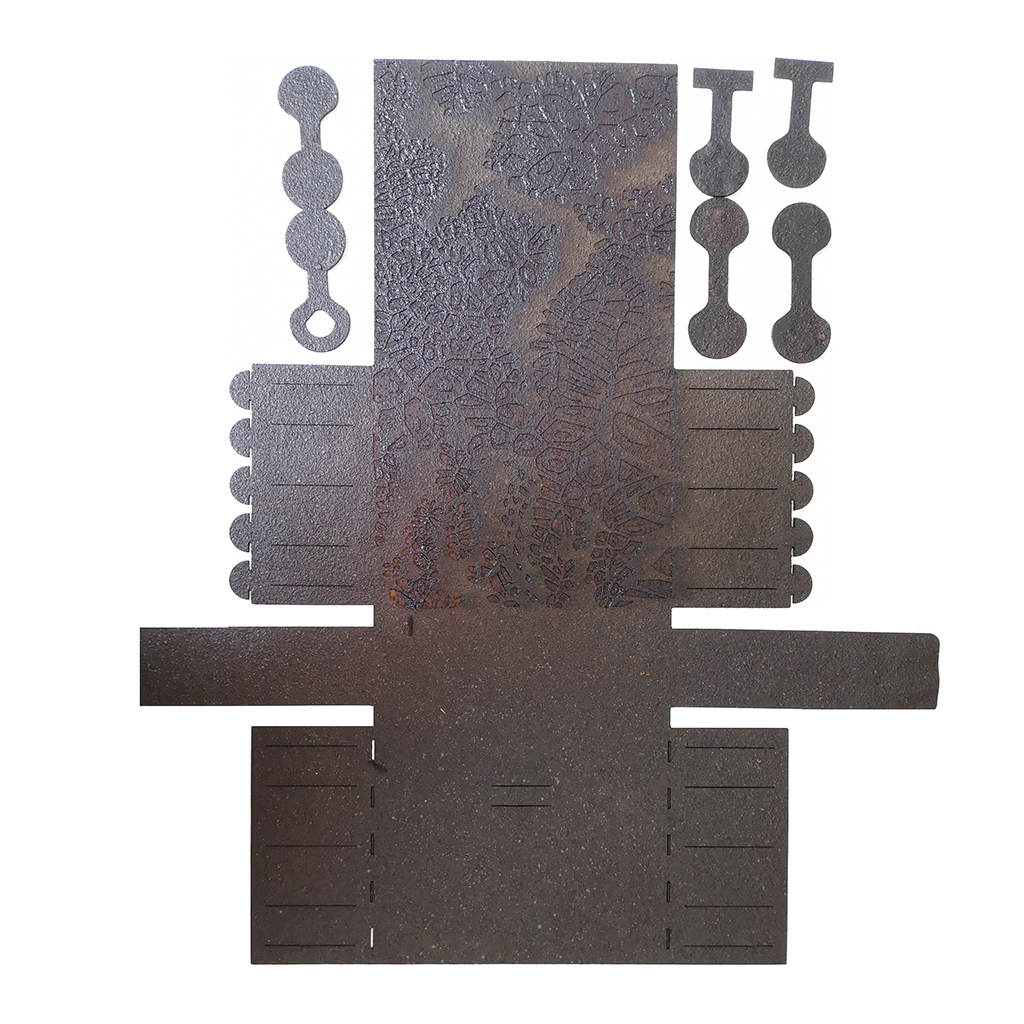

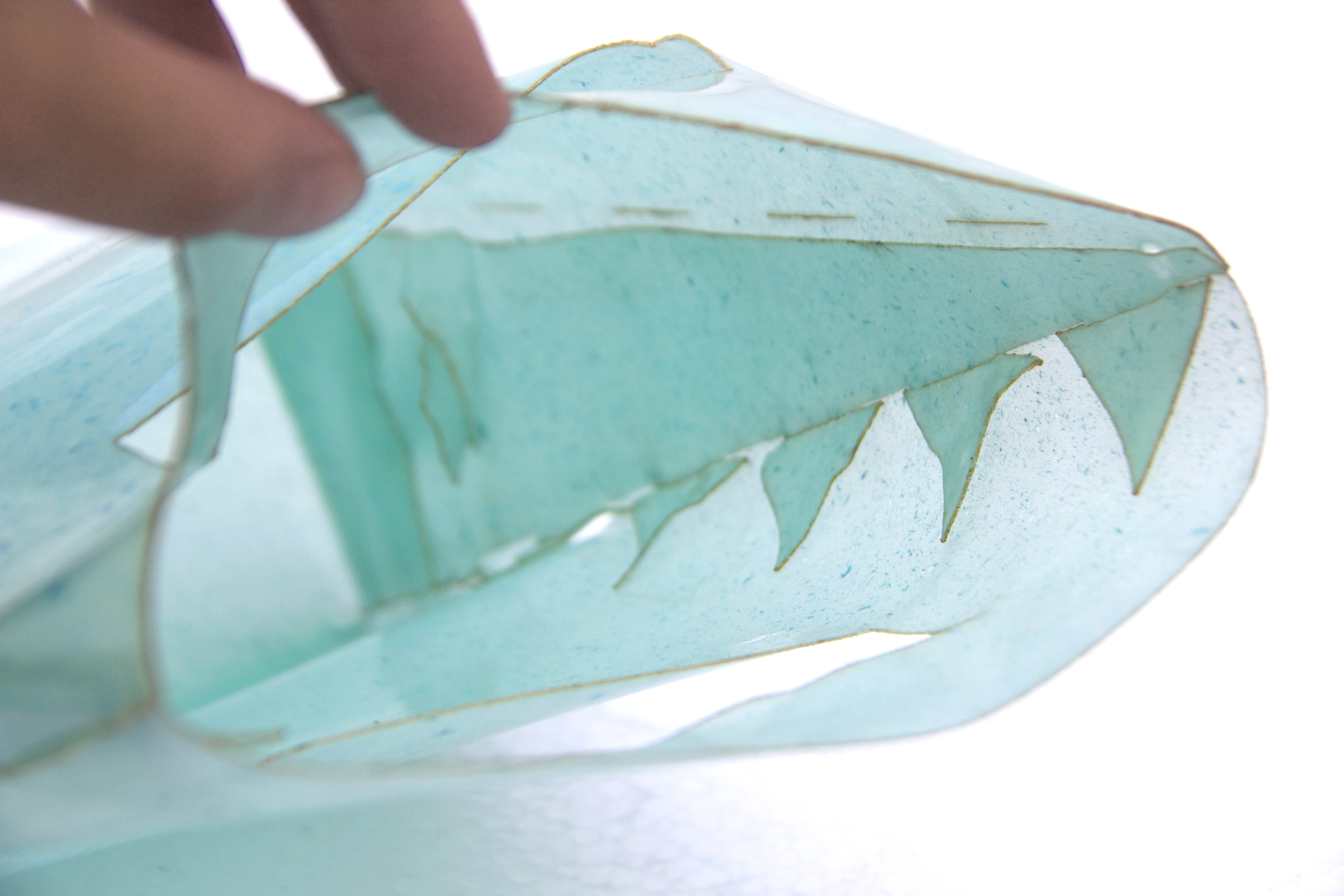

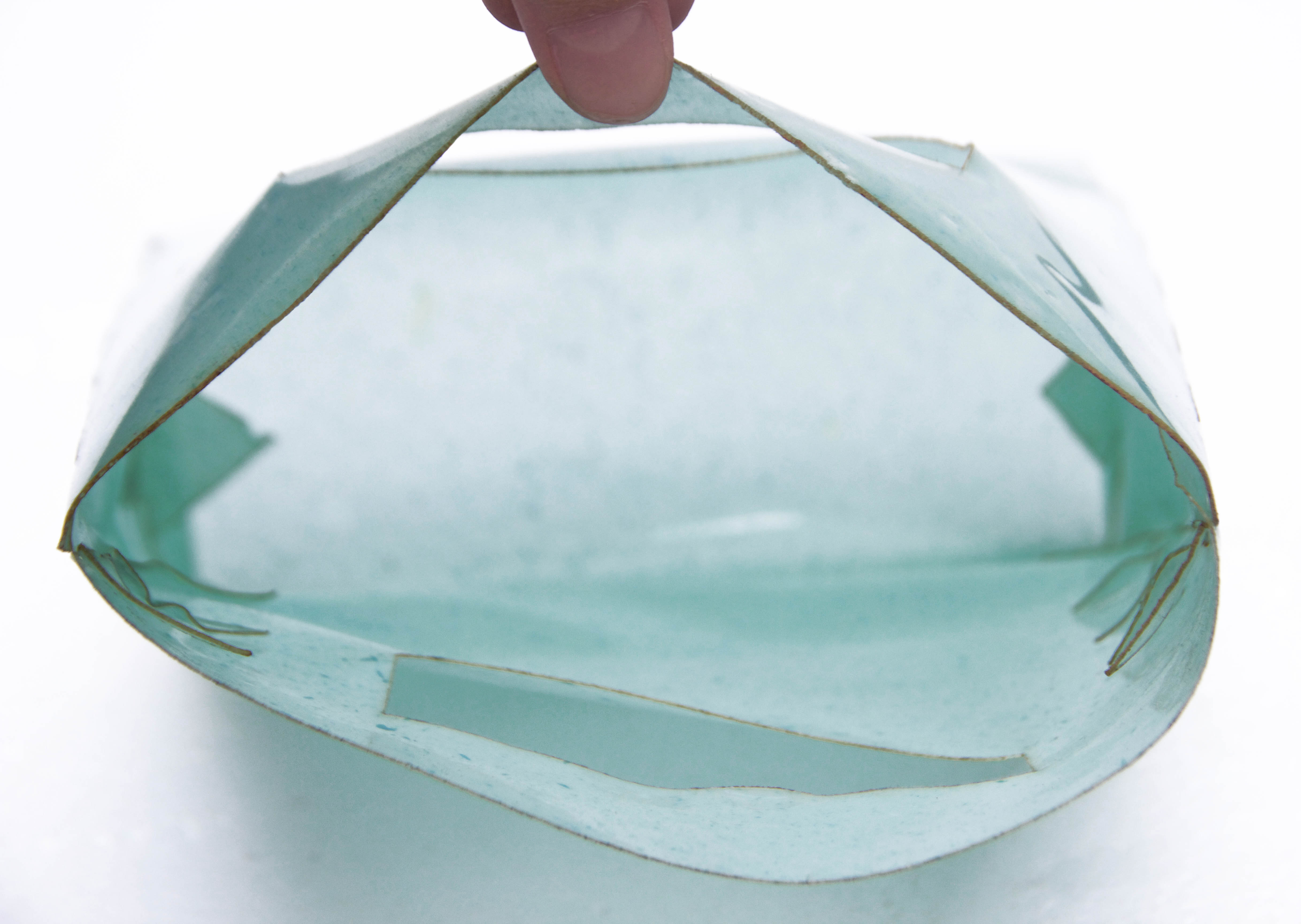

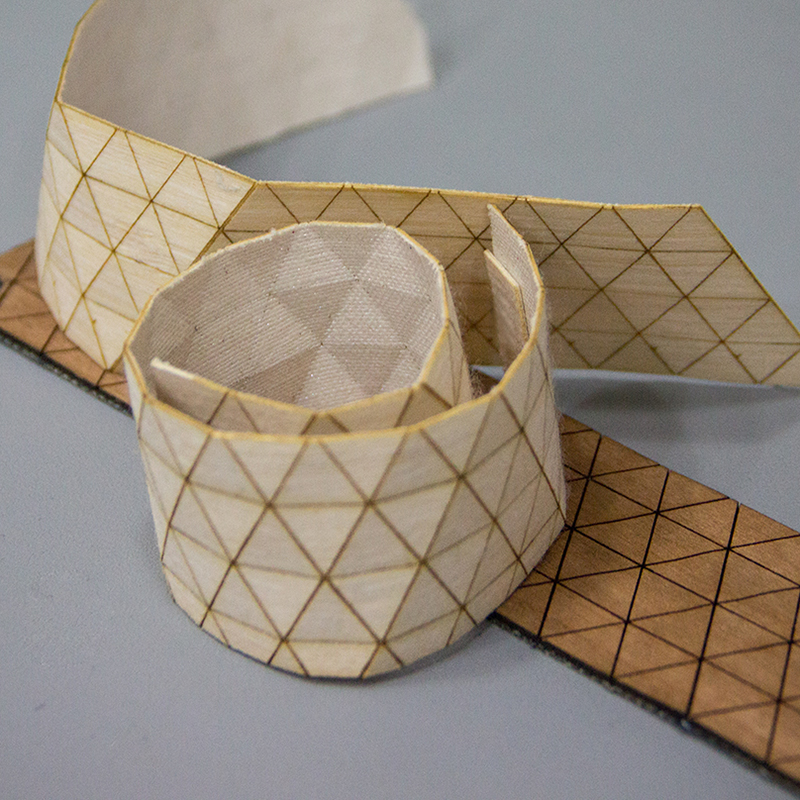

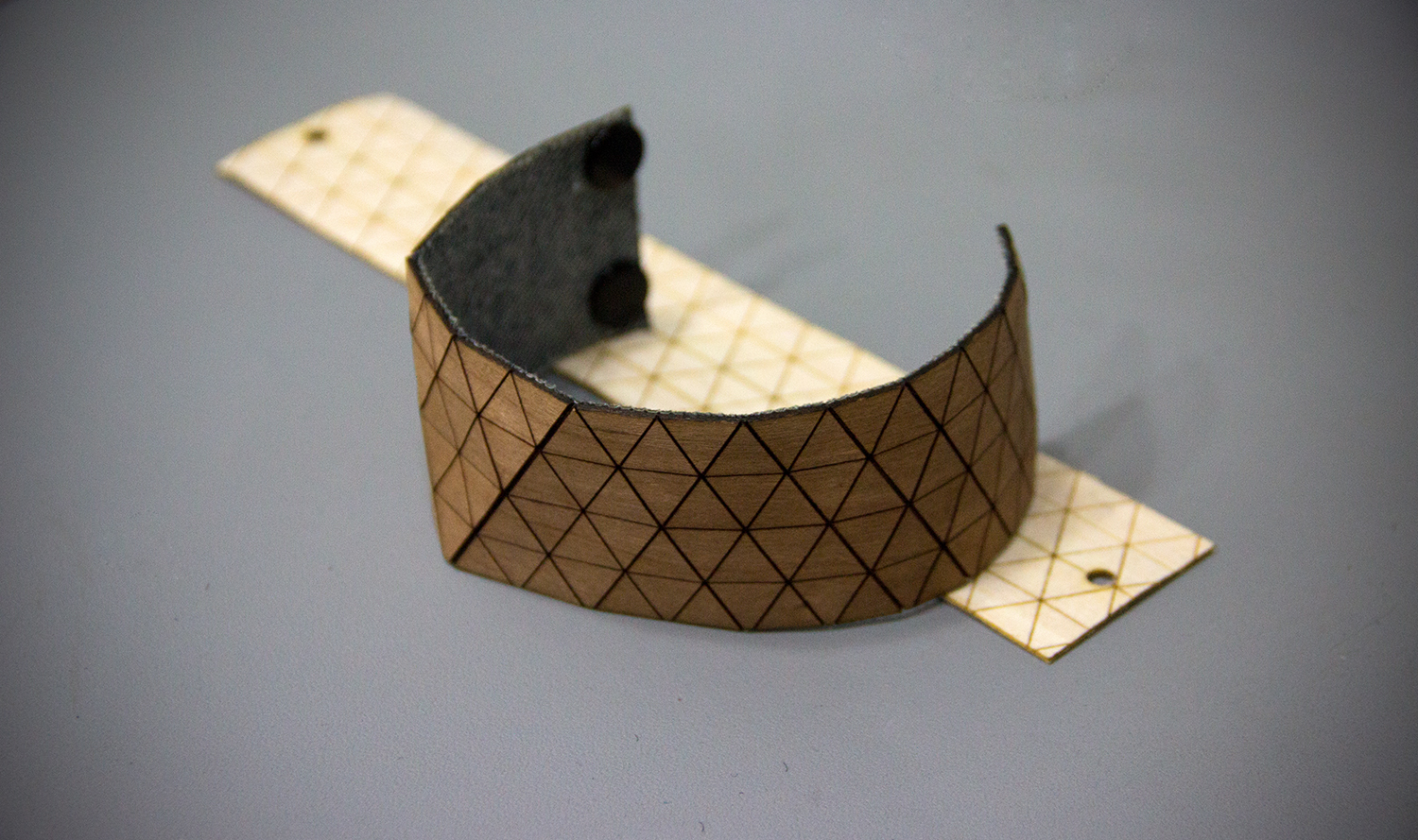

Taska is the Icelandic word for a backpack and also a multifunctional bag made to carry everything from a laptop to all your camping gear. The design of the pattern is simple and the bag can be made from one single piece of almost any textile, which makes it easy to assemble. Eliminating weight-carrying seams gives it more durability and longer life expectancy. With any wood and textile Taska can be easily made in a local fabrication laboratory within the global network of FabLabs.

For us the beauty of this project is not only the backpack itself but the ability of distributed manufacturing. In that way it is possible to eliminate long distance shipping, to use locally sourced materials anywhere and gives the customer a change for easy customization. A product that changes according to culture. Textiles and wood from all over the world take the form of Taska, embracing culture and local production

Taska can be fabricated with the following ways

1) Download the open source creative commons license design that comes with an instruction kit. With the materials of your selection, produce it at the local lab with the compromise of sending a short video of 1 minute of the making of and a picture of your version

2) Let the local fab lab to produce it for you with materials of your choice and pick it up.

3) Place an order from the designer.

Contribute to the growing network of Taska and make your version to reveal the multicultural world we live in. Let’s make distributed manufacturing true.

Contact us to get or make your TASKA!

Designer: Ingi Freyr Gudjónsson

Concept and mentorship : Anastasia Pistofidou