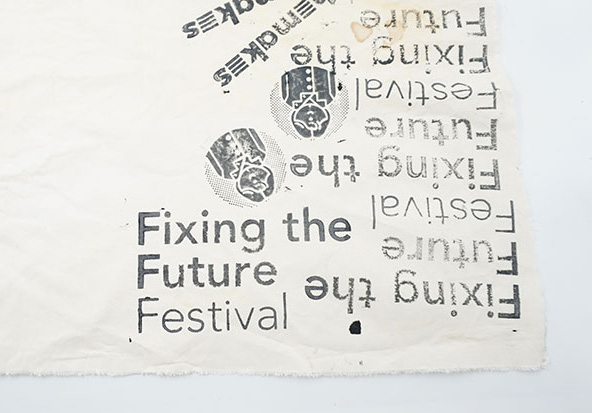

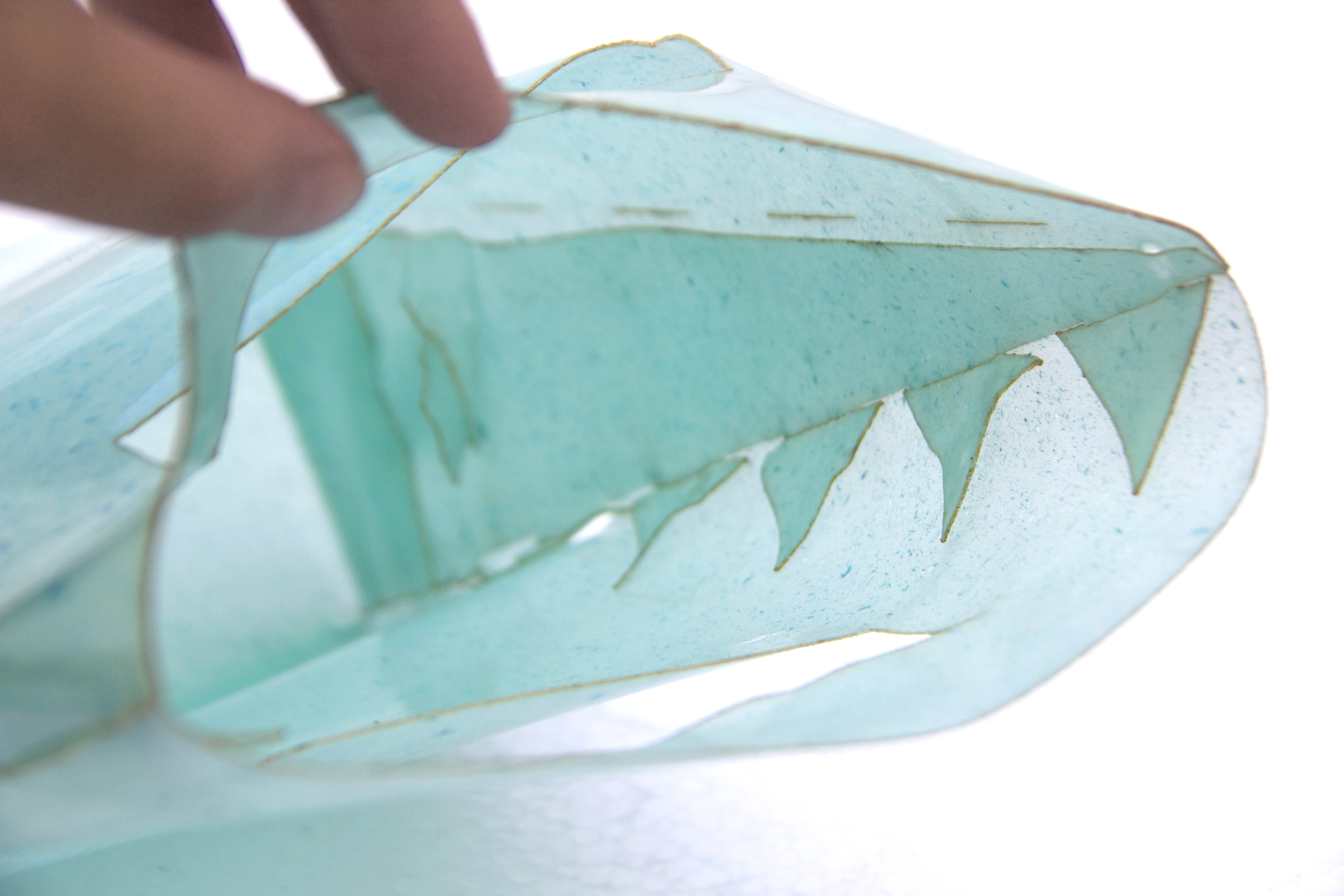

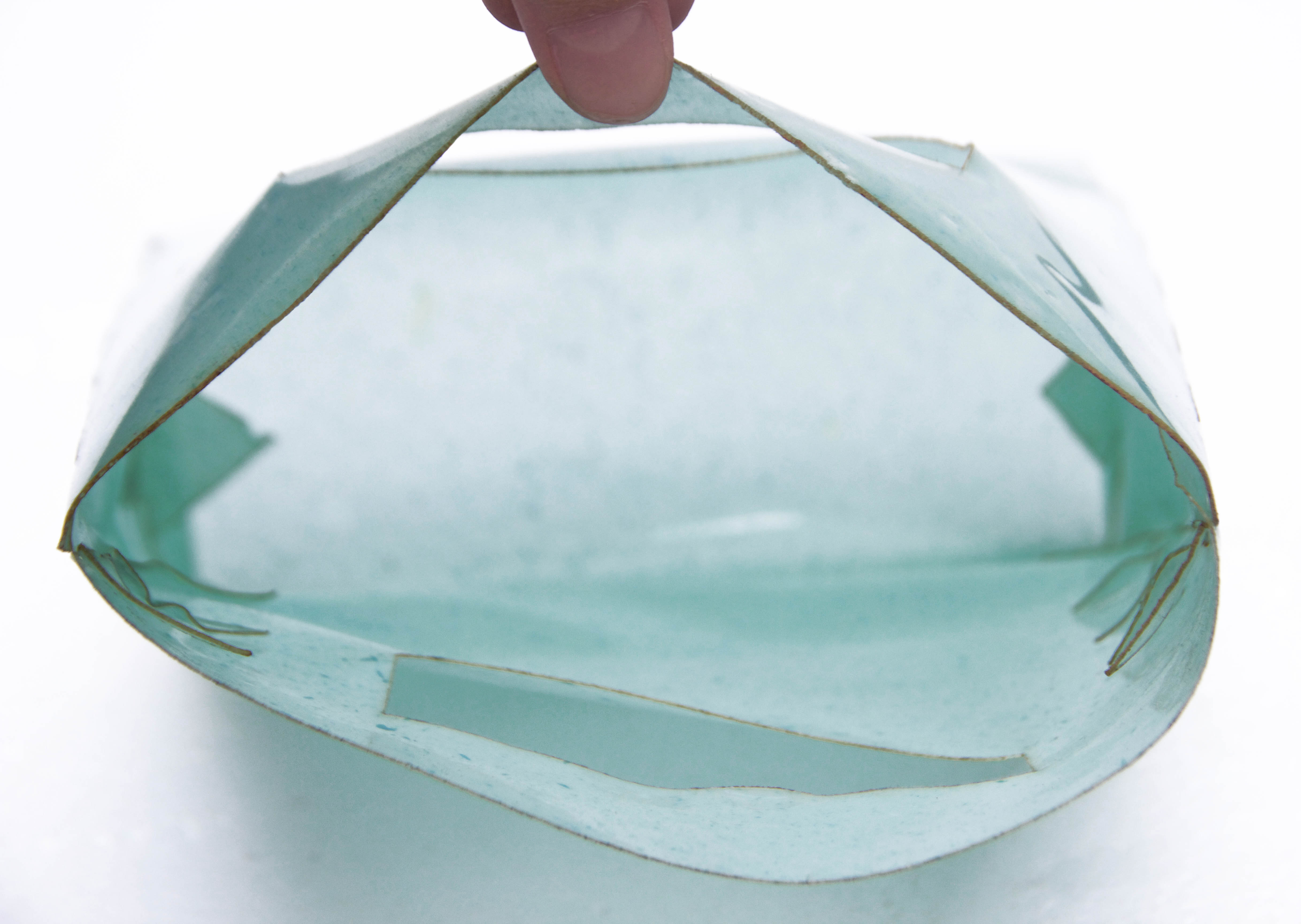

This project is about creating inks and pastes for stamping that can be used as a sustainable alternative for customizing packaging and conference materials such as tote bags, posters, lunch boxes e.t.c. We experimented on the production of black ink from pomegranate peels applied on various surfaces (cotton fabric, paper) with different types of stamps (ewa foam, rubber, wood).

The technique originates from medieval Europe and was also used traditionally for a long time for dyeing oriental carpets. Due to high concentration of tannin in the pomegranate and ease of production, it is currently having a renaissance. It can be used as an ink for silkscreen printing, calligraphy or textile printing.

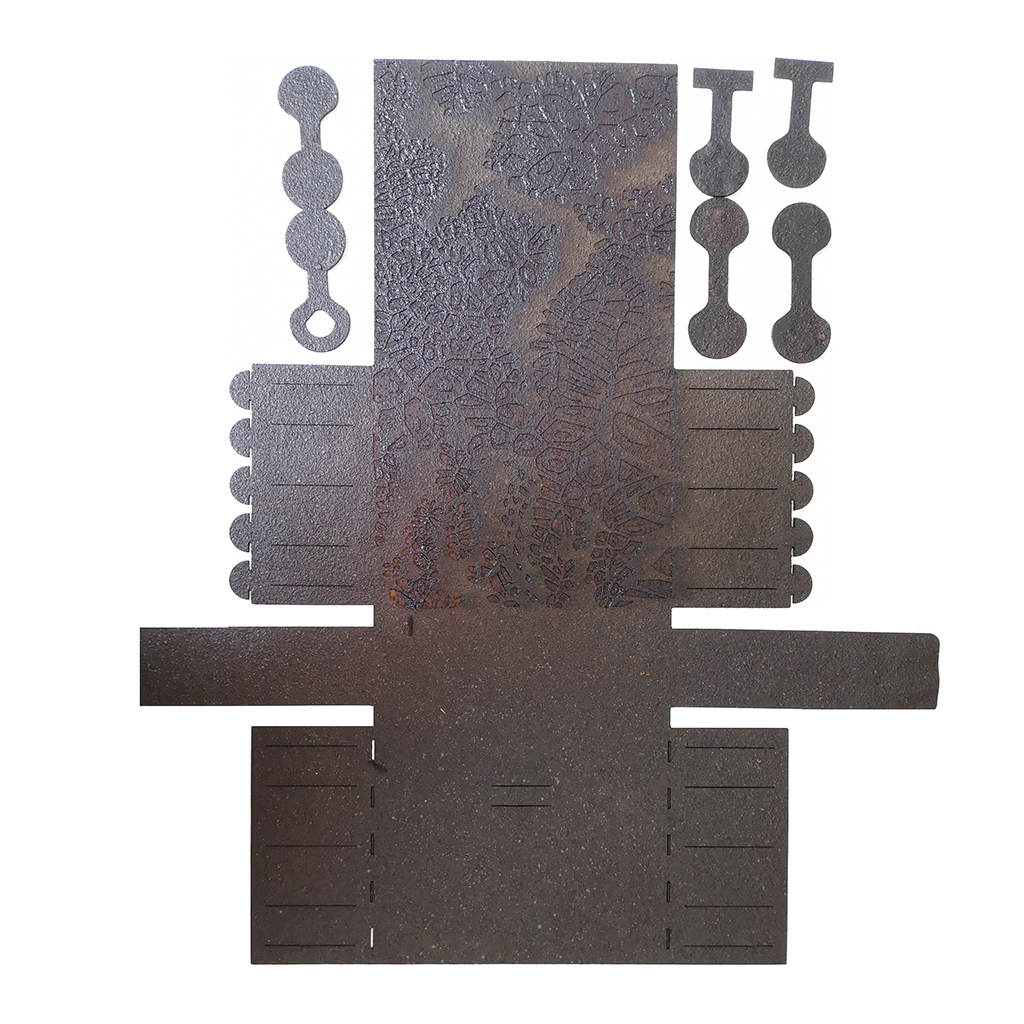

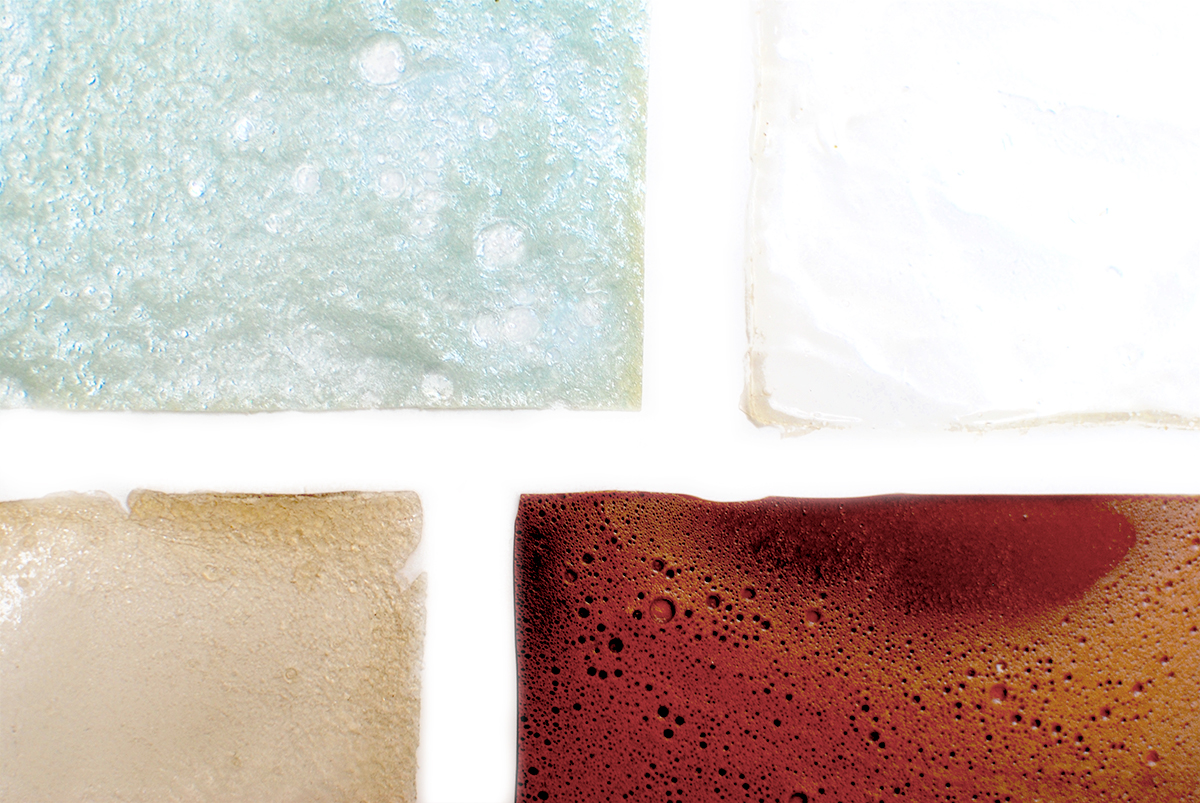

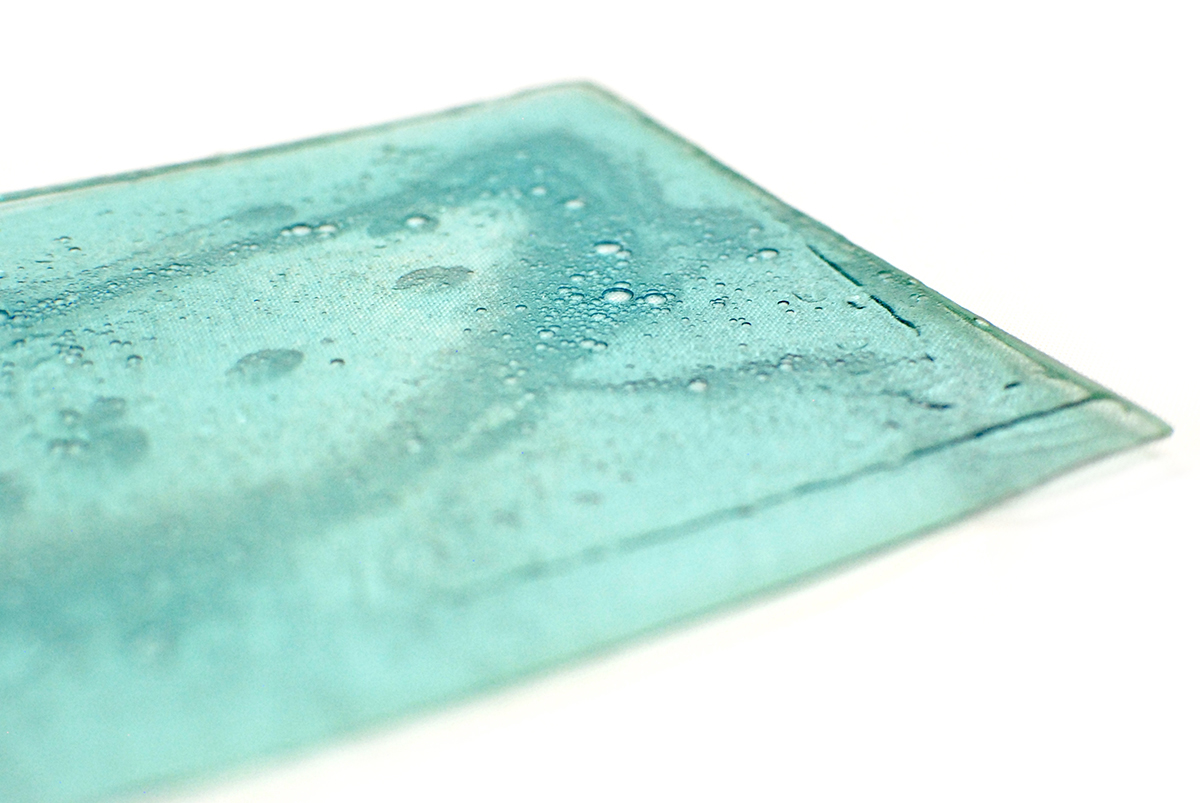

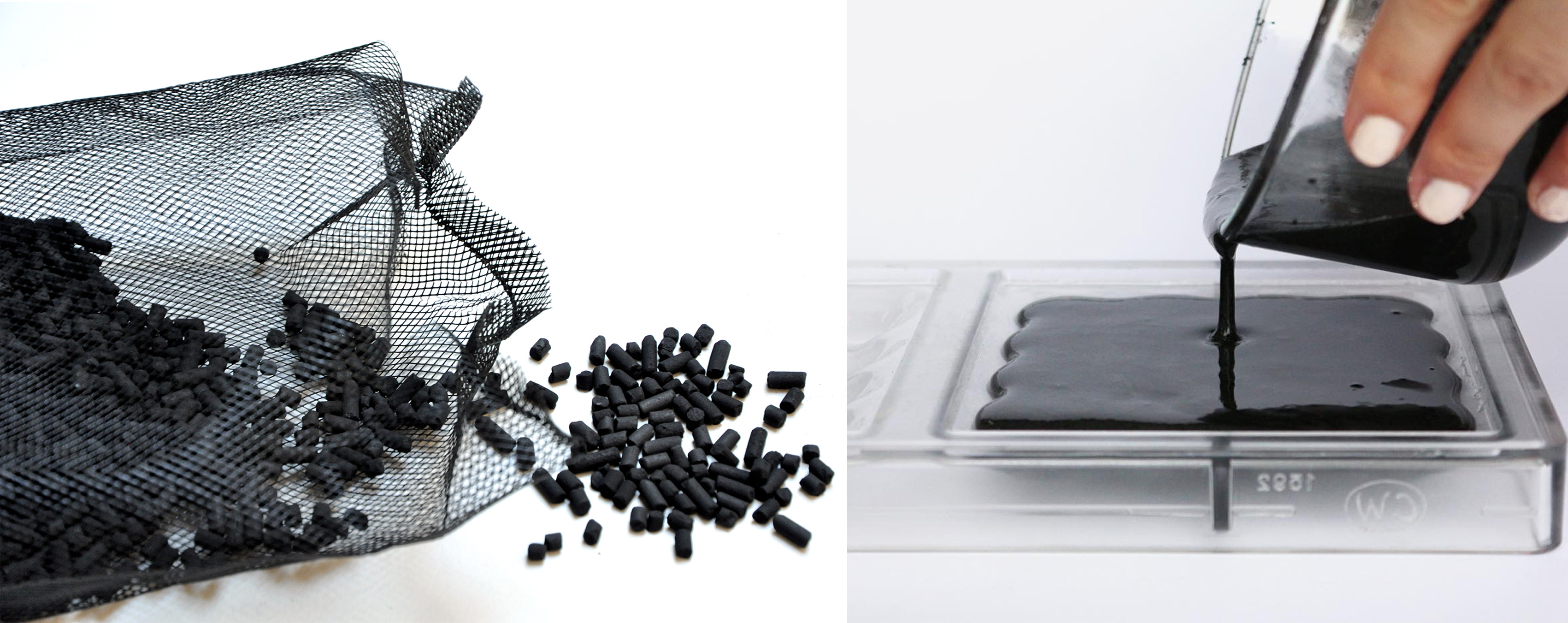

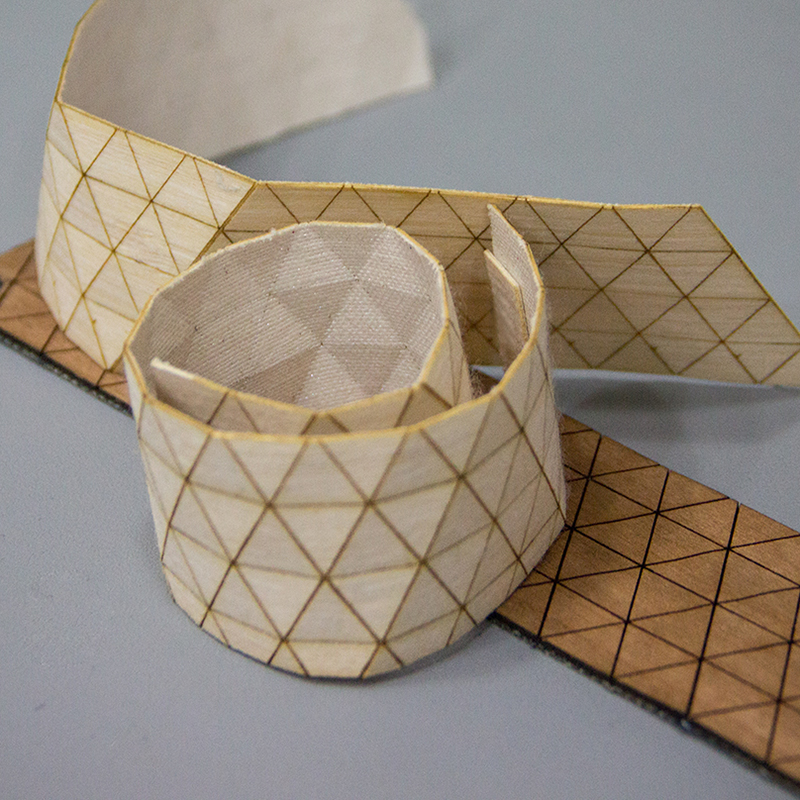

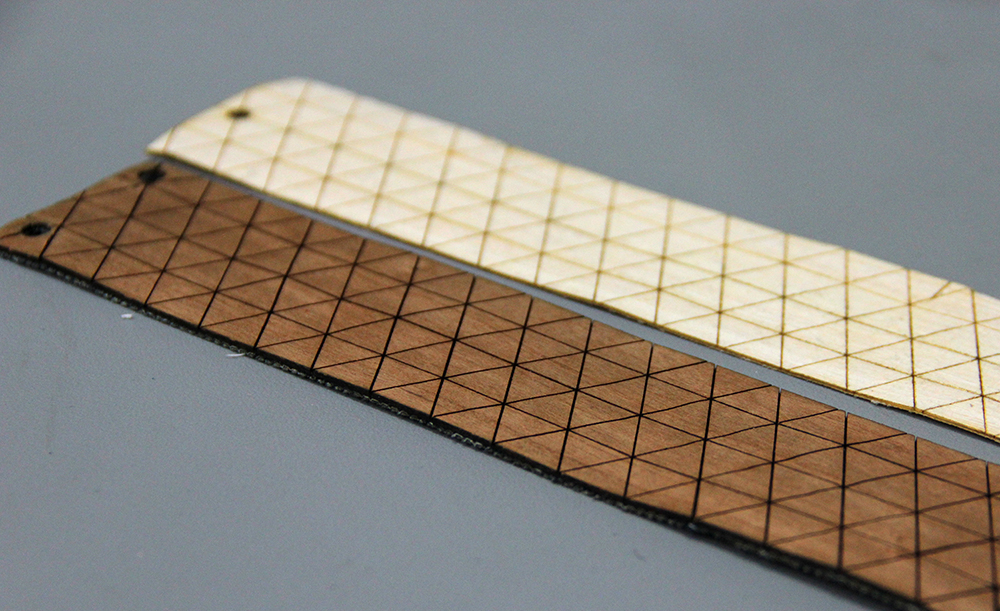

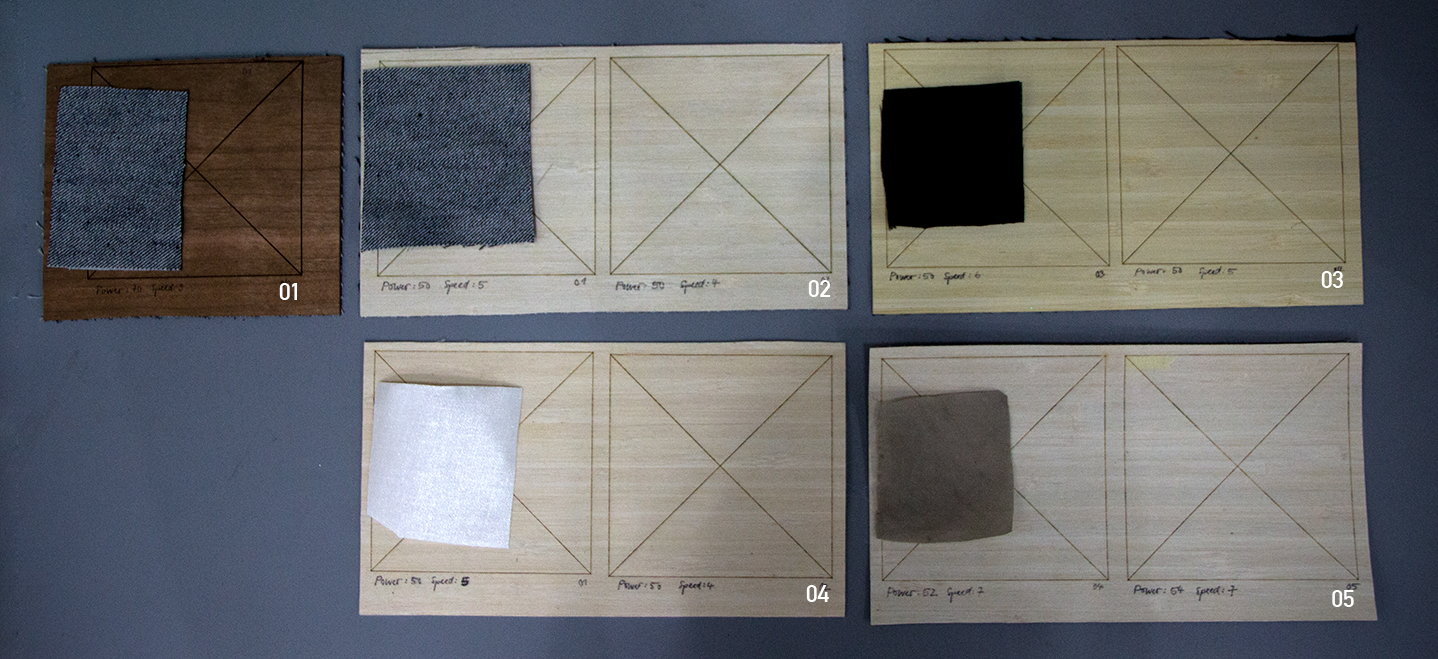

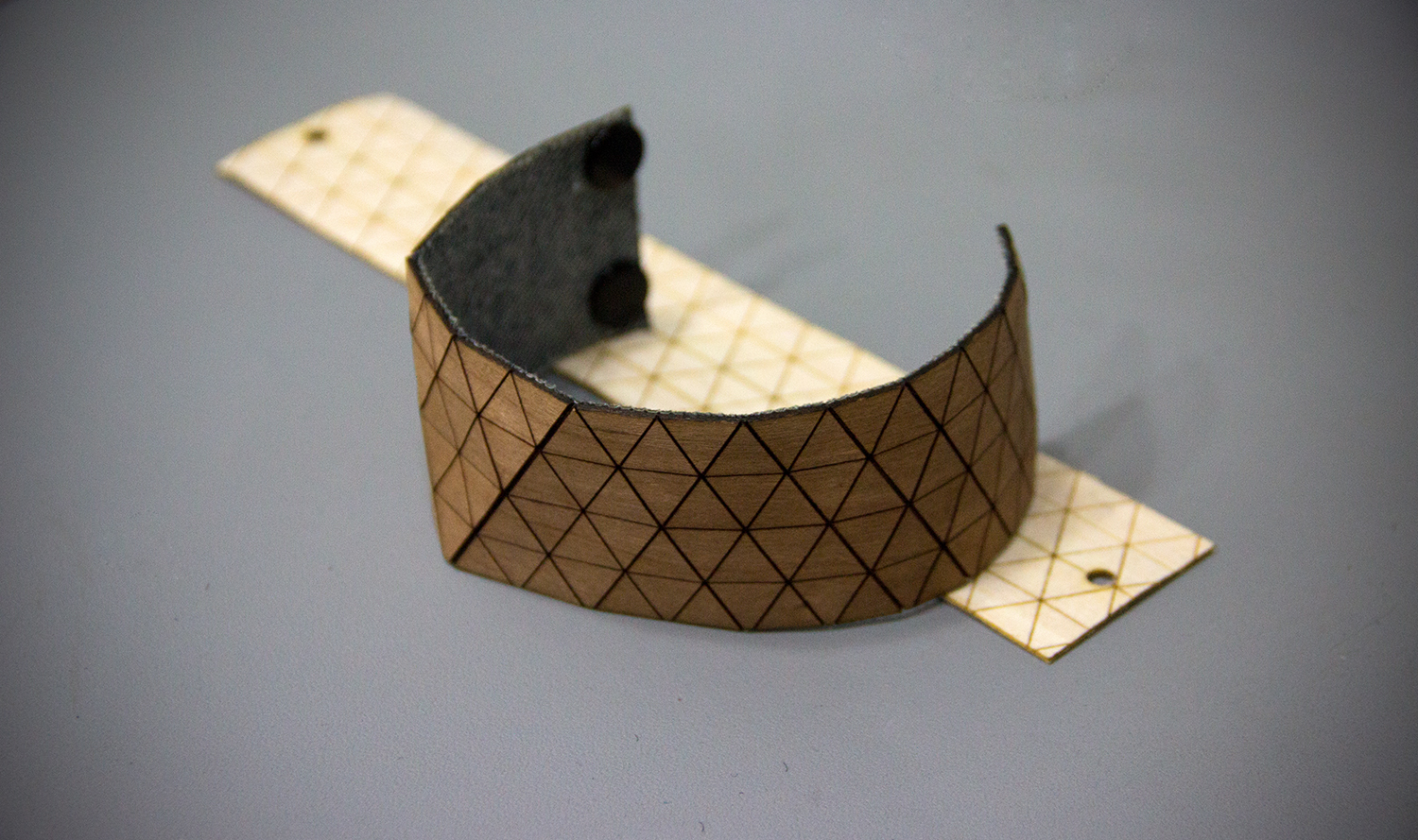

The experiments were carried out with differently proportioned ink-rubber mixtures. Furthermore, we tested the effect of vinegar as an additional base solution for preserving the dye. Basis for our evaluation was the color intensity, the distribution of the ink, the sharpness of contours and the detail of the stamps. The stamps were laser engraved and cut. The files were images in png format or vectors and various tests for adjusting the laser power were conducted. To mix your ink, you can optionally use a magnetic stirrer or mix it by hand with a spoon and heat it to speed up the dissolution of the gum. Do not boil the ink. Adding iron changes the color of the pomegranate liquor to deep black. Vinegar has no effect on the result, but it can still be used as a preservative. Gum arabic and guar gum improve the consistency of the ink (the more viscous the ink, the better the results for stamping on fabric).

1. Recipe – most suitable for rubber and Ewa foam stamps on paper

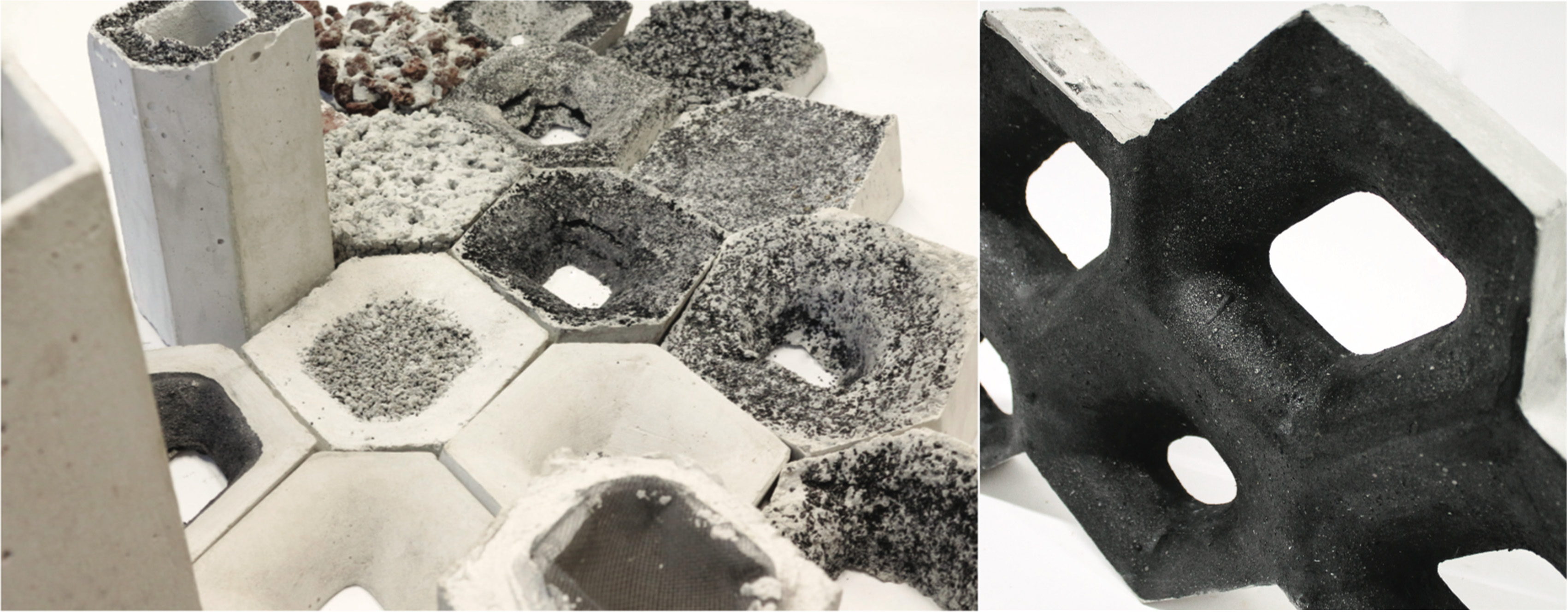

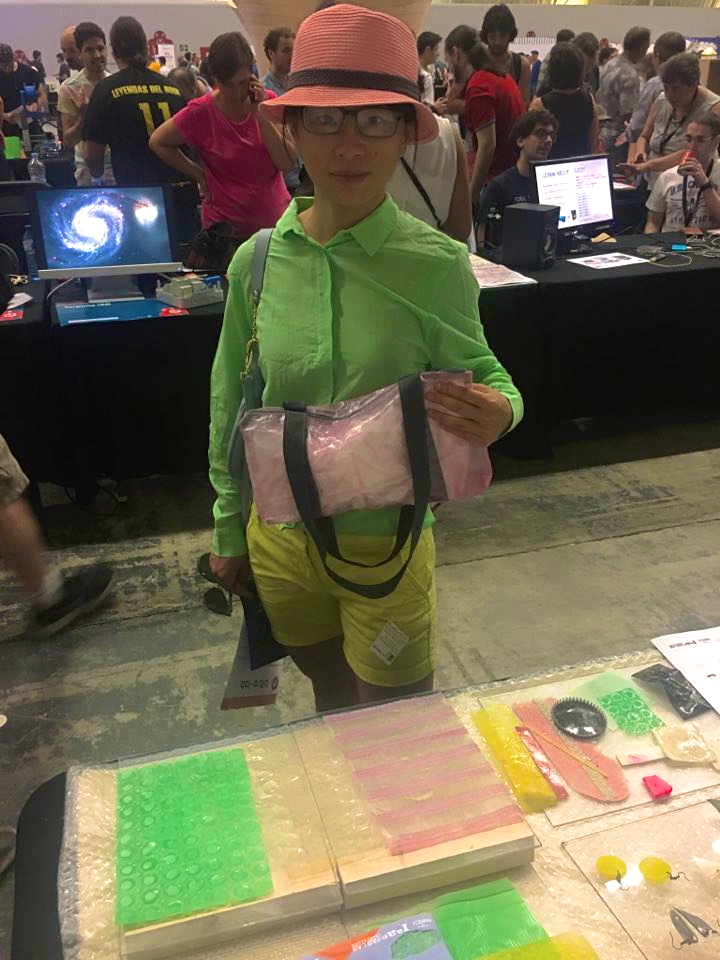

Stamping Remix El Barrio logo for creating a foodwaste biomaterial kit for workshops.

Ingredients: - 25 ml pomegranate dye - 1,5 teaspoons gum arabic - 3 pinches of iron - optional: small amount of vinegar Implementation: - mix the pomegranate dye and the gum arabic until everything dissolved - add the iron and stir the solution - optional: add the vinegar - the ink had to be very viscous, almost like syrup - cast half of the mixture onto the ink pad - spread the ink using the roller - the stamp has to be pushed onto the ink pad so that the letters are fully covered with ink - apply the stamp onto the ground material, putting slowly the stamp on and press down evenly with a lot of force

2. Recipe – most suitable for ewa foam and wooden stamps on fabric

Ingredients: - 50 ml pomegranate dye - a pinch guar gum - 4 pinches of iron Implementation: - mix the pomegranate dye and the guar gum until everything dissolved - add the iron and stir the solution - the ink had to be very viscous, almost like syrup - cast the mixture onto the ink pad - spread the ink using the roller - the stamp has to be pushed onto the ink pad so that the letters are fully covered with ink - apply the stamp onto the ground material, putting the stamp slowly on and pressing down evenly. You can optionally scour the fabrics beforehand.

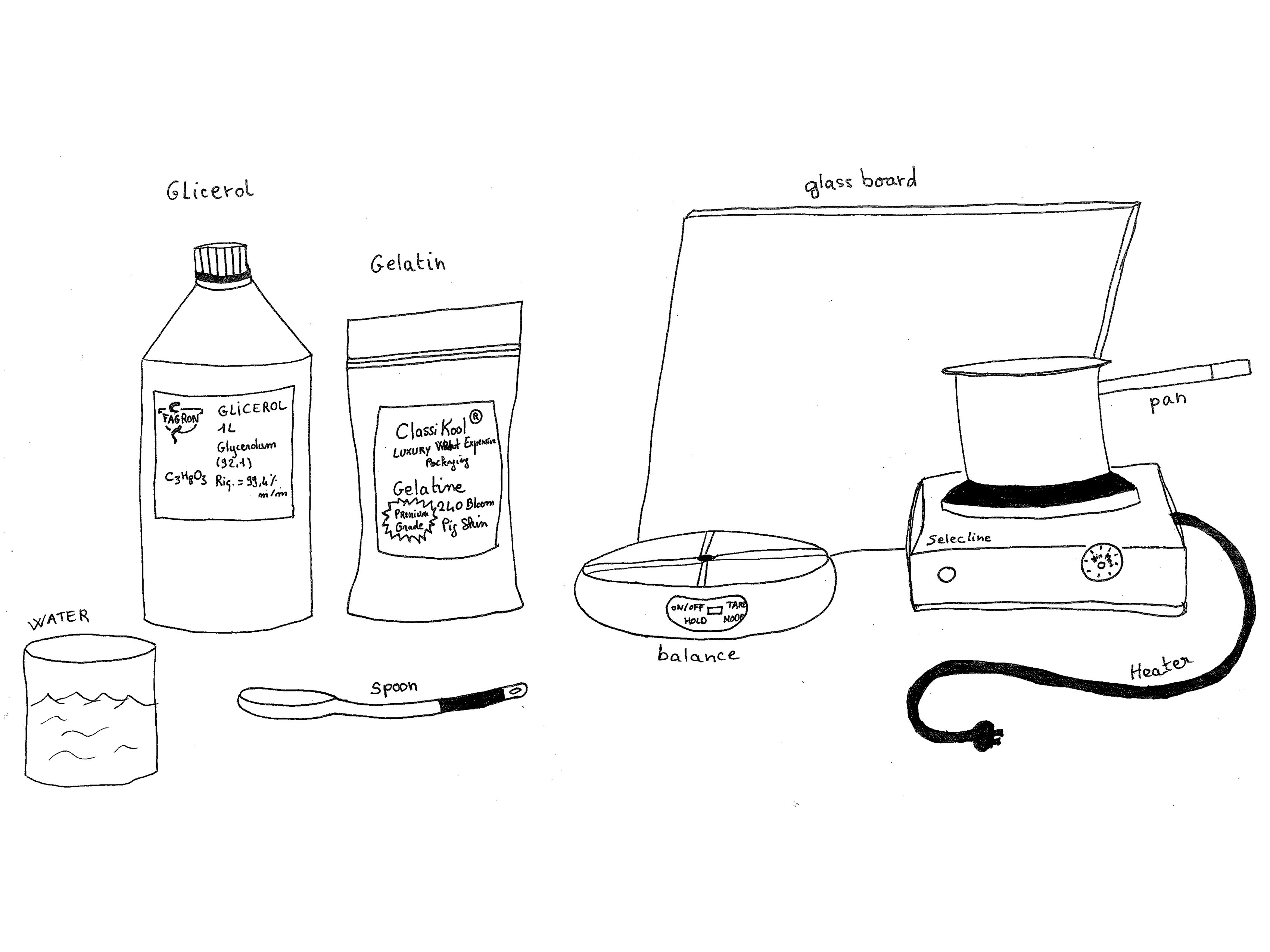

LIST OF MATERIALS Ingredients: - pomegranate ink (water based) - gums (gum arabic, guar gum) - iron - water - optional: vinegar Tools: - ink pad (flat tray with specific material to hold the ink) - roller for applying and spreading the ink in the tray - teaspoon - glass wares (200 ml) - magnetic stirrer (optional) Materials: - paper - cotton fabric - for the stamps: rubber for laser engraving, wood, ewa foam

This research was developed by Anastasia Pistofidou and Pauline Stockmann during her internship at FabTextiles in December 2021.

Many thanks to all the valuable online references:

- https://www.marthastewart.com/1516423/natural-ink-colors

- www.wildcolours.co.uk/html/pomegranate.html

- http://theaxbridgemuseumartistsblog.weebly.com/pomegranate-ink.html

- https://www.suzannedekel.com/post/how-to-make-ink

- https://juliabausenhardt.com/how-to-make-pomegranate-ink-self-made-iron-gall-ink/

- https://www.marthastewart.com/1516423/natural-ink-colors

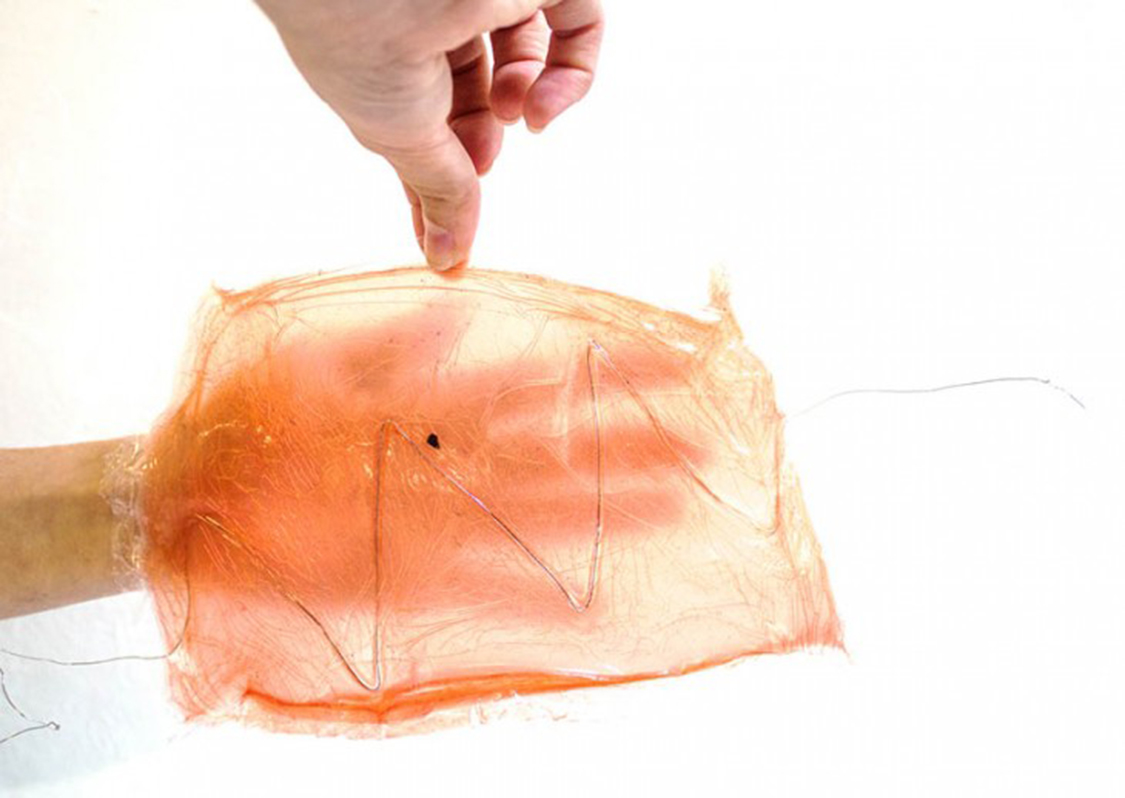

![5_BIO[lum]SKIN](http://fabtextiles.org/wp-content/uploads/2016/05/5_BIOlumSKIN.jpg)