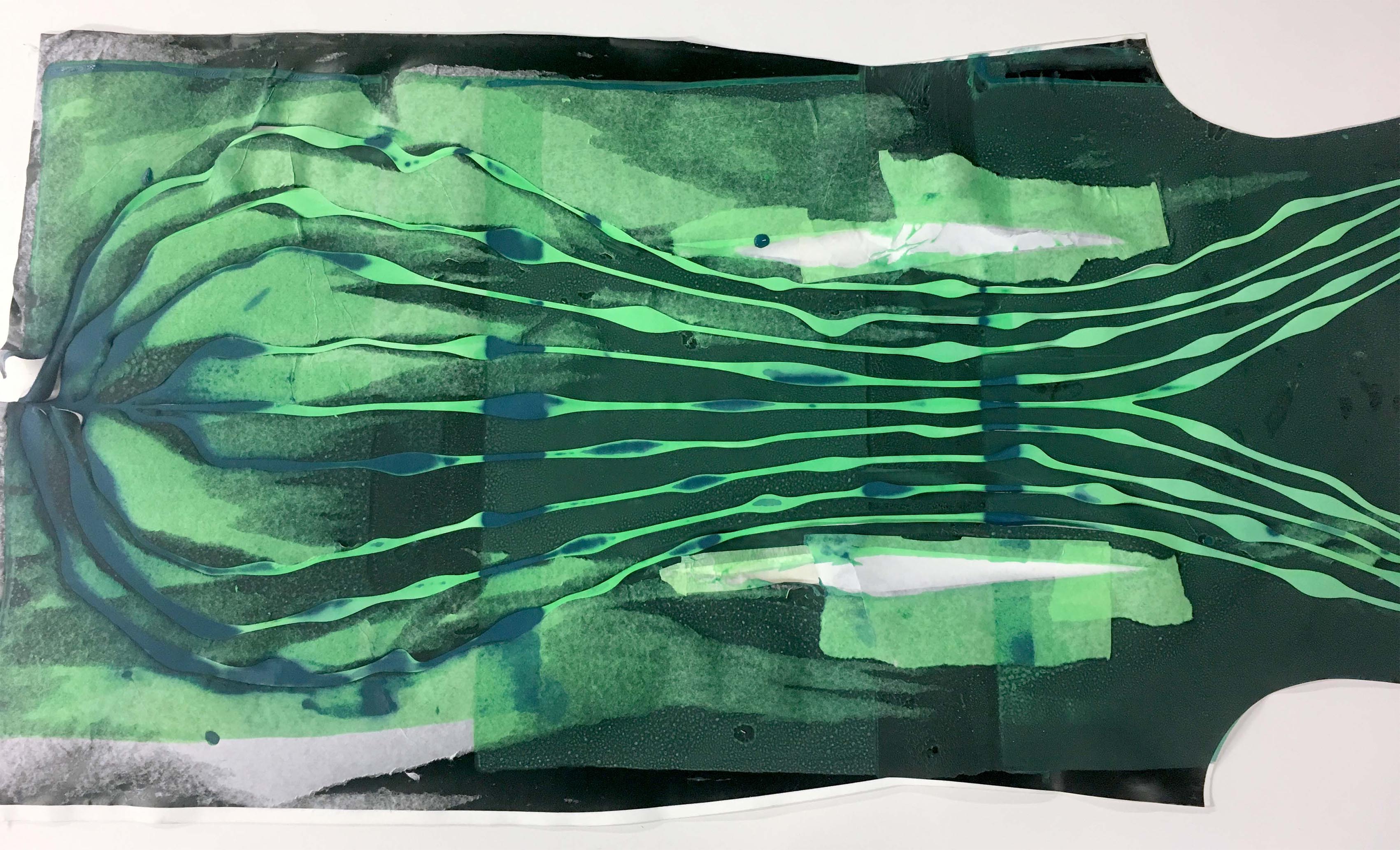

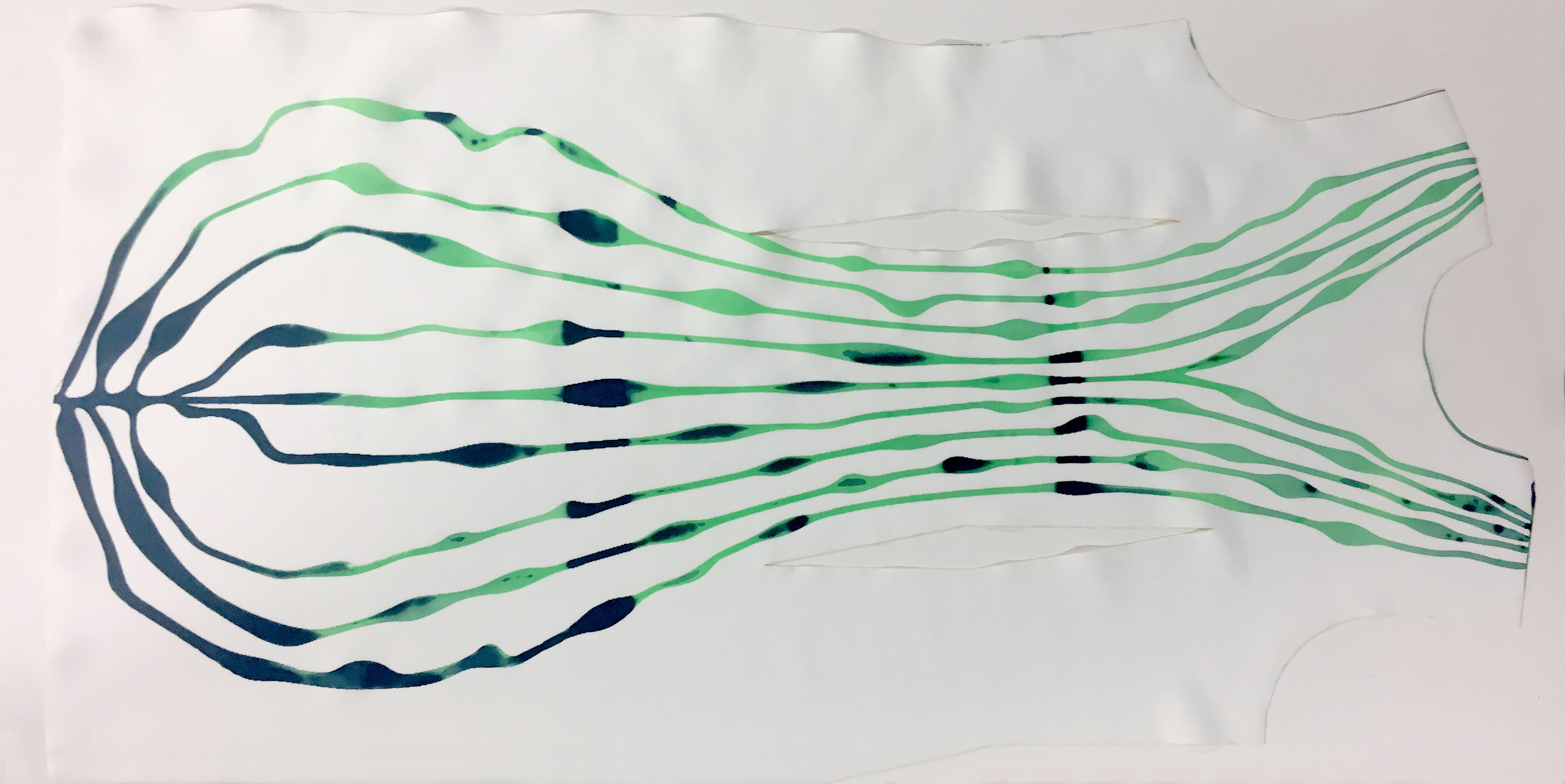

Bacteria textile dyeing

Growing bacteria, dyeing textiles

Growing bacteria, dyeing textiles

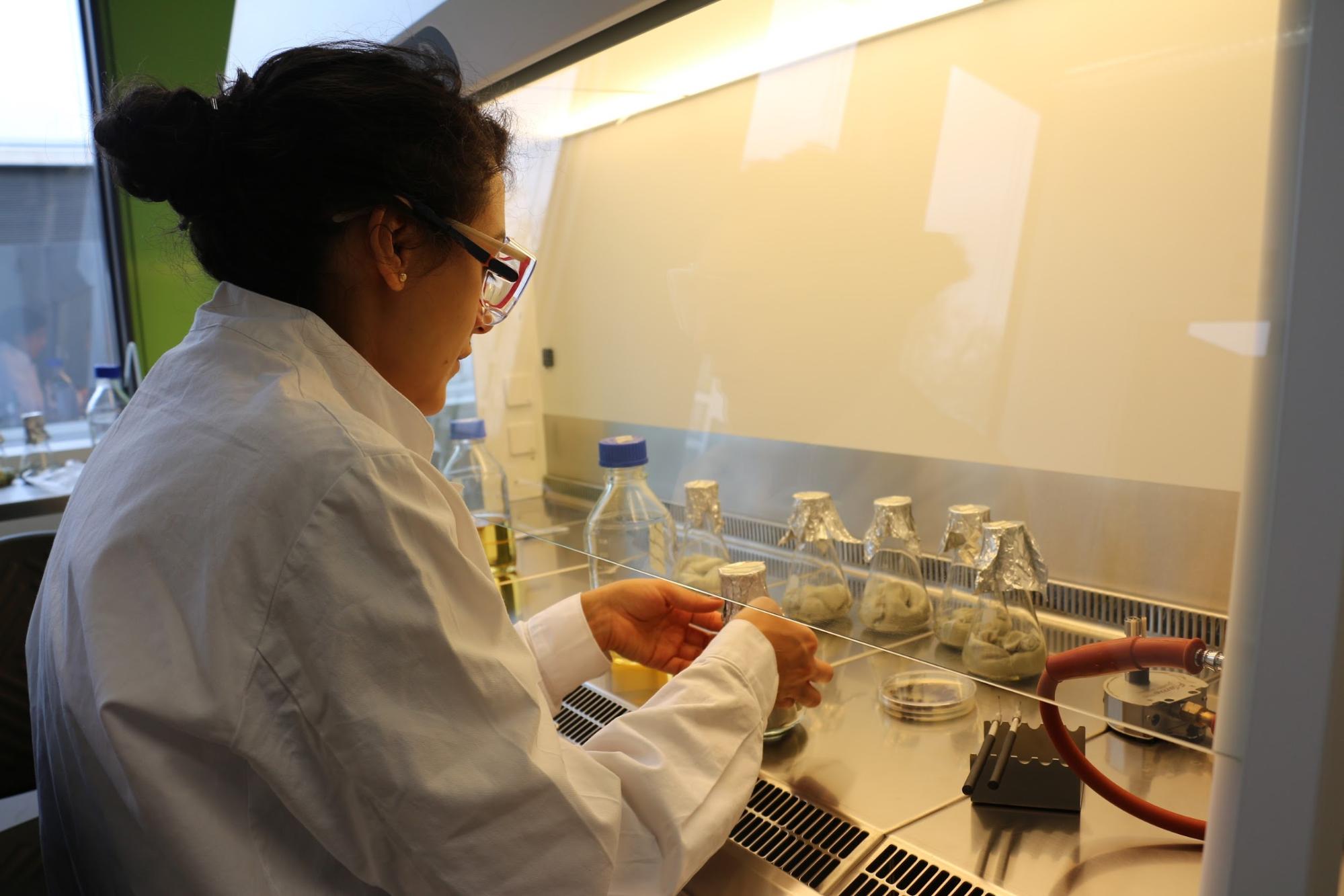

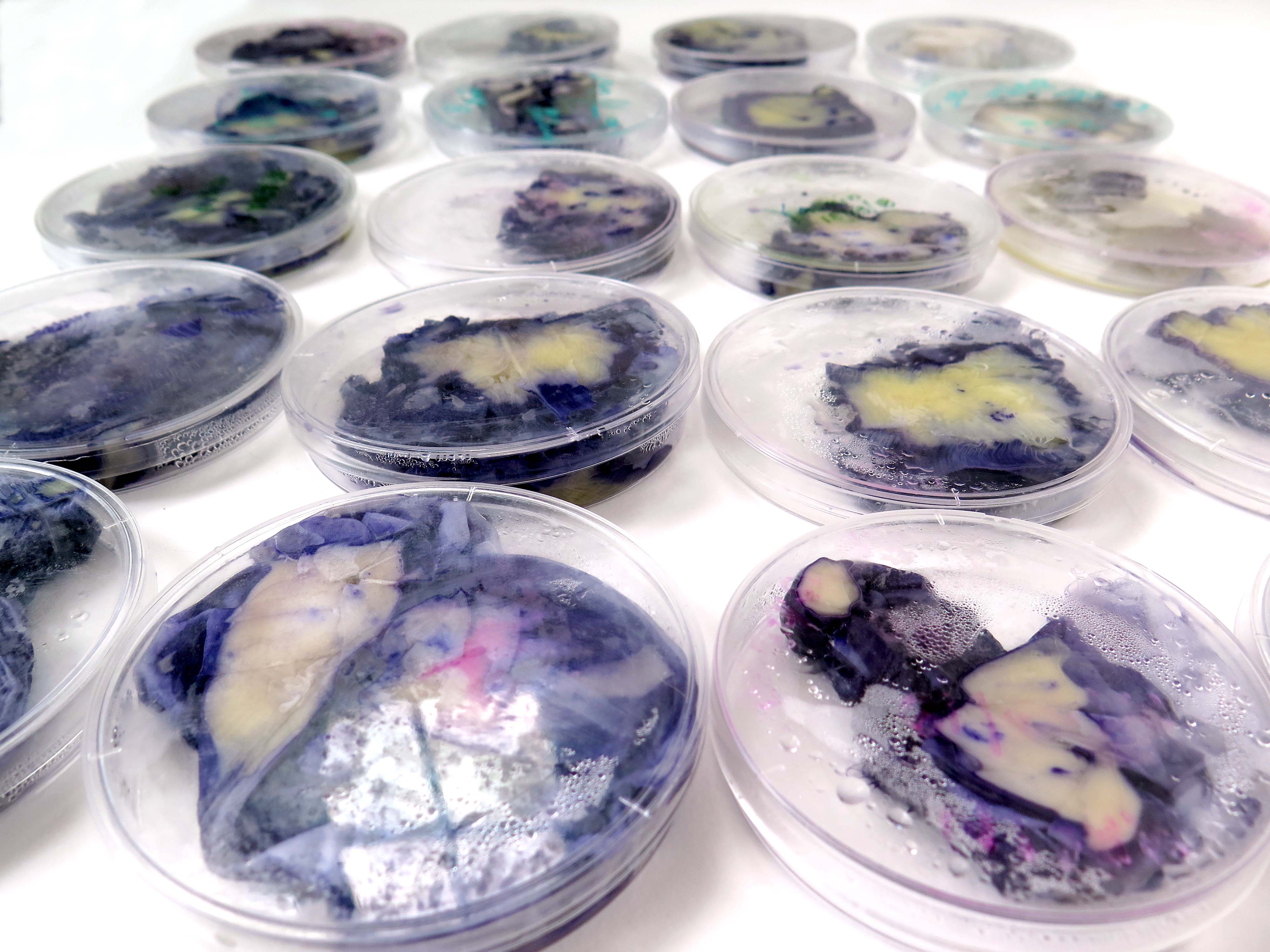

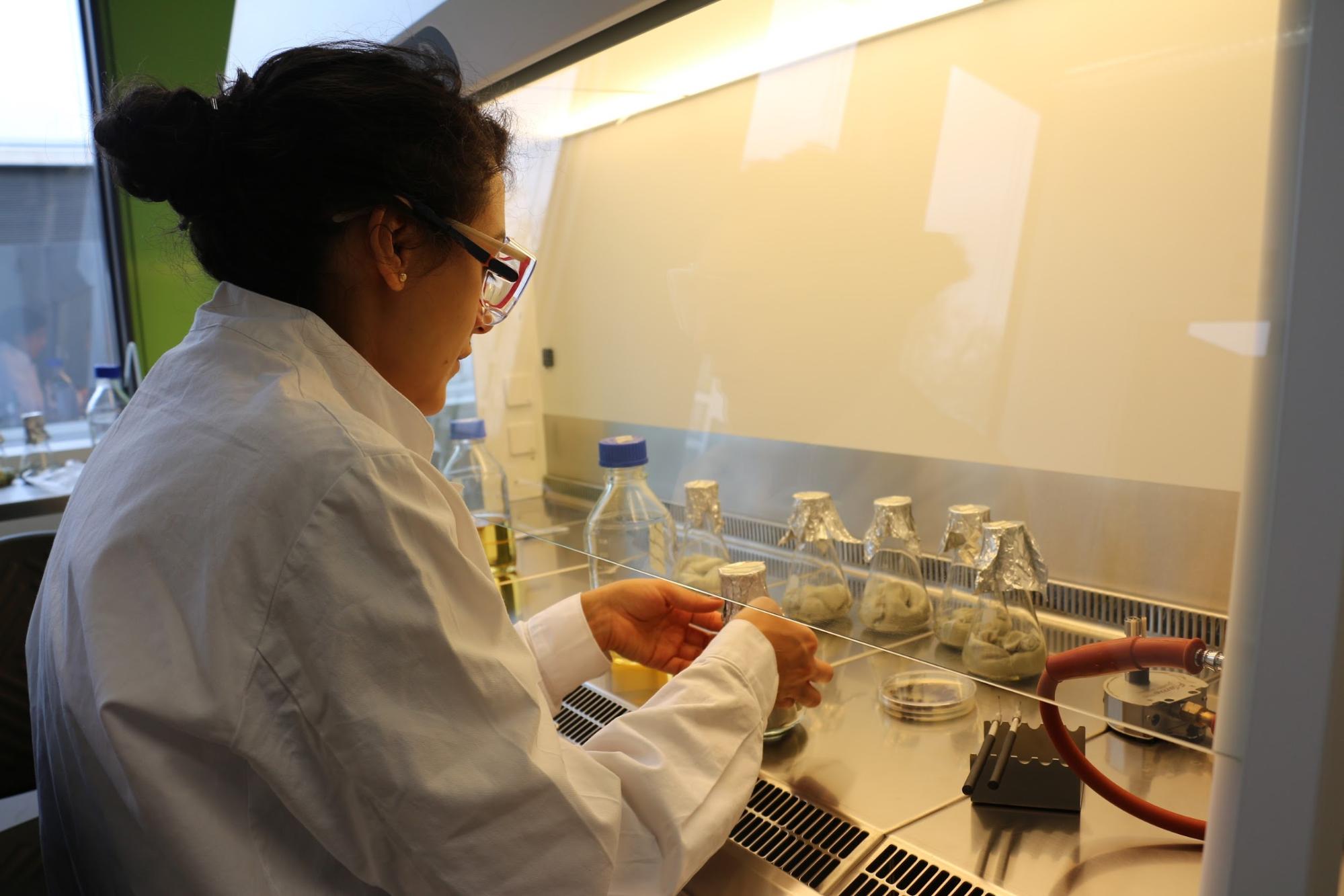

In Germany, the group at Fab Lab Kamp-Lintfort, mentored by Adriana Cabrera following the exercises at their biolab

In Germany, the group at Fab Lab Kamp-Lintfort, mentored by Adriana Cabrera following the exercises at their biolab

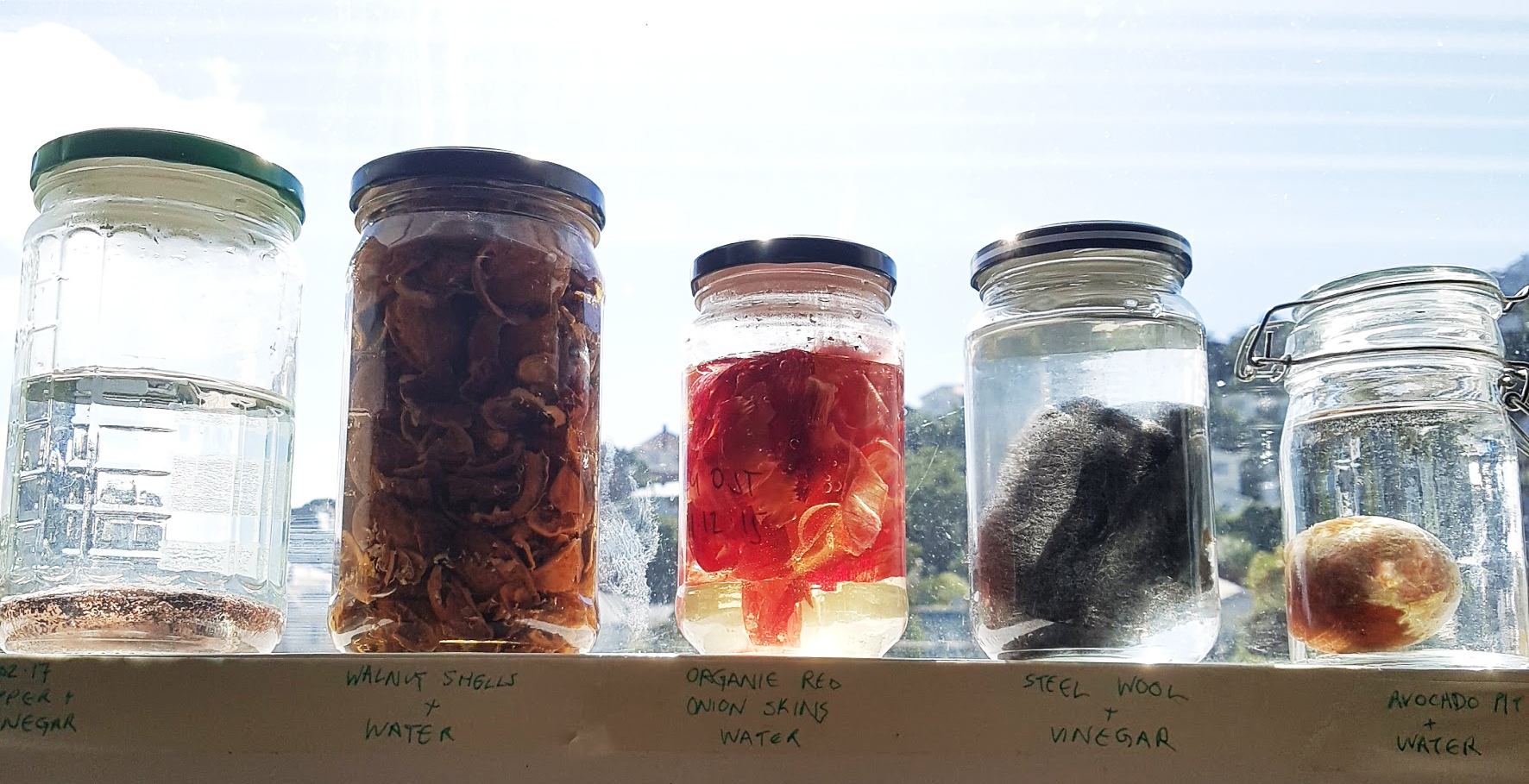

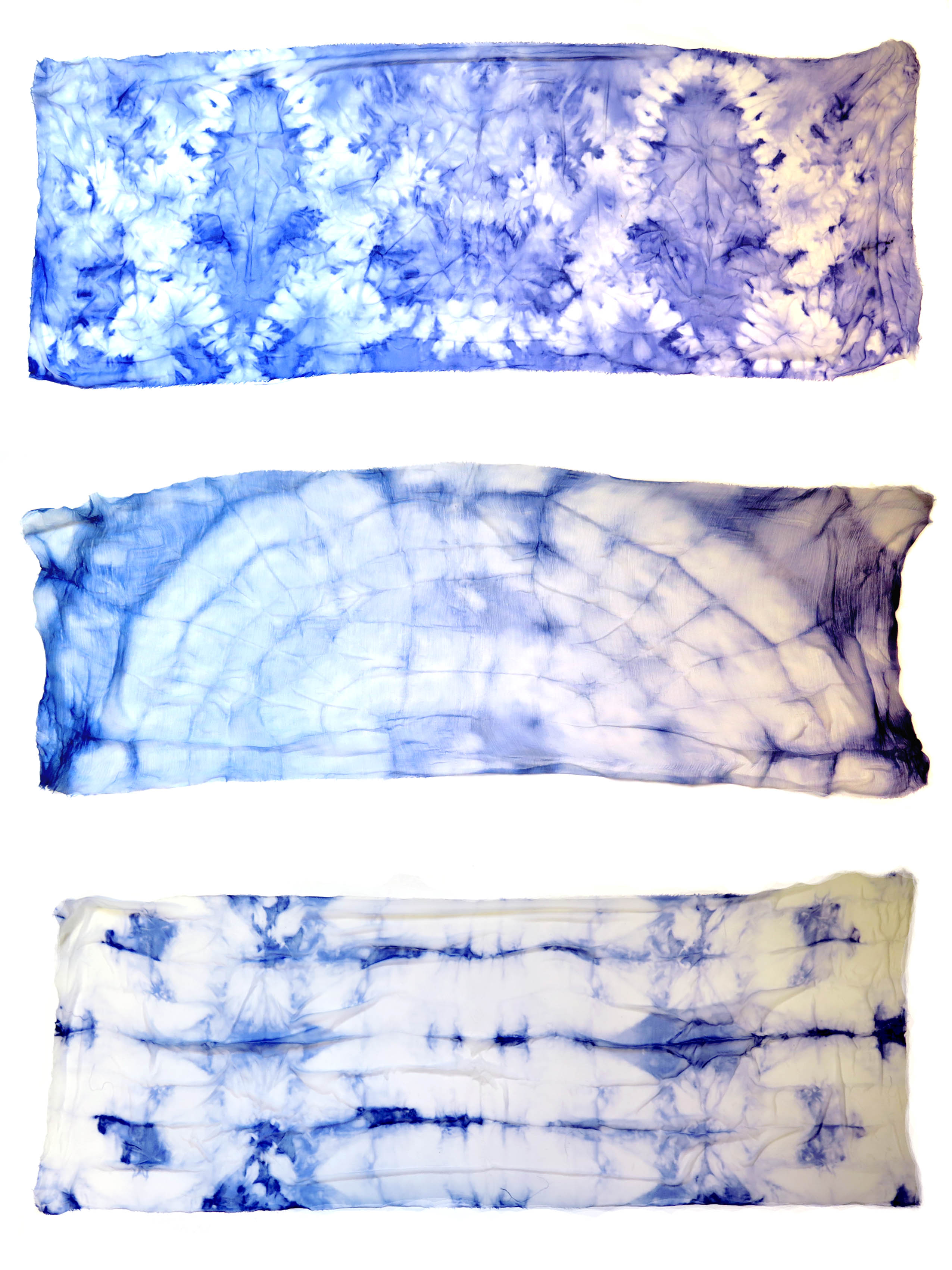

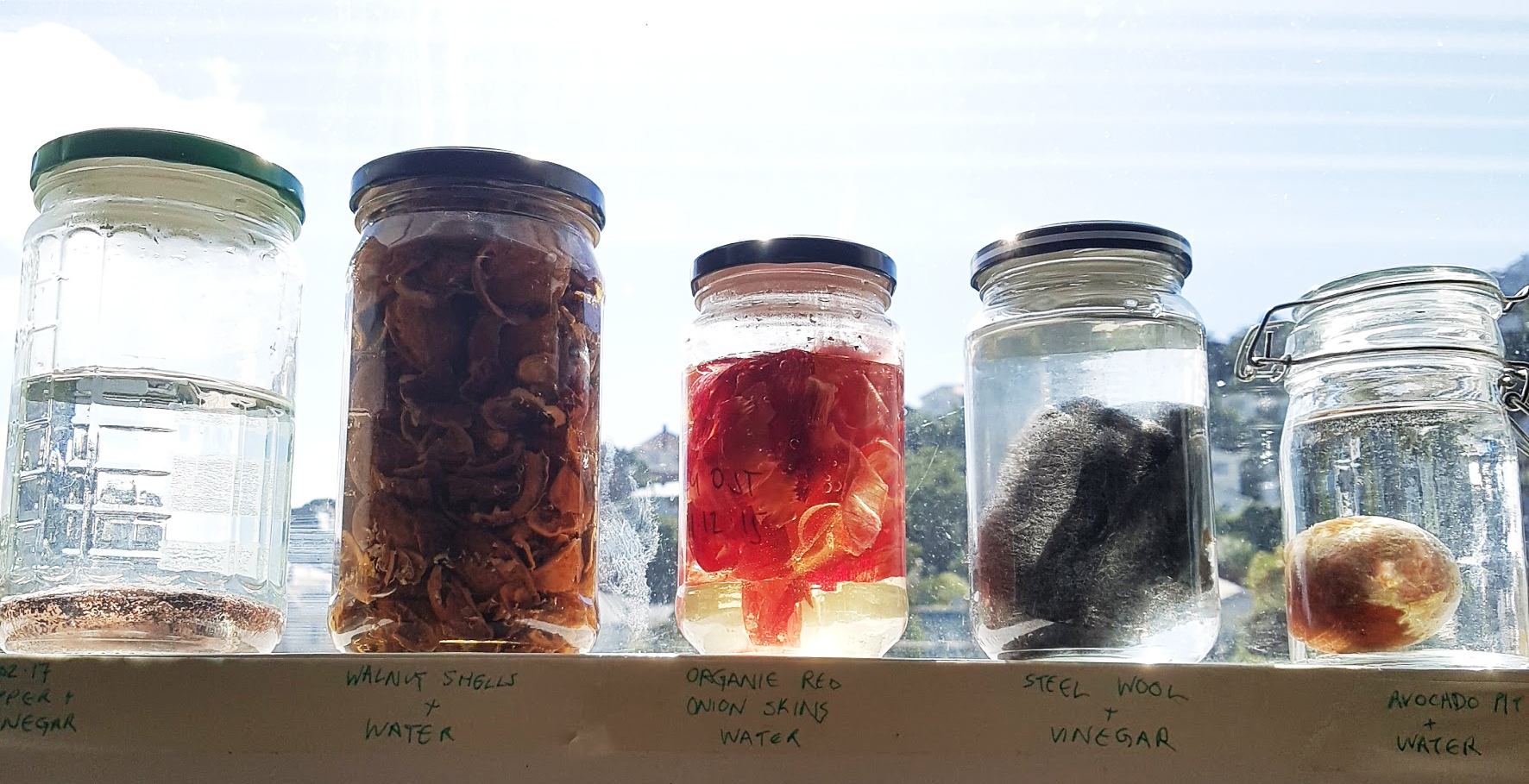

Natural Dyes

Wendy Neale, Creative Director of Fab Lab Wellington in New Zealand preparing her natural dyes.

Wendy Neale, Creative Director of Fab Lab Wellington in New Zealand preparing her natural dyes.

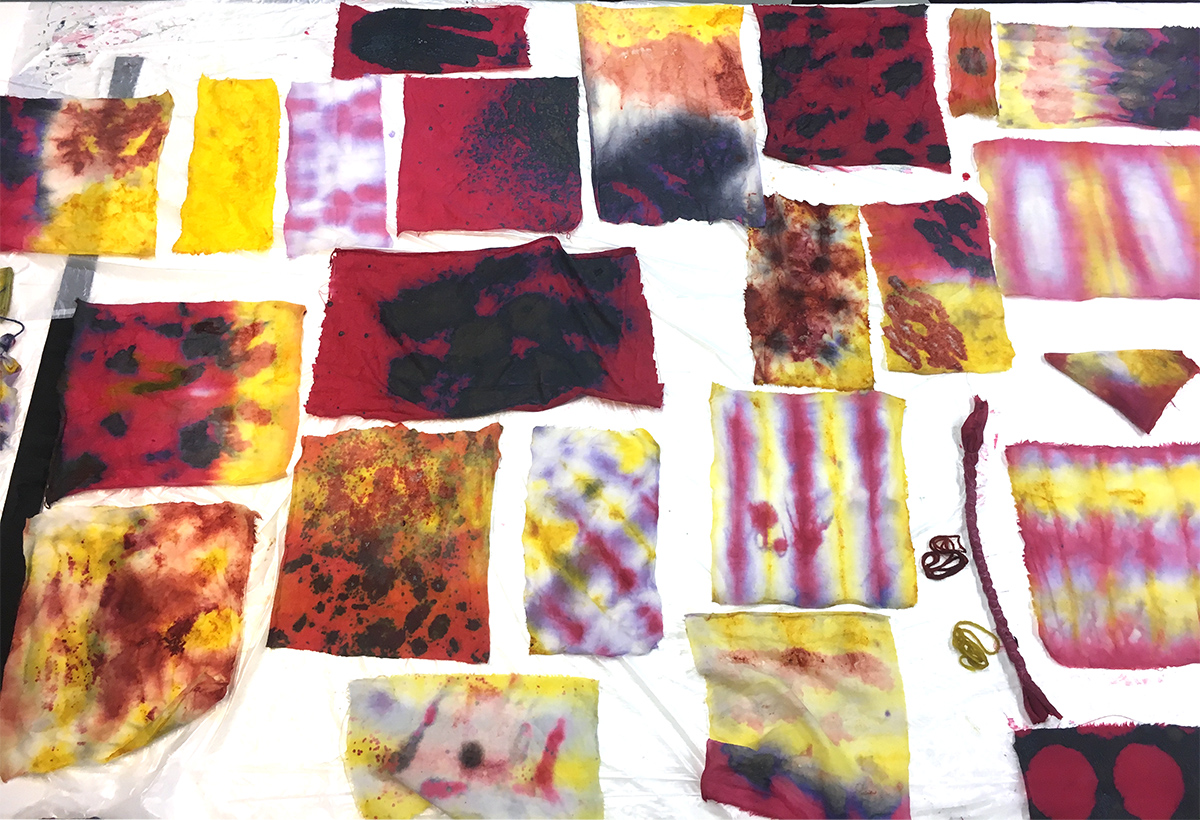

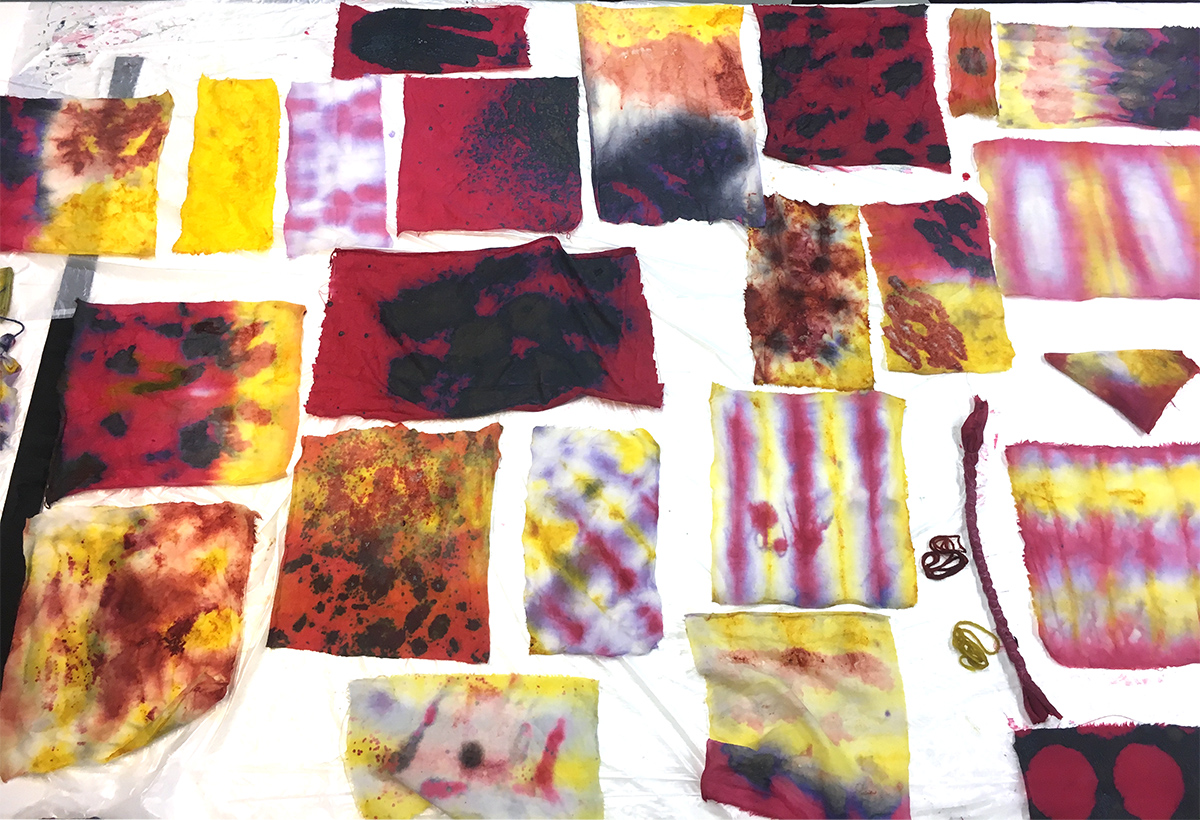

Natural dyeing of textile with turmeric, hibiscus, turmeric and ph modifiers

Natural dyeing of textile with turmeric, hibiscus, turmeric and ph modifiers

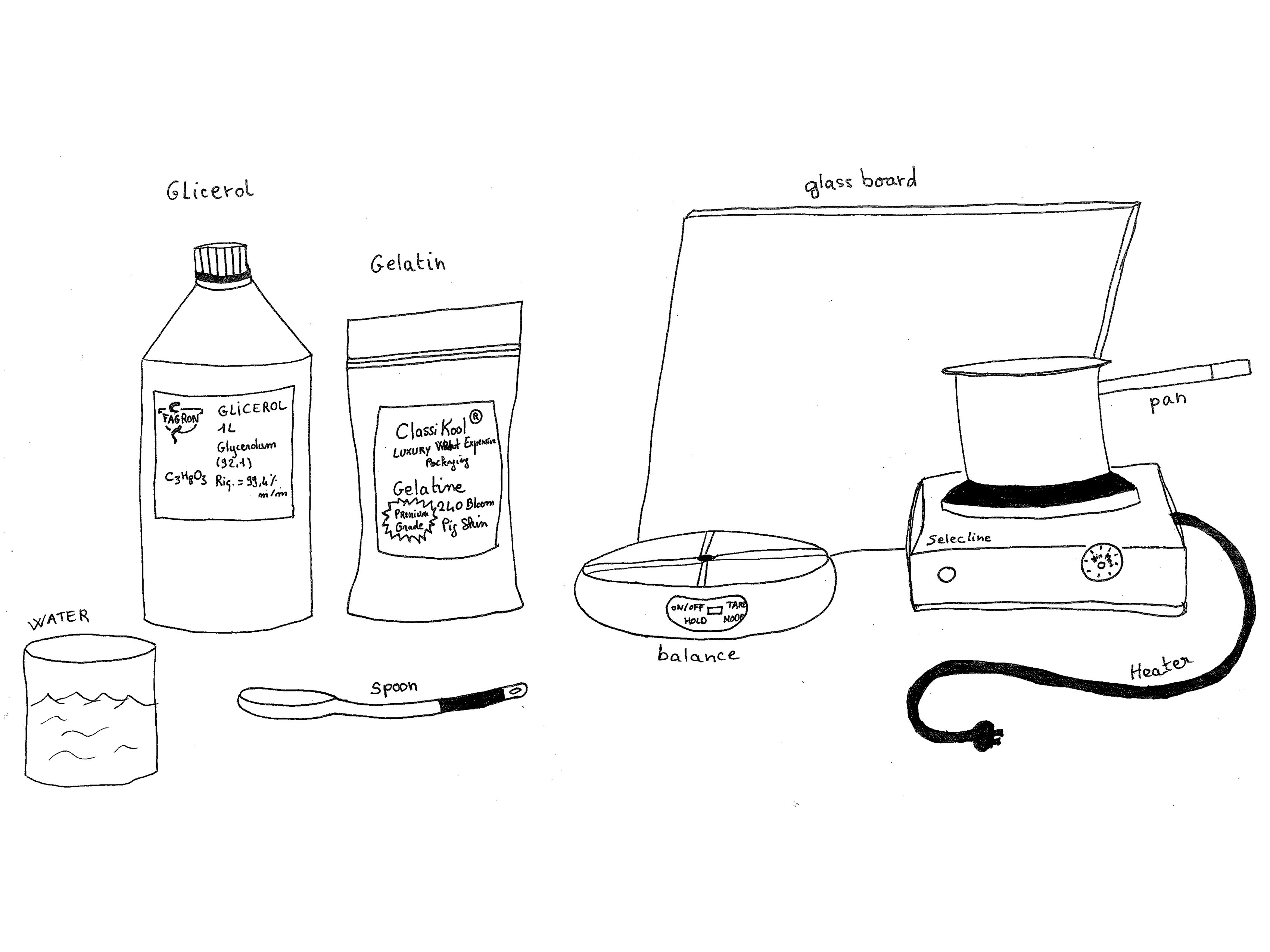

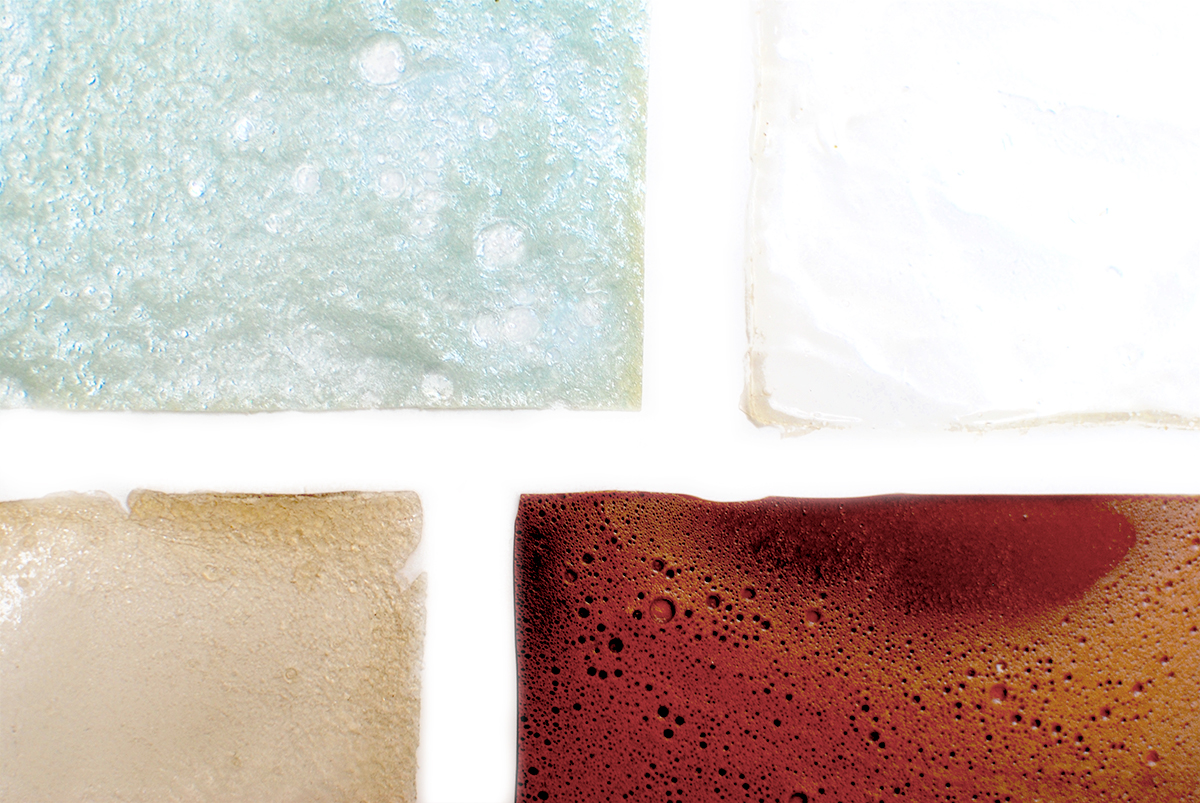

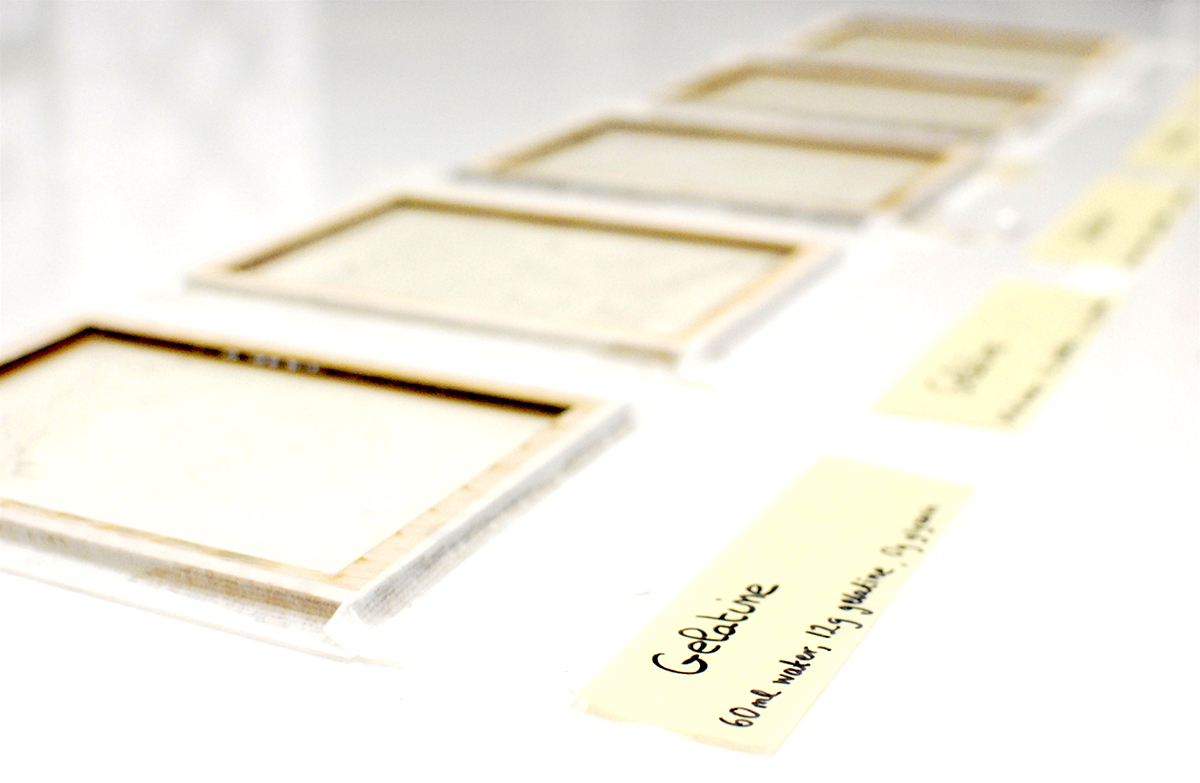

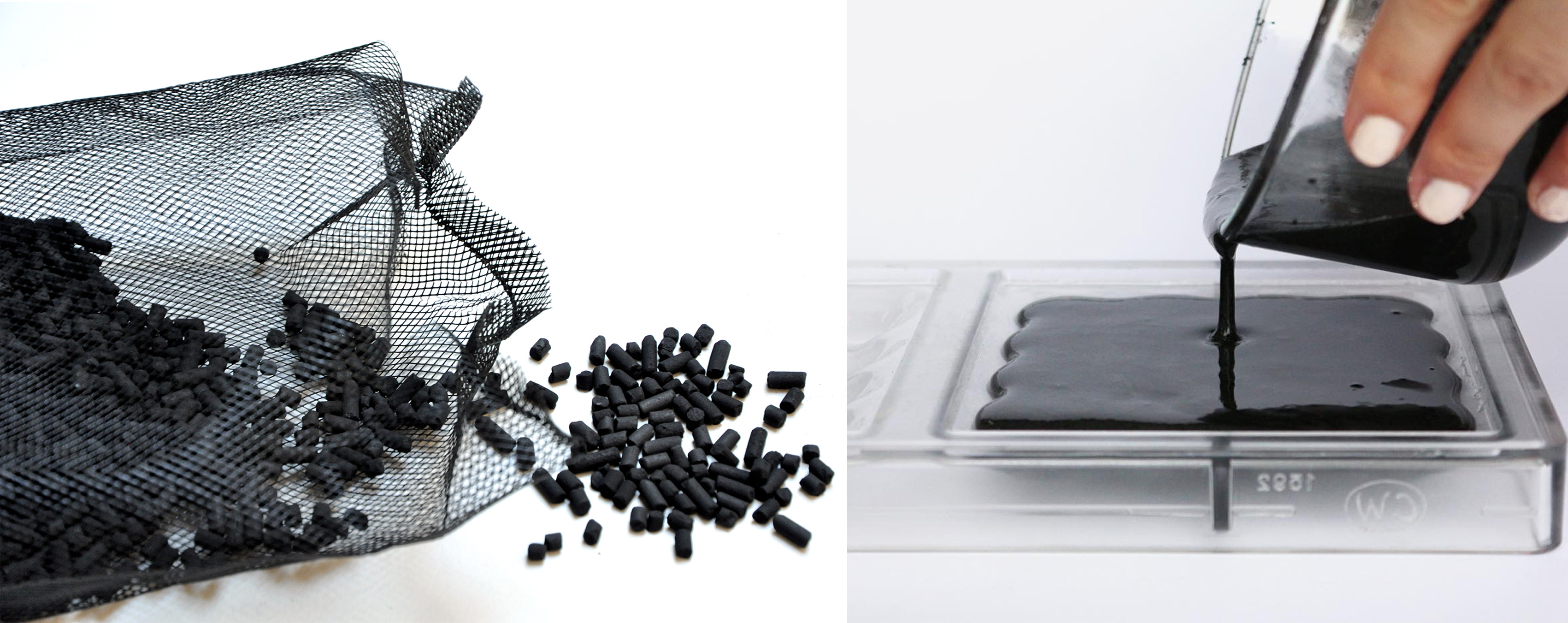

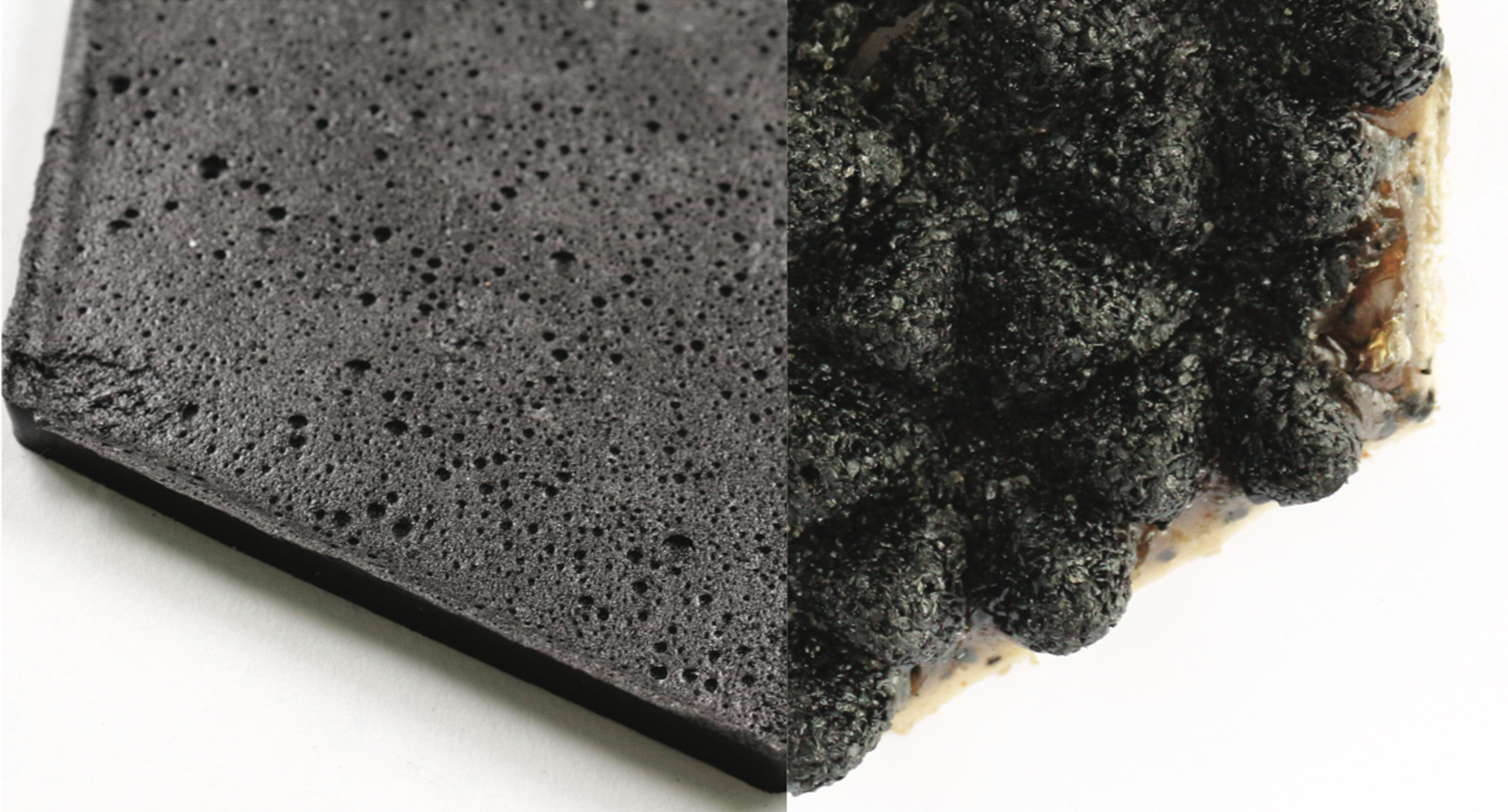

BIOPLASTICS

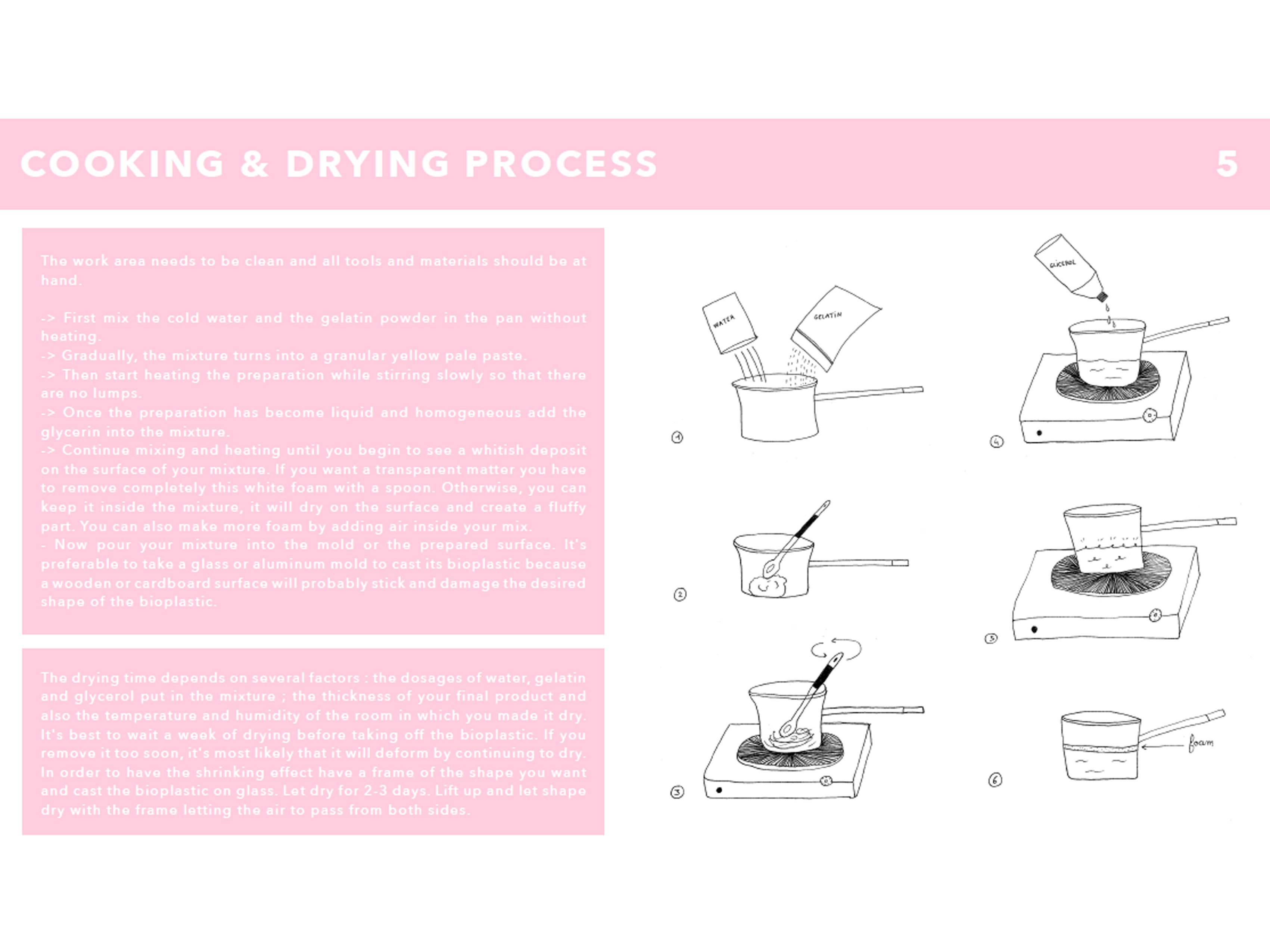

@fabricademy Instagram Cooking Bioplastics based on Glycerine and Glycerol

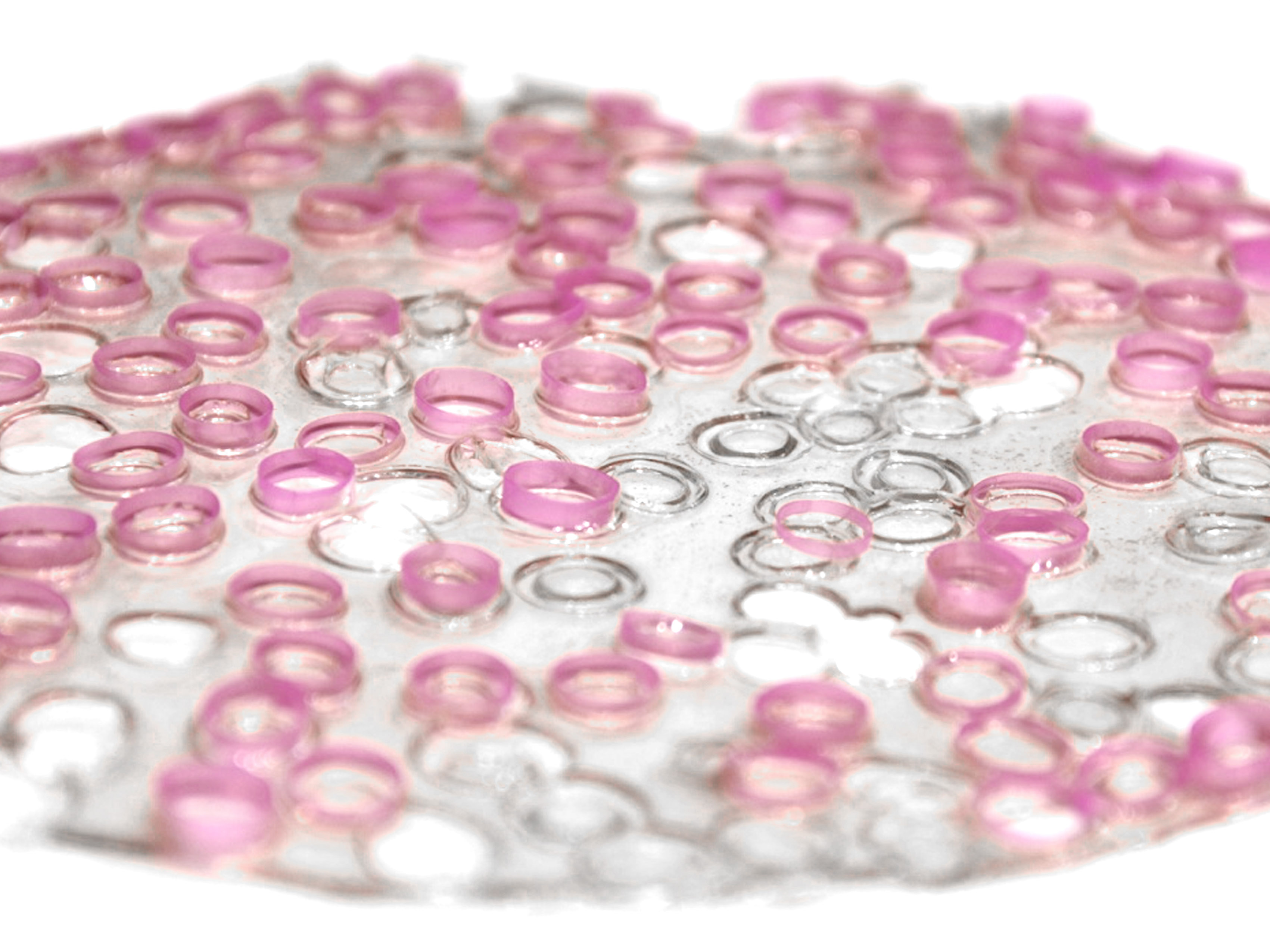

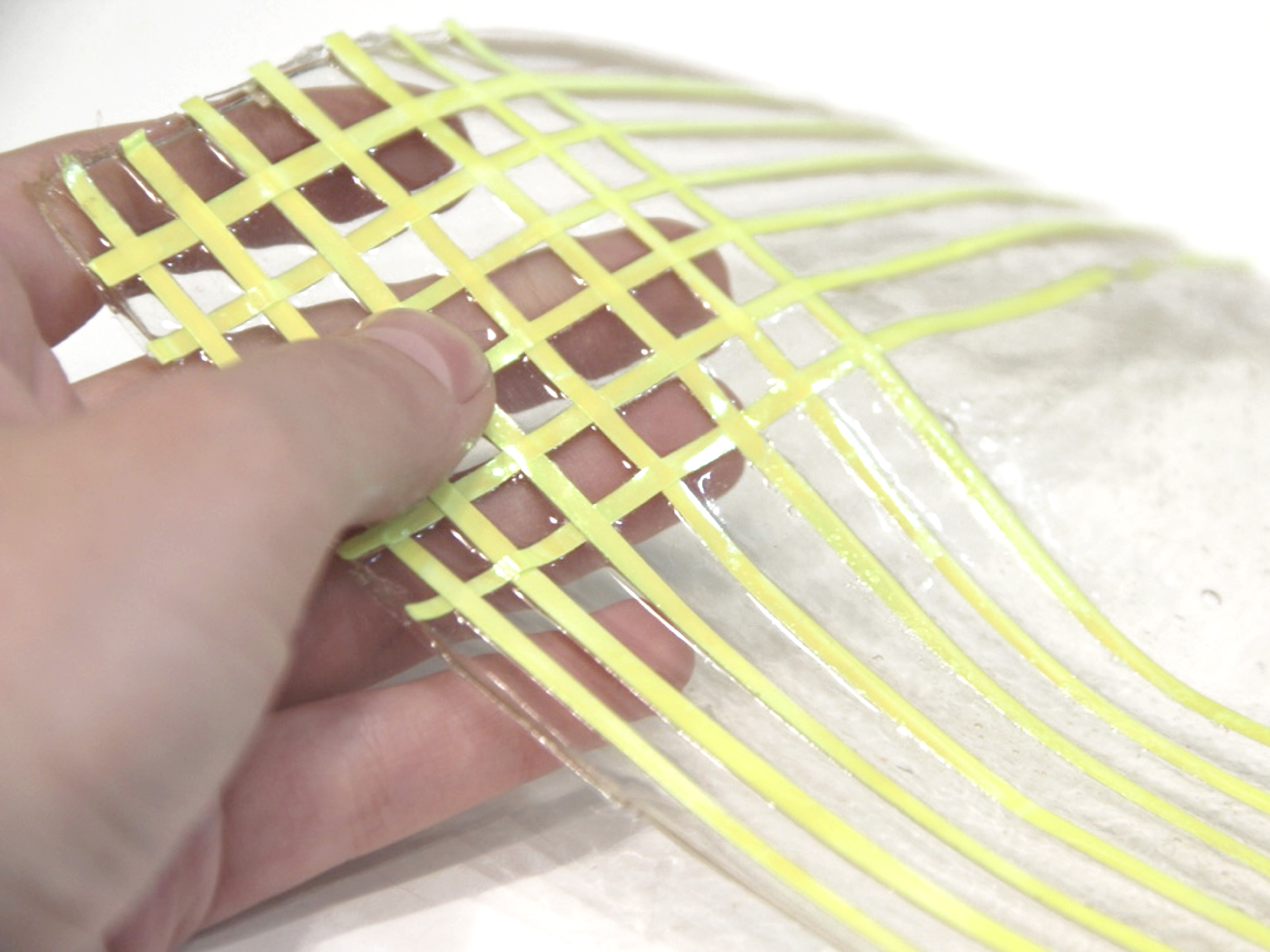

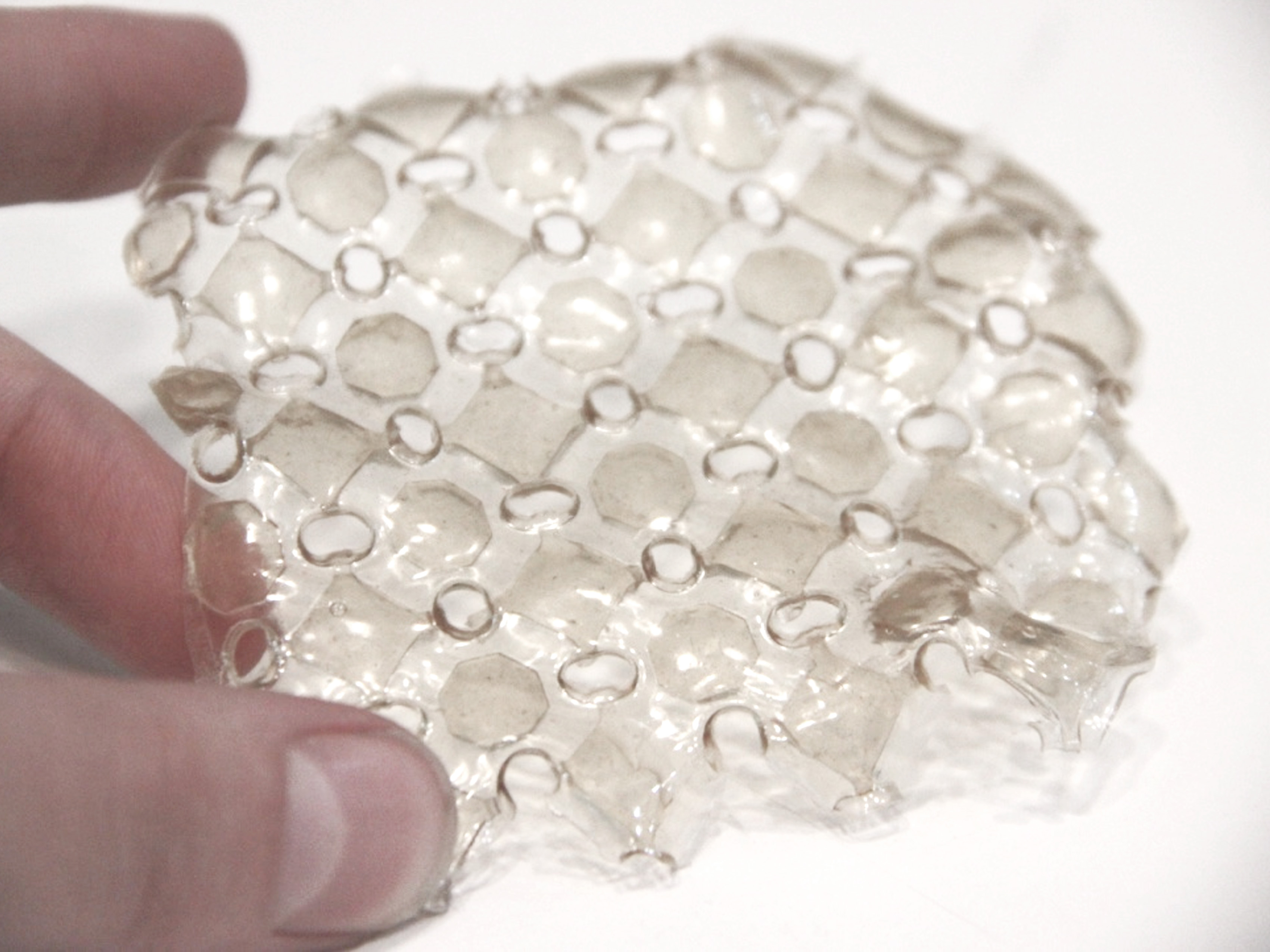

@fabricademy Instagram Cooking Bioplastics based on Glycerine and Glycerol Combination of bioplastics with fabric and pigments applied on a thin surface to create flexible sheets of bioplastic

Combination of bioplastics with fabric and pigments applied on a thin surface to create flexible sheets of bioplastic

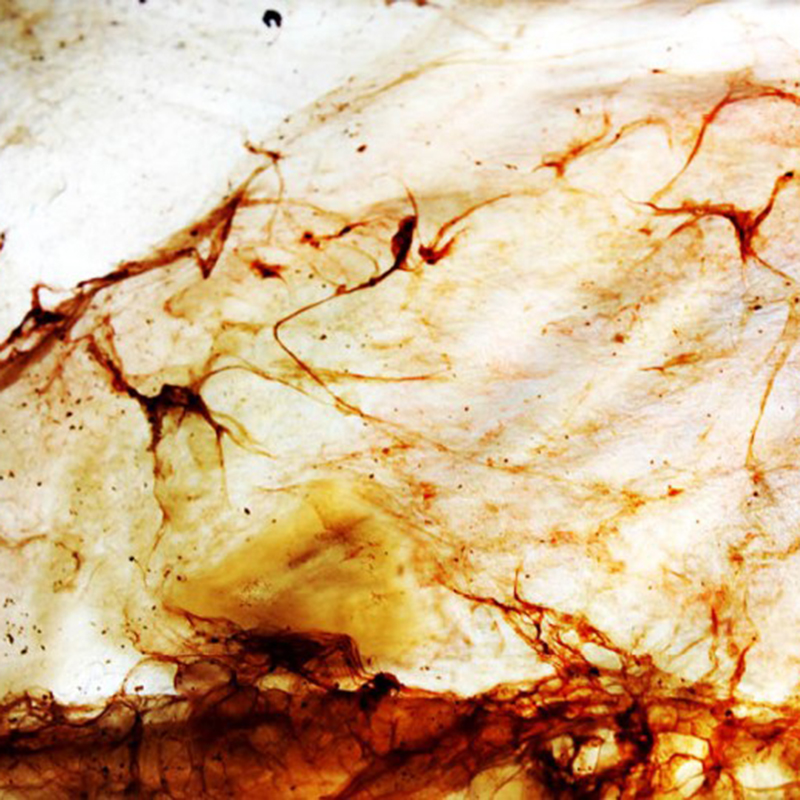

KOMBUCHA CELLULOSE SKIN Kombucha skin of 1mx1m grown for 2 months using the biocouture recipe of Susan Lee for growing your own cellulose fabric

Kombucha skin of 1mx1m grown for 2 months using the biocouture recipe of Susan Lee for growing your own cellulose fabric

Molding kombucha skin and knitting

Molding kombucha skin and knitting  Dried kombucha skin

Dried kombucha skin

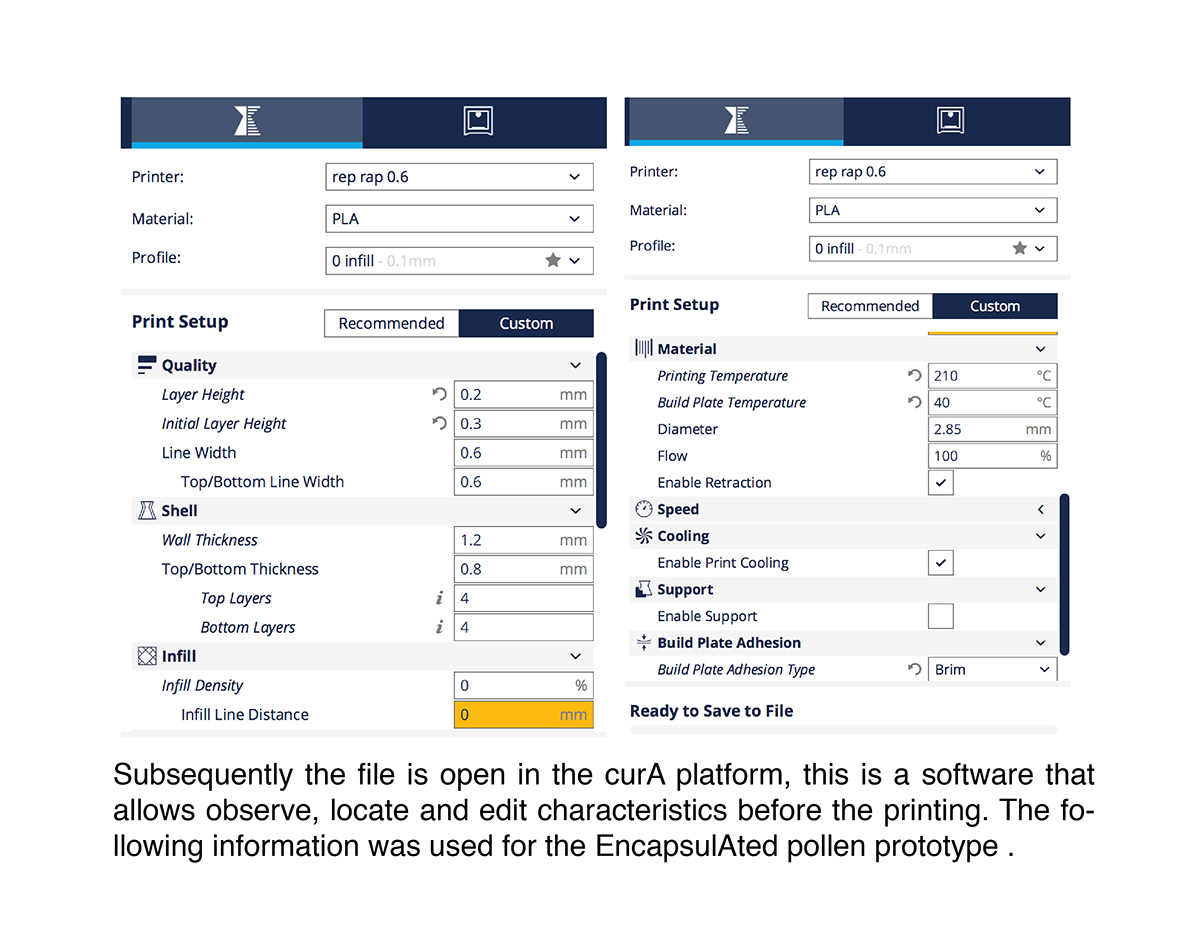

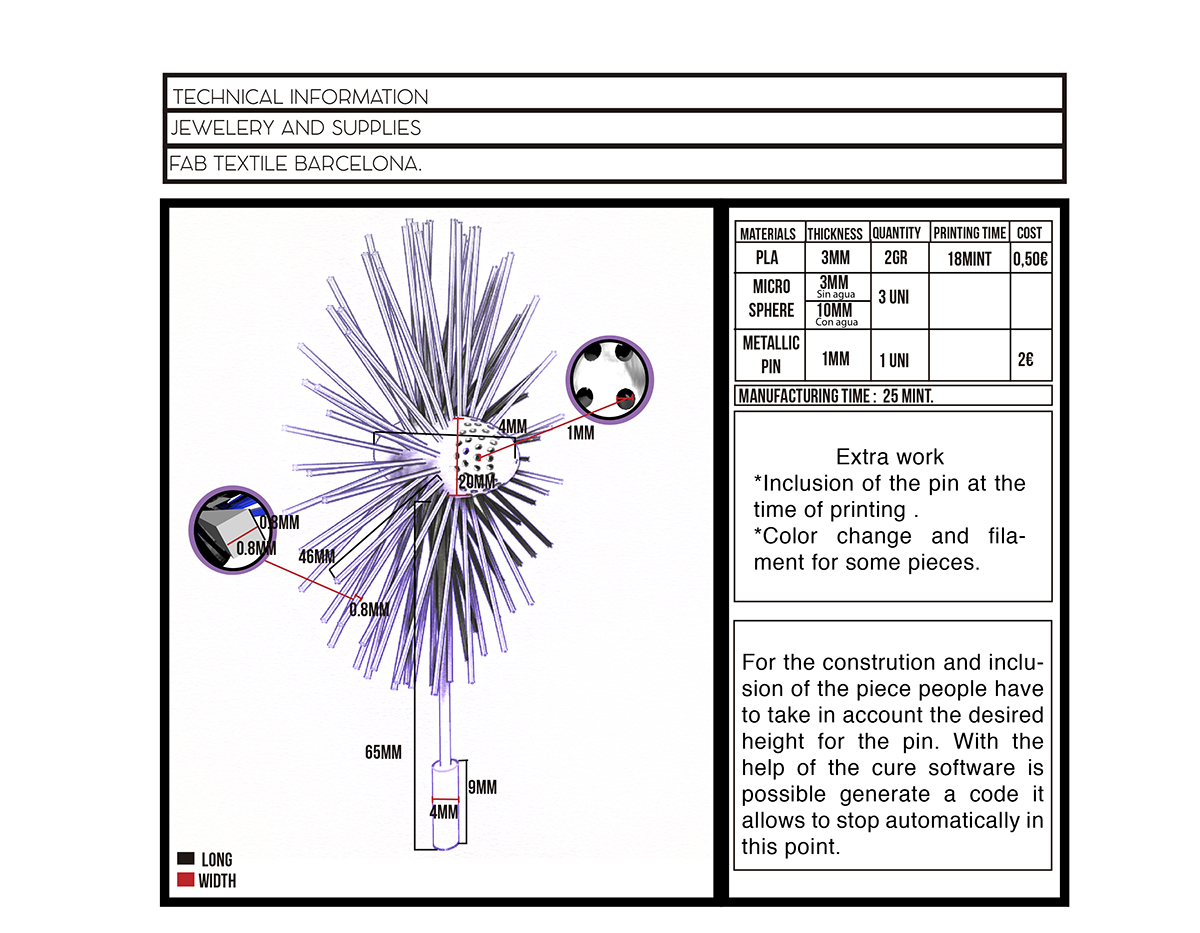

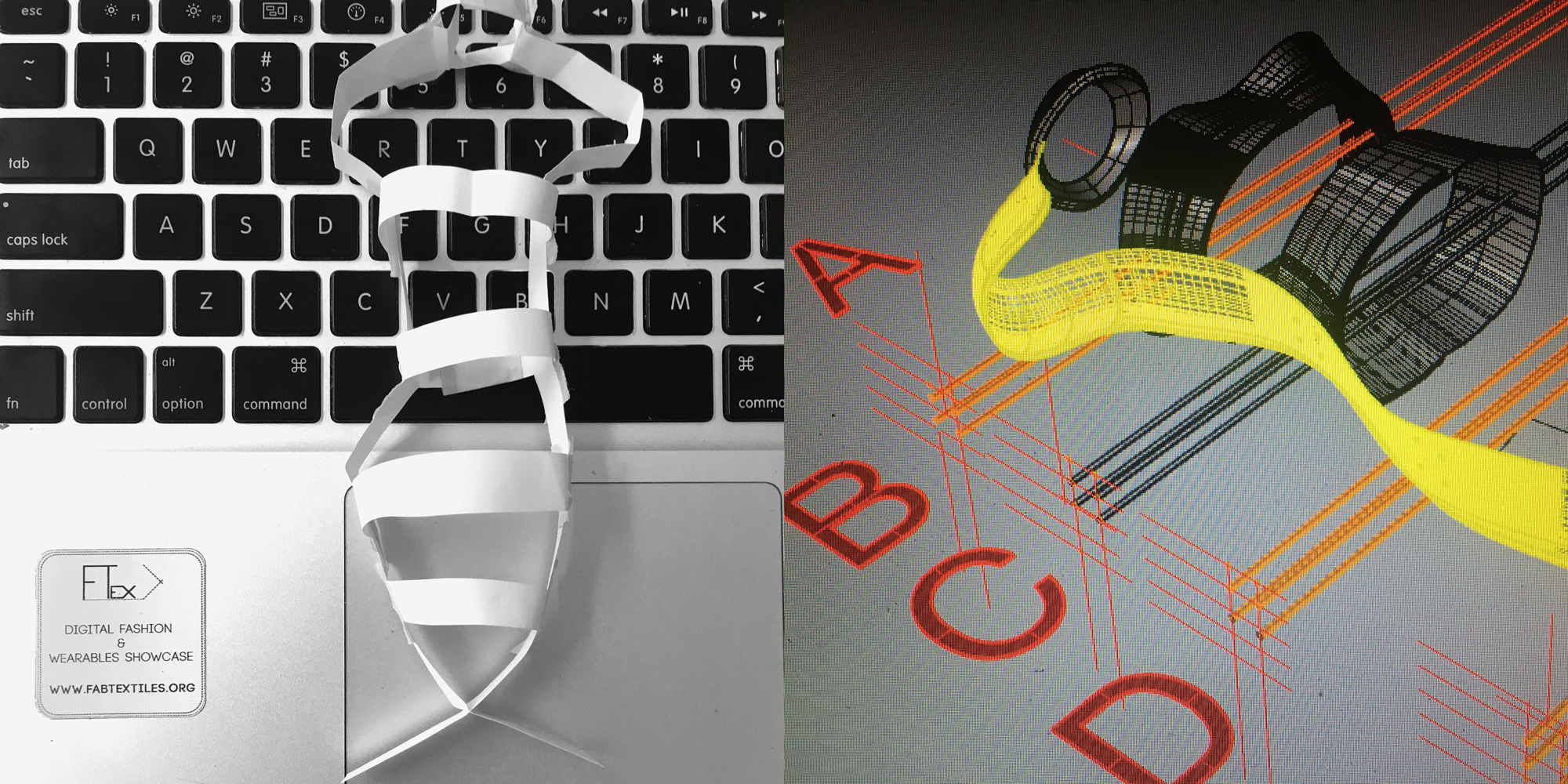

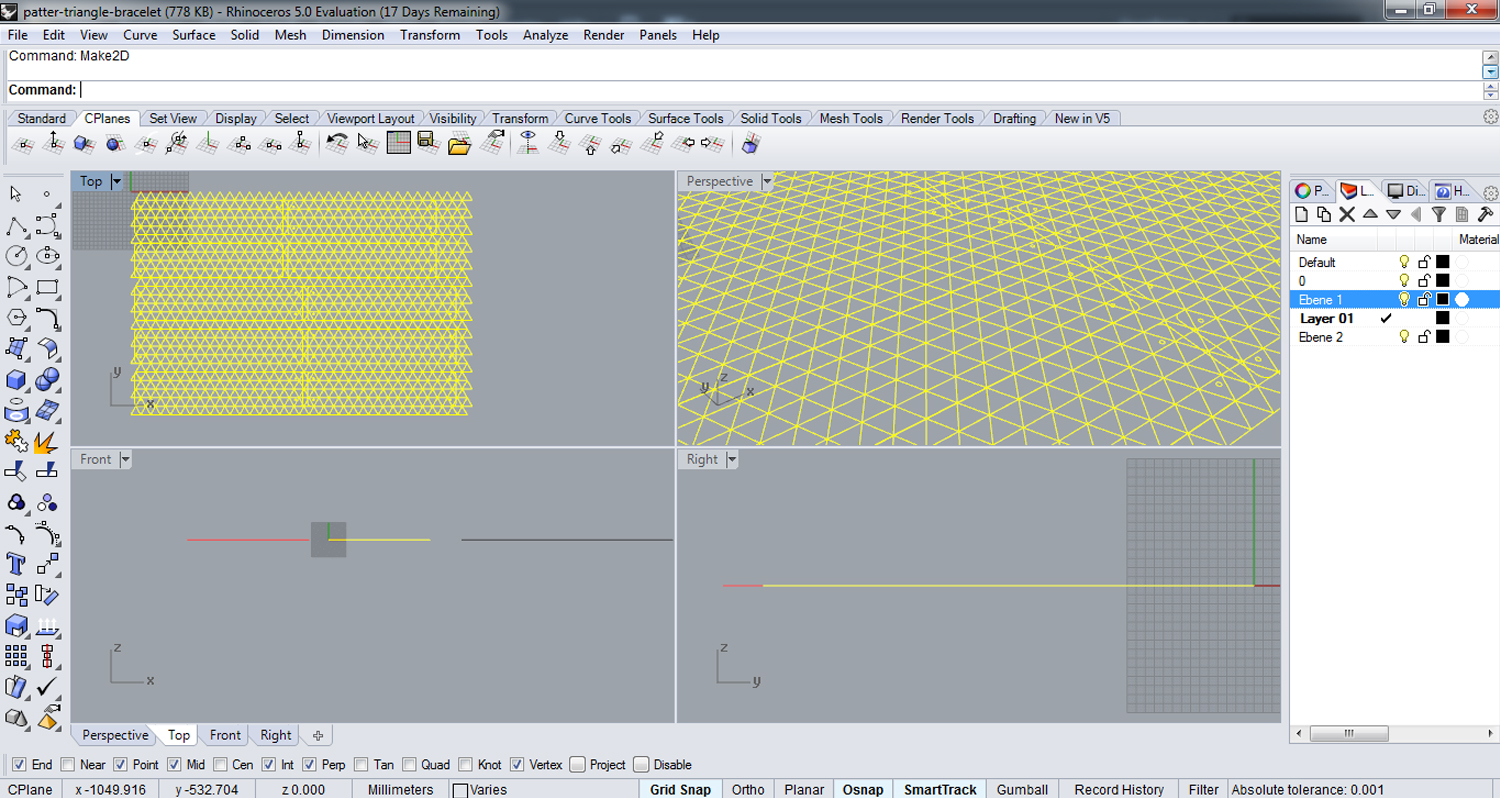

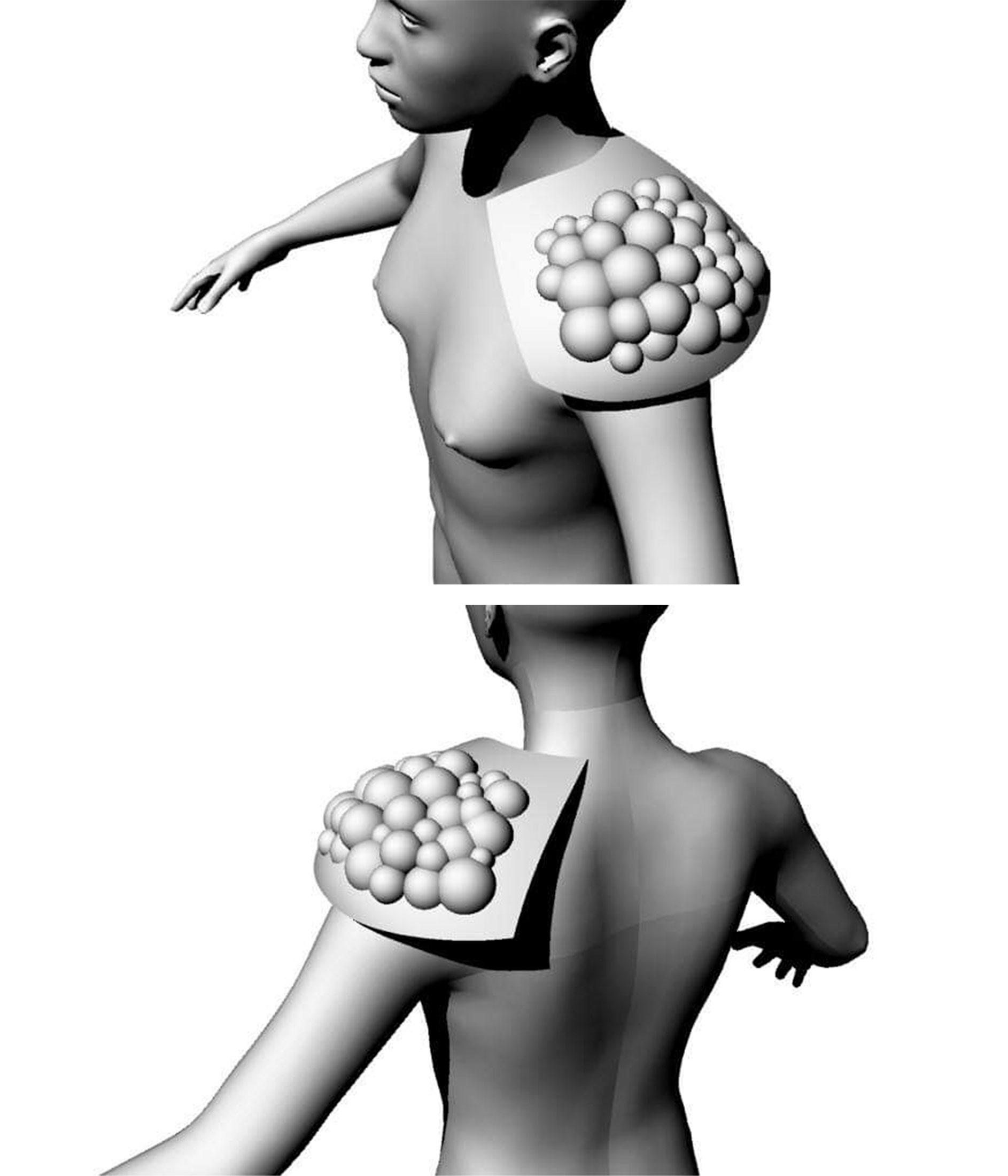

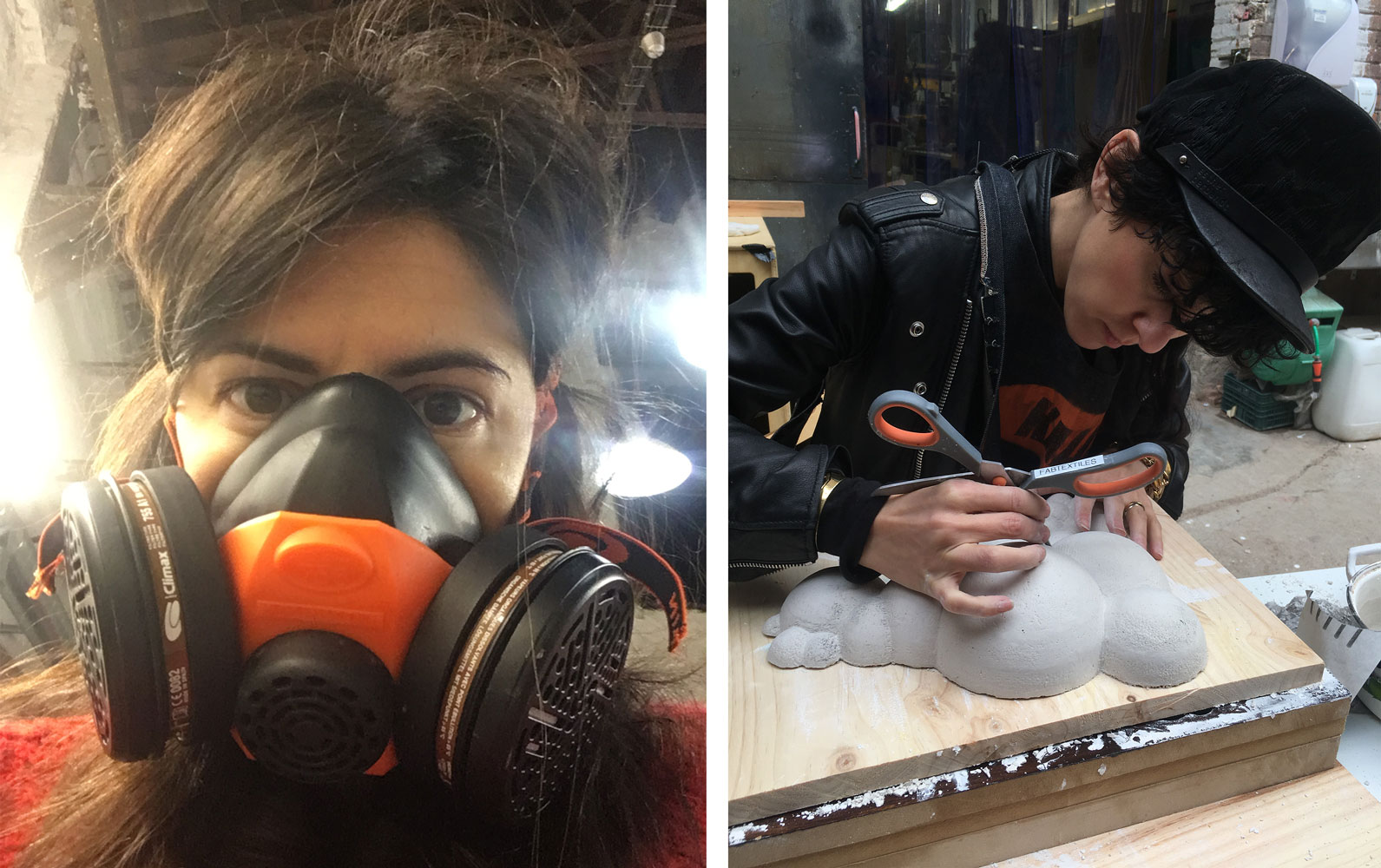

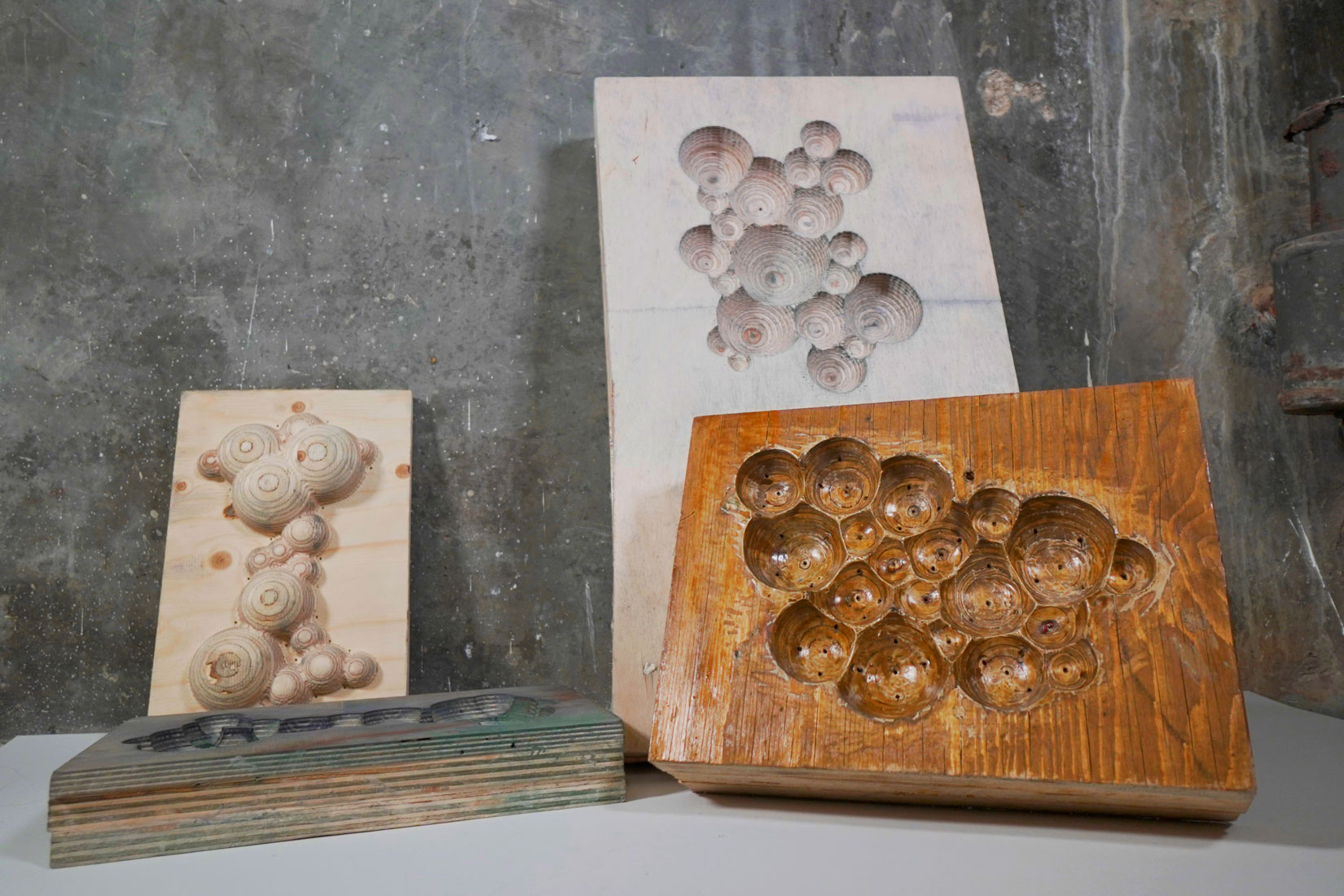

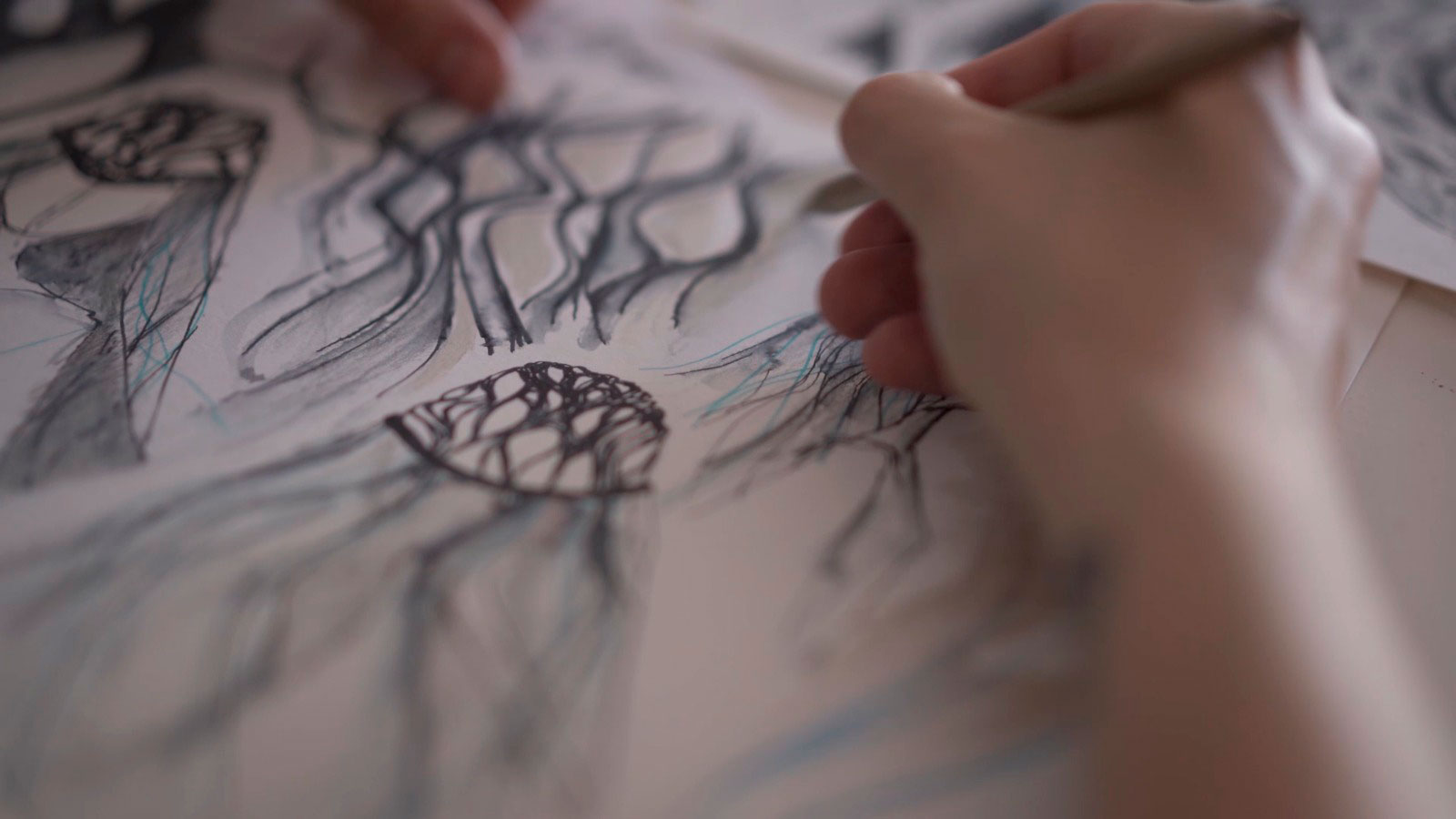

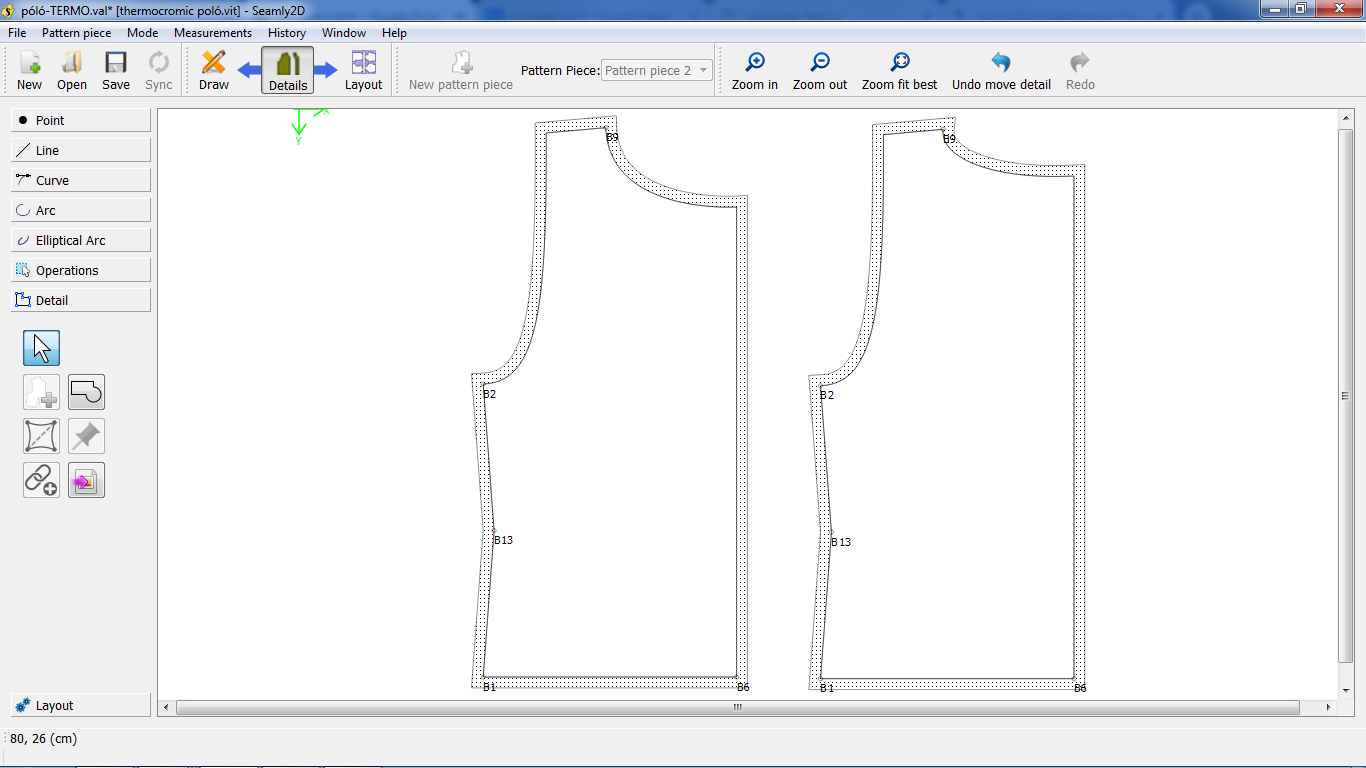

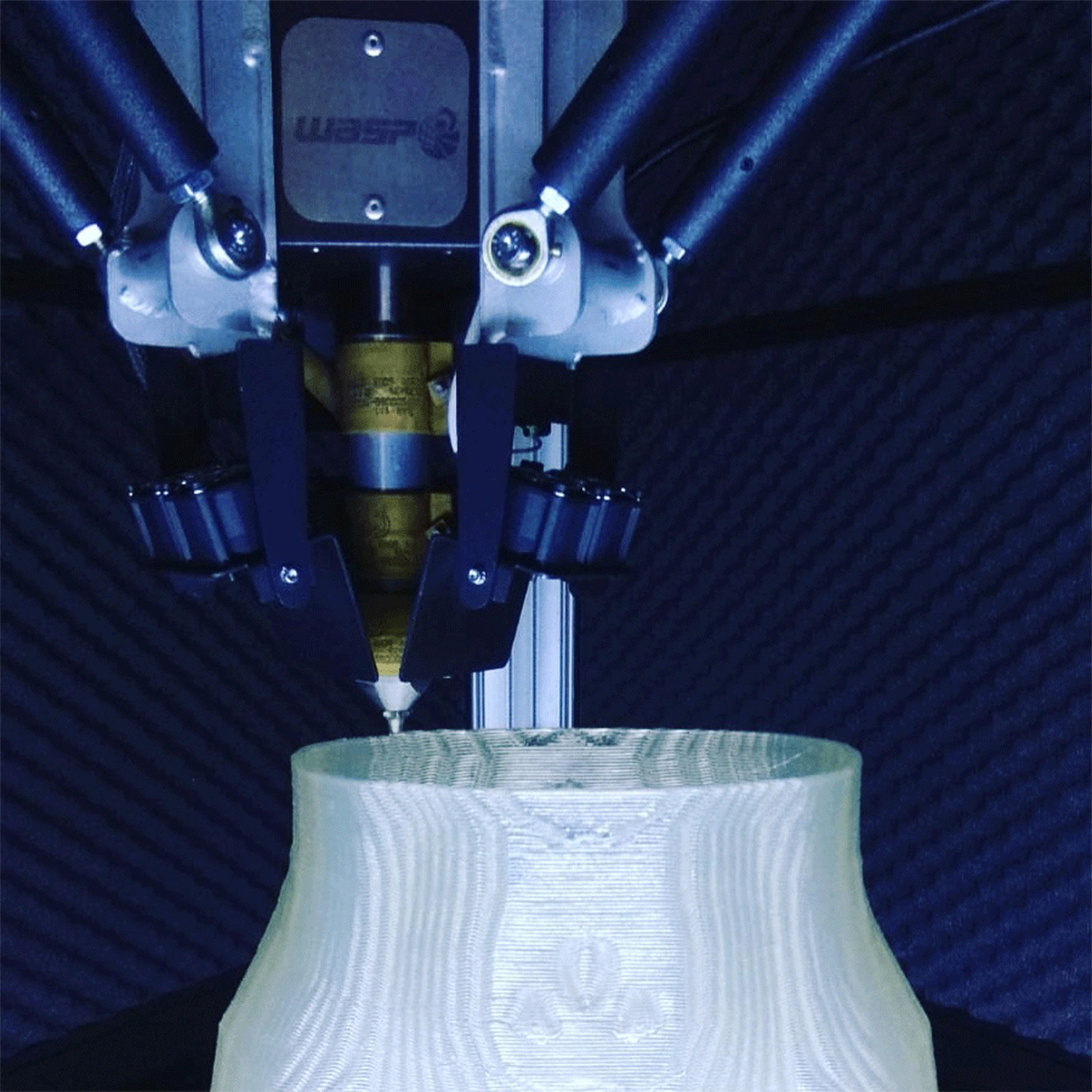

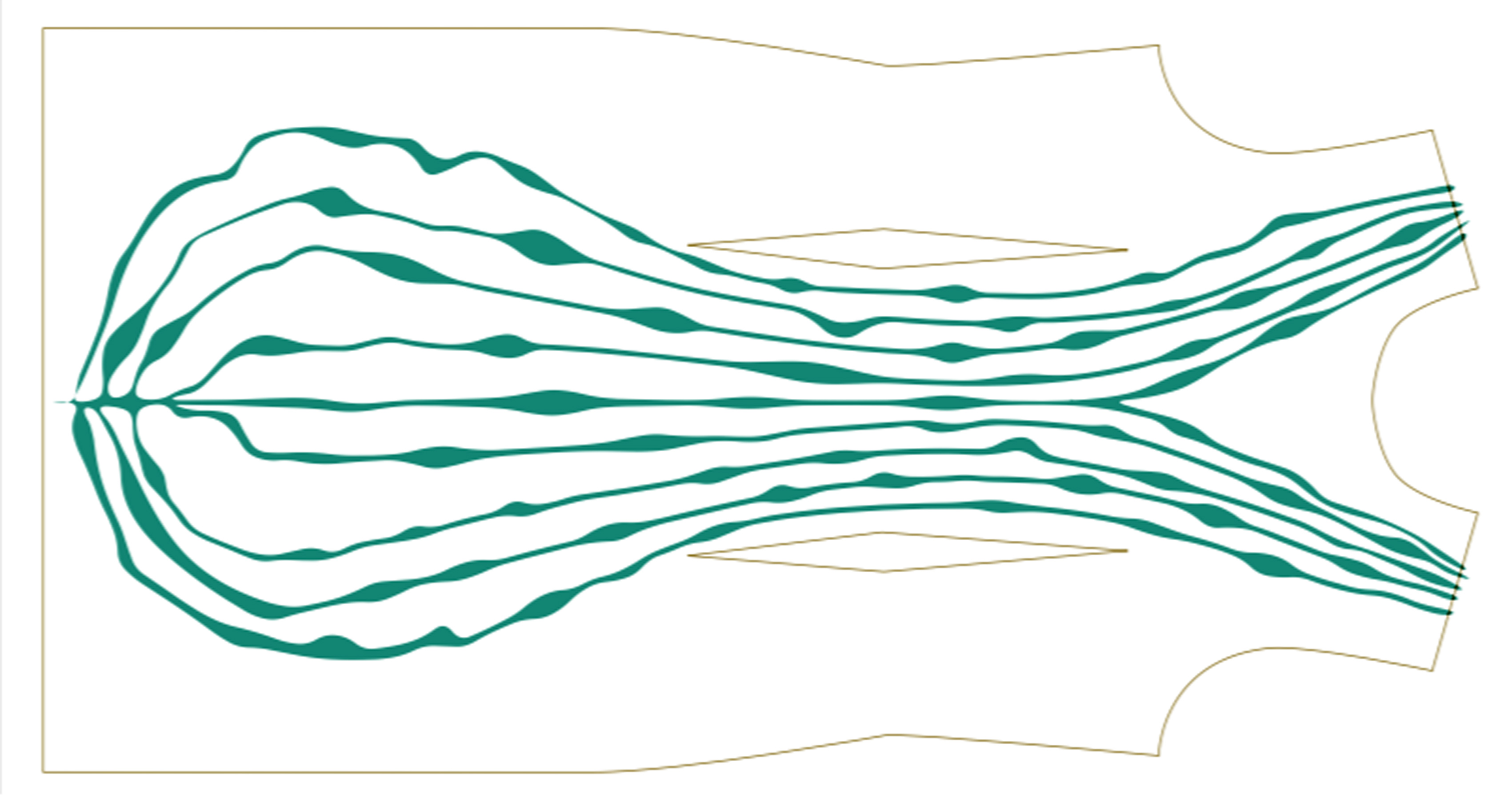

Day 3 – Computation Fashion

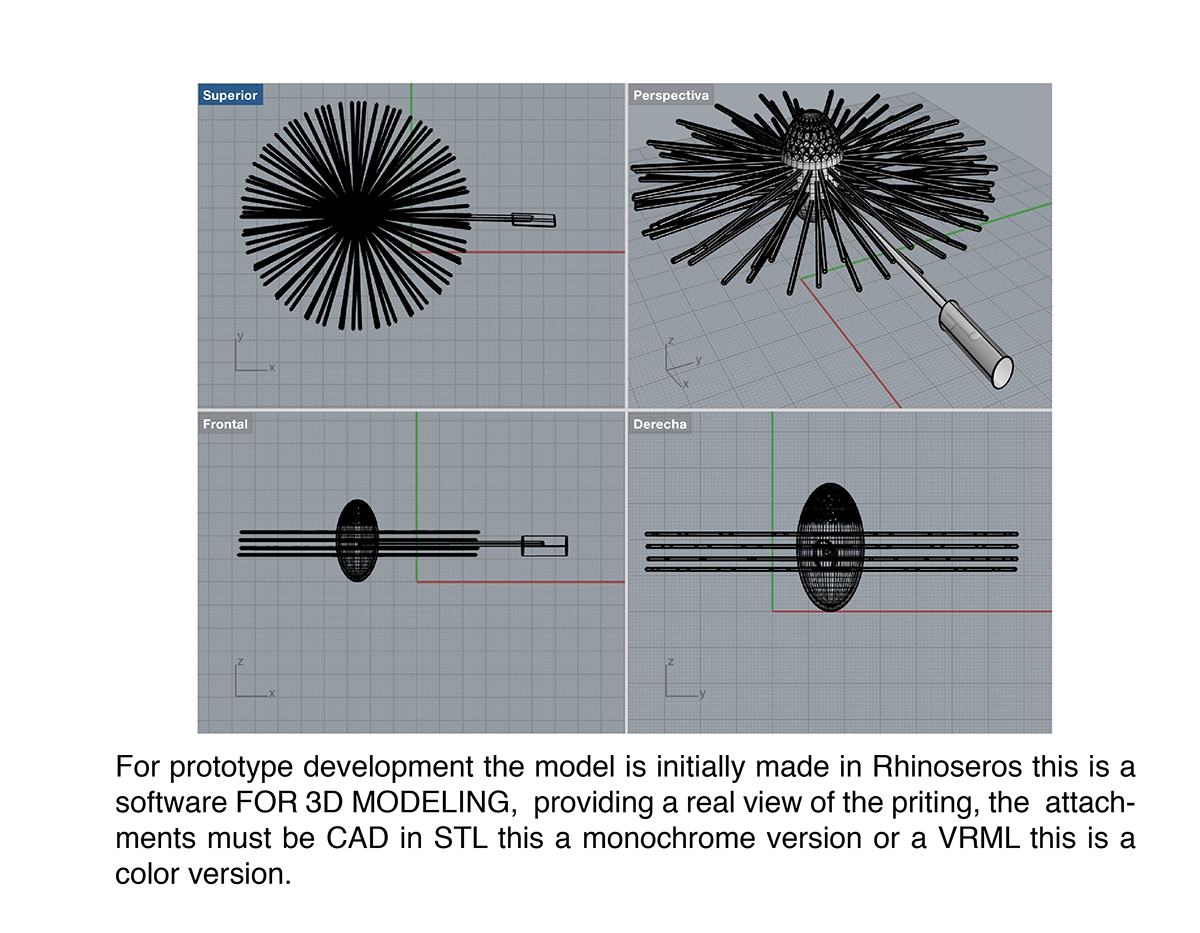

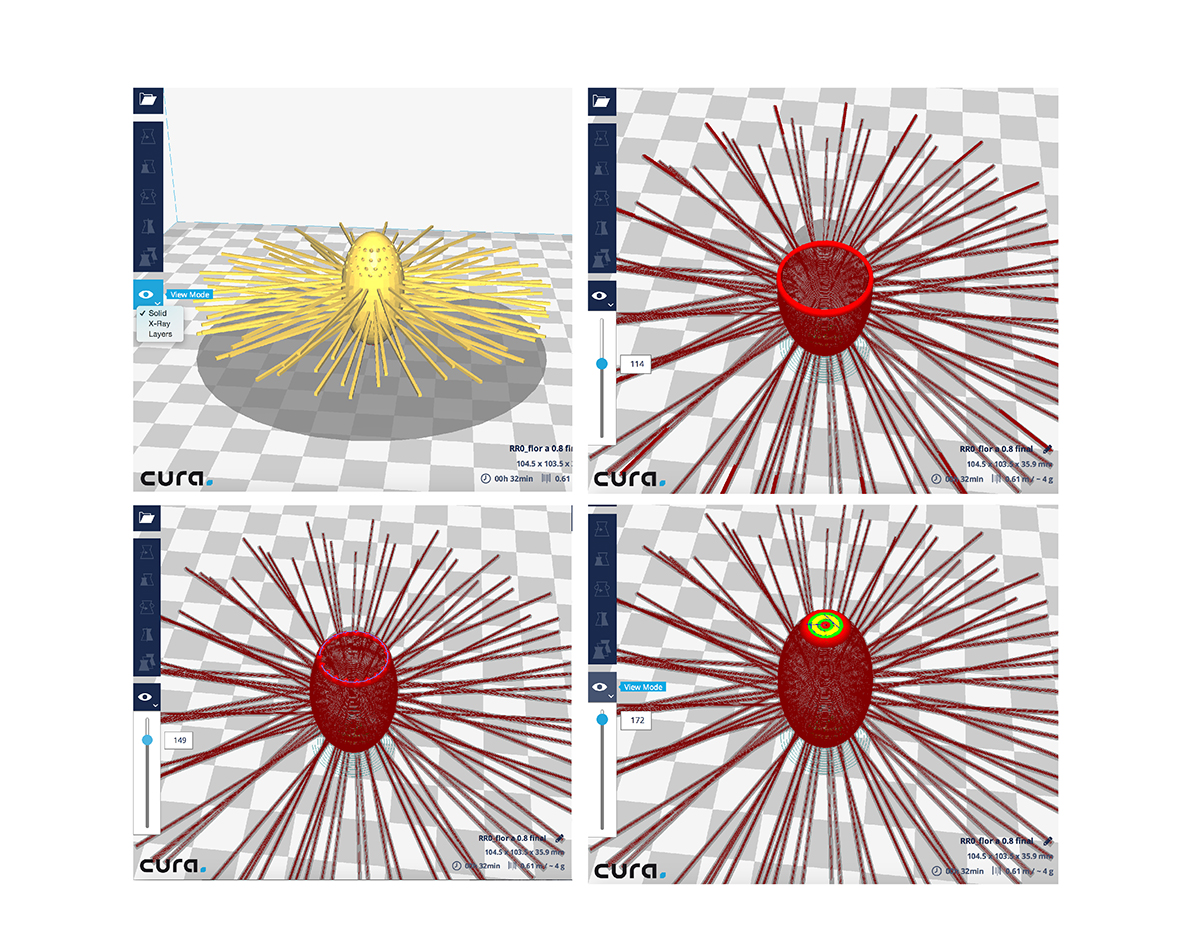

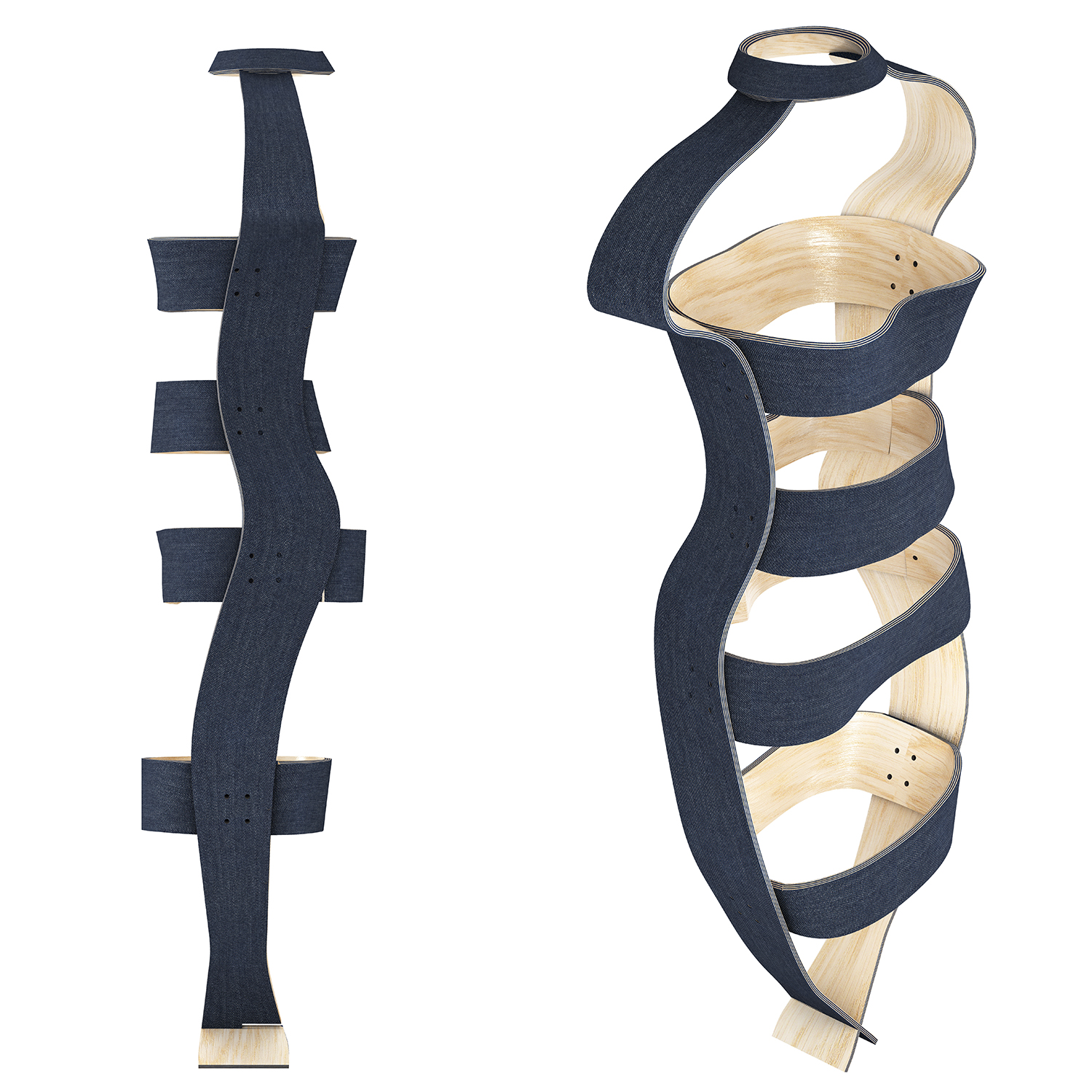

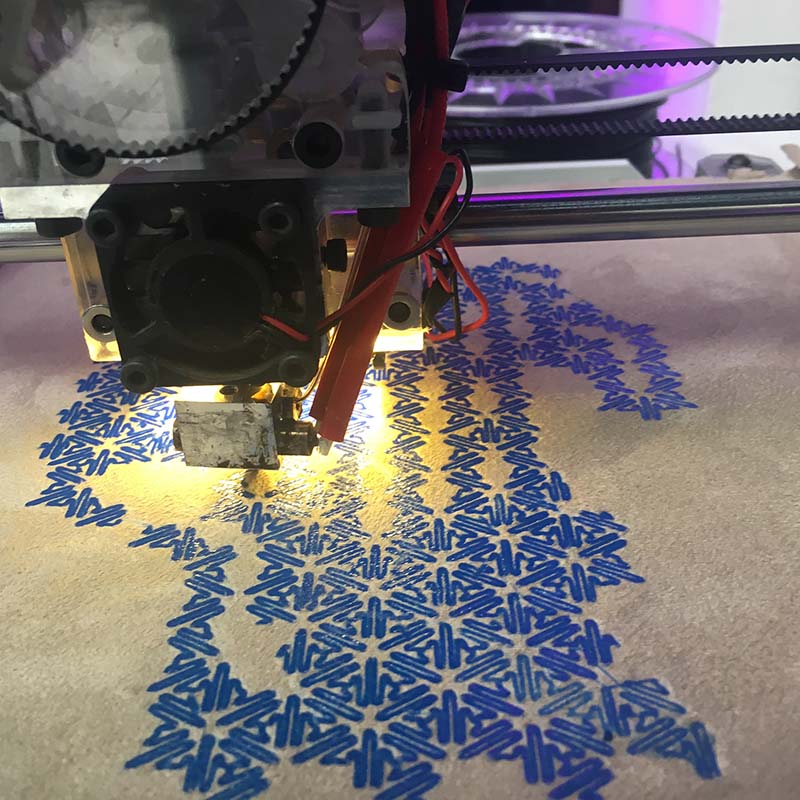

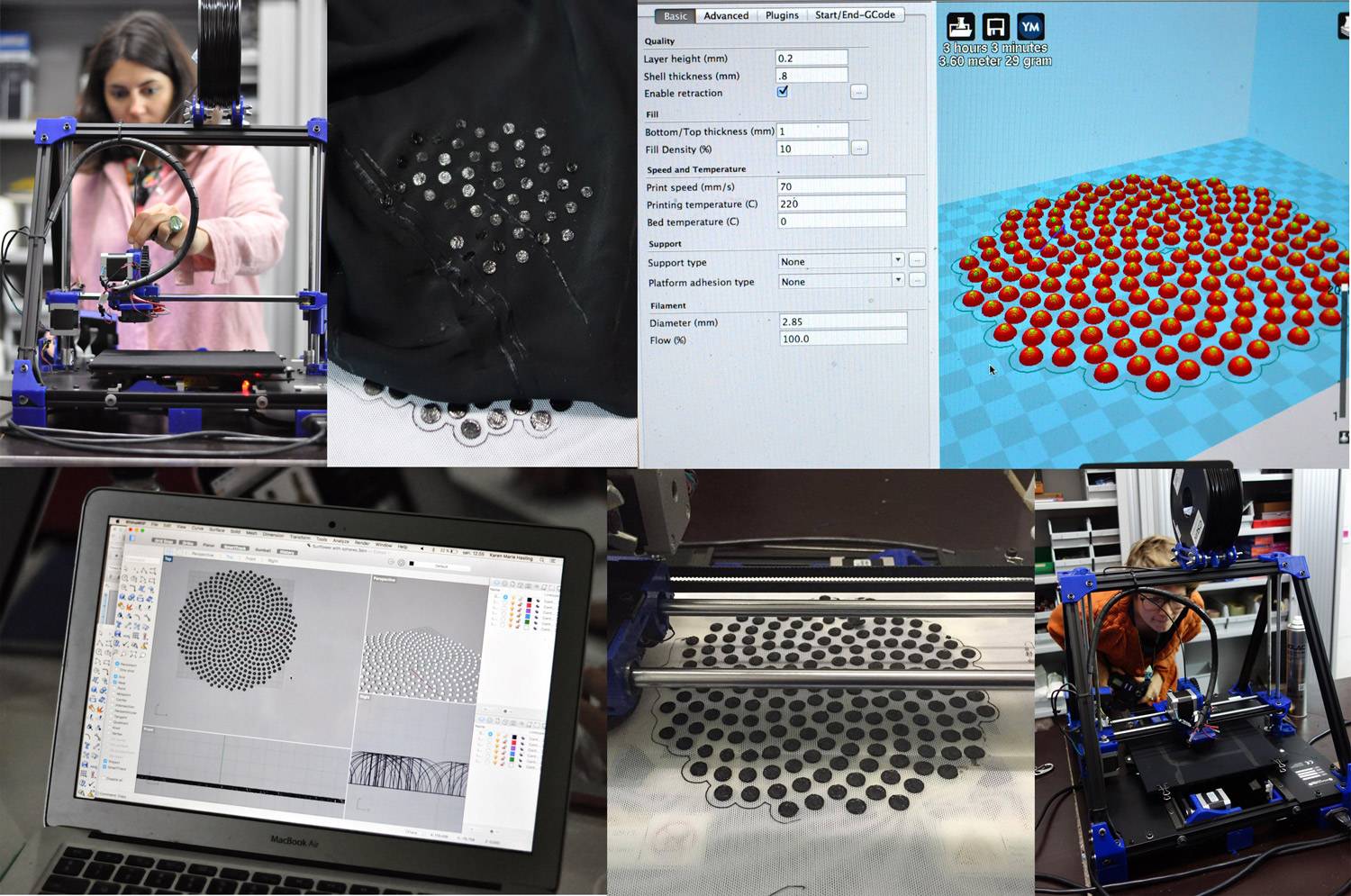

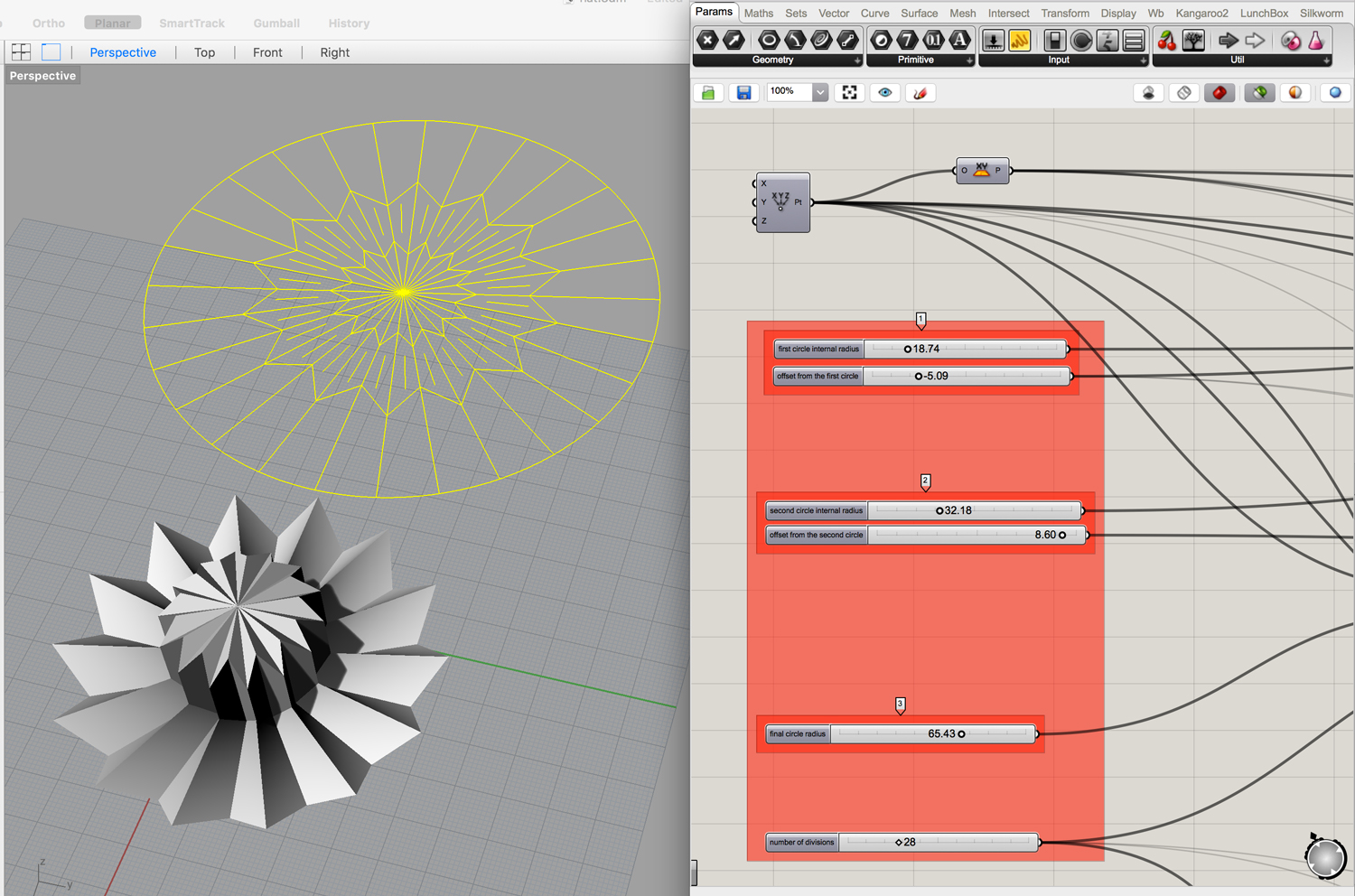

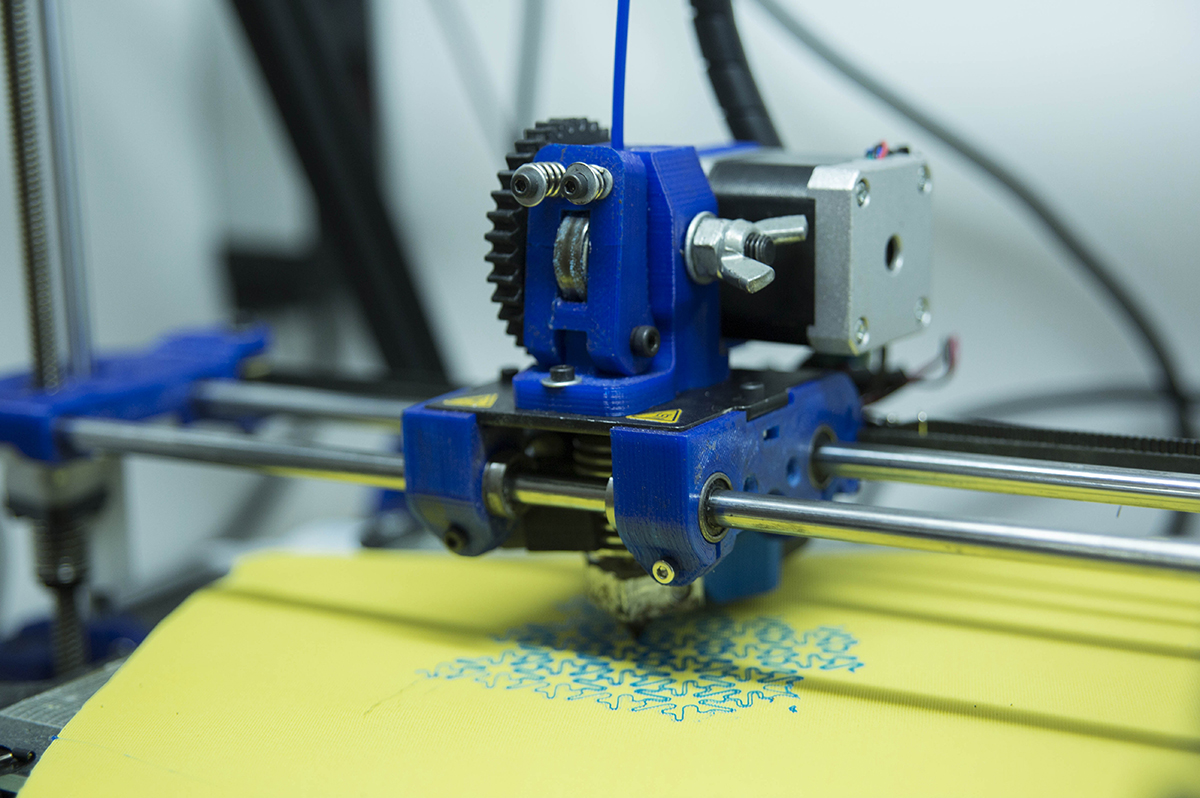

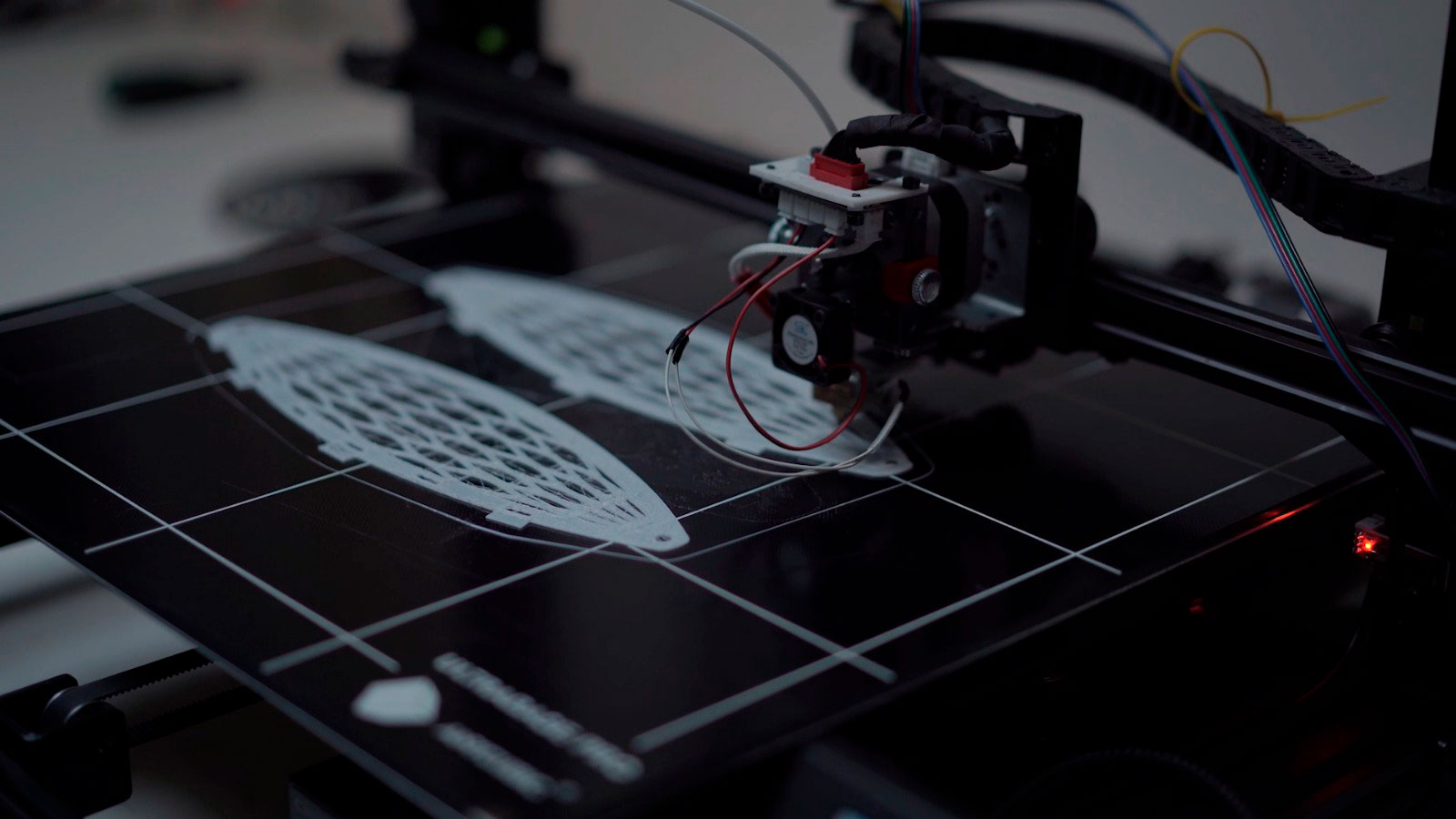

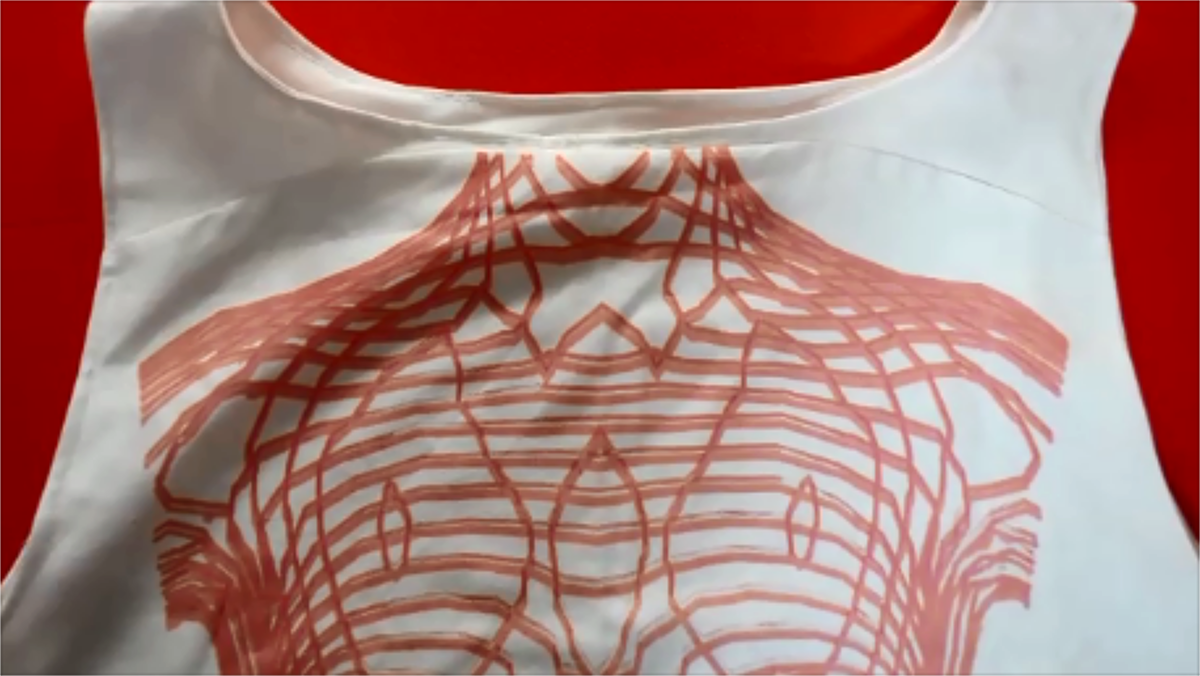

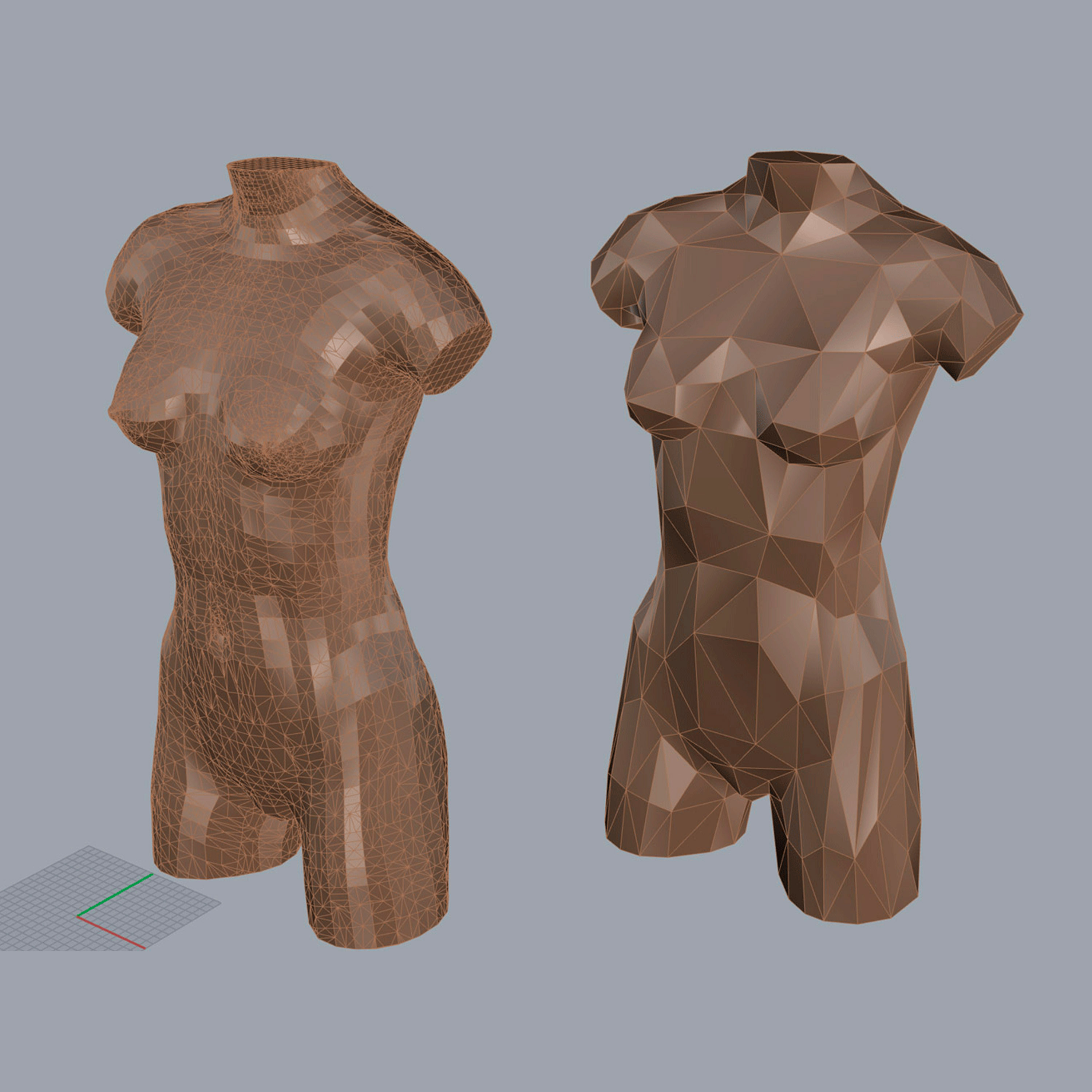

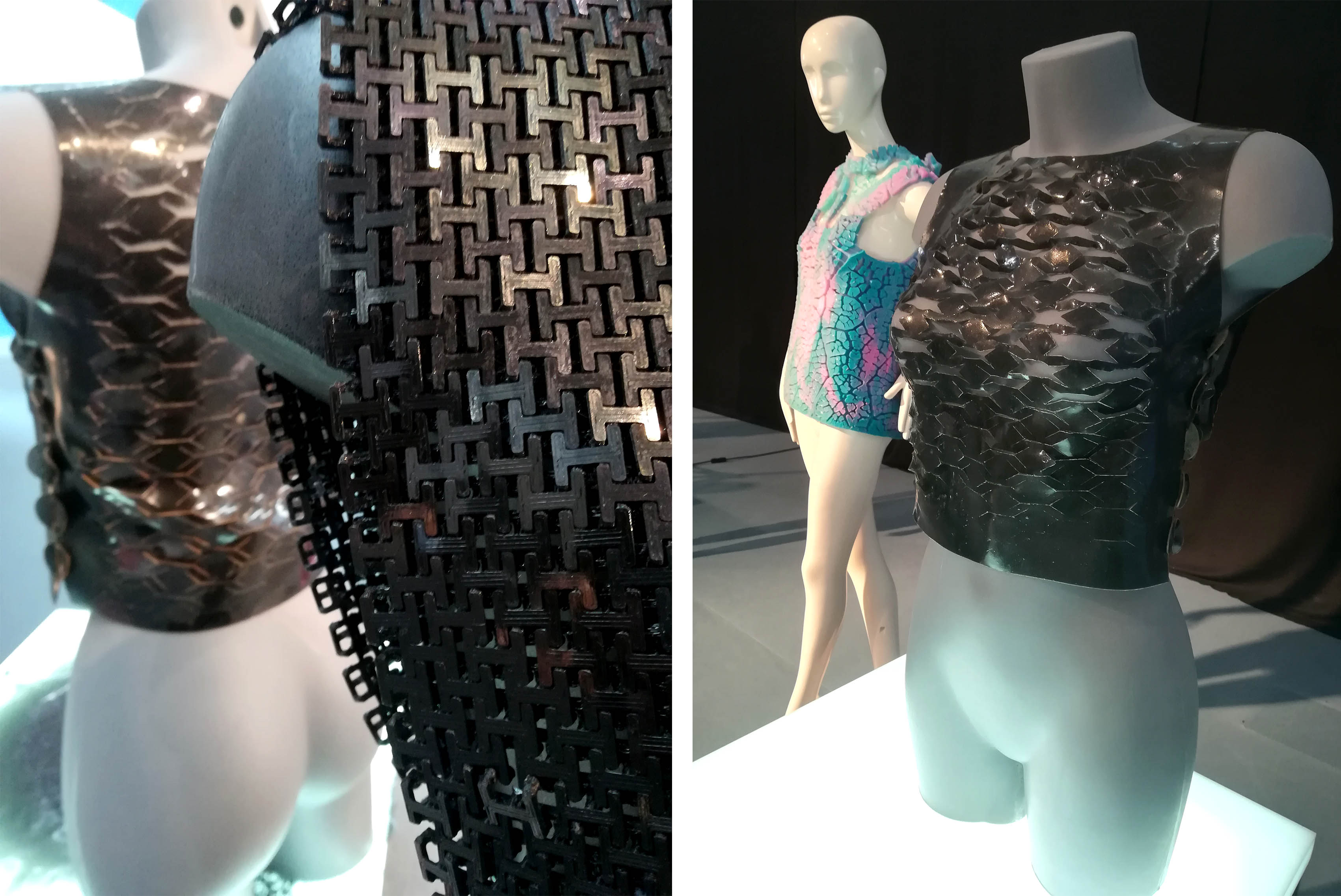

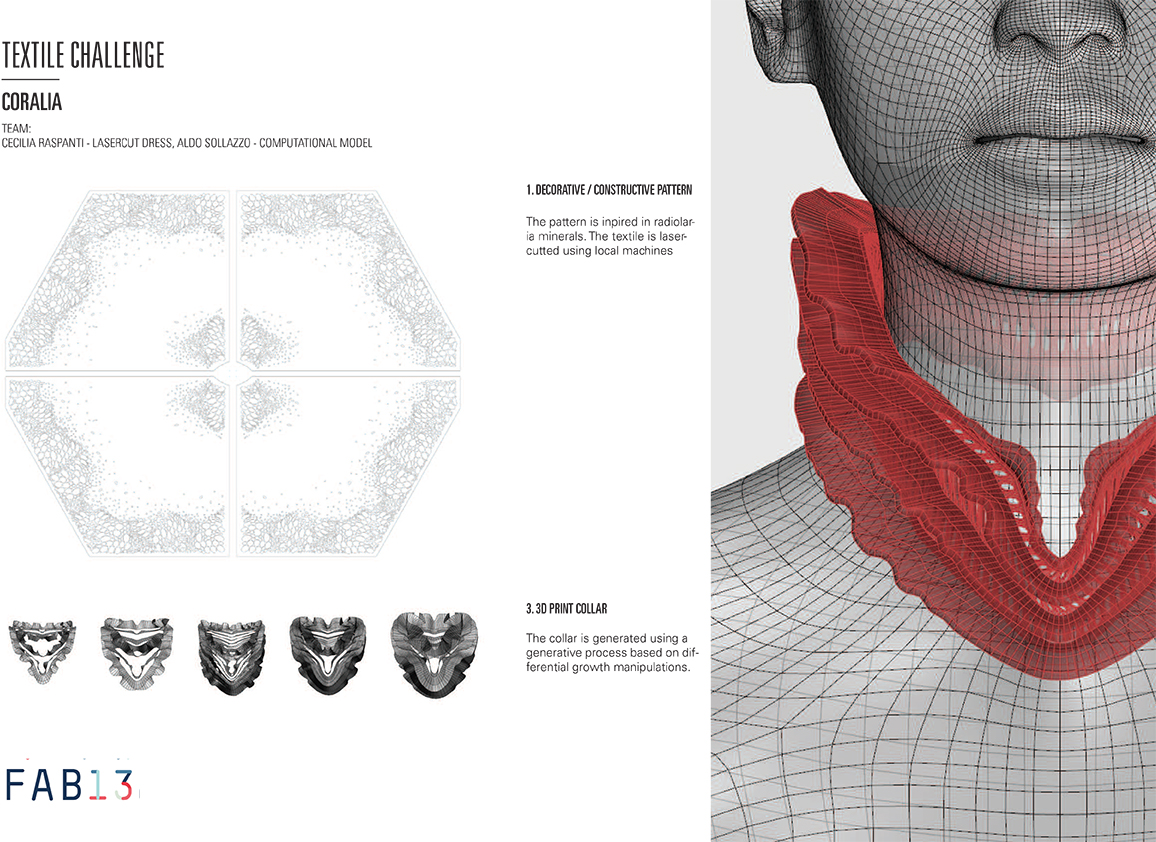

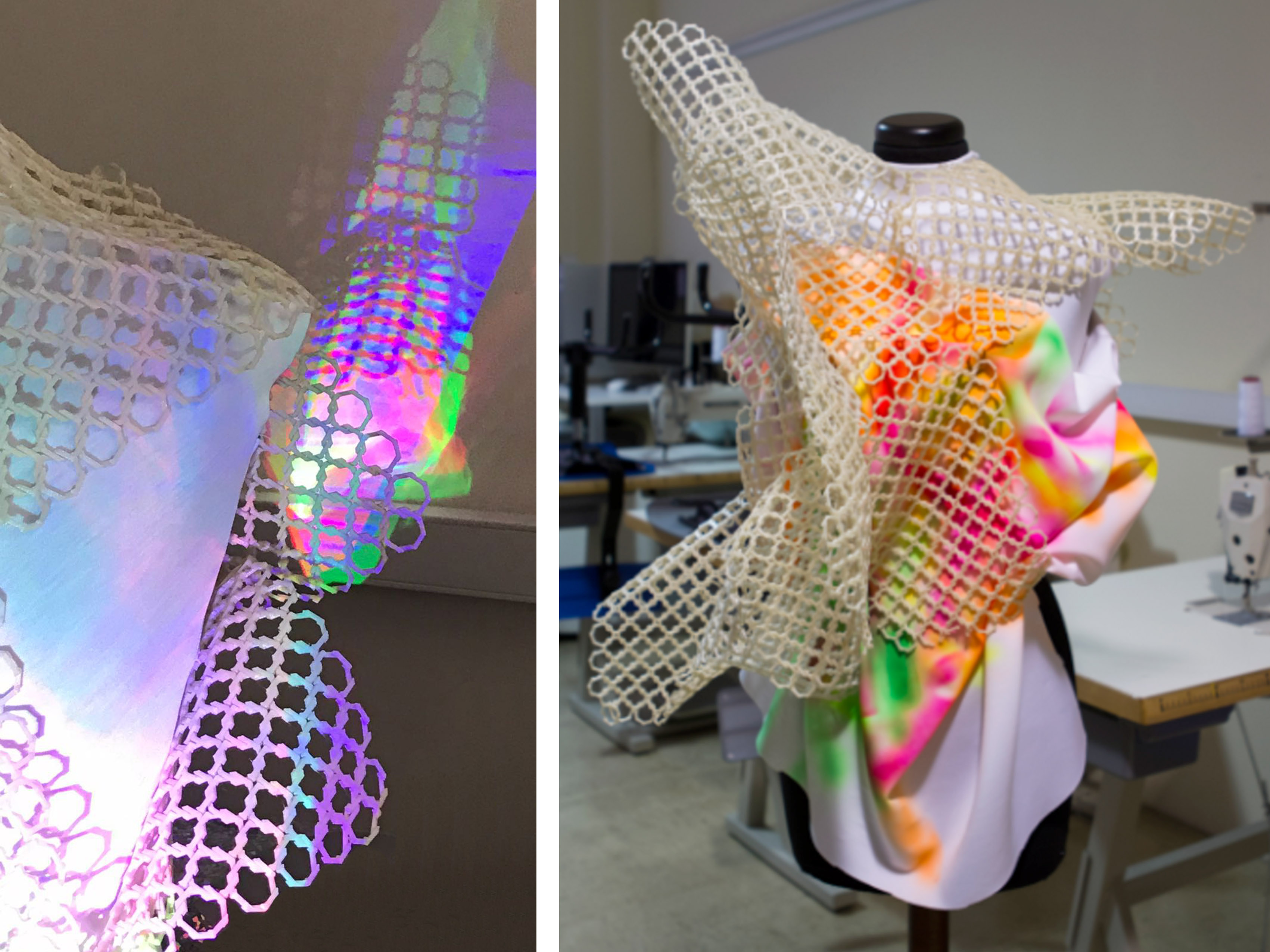

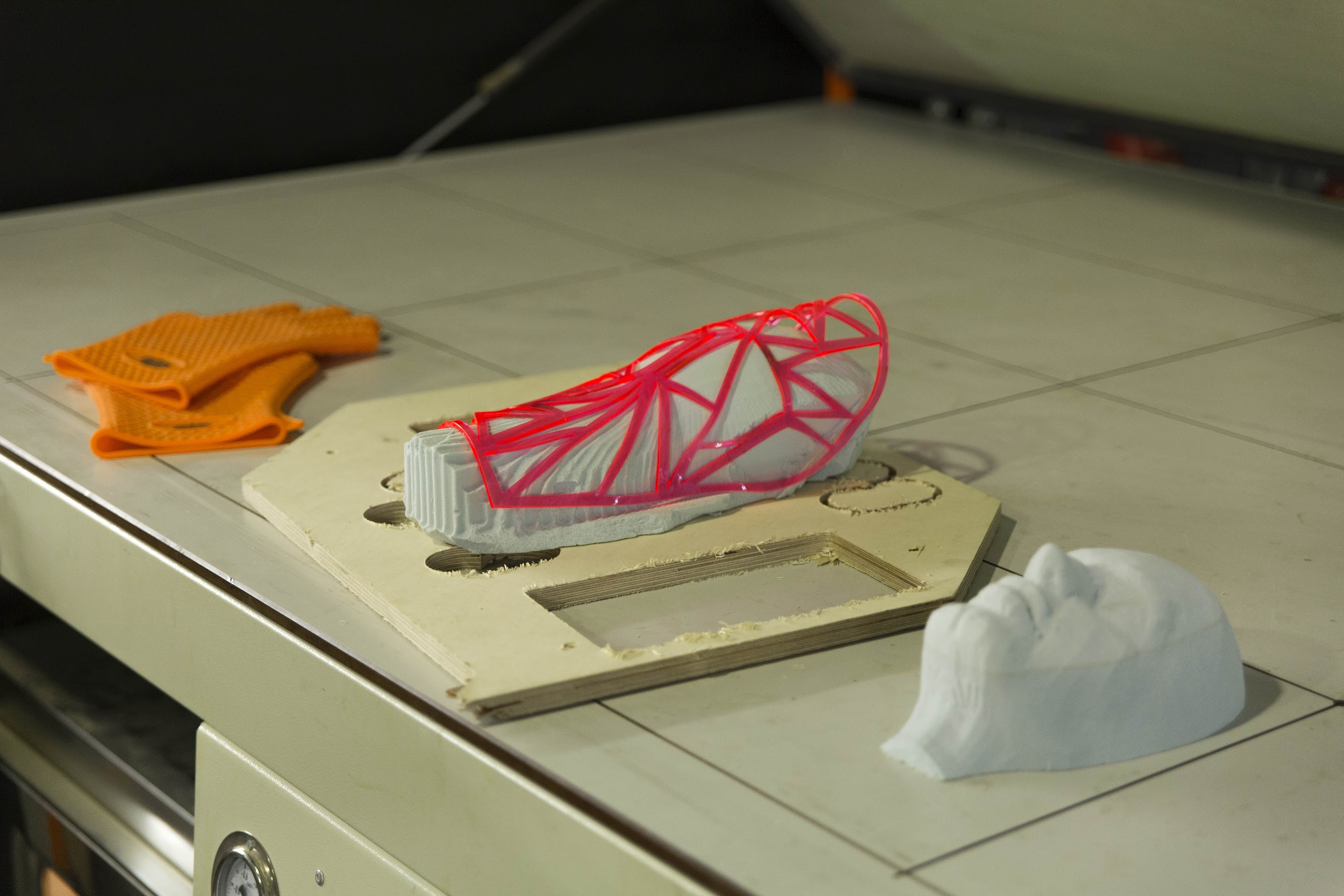

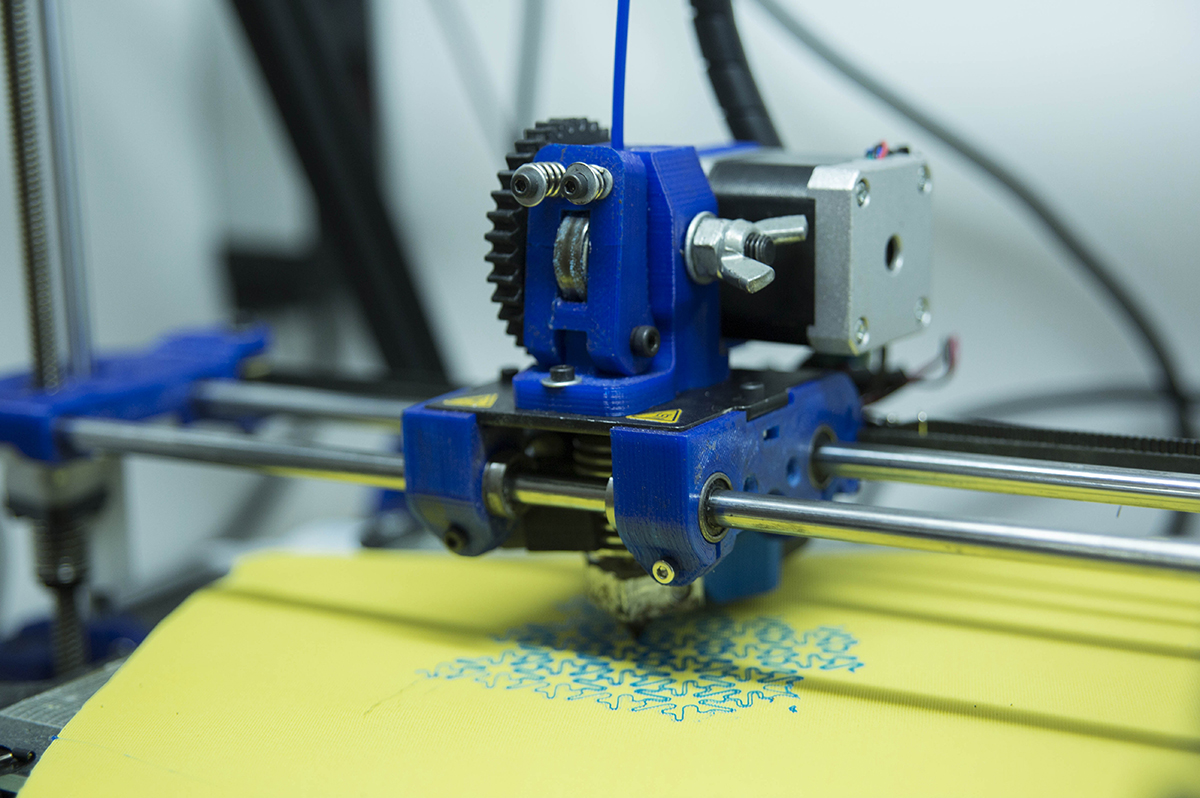

The main theme of this day was to investigate how computers and digital technologies can revolutionize the work of fashion designers and common people alike. The first lecture, by Amber Slooten, a dutch fashion designer, gave participants a glimpse of new ways for designing fashion virtually and digitally, using CAD tools, as well as an overview of the tools used. Aldo Sollazzo from Noumena, a world-renowned expert in computational design, introduced tools such as Grasshopper and plugins needed for computational couture with a really extensive lecture. During the hands-on session he also gave many examples, all ready to be customized, for modeling ready-for-production 3D printed pieces around a digital mannequin. The topics presented are so vast, that many participants promised to get back to it once home, using the resources provided as a starting point for further experimentation. In parallel with the Digital Couture Hands-On session Anastasia presented several fabrication techniques. From 3D printing on textiles, to thermoforming plexiglass on CNC milled body parts.

During the hands-on session he also gave many examples, all ready to be customized, for modeling ready-for-production 3D printed pieces around a digital mannequin. The topics presented are so vast, that many participants promised to get back to it once home, using the resources provided as a starting point for further experimentation. In parallel with the Digital Couture Hands-On session Anastasia presented several fabrication techniques. From 3D printing on textiles, to thermoforming plexiglass on CNC milled body parts.

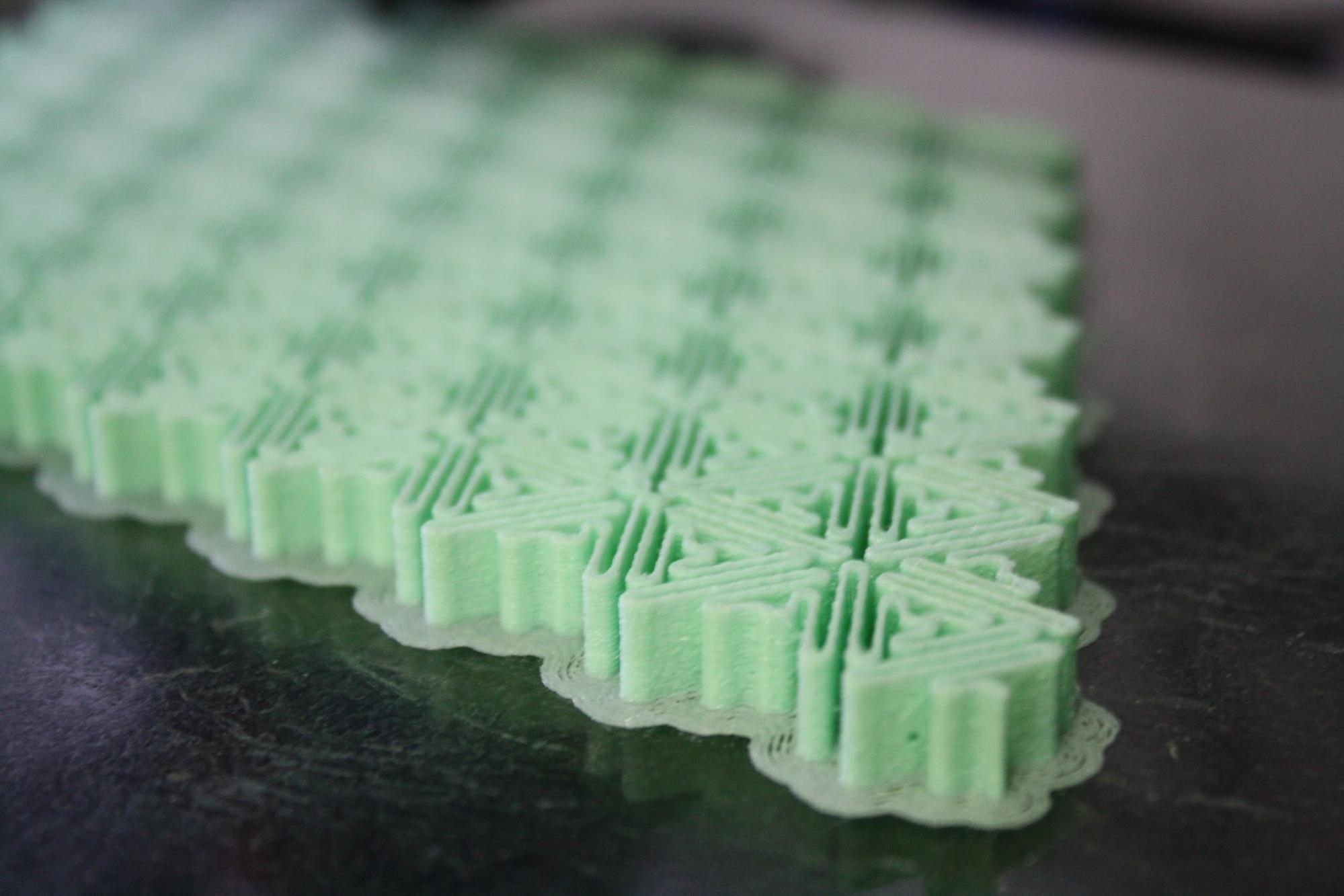

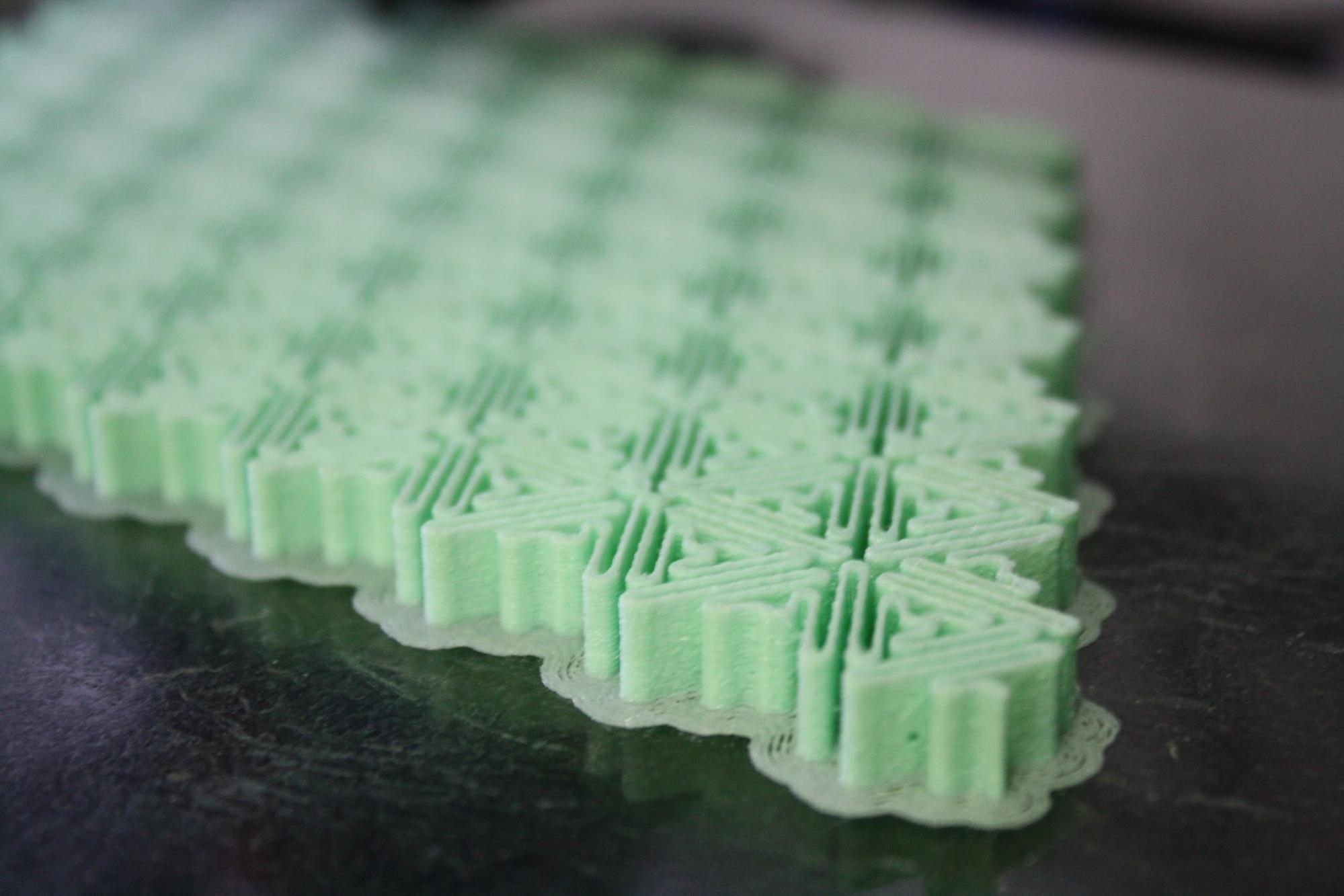

More 3D printing on Fabrics and 3d printing with Filaflex auxetic structures.

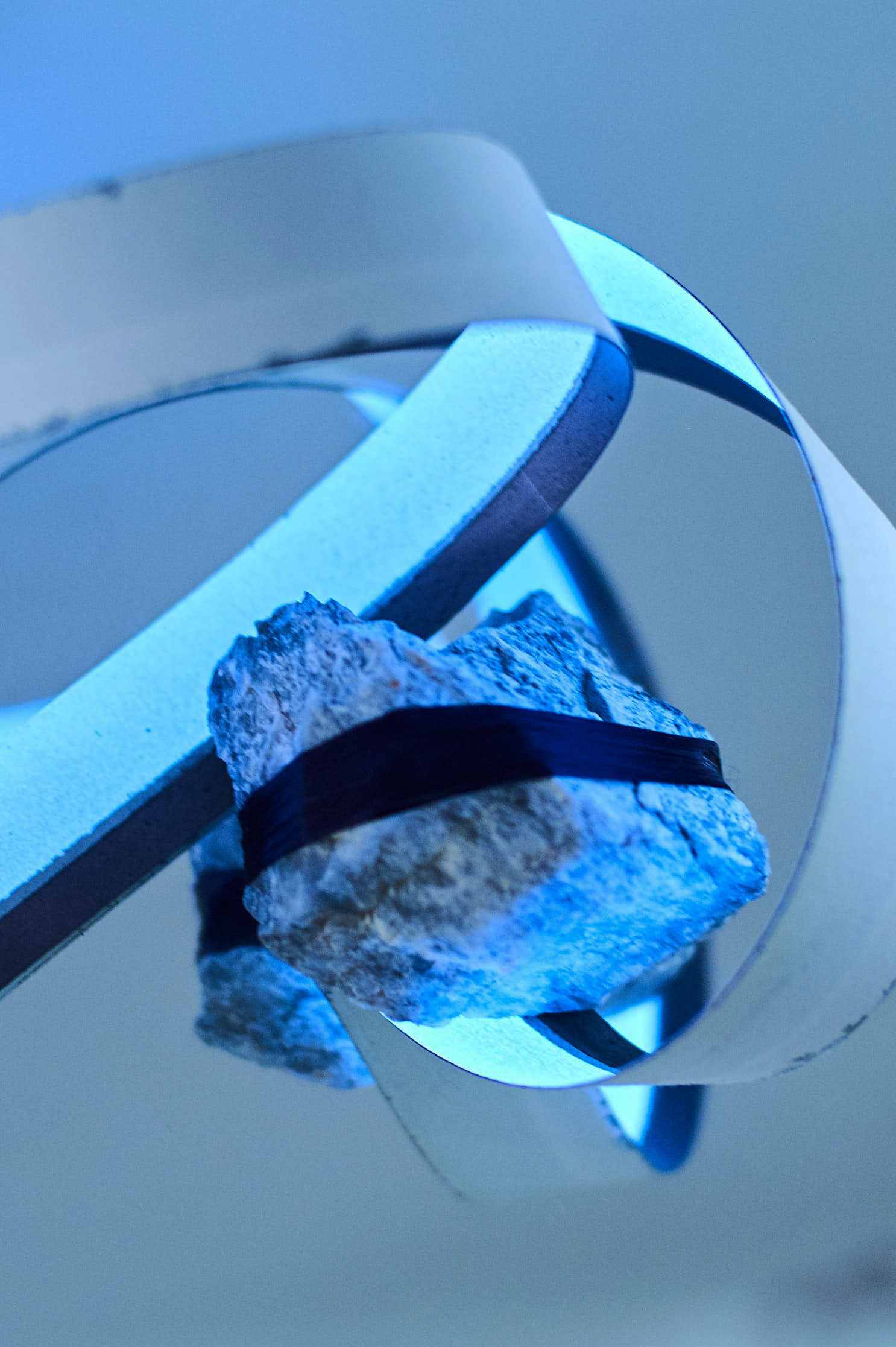

More 3D printing on Fabrics and 3d printing with Filaflex auxetic structures. CnC milling of high density foam parts of the human body made in MakeHuman serve as the mold for thermoforming laser cut acrylic.

CnC milling of high density foam parts of the human body made in MakeHuman serve as the mold for thermoforming laser cut acrylic.  Wendy Neale documented her bootcamp outcomes in her blog where you can see interesting experiments with dyeing, digital couture with grasshopper and more.

Wendy Neale documented her bootcamp outcomes in her blog where you can see interesting experiments with dyeing, digital couture with grasshopper and more.

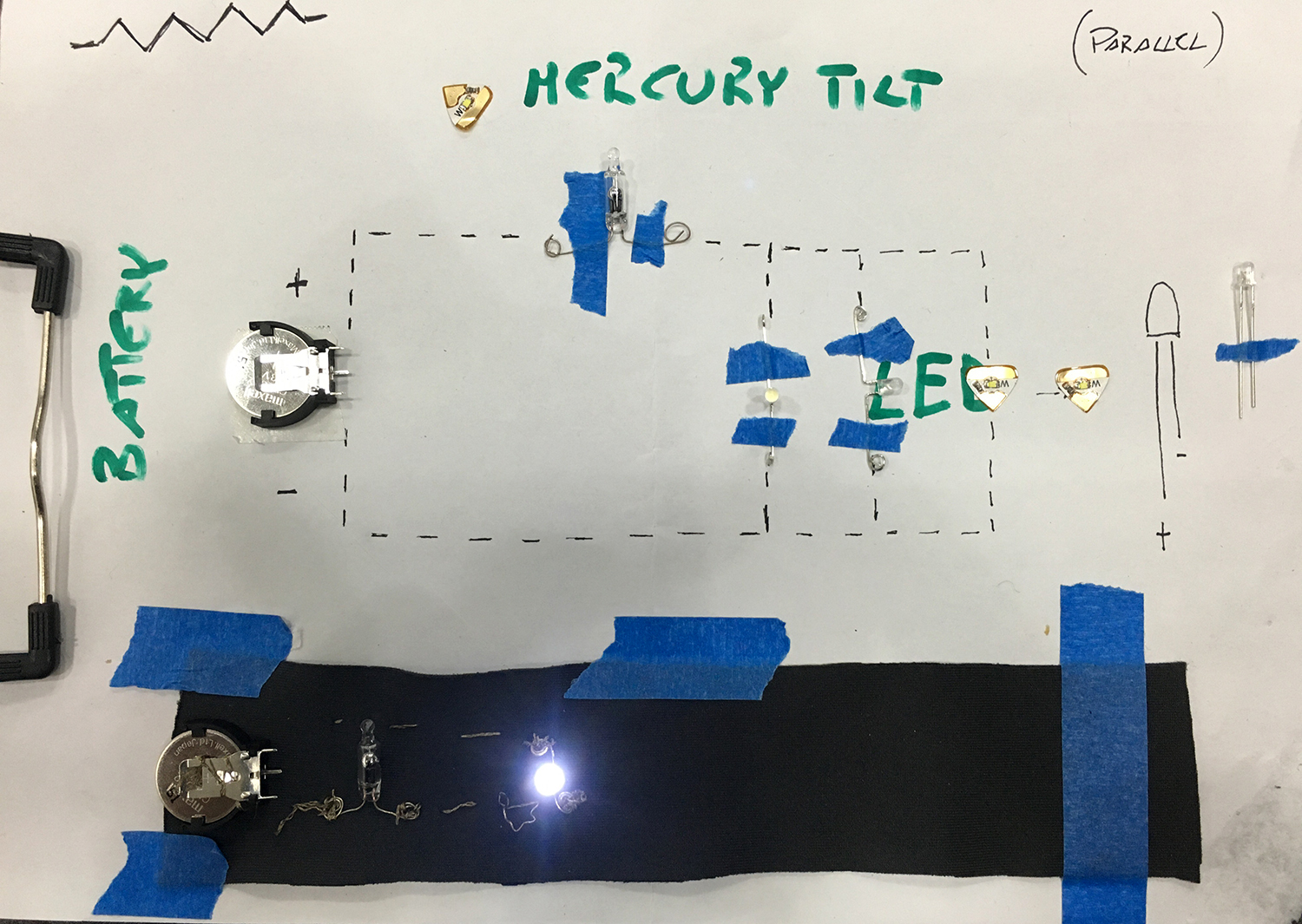

Day 4 – Electronics – Soft Sensors- Attiny – Open Hardware

Electronic components kits for bootcamp attendees in Barcelona

Electronic components kits for bootcamp attendees in Barcelona

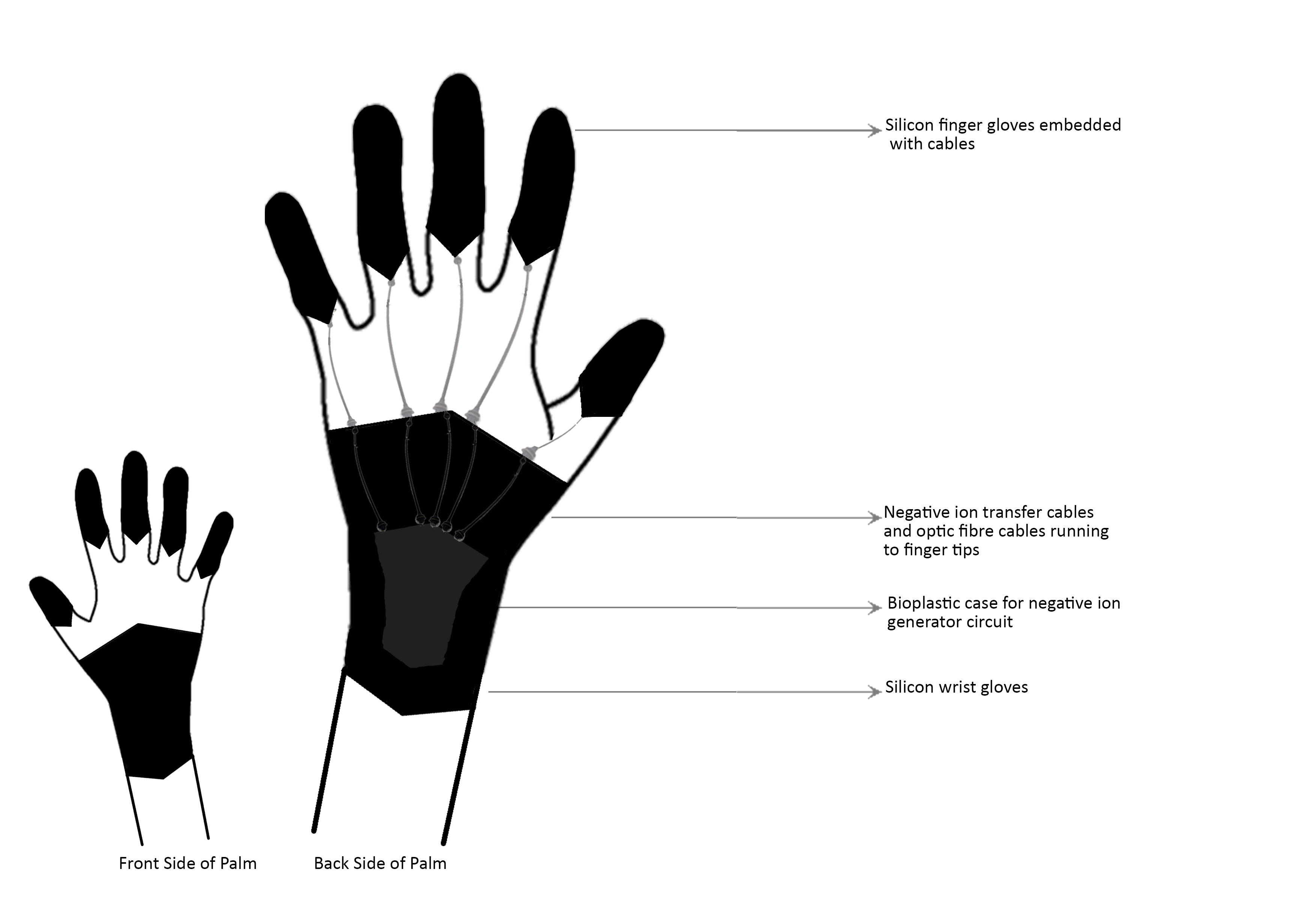

The focus of the day was to enter the electronics, wearables field and the development of soft sensors using conductive fabric. With the help of Angel Muñoz and Christian Rizzuti participants explored the possibilities of smart leds, the Arduino family of platforms, e-textile sensors, motors, SMA, and fabric speakers. Christian Rizzuti introducing DIY soft sensors, bend, stretch and pressure.

Christian Rizzuti introducing DIY soft sensors, bend, stretch and pressure.

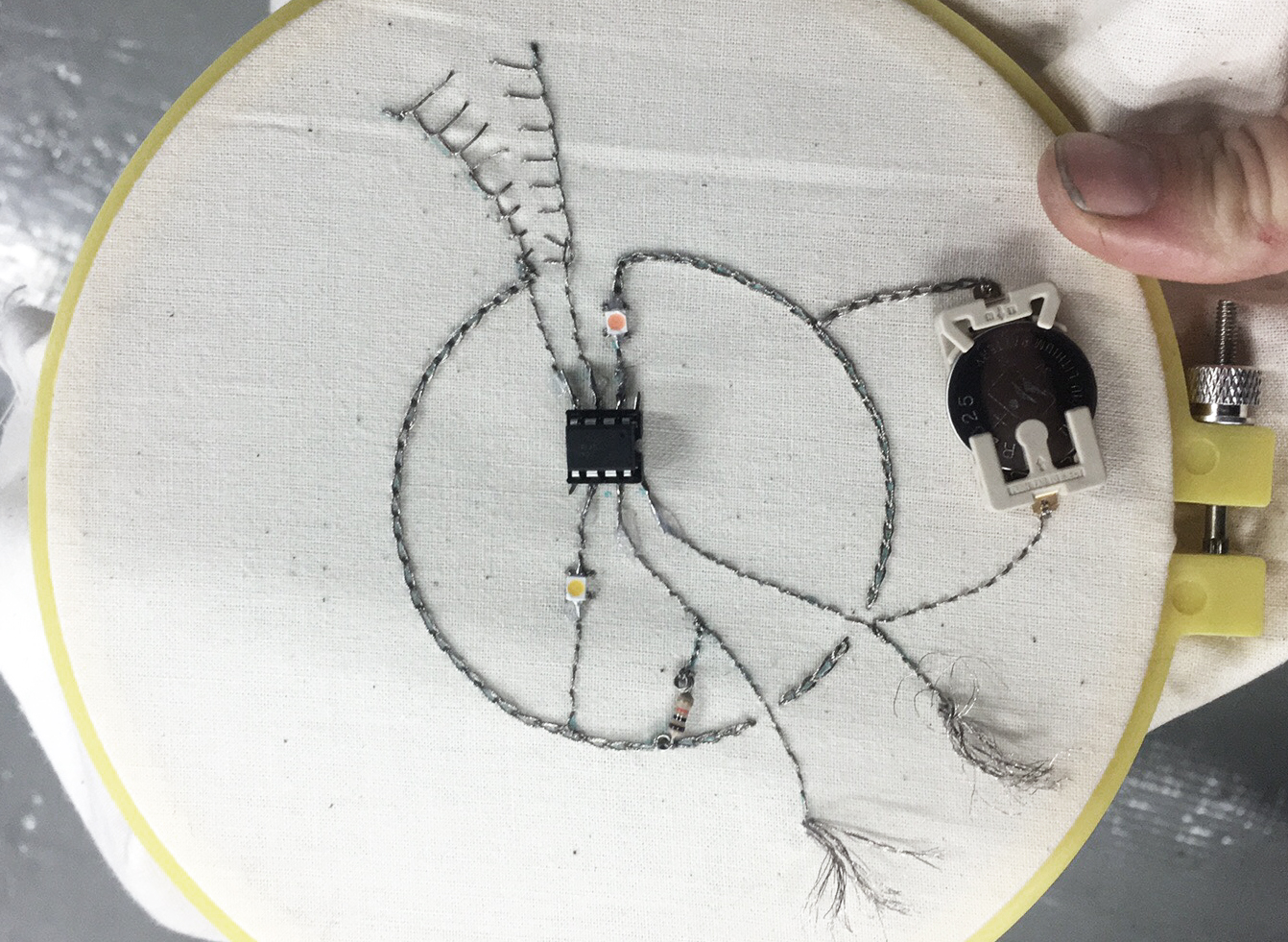

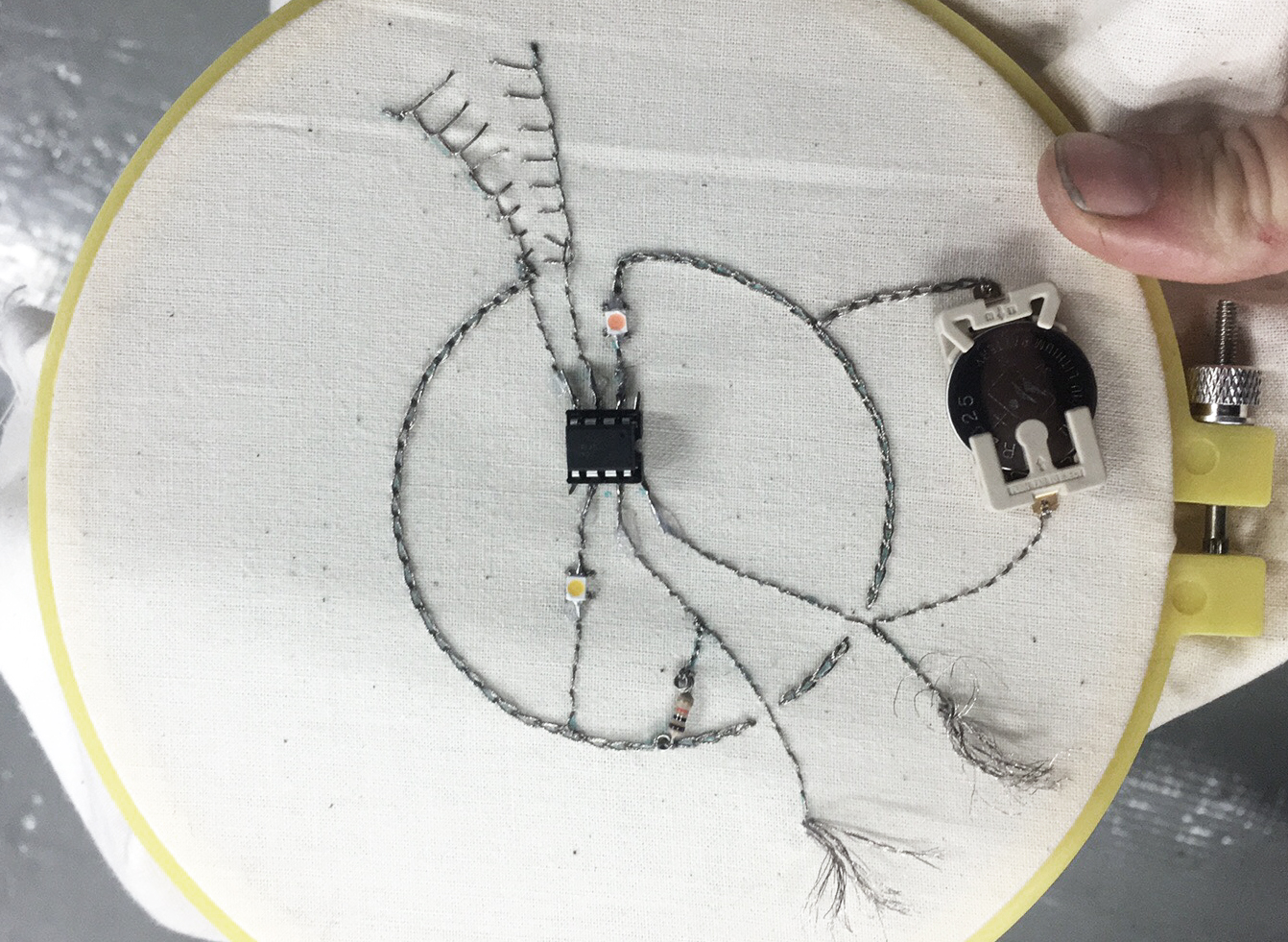

For the hands-on session Liza Stark, Content + Community Lead at littleBits showed interesting projects based on the ATTiny microcontroller, and participants engaged soldering, assembling and integrating basic textile circuits under the mentor’s supervision. What we all will remember about this session is Liza telling us that “the ATTiny is our new best friend”. She presented a wonderful selection of projects she developed, one of which, was her actual wedding dress, displaying though led lights her heart beat and the one of her husband.

What we all will remember about this session is Liza telling us that “the ATTiny is our new best friend”. She presented a wonderful selection of projects she developed, one of which, was her actual wedding dress, displaying though led lights her heart beat and the one of her husband. Liza Stark doing the tutorial and hands-on for the ATtiny Embroidery Swatch.

Liza Stark doing the tutorial and hands-on for the ATtiny Embroidery Swatch.

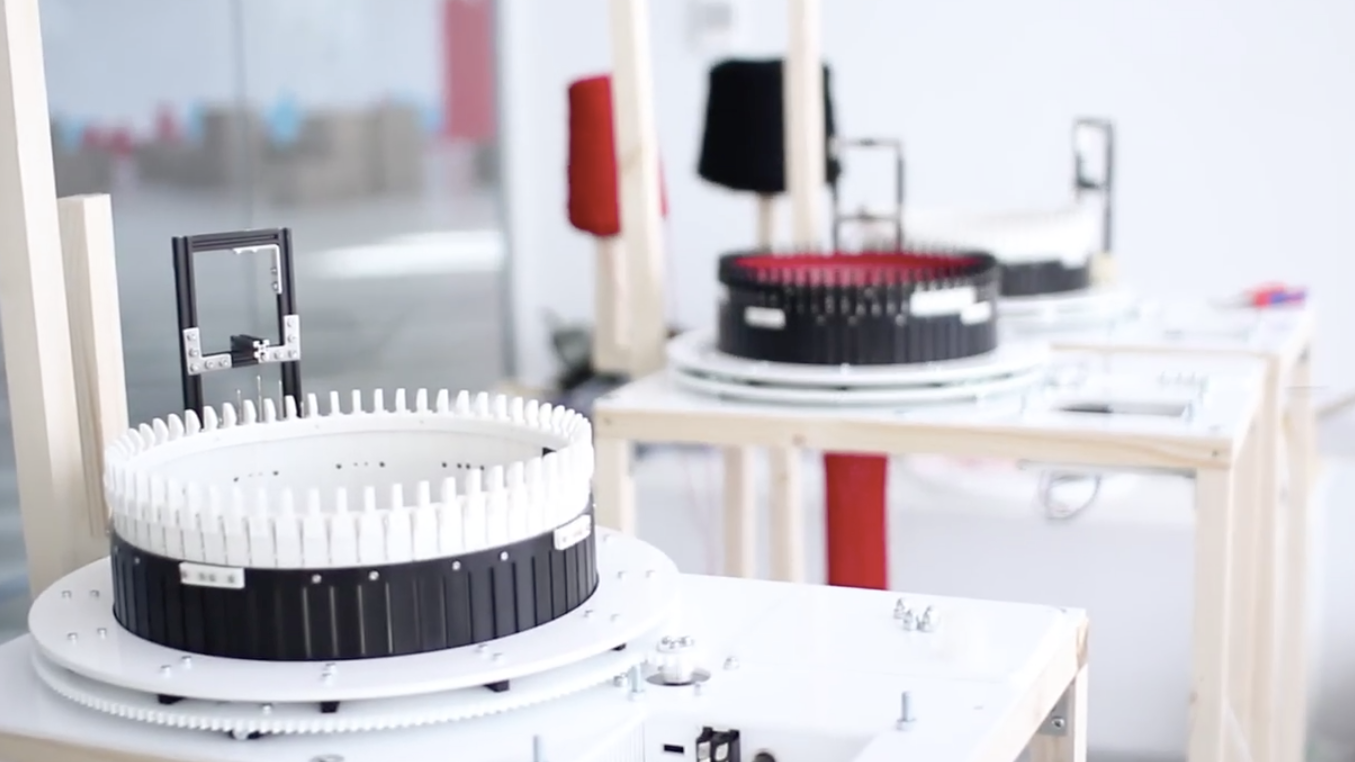

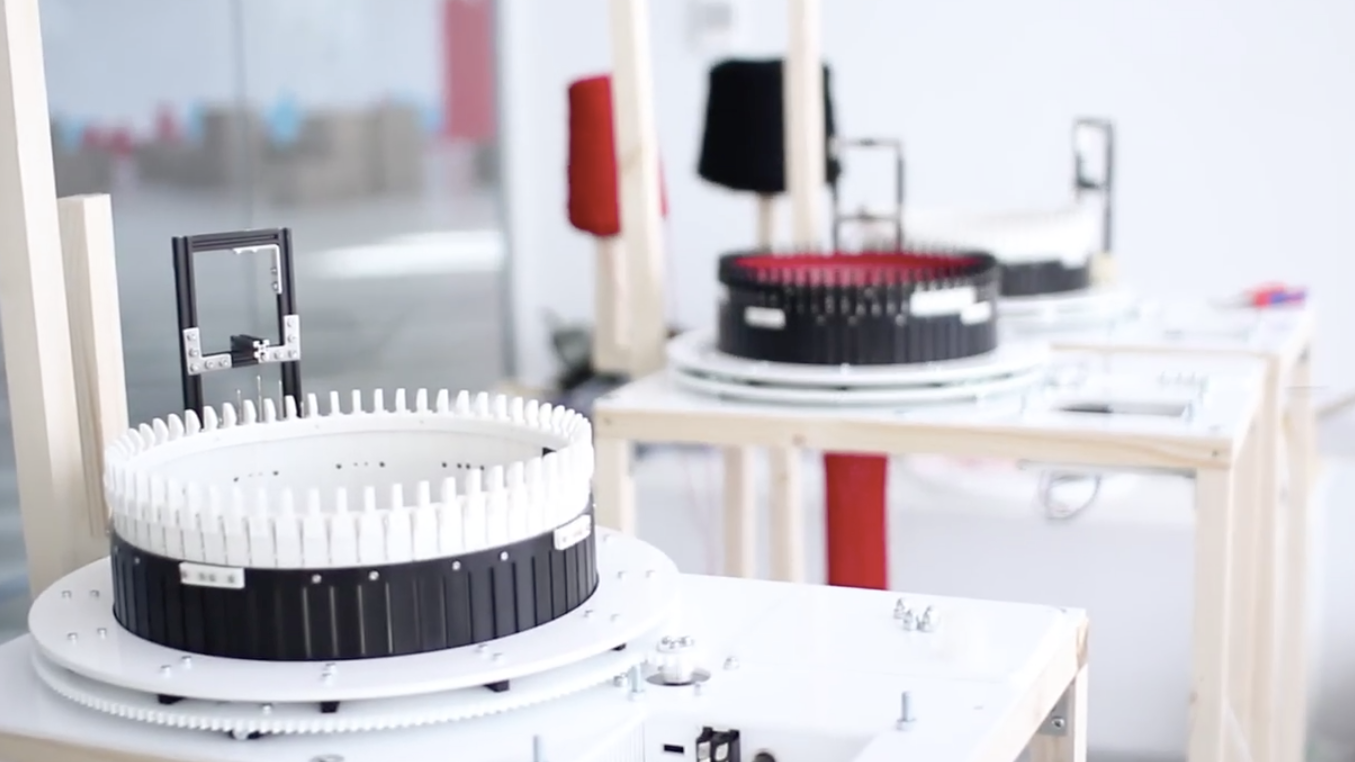

The artist duo Varvara Guljajeva & Mar Canet introduced participants to the topic of open source machines for the textile industry. Their Knittic and Circular Knittic projects are pioneer experiments of bringing soft fabrication tools and machines at low cost into the fab lab network. Circular Knittic project by Var & Mar

Circular Knittic project by Var & Mar

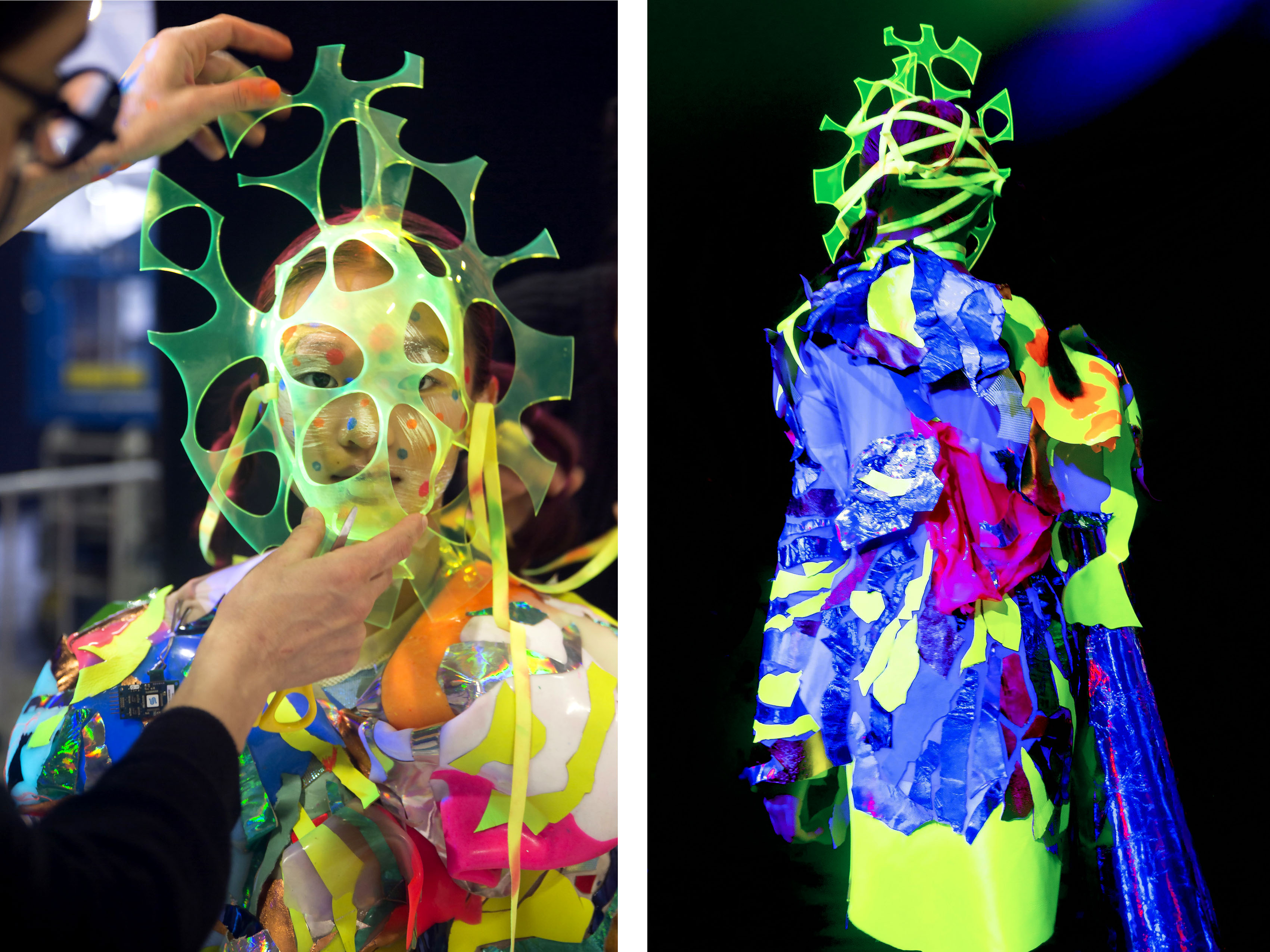

Day 5 – JAM

After a super full week, the JAM day was the perfect moment to bring together all the lessons learnt during the bootcamp and make stuff! We had an amazing team of mentors helping the participants in the project fabrication, a great thanks goes to them for the support and passion.

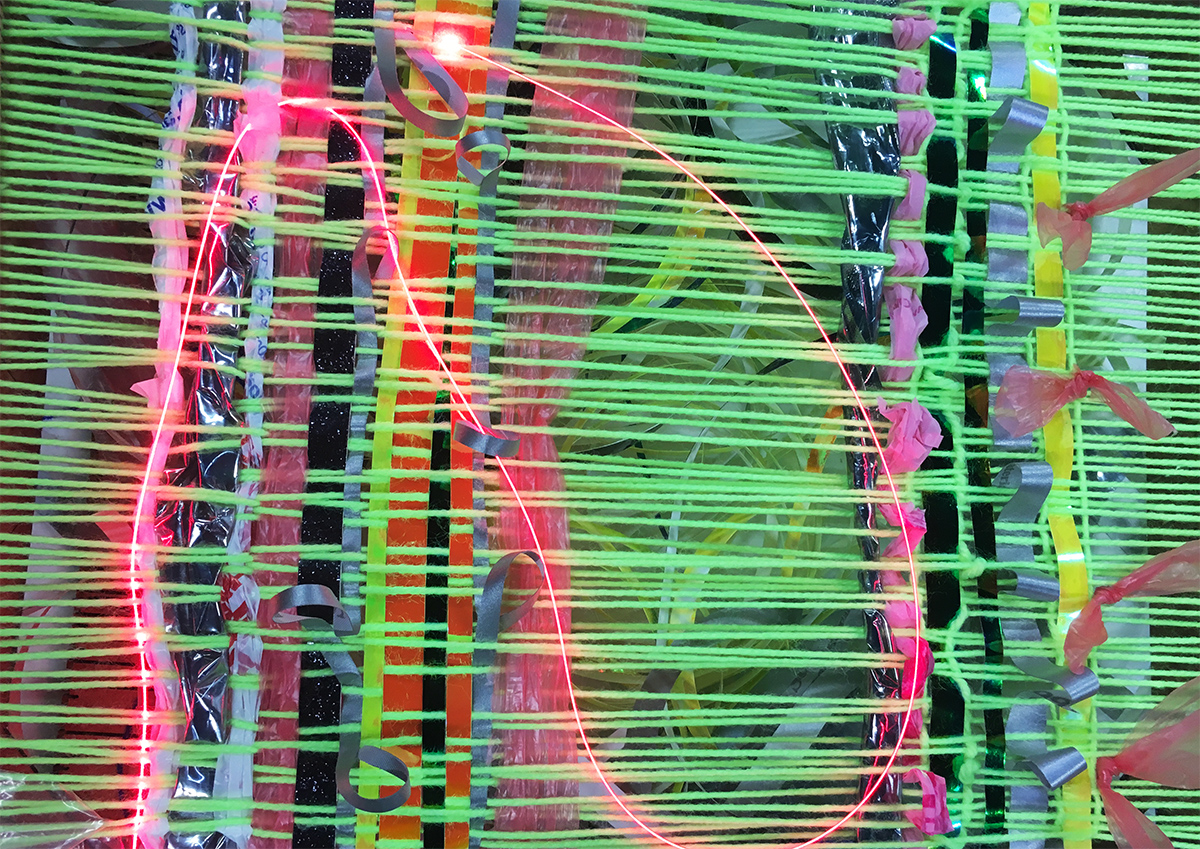

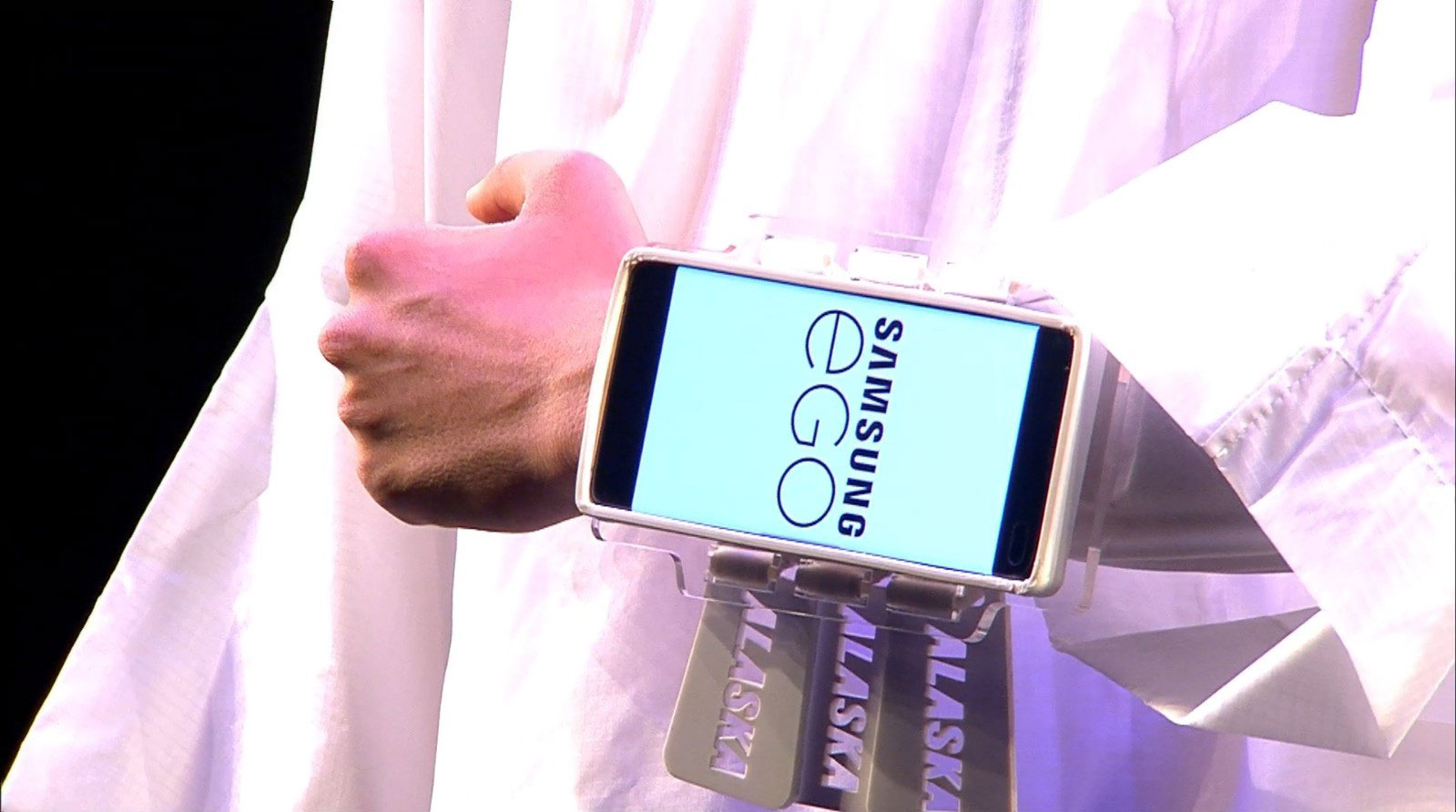

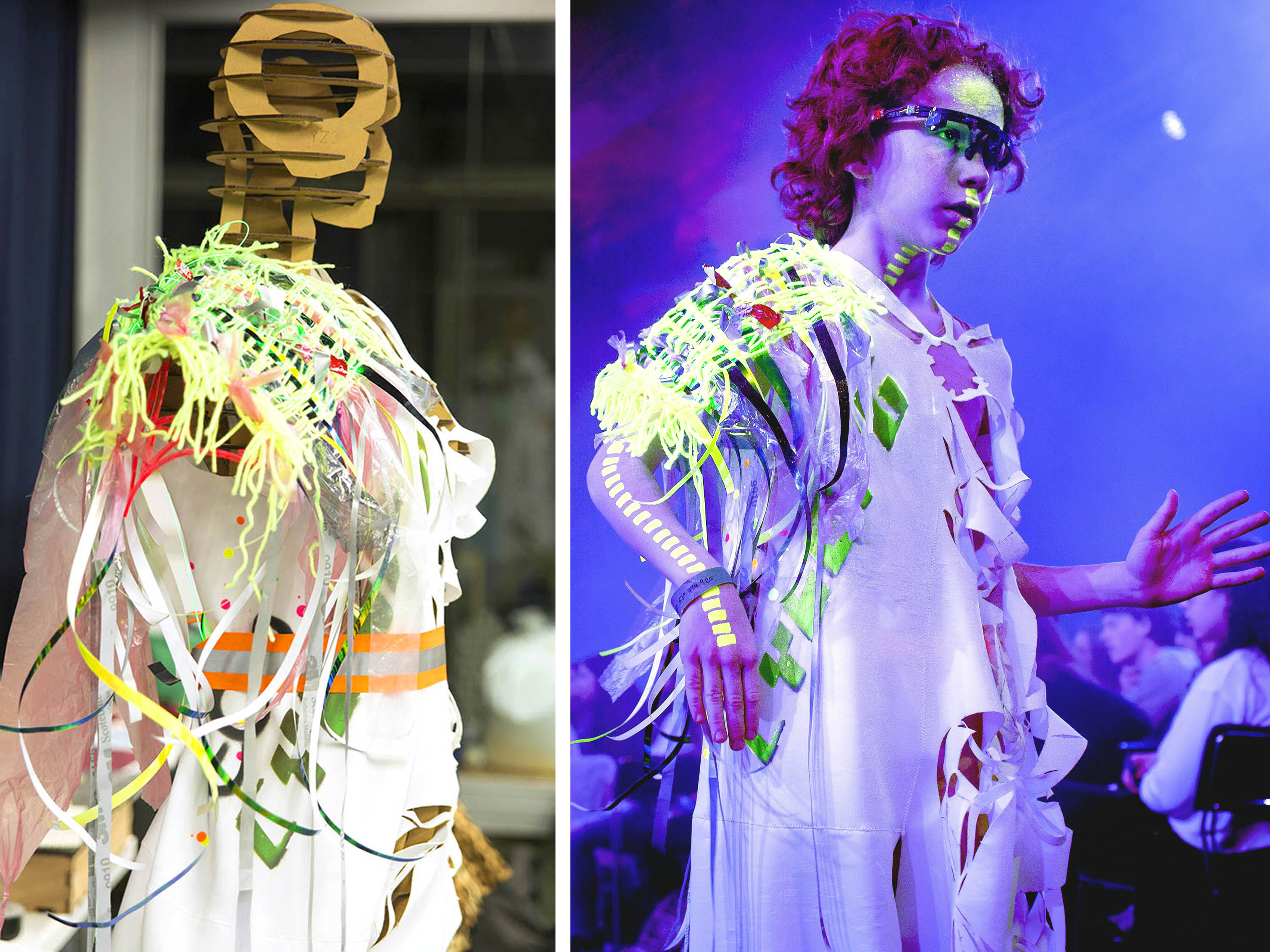

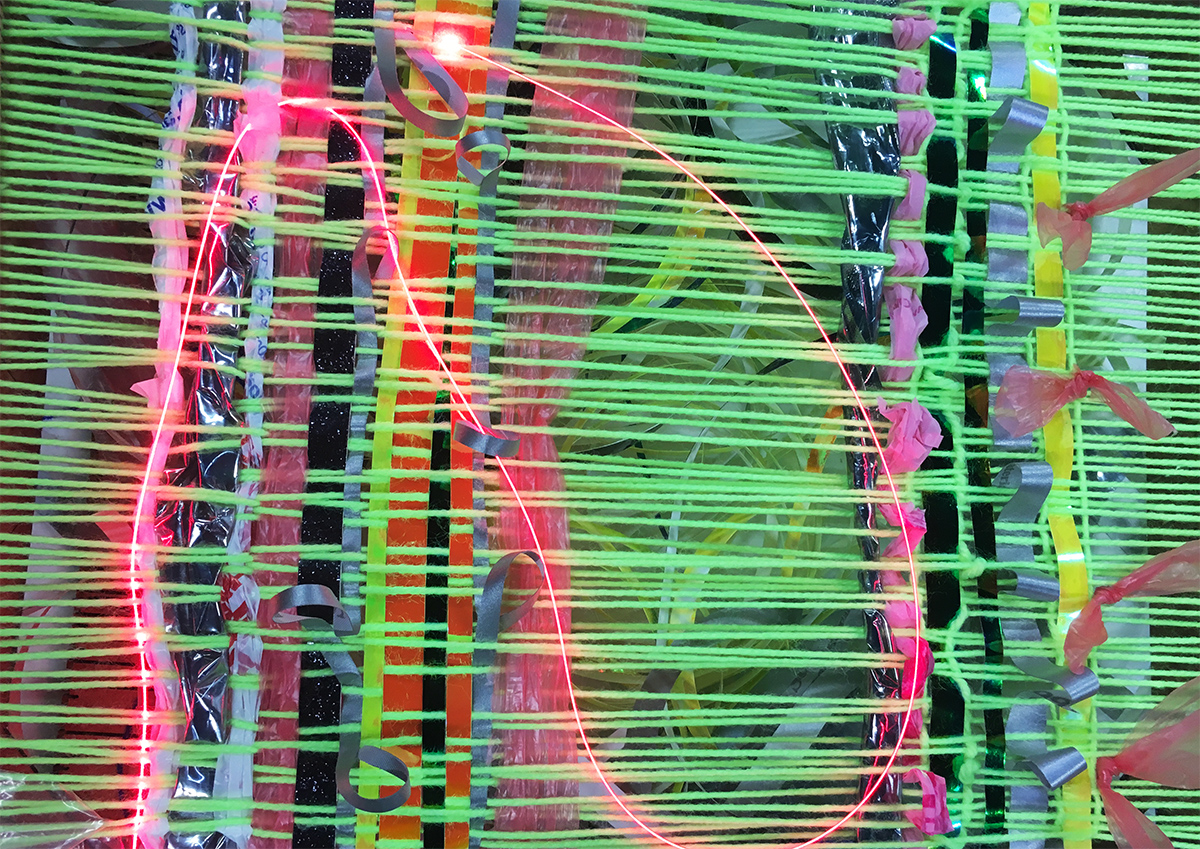

The group mentored by ALEX MURRAY-LESLIE, developed a woven shoulder piece that embedded Corning Fibrance Light-Diffusing Fibers from Versalume, reflective textiles and other types of yarns.

They 3d wove the piece using a loom that was laser-cut at Fab Lab Barcelona, and the elements developed during the jam became part of the “eco cyborg” outfit for the performance YoMo for MWC, the Mobile World Congress held in Barcelona, that was directed by Alex herself.

They 3d wove the piece using a loom that was laser-cut at Fab Lab Barcelona, and the elements developed during the jam became part of the “eco cyborg” outfit for the performance YoMo for MWC, the Mobile World Congress held in Barcelona, that was directed by Alex herself.

A laser cut cape combined different techniques learnt along the way during the course, was animated through electronics components, in which it’s shoulder elements moved according to the stretch achieved with a soft, knitted sensor. CRISTIAN RIZZUTI lead this group exploring with them extensively all the different possibilities in implementing electronics in the garment.

The third group, mentored by ZOE ROMANO developed an entire outfit, composed by a bolero and skirt, entirely constructed by variations of the same modular element that were laser cut in neoprene and integrated a sewn circuit with a lilypad and a stretch sensor. The combined modules created a structural and decorative tridimensional pattern creating an incredibly complex and beautiful look. The choice of material also impacted the final result, neoprene has clean, structured but soft properties that enhance the pattern and shape of the garments.

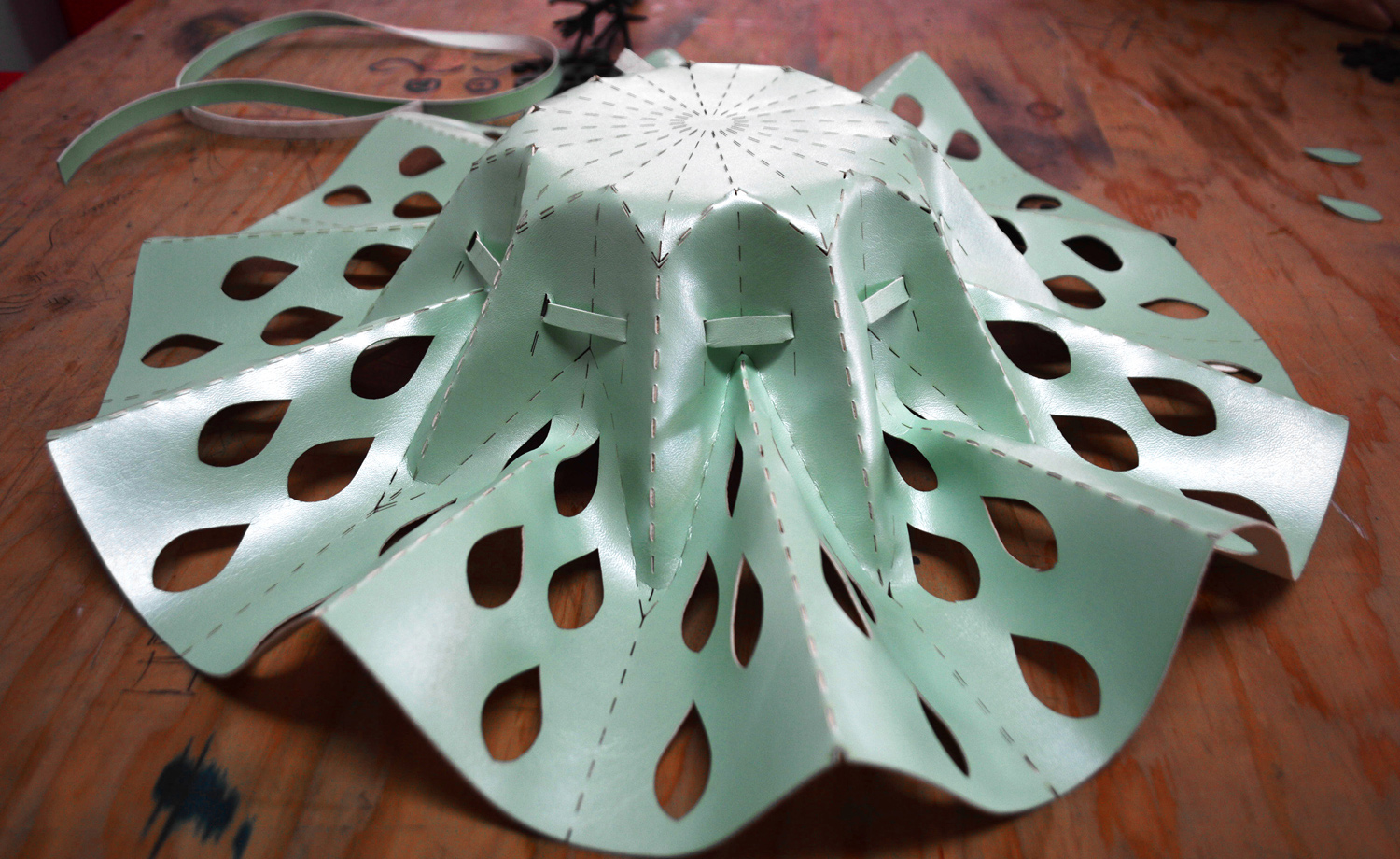

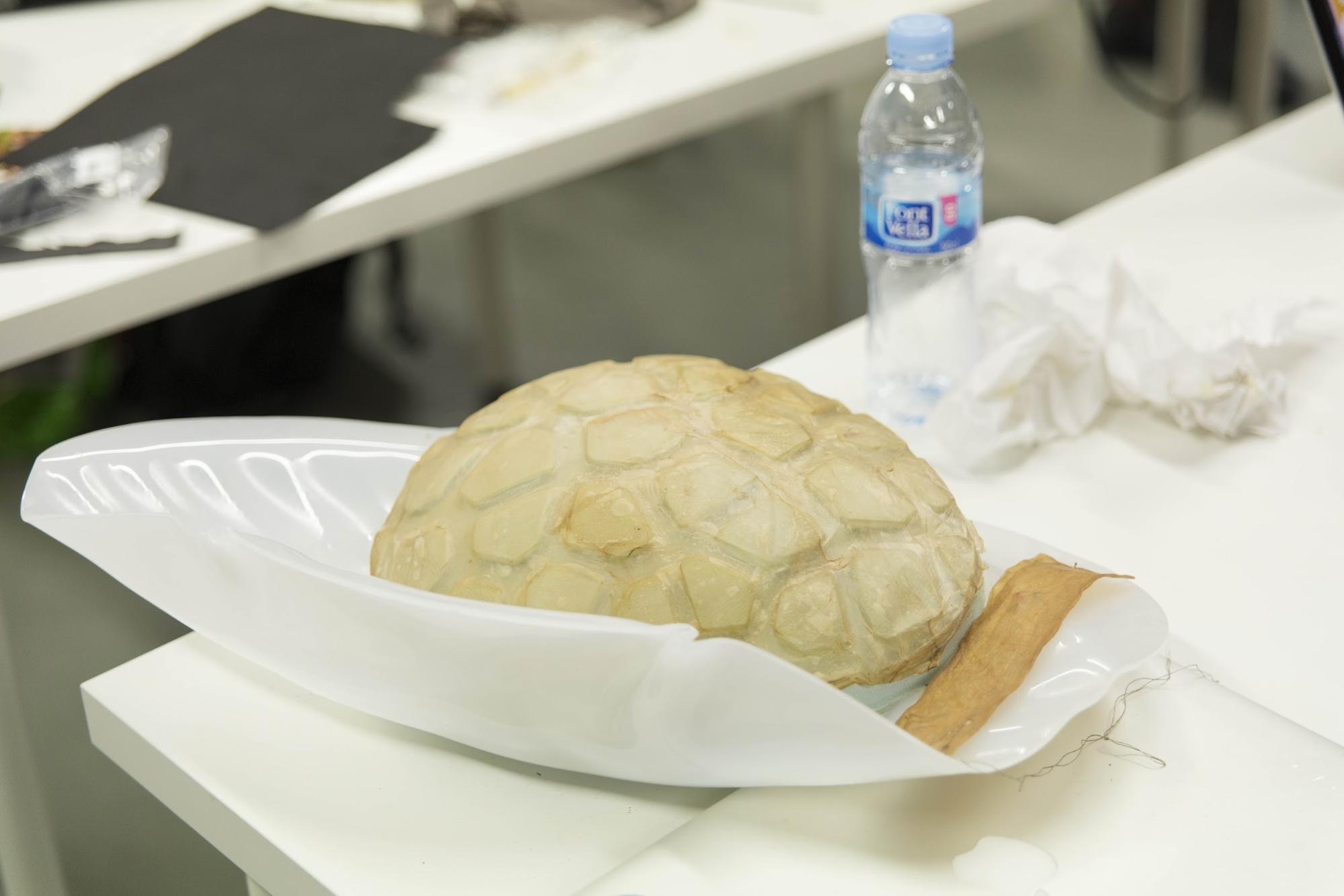

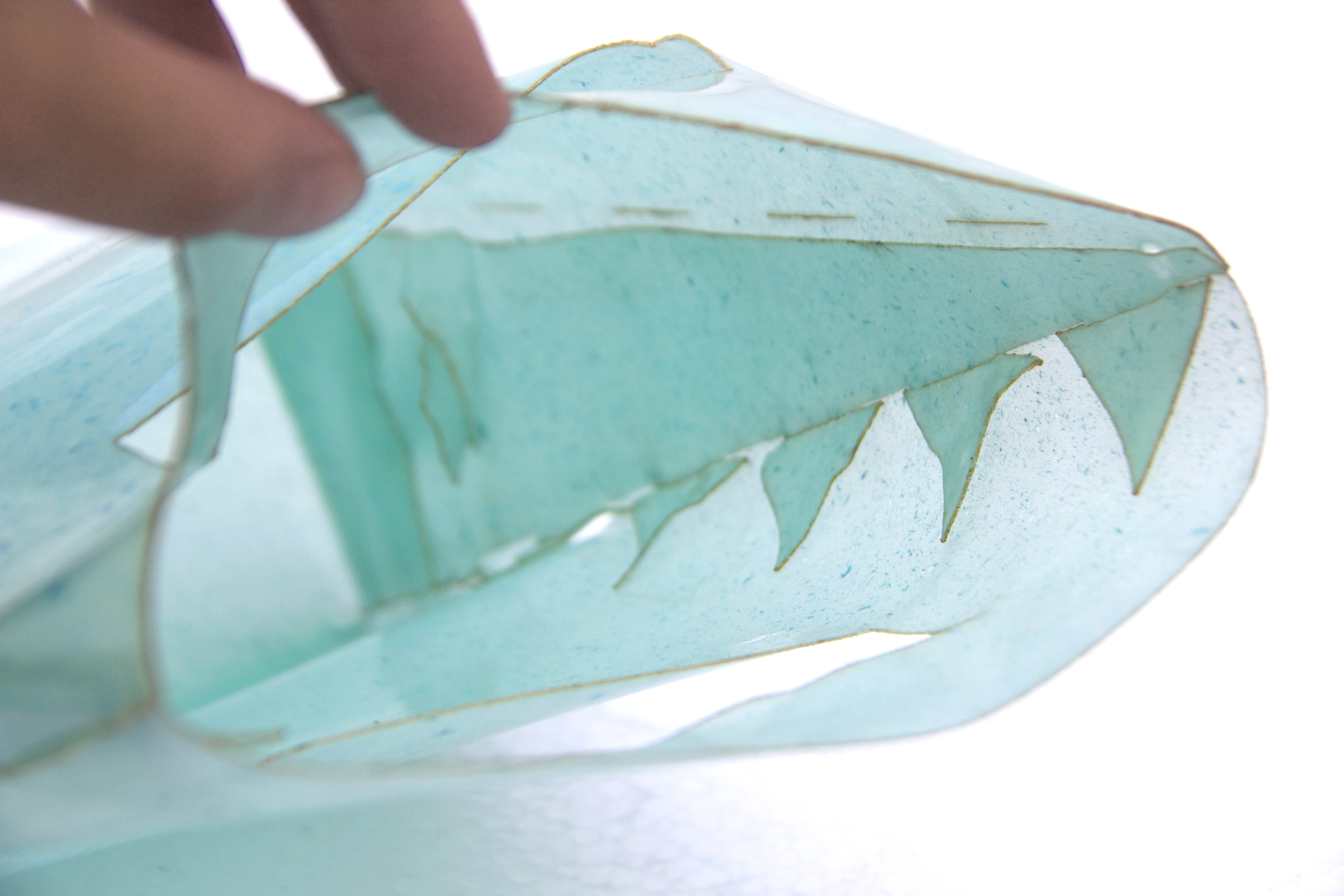

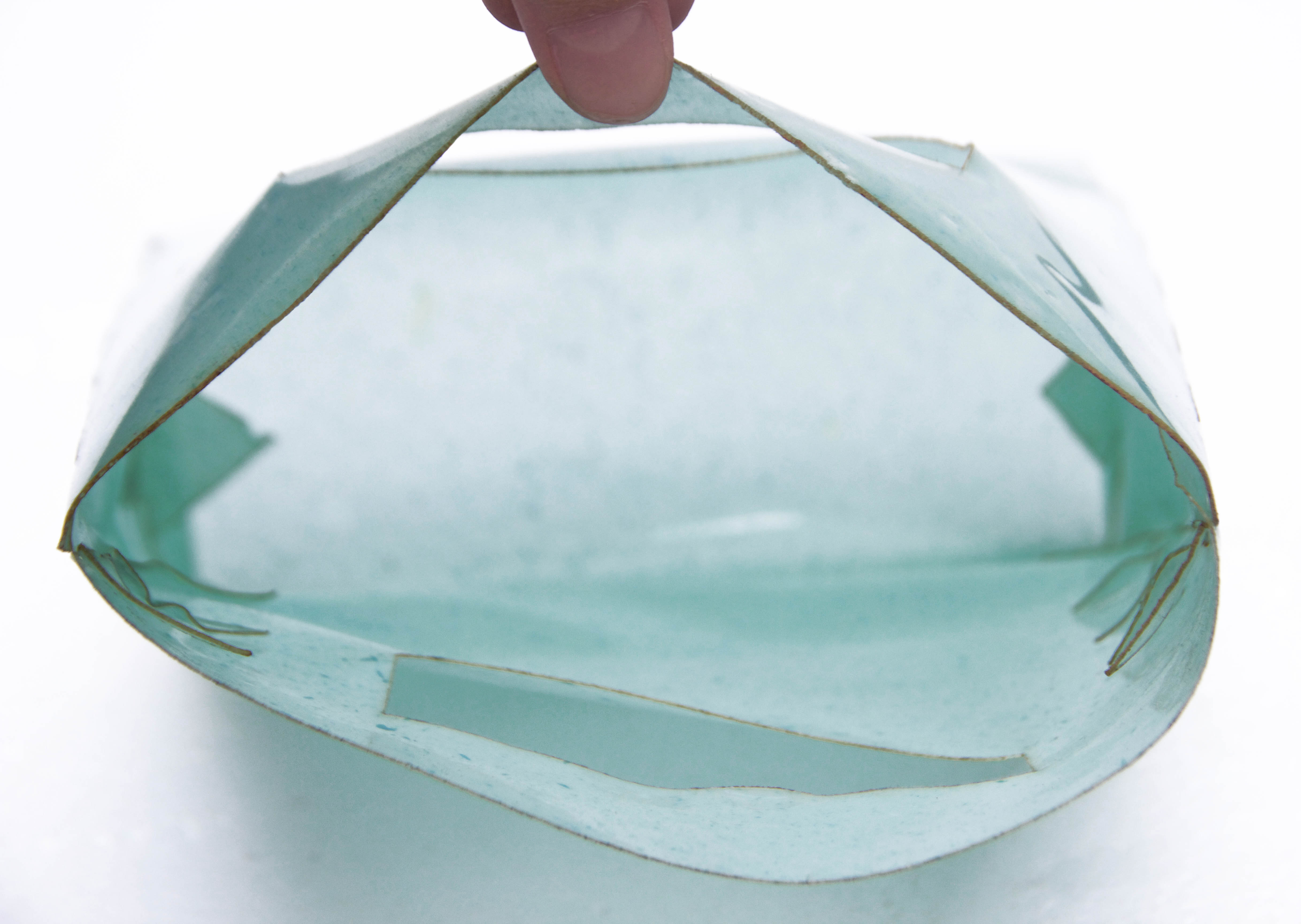

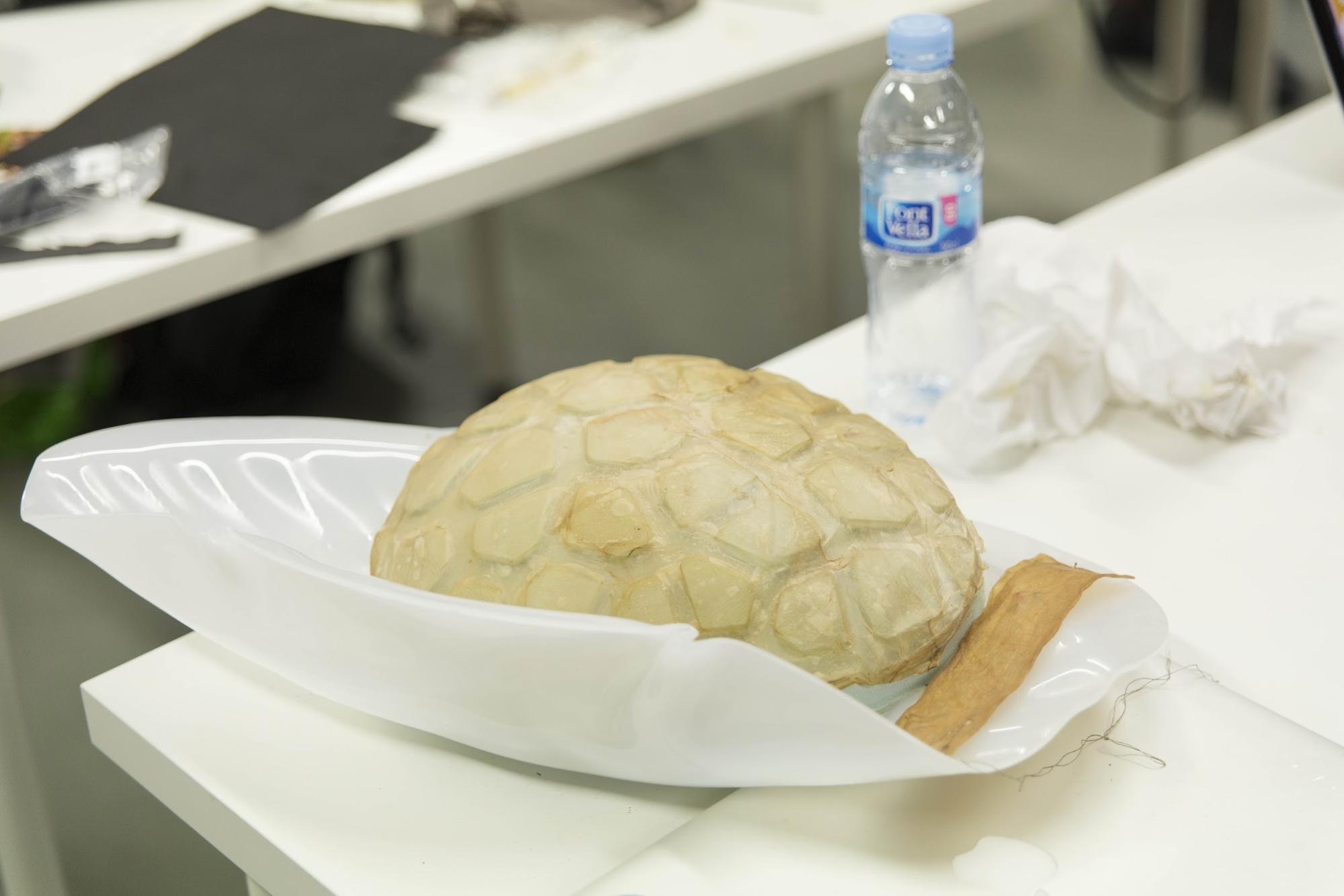

The fourth group, mentored by ANNEMIE MAES, tested the use of kombucha, the vegan leather, for molding tridimensional objects. They implemented conductive wires between the layers, to understand the possibilities to embed electronic sensor in the still wet kombucha in order to create a seamless object. They also tested the effect of different types of natural dyes on the wet kombucha, to further study the outcomes once the material is dry.

This series of experiments have the aim to bring the research of Annemie in order to ¨ grow your beehive ¨ project a step further.

Kombucha skin dyed with Hibiscus, Kurkuma, bois de campèche

Kombucha skin dyed with Hibiscus, Kurkuma, bois de campèche  Molding Kombucha skin on a CNC high density foam fractal pattern.

Molding Kombucha skin on a CNC high density foam fractal pattern.

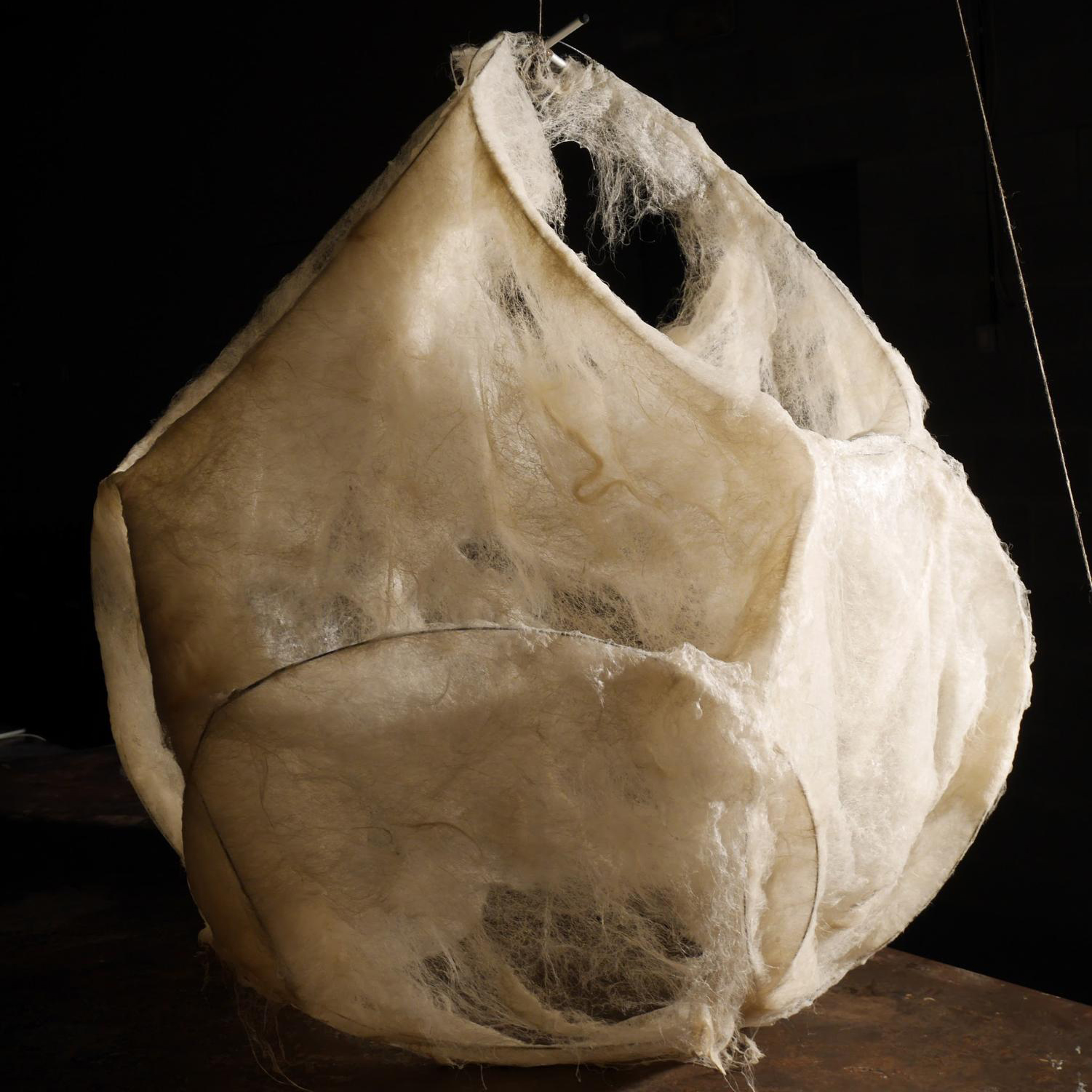

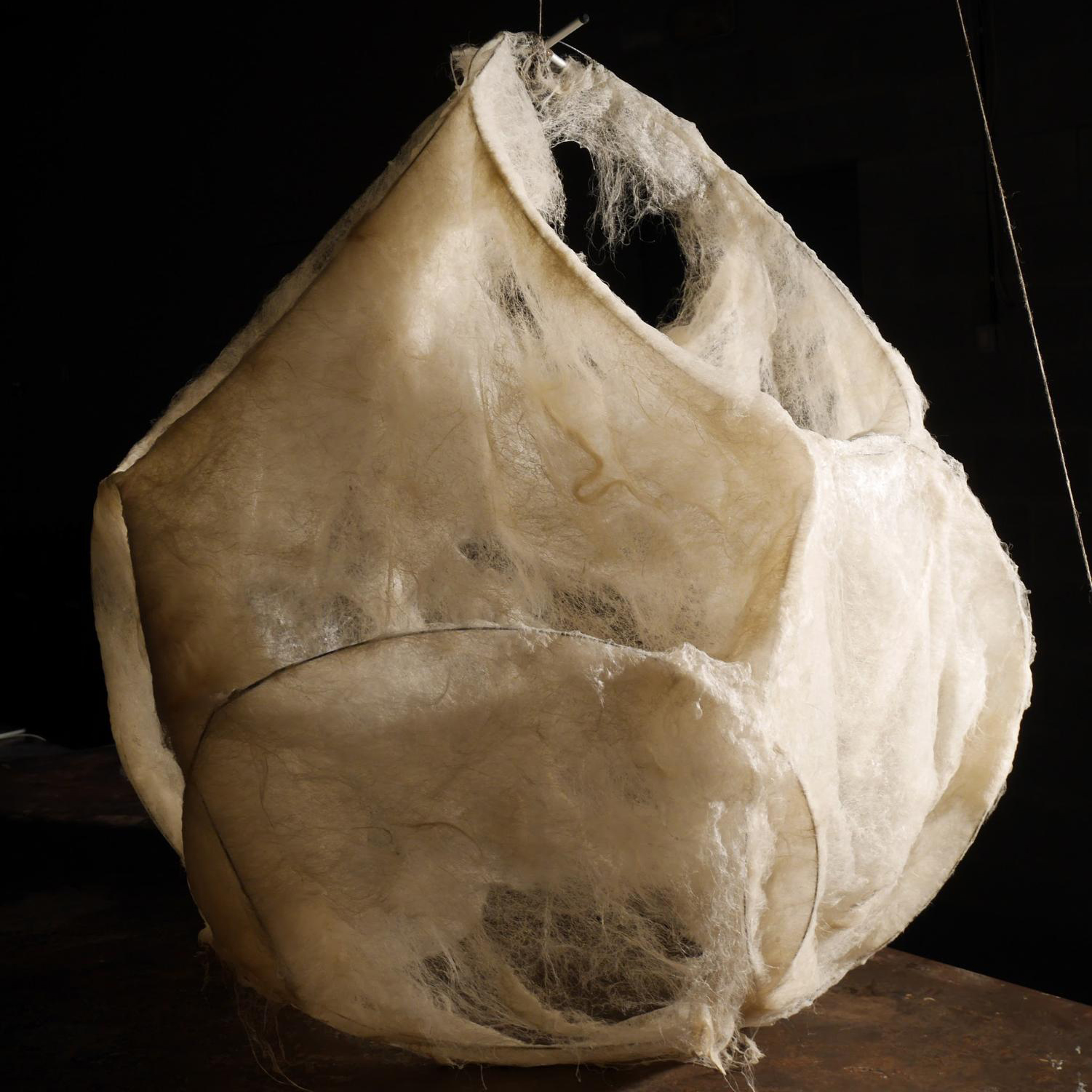

During the afternoon ALI YERDEL came and gave a demo of spraying fibers using his ¨Candy Tool¨, this is the method that ¨Fiber Dress¨of FabTextiles was made.

Completed cocoon made with natural fibers Ali Yerdel showing the Candy Gun operation

Completed cocoon made with natural fibers Ali Yerdel showing the Candy Gun operation

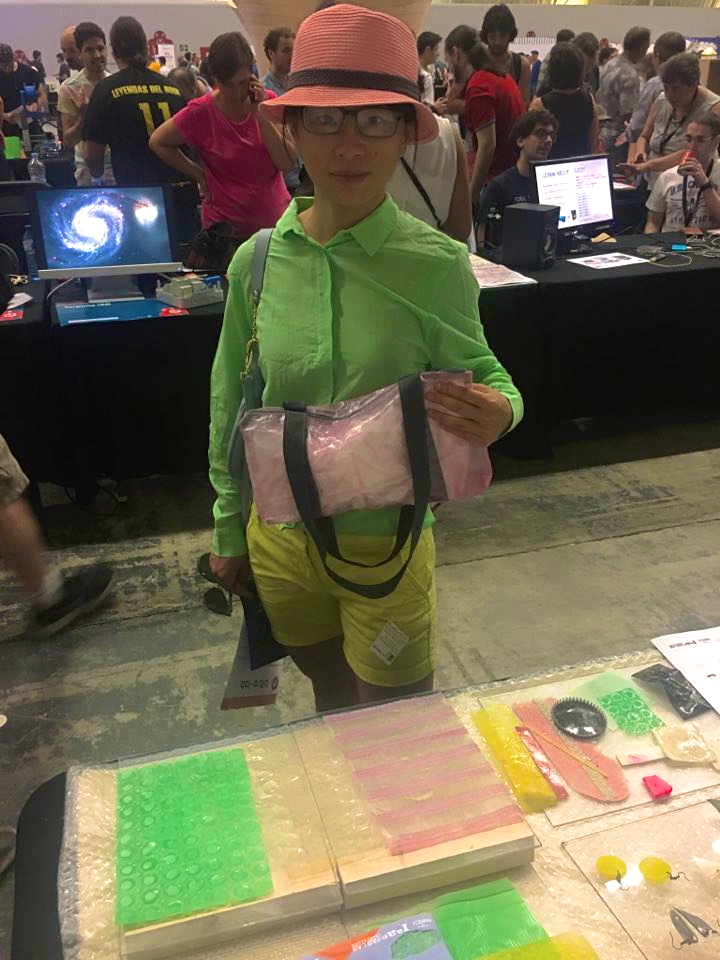

The outcome of the bootcamp are many projects, made in Barcelona and around the globe, by the great community born out of the course. In Germany, the group at Fab Lab Kamp-Lintfort showing their week’s activities and projects they made.

In Germany, the group at Fab Lab Kamp-Lintfort showing their week’s activities and projects they made.

Conclusions

We consider the Textile Academy Bootcamp a great proof that these topics are valuable to the Fab Lab network but also to a larger audience of artists, professionals and individuals. It also makes us even more motivated to work on the Fabricademy course for this autumn, which will include many more topics and more in depth investigations than those covered by the short and intense bootcamp. We hope to be able to host it in as many labs as possible, so people around the world would have the opportunity to join and participate in this amazing fast growing network.  In Germany, the group at Fab Lab Kamp-Lintfort showing their week’s activities and projects they made.

In Germany, the group at Fab Lab Kamp-Lintfort showing their week’s activities and projects they made.

Next Events

We’ll be participating to the Fab Lab Festival 2017 in Toulouse on the 11-14 May, were we will present the program to the European network. You will also be able to join us at the upcoming FAB13 Conference in Santiago de Chile on 31 July - 06 August. If you are interested in joining or participating with your lab to the program, write us at [email protected]

Organized with love by : Anastasia Pistofidou, Cecilia Raspanti, Fiore Basile with the support of IaaC Fab Lab Barcelona

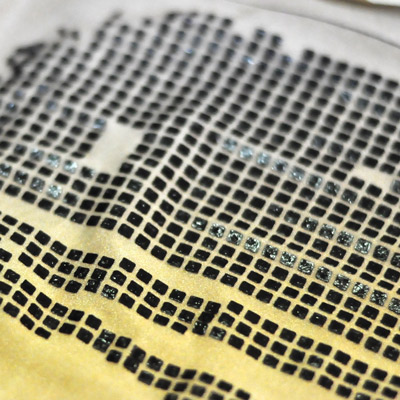

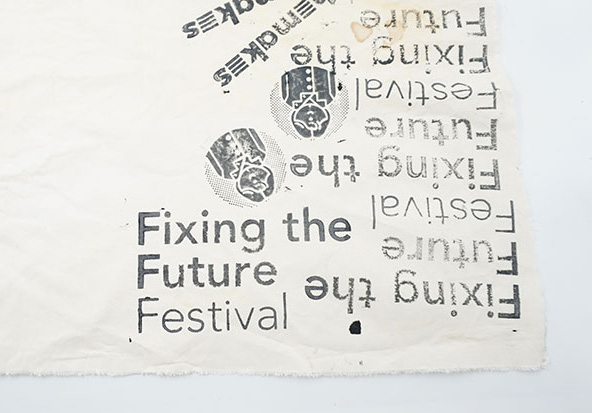

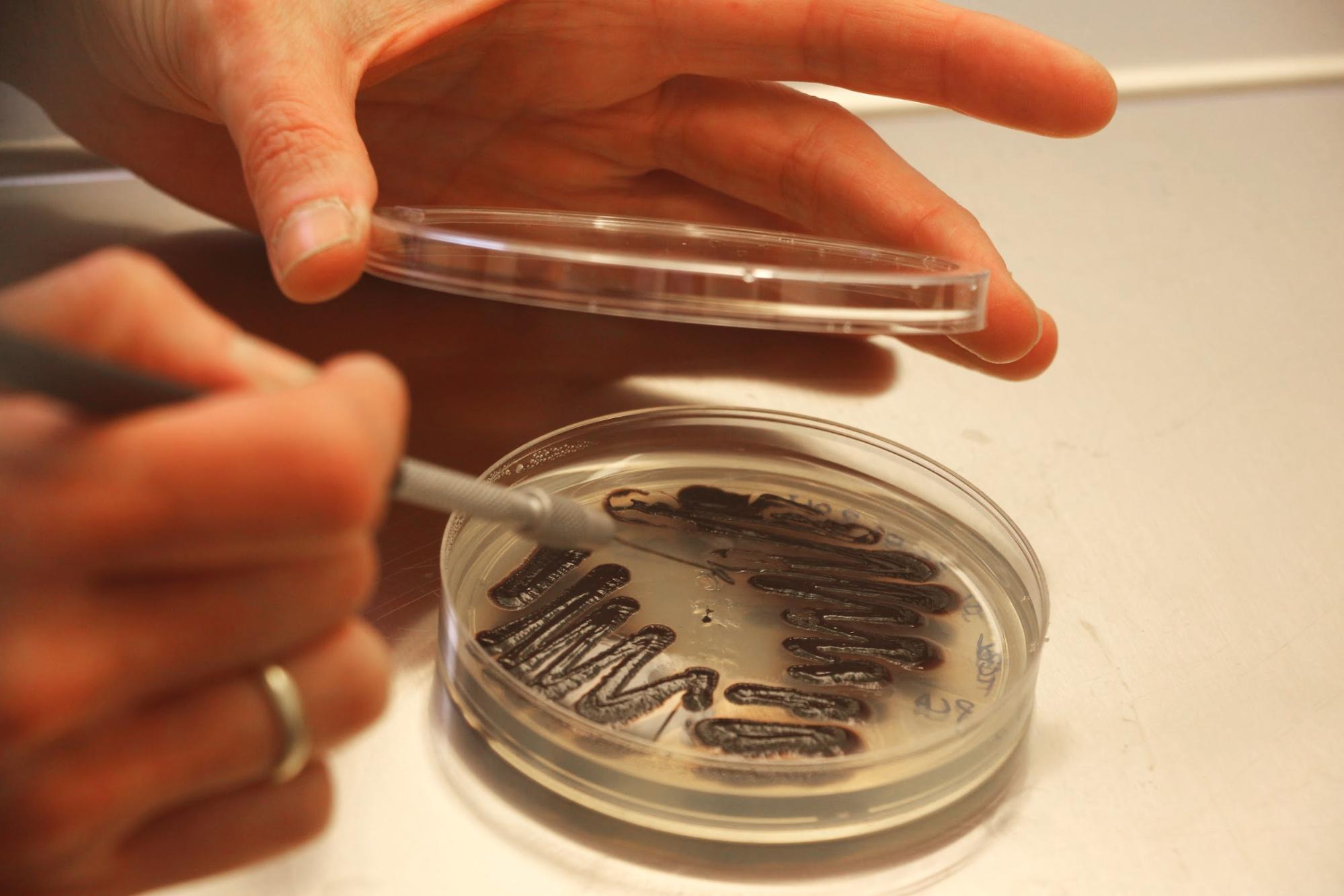

This project is about creating inks and pastes for stamping that can be used as a sustainable alternative for customizing packaging and conference materials such as tote bags, posters, lunch boxes e.t.c.

We experimented on the production of black ink from pomegranate peels applied on various surfaces (cotton fabric, paper) with different types of stamps (ewa foam, rubber, wood).

This project is about creating inks and pastes for stamping that can be used as a sustainable alternative for customizing packaging and conference materials such as tote bags, posters, lunch boxes e.t.c.

We experimented on the production of black ink from pomegranate peels applied on various surfaces (cotton fabric, paper) with different types of stamps (ewa foam, rubber, wood).

The technique originates from medieval Europe and was also used traditionally for a long time for dyeing oriental carpets. Due to

high concentration of tannin in the pomegranate and ease of production, it is currently having a renaissance.

It can be used as an ink for silkscreen printing, calligraphy or textile printing.

The technique originates from medieval Europe and was also used traditionally for a long time for dyeing oriental carpets. Due to

high concentration of tannin in the pomegranate and ease of production, it is currently having a renaissance.

It can be used as an ink for silkscreen printing, calligraphy or textile printing.

The experiments were carried out with differently proportioned ink-rubber mixtures. Furthermore, we tested the effect of vinegar as an additional base solution for preserving the dye.

Basis for our evaluation was the color intensity, the distribution of the ink, the sharpness of contours and the detail of the stamps.

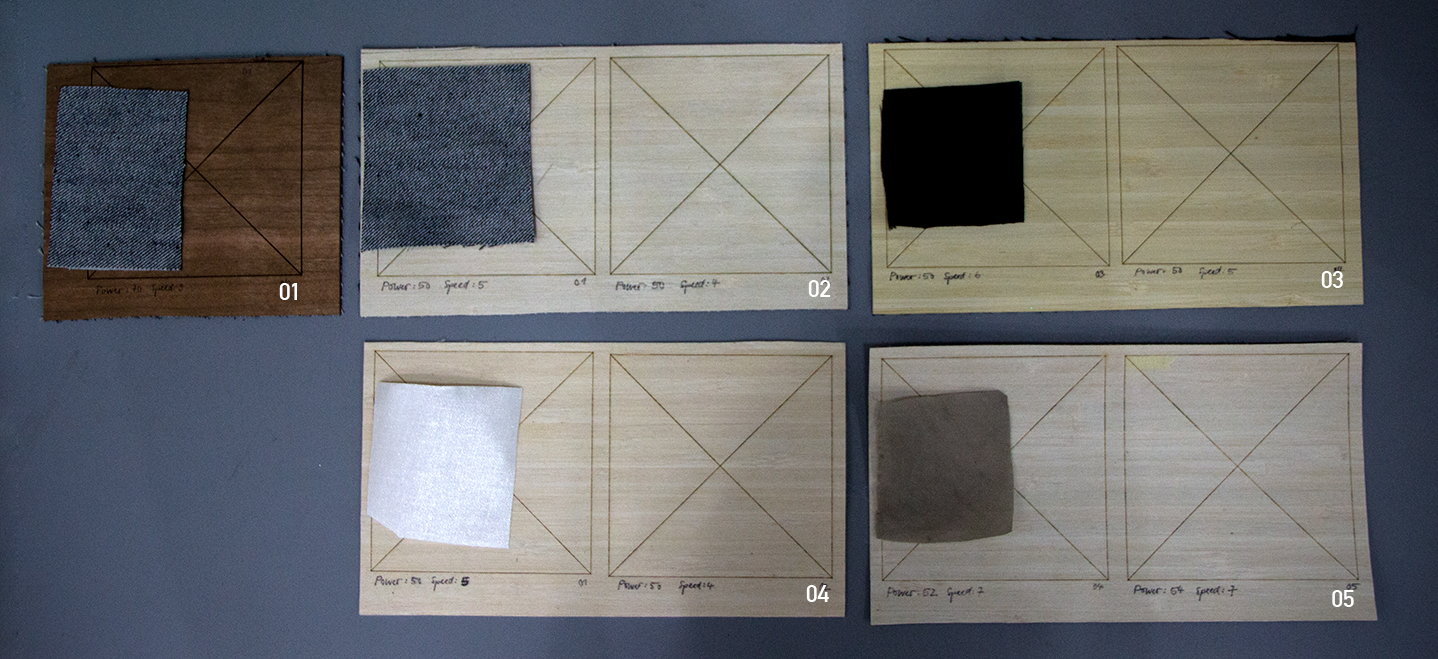

The stamps were laser engraved and cut. The files were images in png format or vectors and various tests for adjusting the laser power were conducted.

To mix your ink, you can optionally use a magnetic stirrer or mix it by hand with a spoon and heat it to speed up the dissolution of the gum. Do not boil the ink.

Adding iron changes the color of the pomegranate liquor to deep black. Vinegar has no effect on the result, but it can still be used as a preservative.

Gum arabic and guar gum improve the consistency of the ink (the more viscous the ink, the better the results for stamping on fabric).

The experiments were carried out with differently proportioned ink-rubber mixtures. Furthermore, we tested the effect of vinegar as an additional base solution for preserving the dye.

Basis for our evaluation was the color intensity, the distribution of the ink, the sharpness of contours and the detail of the stamps.

The stamps were laser engraved and cut. The files were images in png format or vectors and various tests for adjusting the laser power were conducted.

To mix your ink, you can optionally use a magnetic stirrer or mix it by hand with a spoon and heat it to speed up the dissolution of the gum. Do not boil the ink.

Adding iron changes the color of the pomegranate liquor to deep black. Vinegar has no effect on the result, but it can still be used as a preservative.

Gum arabic and guar gum improve the consistency of the ink (the more viscous the ink, the better the results for stamping on fabric).

Stamping

Stamping

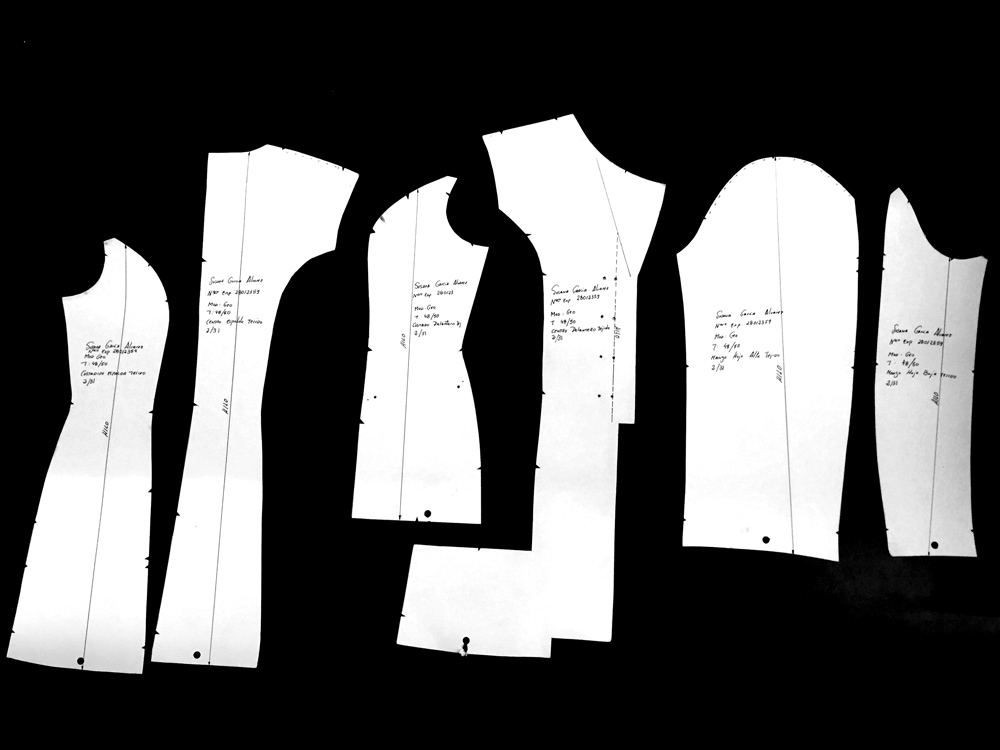

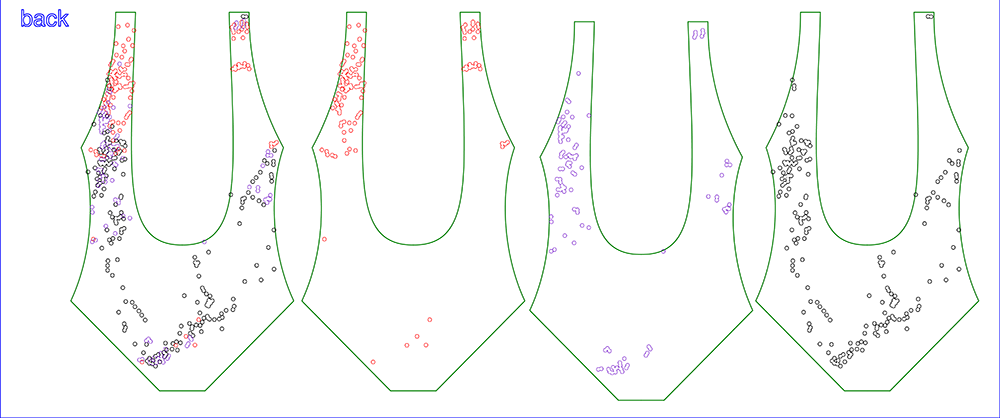

Runway Mercedes Benz Madrid Fashion Week / July 2019

Runway Mercedes Benz Madrid Fashion Week / July 2019

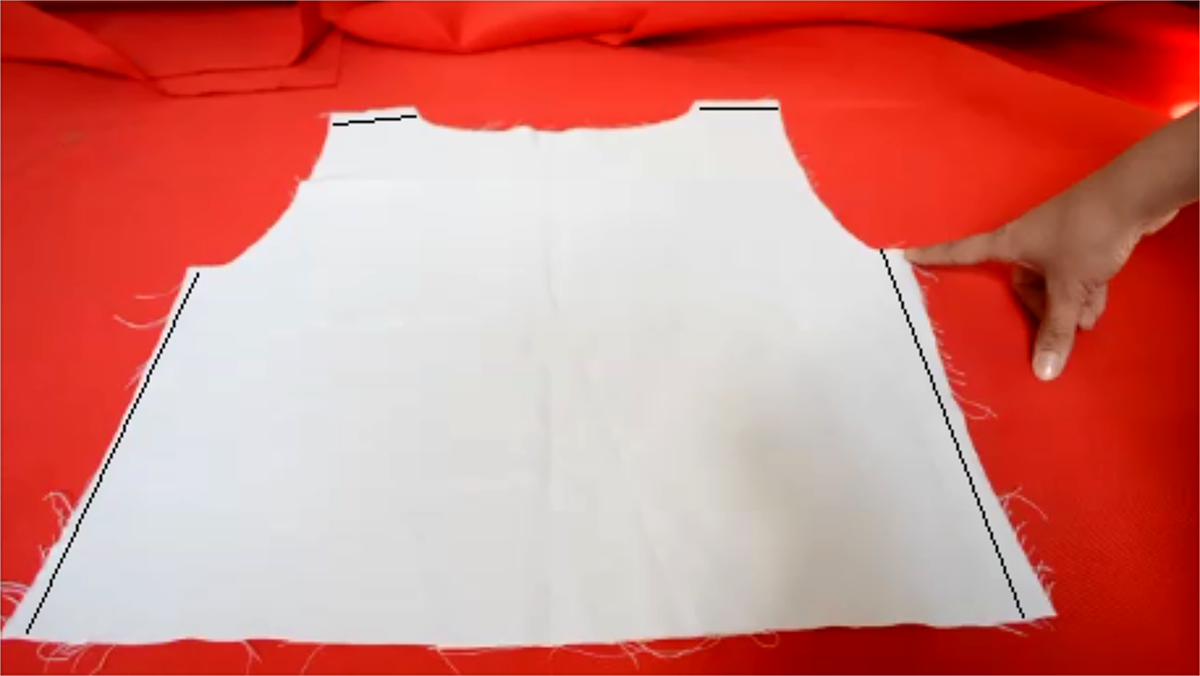

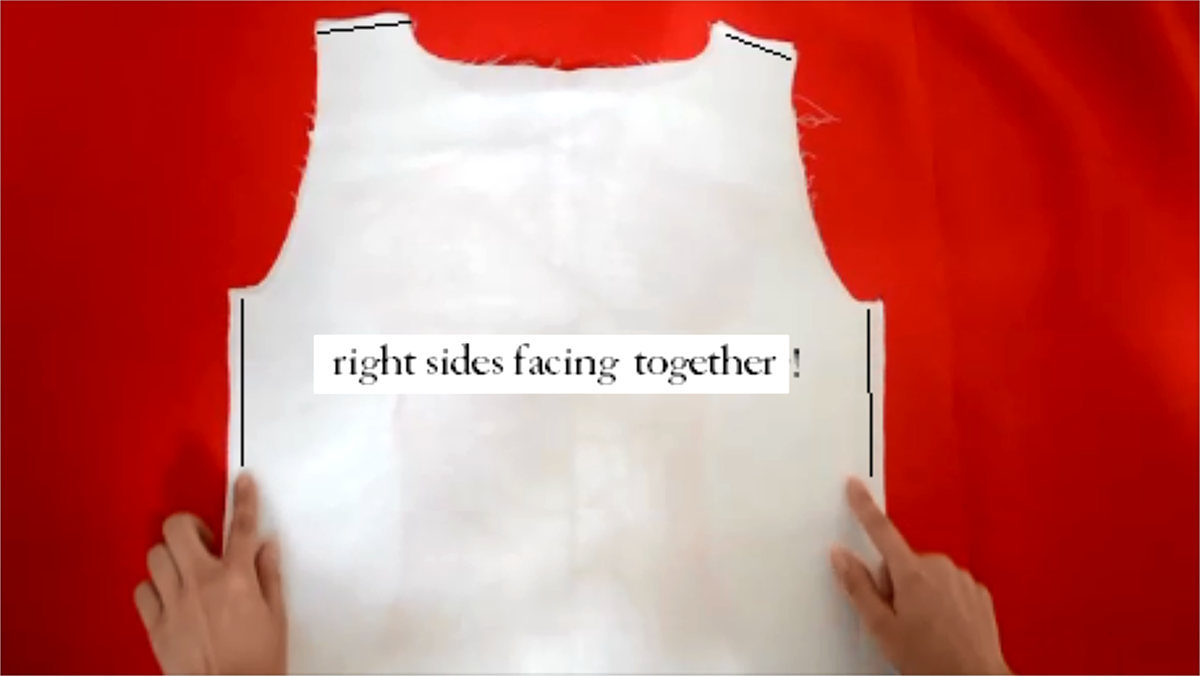

4.Press the seams

4.Press the seams

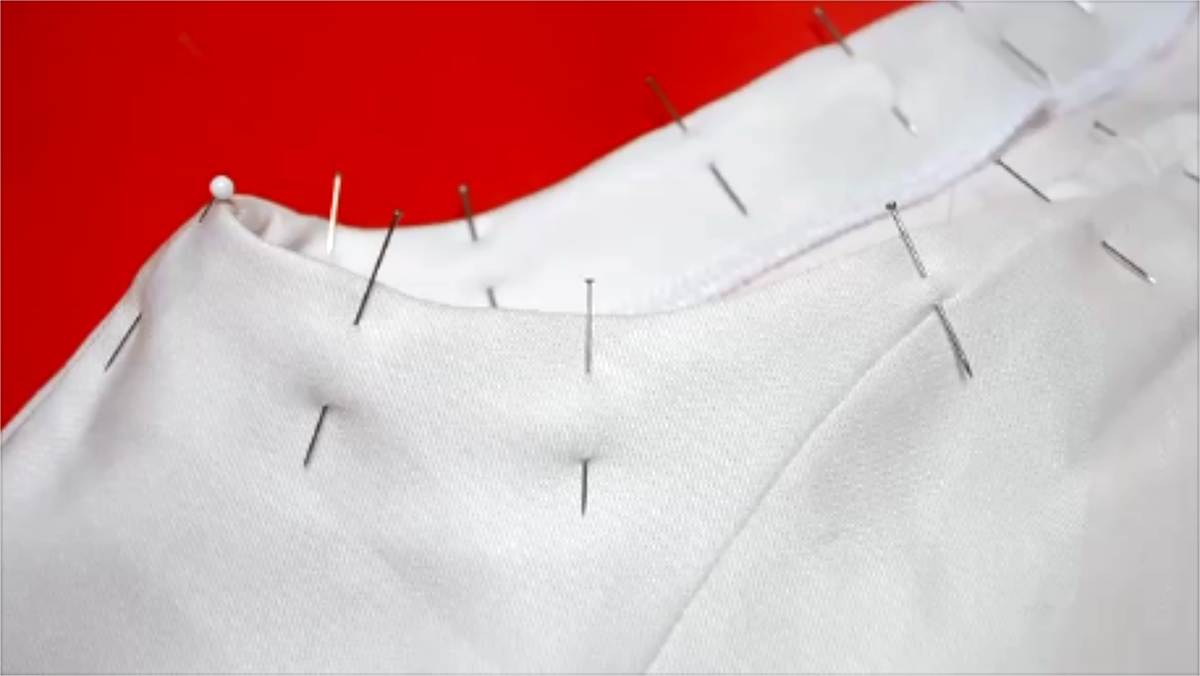

7.Make cut-ins on seam allowance with small scissors. Make sure that you don’t cut the actual seam or other parts of the T-Shirt.

7.Make cut-ins on seam allowance with small scissors. Make sure that you don’t cut the actual seam or other parts of the T-Shirt.

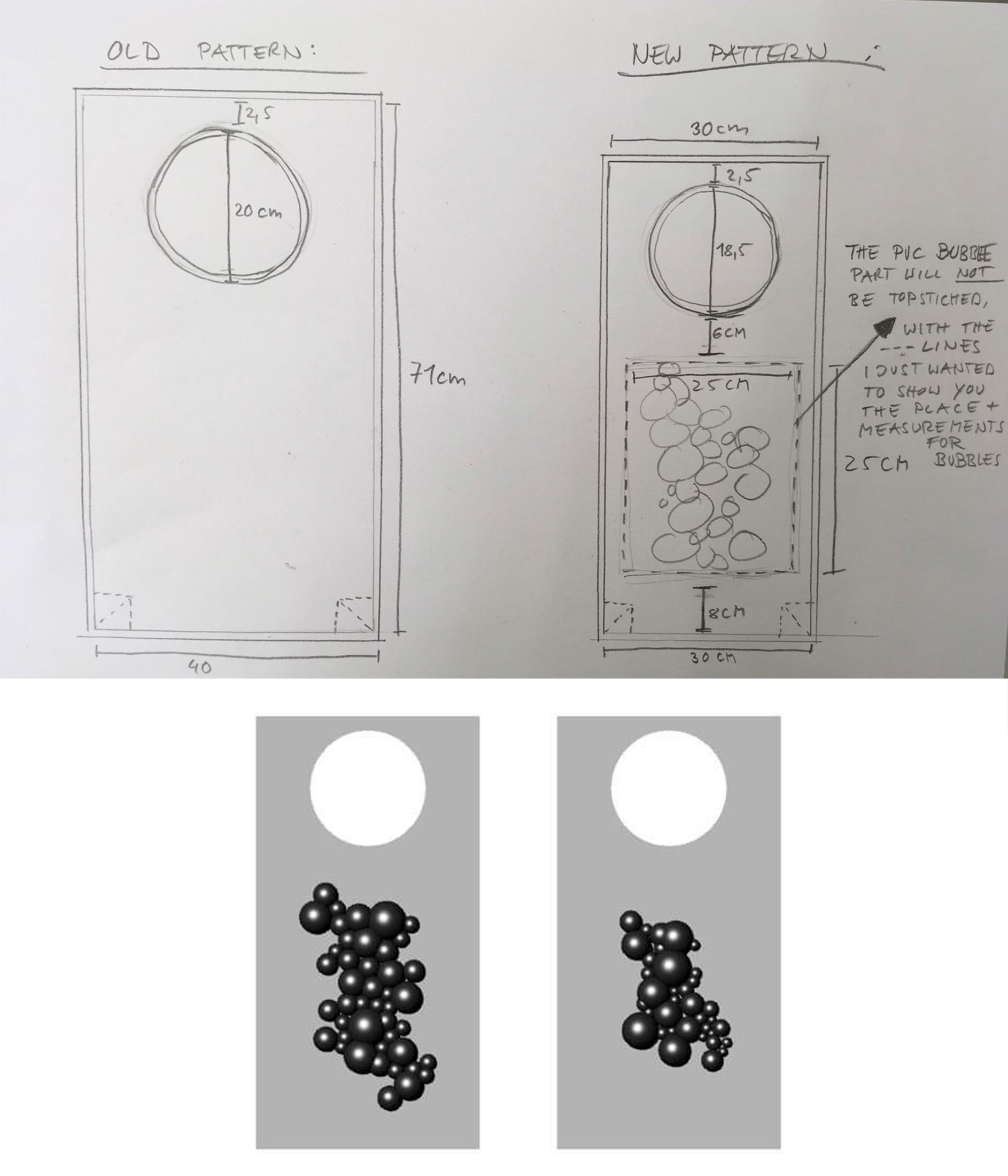

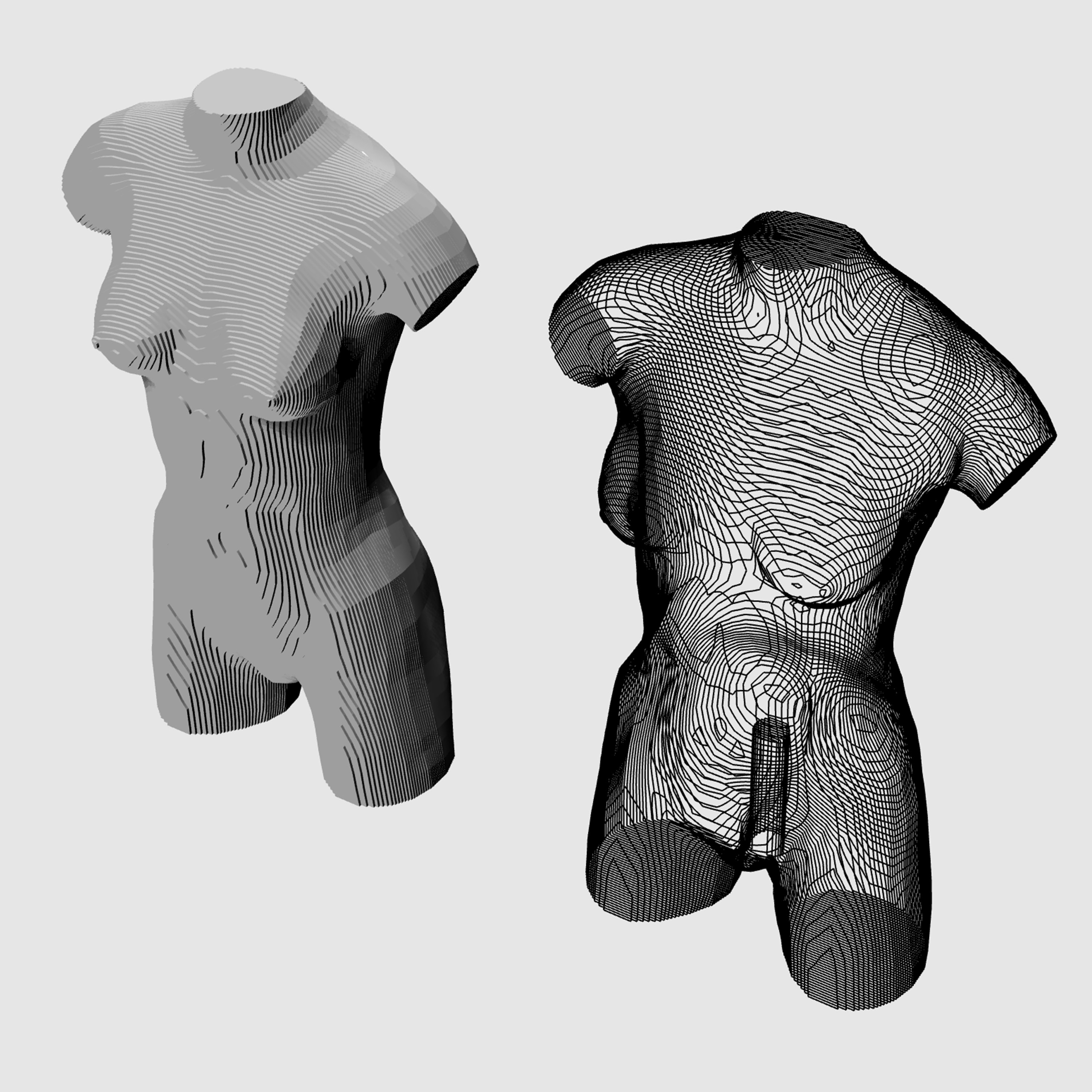

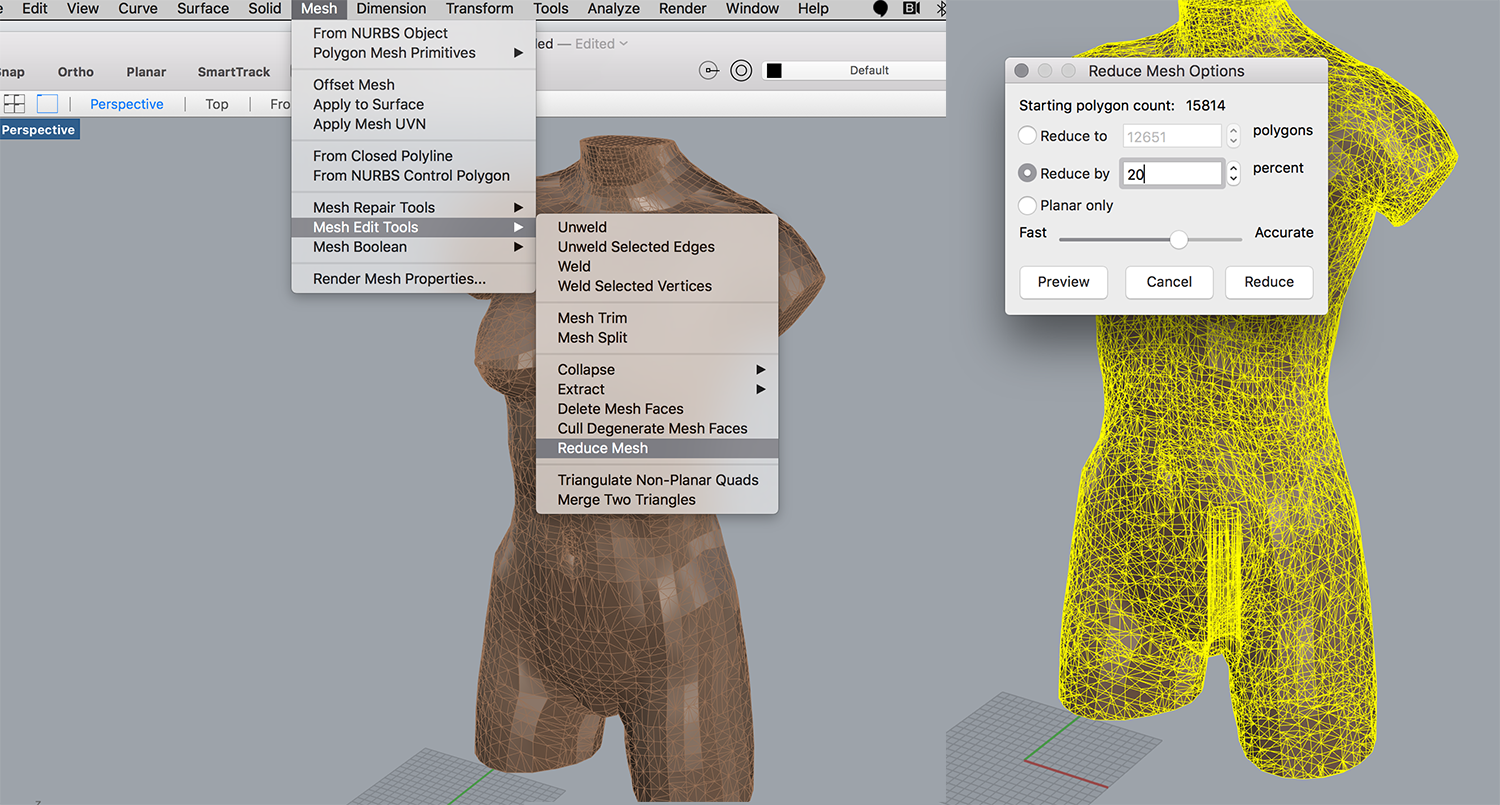

Contouring command in rhinoceros3D for creating one of the 3D mannequins version

Contouring command in rhinoceros3D for creating one of the 3D mannequins version Reduce Mesh command that creates lower resolution triangulated meshes.

Reduce Mesh command that creates lower resolution triangulated meshes.

It´s very crowded here!

It´s very crowded here!

contact me for the files!

contact me for the files!

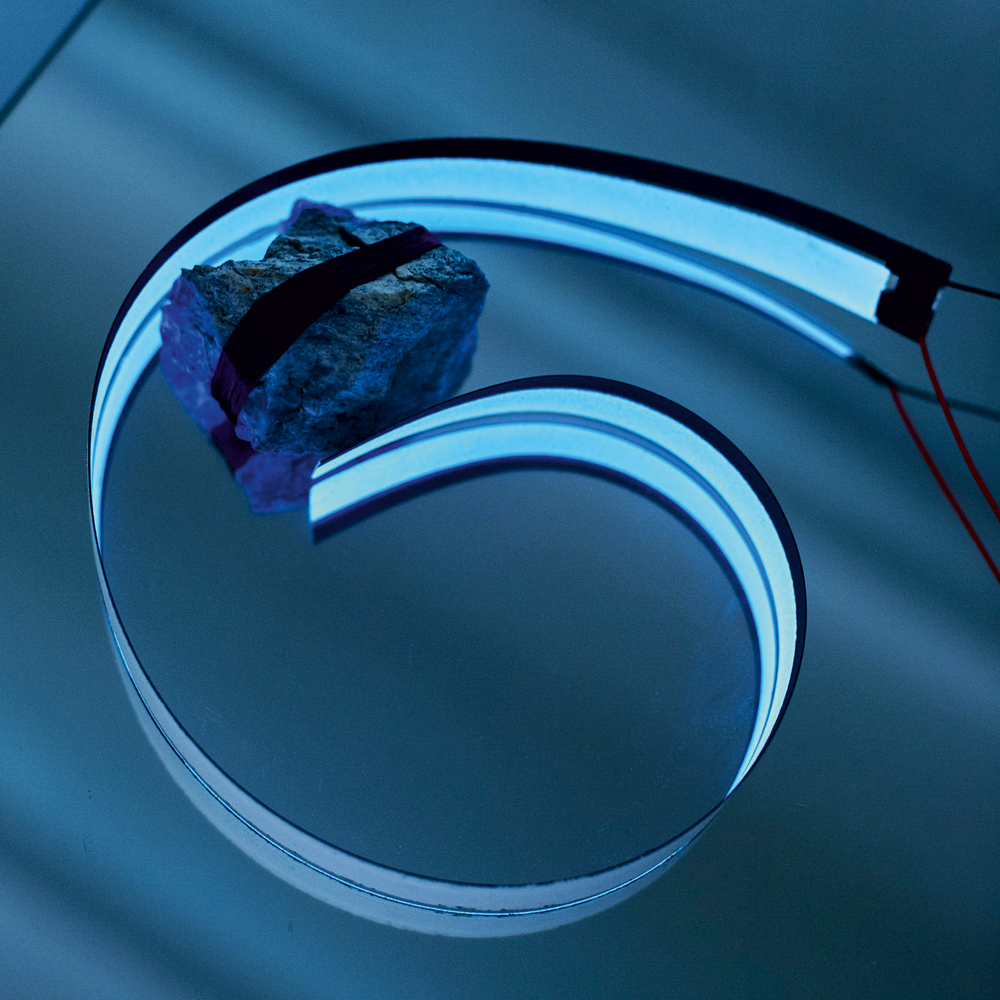

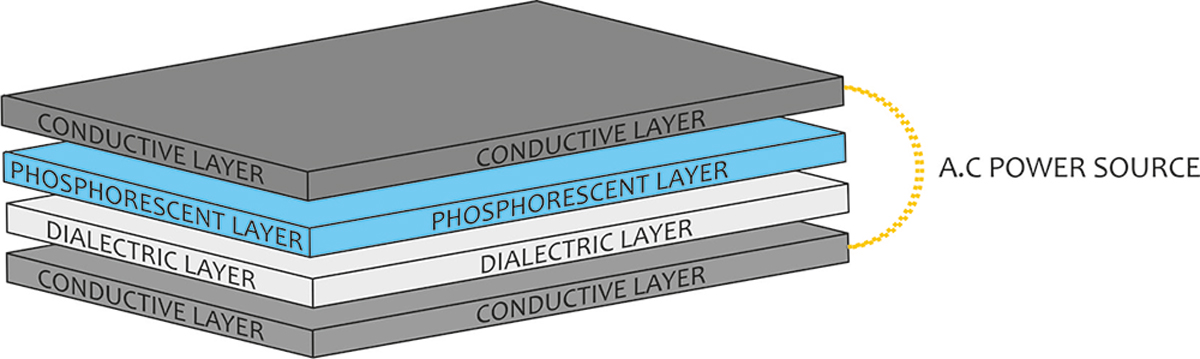

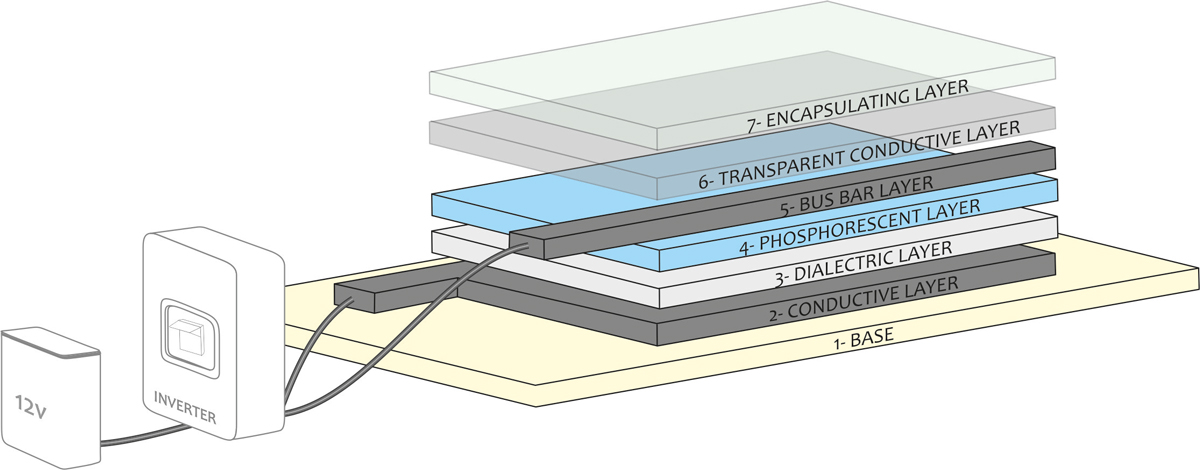

Electroluminescent

Electroluminescent

Pictures from Refraccions Exhibition, Cristina Noguer

Pictures from Refraccions Exhibition, Cristina Noguer

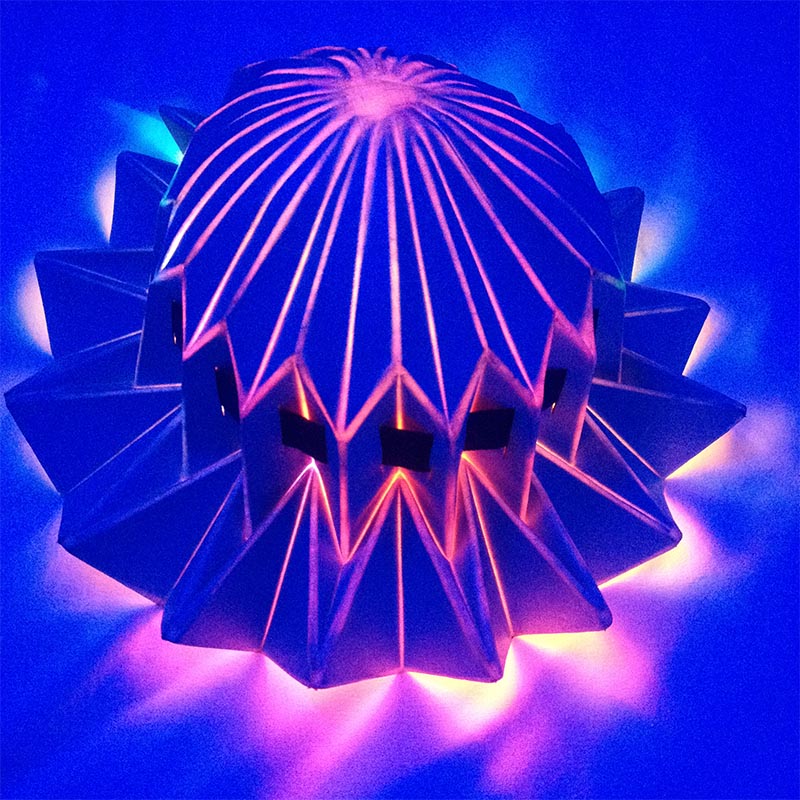

Coralia by Cecilia Raspanti and Aldo Sollazzo

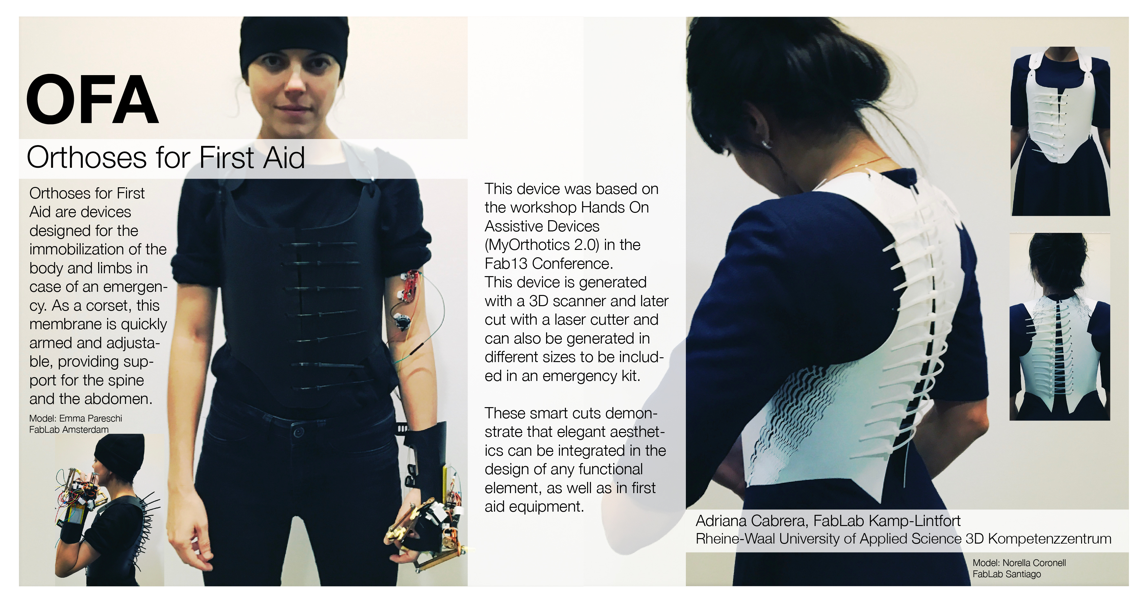

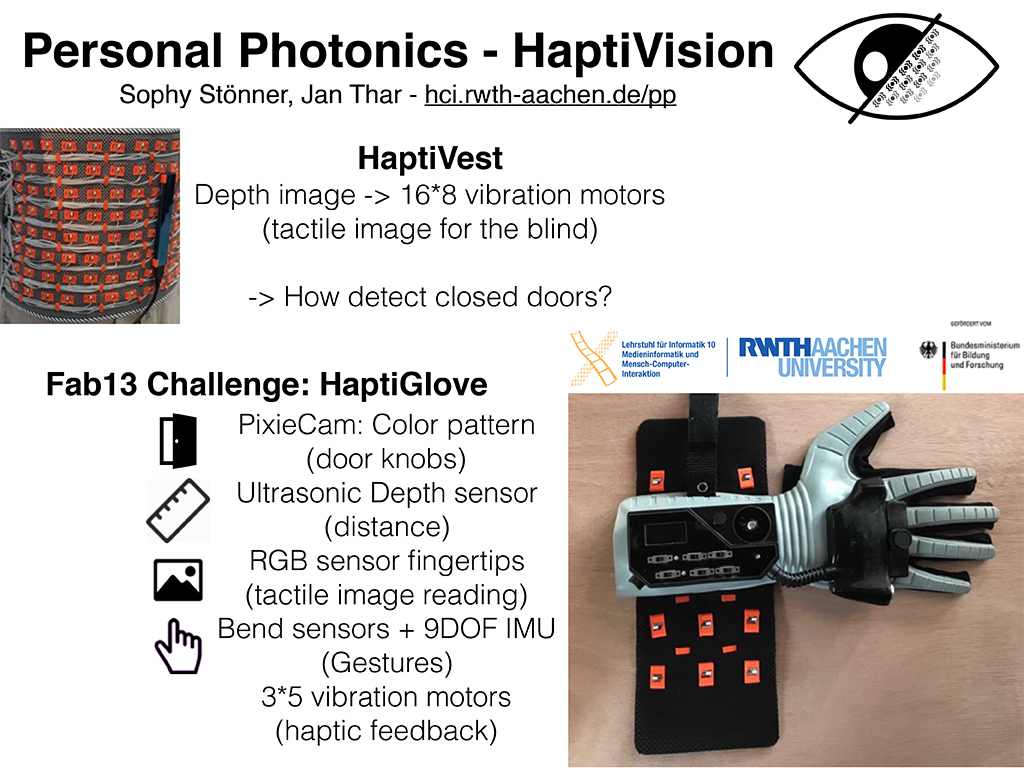

Coralia by Cecilia Raspanti and Aldo Sollazzo HaptiVest by Sophy Stönner and

HaptiVest by Sophy Stönner and  Ana de Lara, OpenTextiles, Fab Lab Santiago

Ana de Lara, OpenTextiles, Fab Lab Santiago

Liza Stark doing the

Liza Stark doing the

In Germany, the group at

In Germany, the group at  In Germany, the group at

In Germany, the group at