We are thrilled to announce the Textile Academy 2024 Bootcamp in Armenia!

This May, join us for an intensive week of hands-on workshops with international experts and locals, cultural visits and social events, distributed across the country, among the cities of Yerevan, Dilijan and Gyumri.🏞

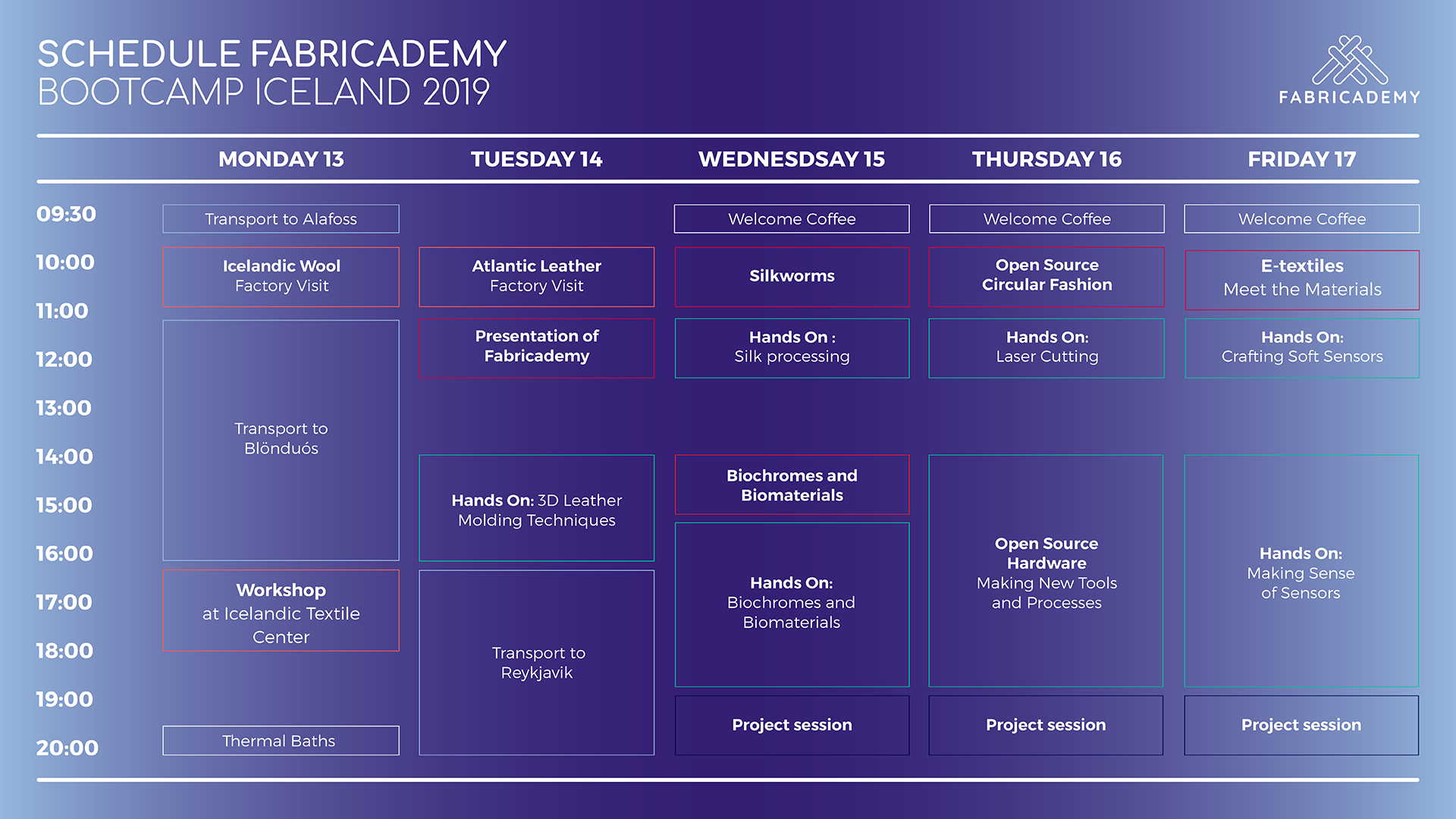

Together with Fabricademy, during the week participants will explore crafts, digital and bio fabrication through a series of activities hosted at Fab Lab Armenia and in specific locations.

Participants will engage in various traditional practices, such as weaving kilim and rugs, felting, and dyeing wool using locally sourced ingredients. They will also delve into ancient techniques like batik, cyanotype, and linotype, merging craftsmanship with digital fabrication technology and DIY machines.

Moreover, they will learn how to biofabricate biomaterials as sustainable alternatives to the current ones. They will apply principles of digital and computational design for 3D printing on textiles and develop 3D models for leather molding.

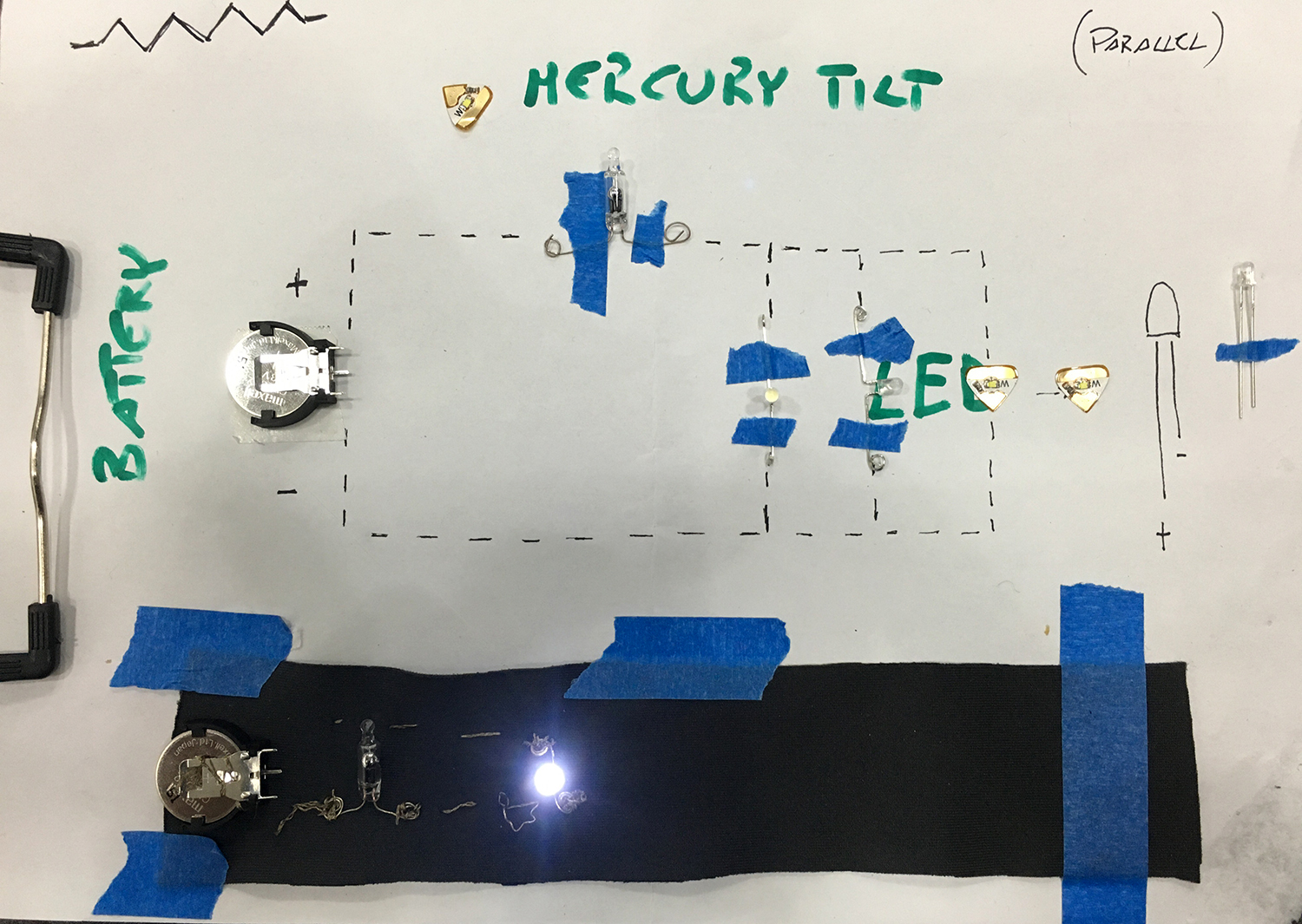

In addition, participants will explore the world of soft robotics and wearable technology. The focus will be on creating inflatable designs and soft robots, while also learning about conductive materials and crafting soft sensors and circuits for wearable applications.

Limited seats available.

🔗 Check the Schedule and Book your spot today at bootcamp.textile-academy.org

📔 Plan your travel ahead! Learn everything you need to know about Armenia and Fabricademy Bootcamp 2024.