Your waste is my treasure!

Working with organic waste can bring circular solutions for the implementation of closed loops of organic feedstocks. At Fab Textiles we have been working with food waste since October 2018 and many researchers through their internship developed and evolved recipes for making food waste biocomposites. There are already some small companies that produce bioleathers with waste, one of them from Mexico called ECOPLASO that I had the possibility to get to know in one of my conferences at ¨Demand Solutions¨ in Miami 2018.

RECIPE / COFFEE BIOLEATHER 2G sodium alginate 2G dried coffee grains of any organic waste in powder 2G olive oil 5G glycerin 33G water (everything is in grams using a precision scale) MIX for calcification 7G of calcium chloride in 100ml of water

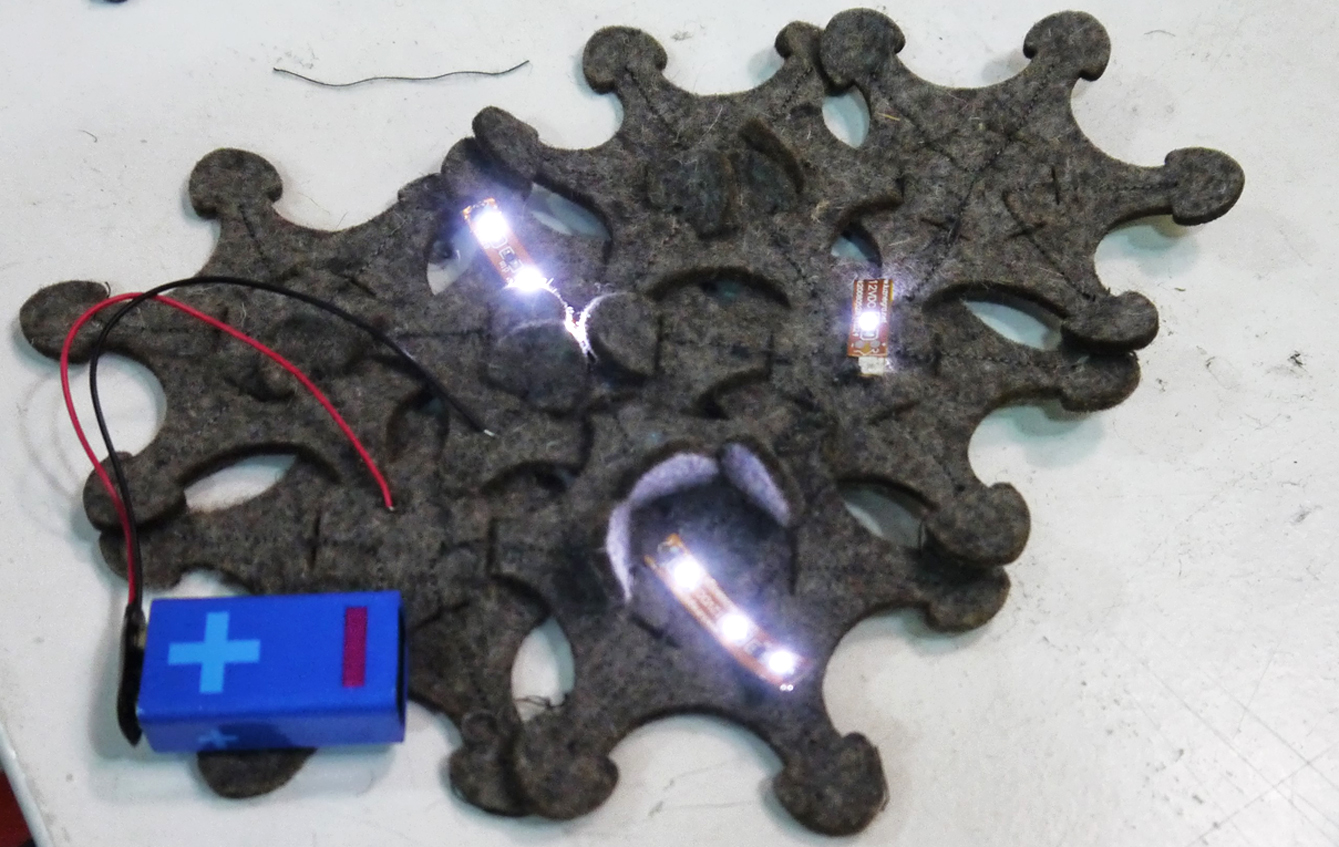

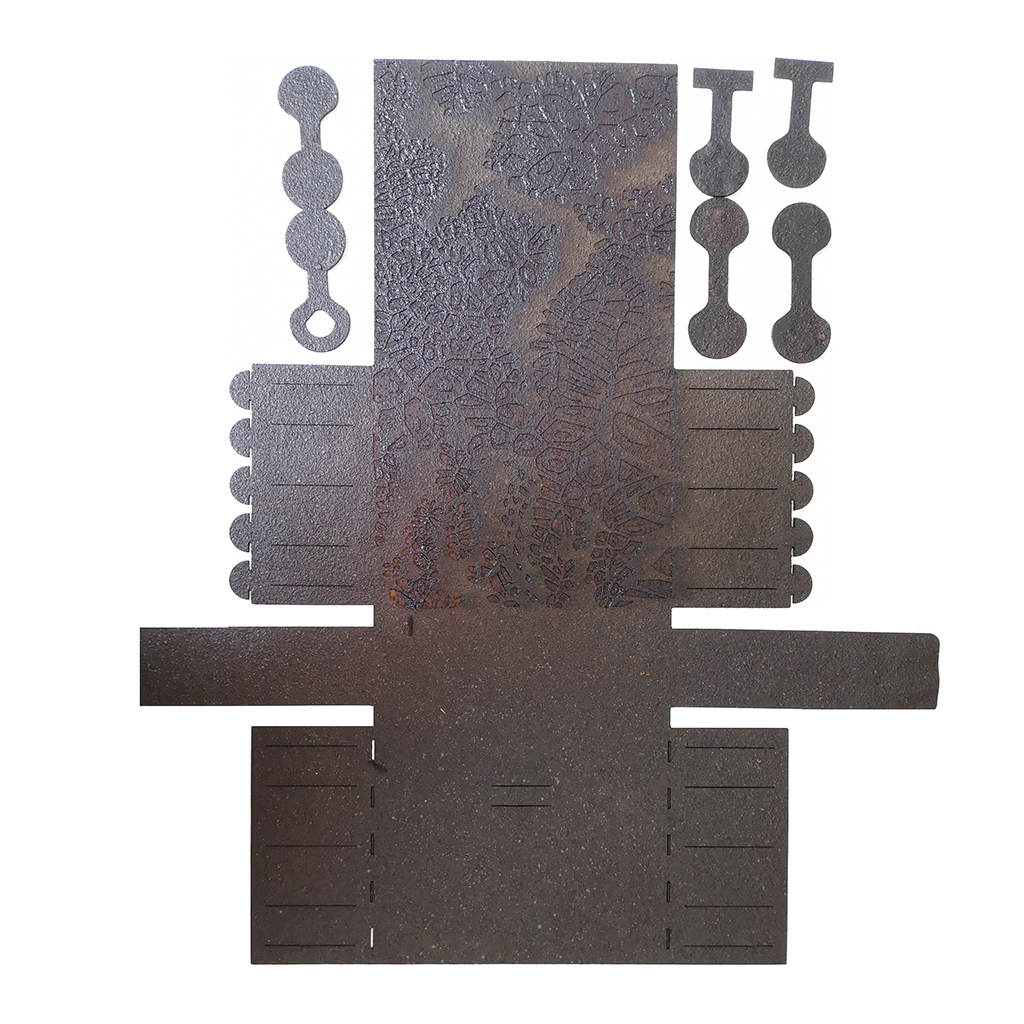

Various organic waste bio-leather samples

STEP BY STEP INSTRUCTIONS: 1- Weight all the ingredients with a precision scale. 2- Mix the powder together with the glycerin and the olive oil. 3- Add the water and use a mechanical blender to obtain an homogeneous solution. 4- Cast in a silk screen print frame ( you can create your own using any textile and wood) 5- Mix the Calcium chloride with water in a sprayer bottle. 6- Spray the biomaterial on top and bottom with the calcium chloride solution. 7- Let the calcium chloride act for 5´ and rinse with clean water. 8- Let the composite sample dry in a dry and warm place for one week. Depending on the thickness and the size of the sample it may take longer. It will also vary due to the local temperature and humidity. 9- When the product is dry you can separate it from the frame. Note: As the sample dries, it can become curved, so place it between two level surfaces and some weight on top so at the end we can obtain a really flat sheet

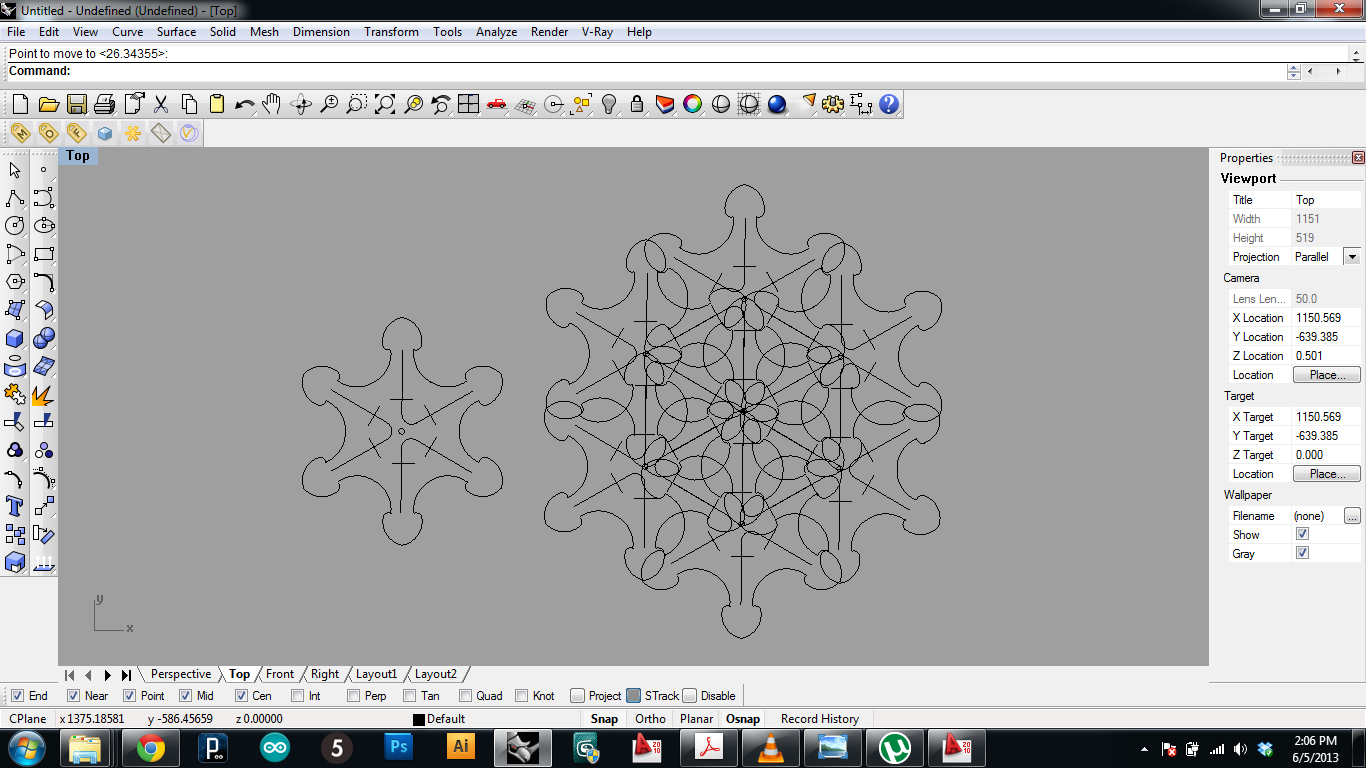

The laser cut pattern can be found and downloaded HERE