Materia Bruta is a Limited collection of garments from new and old biomaterials

Bacterial-dyed buryat modernised dress

Presenting a year-long collaboration with Surzana Radnaeva from Traditional Futures that was supported by Worth Partnership project. This garment was made from Bacterial-dyed linen using Shibori tie-dye technique. The design is inspired by Surzhana’s Buryat traditional costume «Degel». It directly relates to and nourishes her explorations within the Traditional Futures brand. This brand is about modernization of traditional costumes, and making them continue living, being worn and not end up behind the glass in museums. It is exciting to see how old things meet new things in harmony, I think its a right way to live.

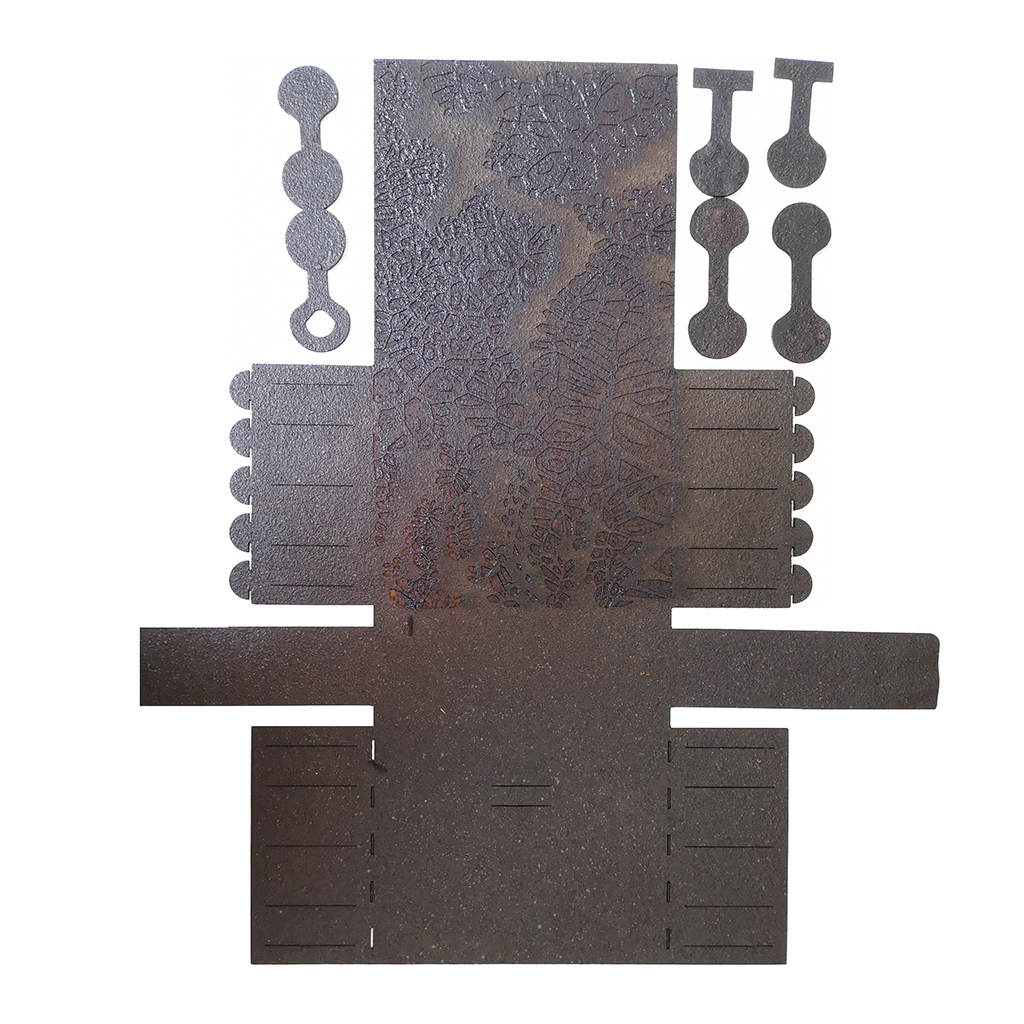

Algae-based vest Charcoal-dyed and reinforced with wool fibers.

Surzhana loved the alien look of this material that she asked for this specific design the moment she touched it. I helped her get inspiration from the material, through the way it feels- and imagine the ready garment.

.

Another piece that was produced during this project is Amadou fungi hat made by one of the last artisans in Transylvania. The design of this hat is inspired by Buryat traditional hat, after having consulted Surzhana about fungi biomaterial producers. She combined the fungus material and the traditional hat design will the intention to prolong life of both disappearing traditions.

It was a great year of work to develop together with Jessica Dias from @formalisedcuriosities in the lab of @fablabbcn the materials for Surzhana Radnaeva from @traditionalfutures.