Currently a 3d printer that prints clothes does not exist. In the sense that there is not any popular, low cost, numerically controlled deposition of textile matter (fibers) such as a textile 3d printer. There were some previous projects that failed, but it is something that we will see in the near future. While I am writing this article, I am already foreseeing posibilites of textile printing and I hope can get some time to make some experiments. A good example of a new digital fabrication method would be the robotic weaving, but I guess that this is something old for the automotive industry and the weaving of carbon fibers. The textile industry is extremely advanced and uses digital tools for producing patterns, stamps, techniques since long time now and we should be careful when saying ¨the first 3D printed cloth¨. The most usual ways of using popular 3D printing in Fashion is to Make ¨chain like¨ structures in order to obtain a textile behavior or use flexible filaments or even 3D print on Fabric.

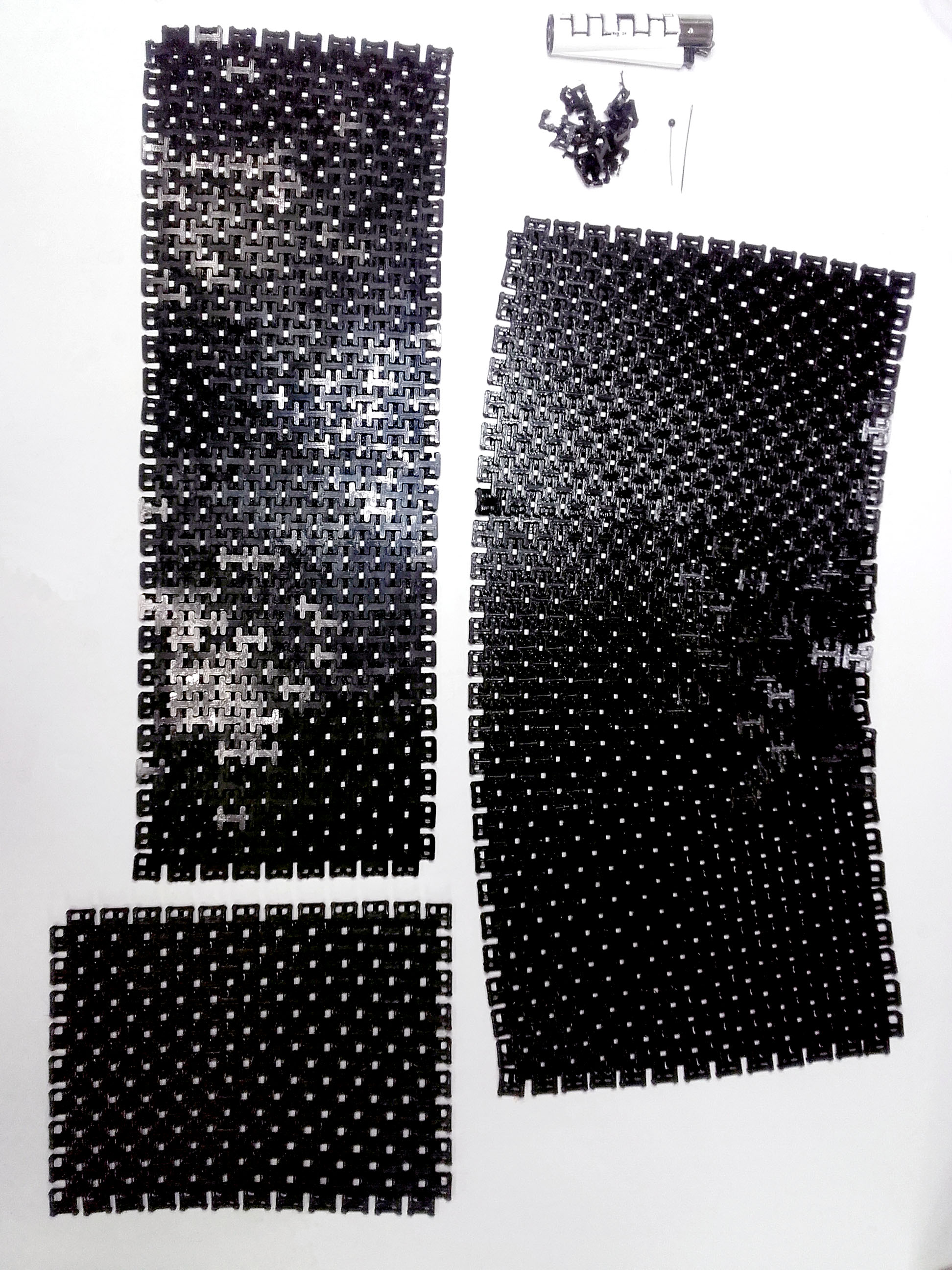

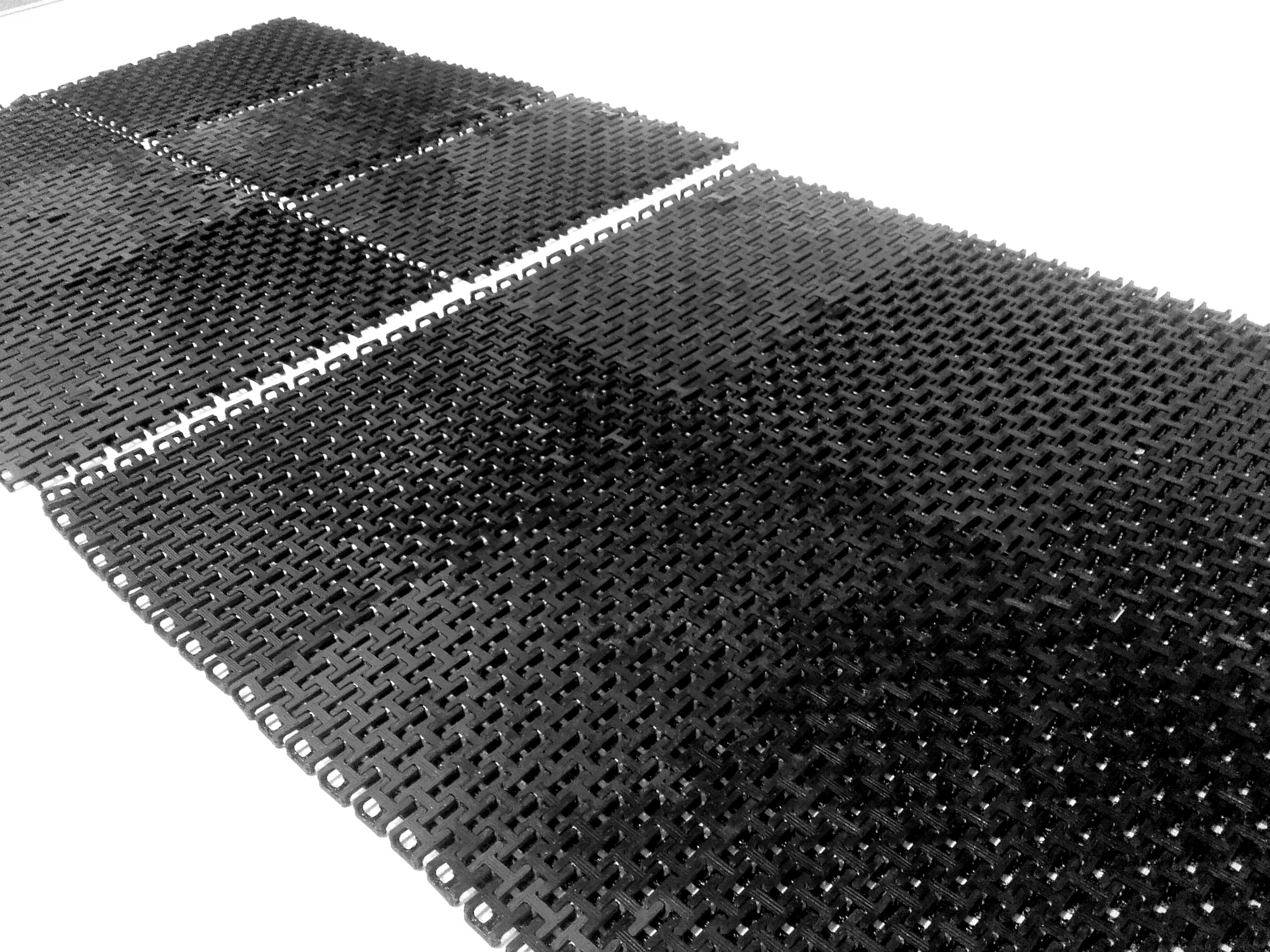

This 3D printed TOP is made out of many pieces soldered together. due to the limitations of the machine size. The file is open source and can be found on thingiverse as a customizable thing, anyone can use the customizer to prescribe the width and length. Here you can download the file.

The Customizable Chain Mail on Rhinoceros software.

The Customizable Chain Mail on Rhinoceros software.

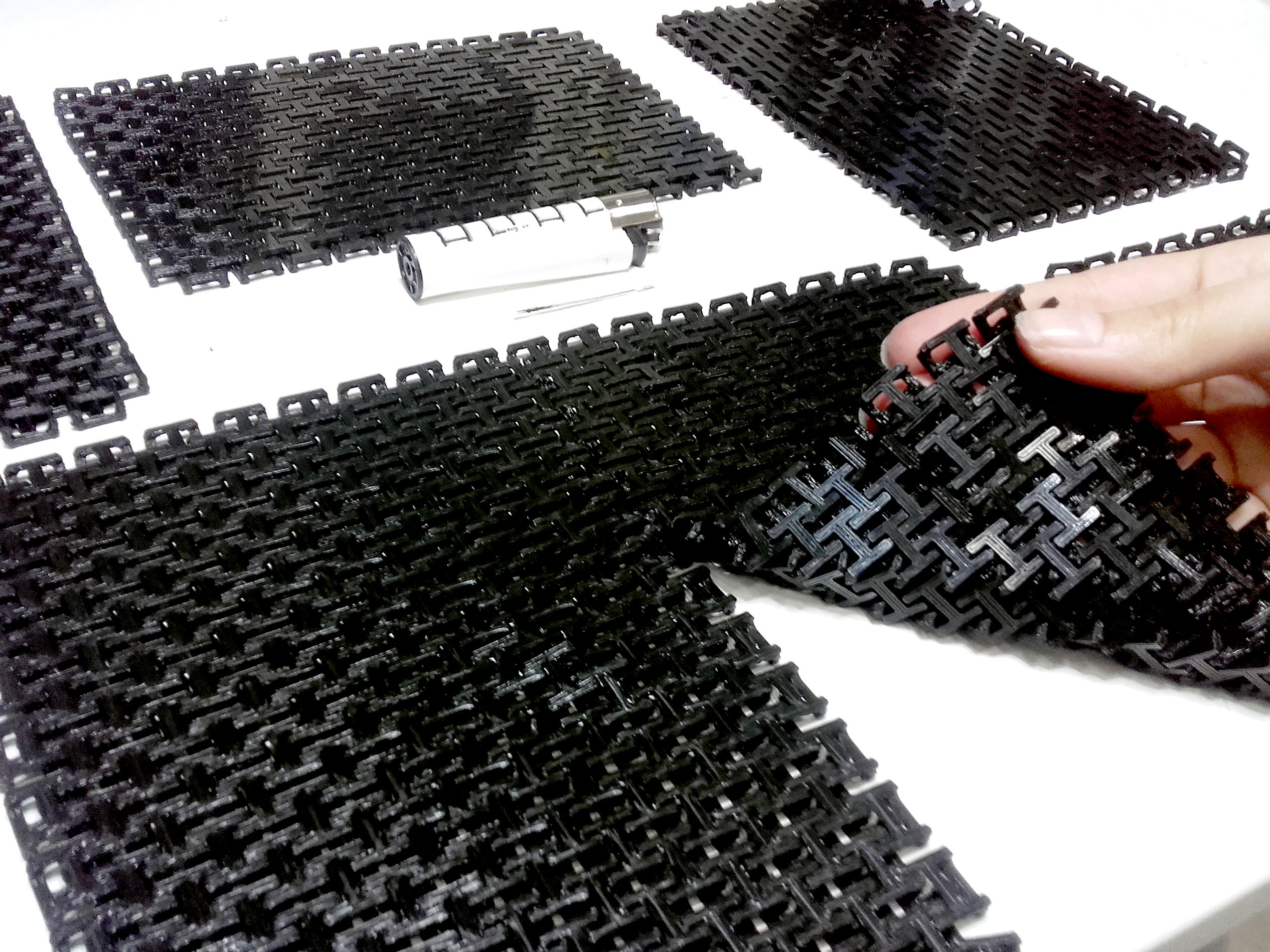

The technique of joining the pieces is actually melting the chain with a hot needle, opening it on one side, add it a new piece and re-closing it with the same PLA filament. It is meticulous but finally there is no other piece added and it’s clean work.

For creating this 3d printed TOP you need to assemble 12 pieces. You have to know that 1 piece take 12 hours to print, so do the math for 12 pieces… 144 hours without counting the assembled part. Today, it still take a lot of time to create a 3d print garment but we can imagine that it’s gonna change fast ! Still the amount of material it uses is only 84grams and it makes a proof of the theory ¨ optimize in the material, take your time to make ¨ , well, in this case, it is ¨take your time to make 3D printer!¨cause you just leave the print overnight.