In 1831, Mr. Touery, a professor at the French Academy of Medicine, drank strychnine, a deadly poison, in front of all his colleagues. He survived. How ? He had combined the lethal dose with activated charcoal. “That’s how powerful activated charcoal is as an emergency decontaminant in the gastrointestinal (GI) tract, which includes the stomach and intestines. Activated charcoal is considered to be the most effective single agent available. It is used after a person swallows or absorbs almost any toxic drug or chemical.”*

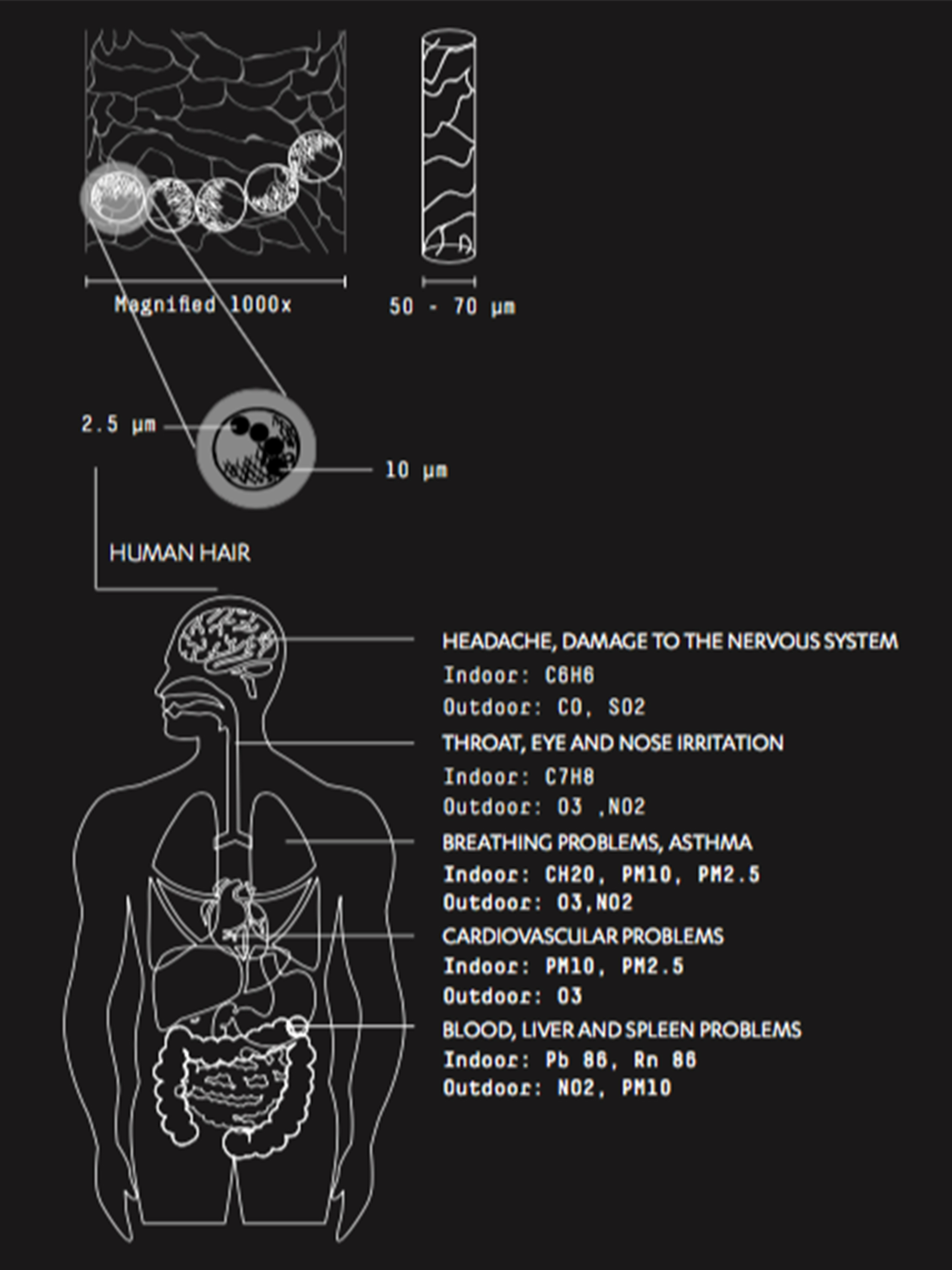

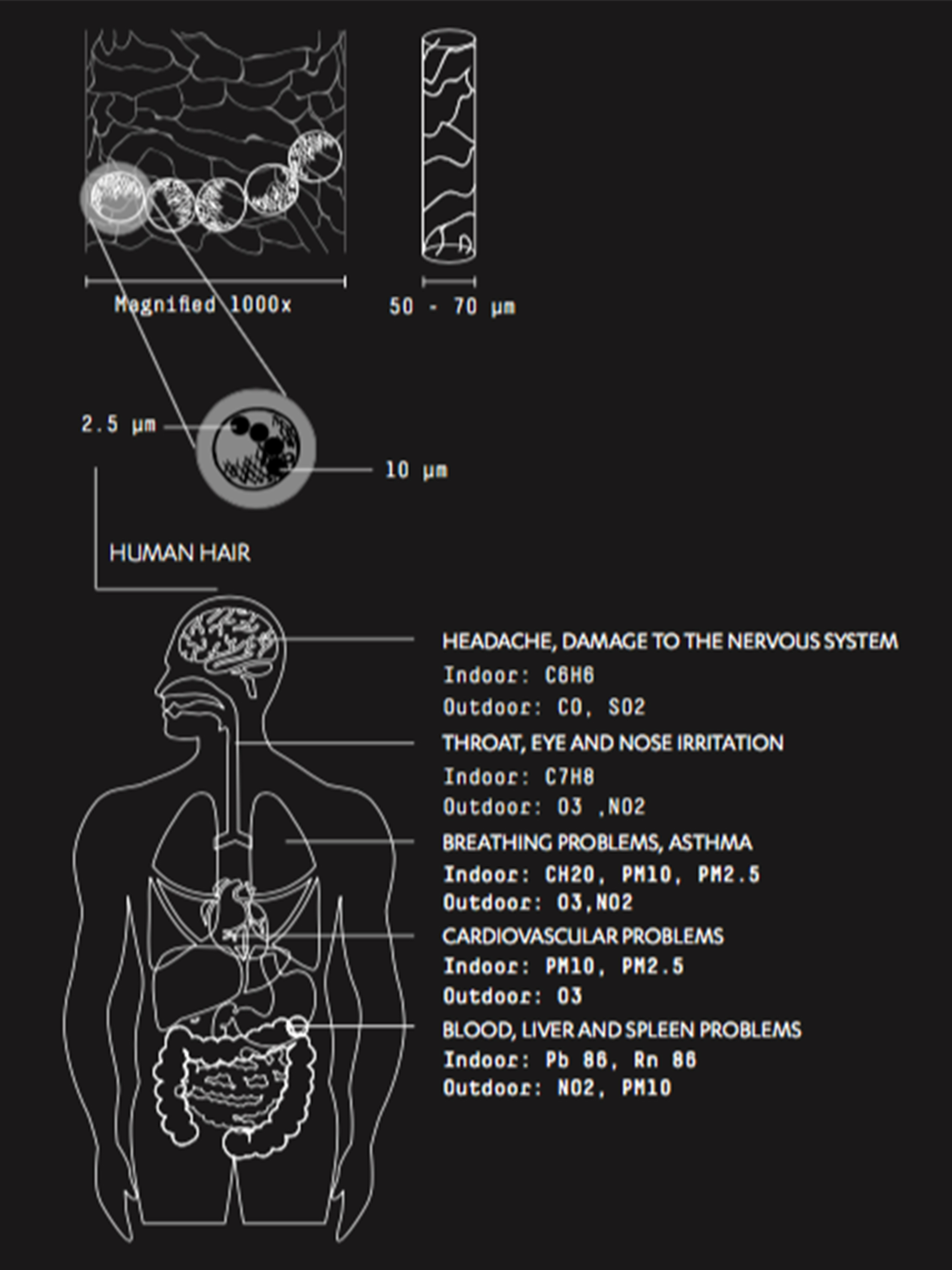

Diagram displaying the major health effects of air pollution, CEDIM Lab by Restology project, 2017

.

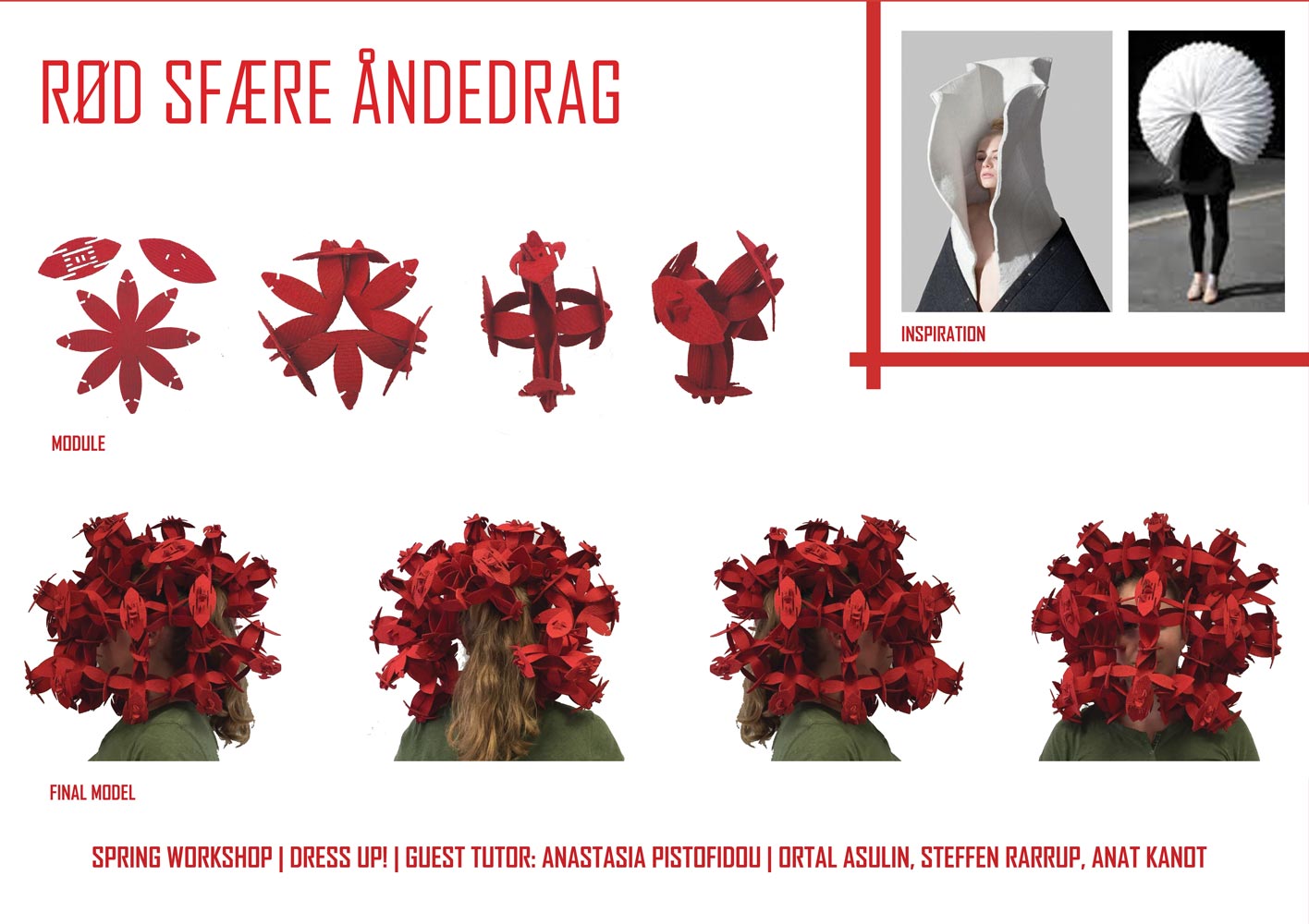

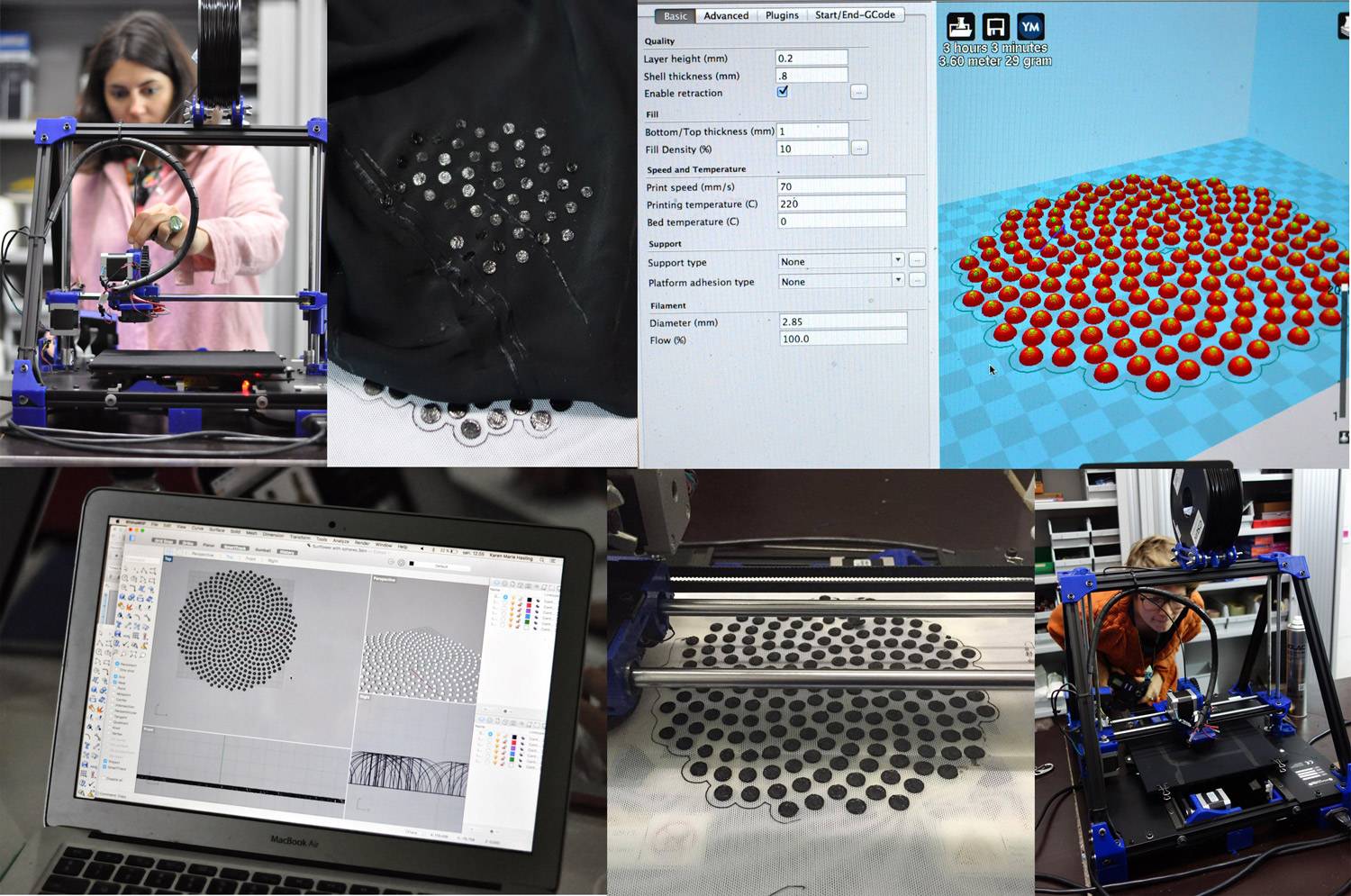

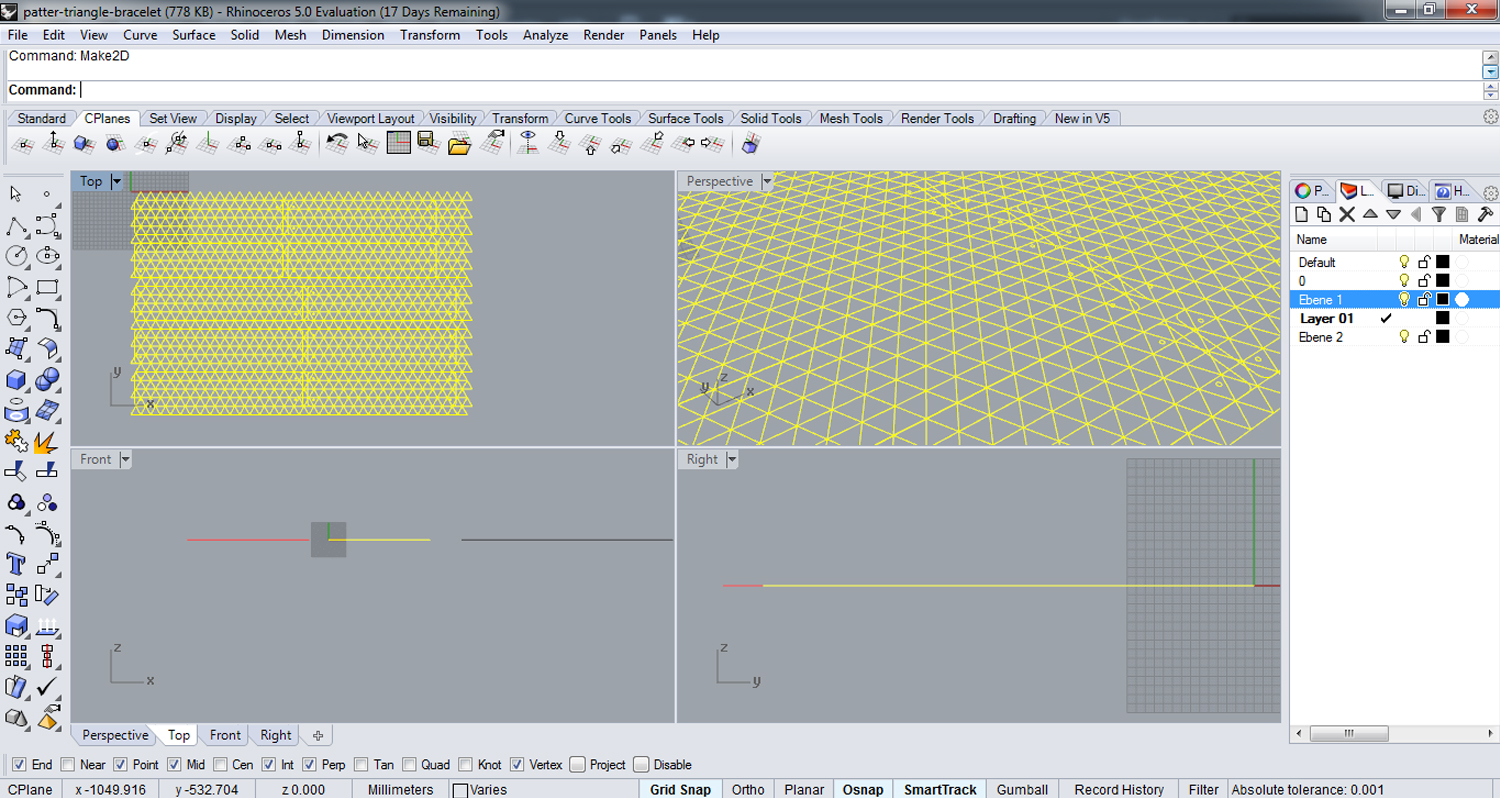

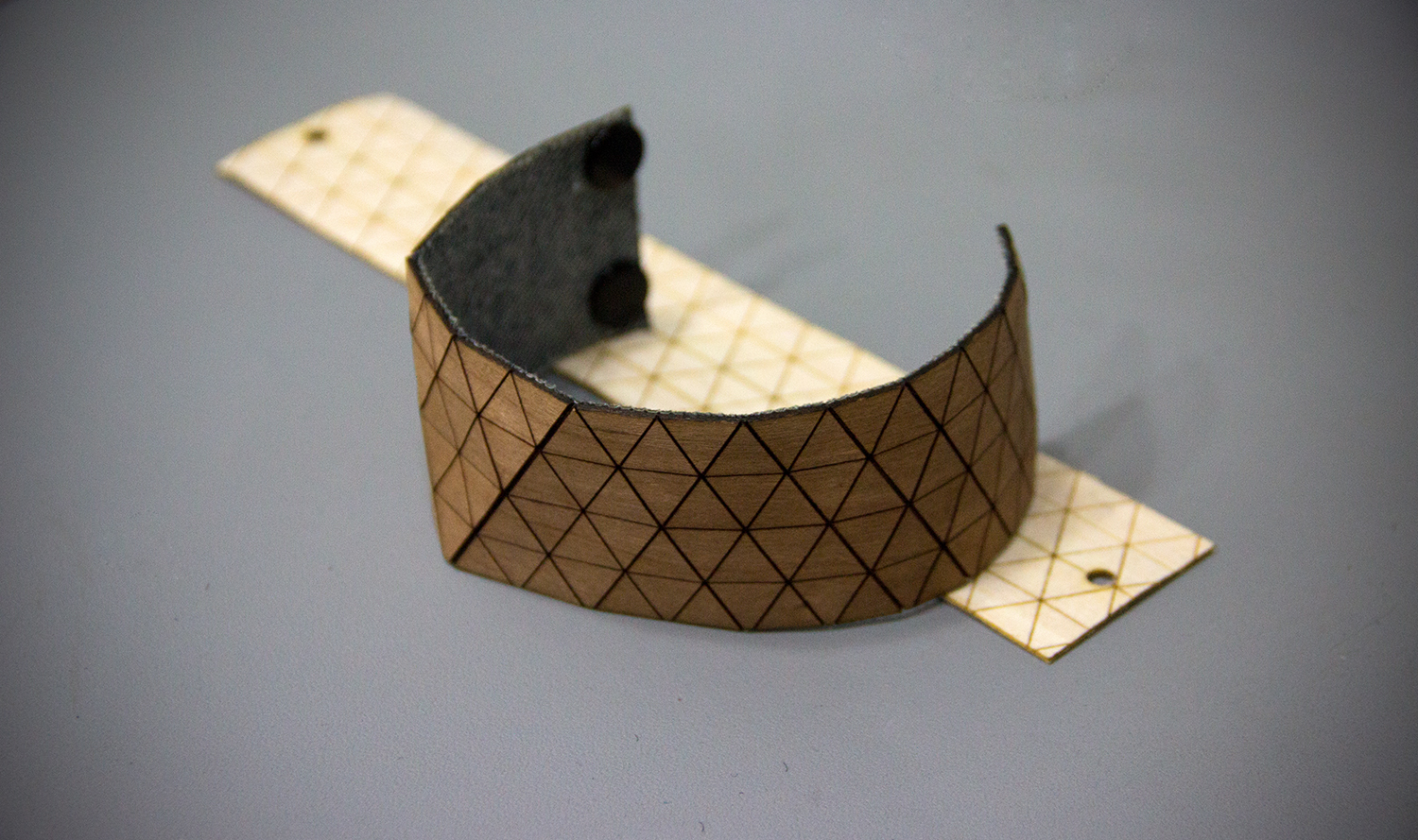

Last year Fab Textiles worked on a flexible bio filter design to reduce the pollution of Monterrey, the most polluted city in Mexico. This research was undertaken for an architecture project named Restology, a multidisciplinary project between architects, interior designers, product designers, fashion designers, material designers, graphic designers, electronic engineers and marketing strategists. During one month, Maria Luisa Becerril and I collaborated at Fab Textiles, Fab Lab Barcelona on the development of a bio-composite made of bioplastic mix with activated charcoal.

.

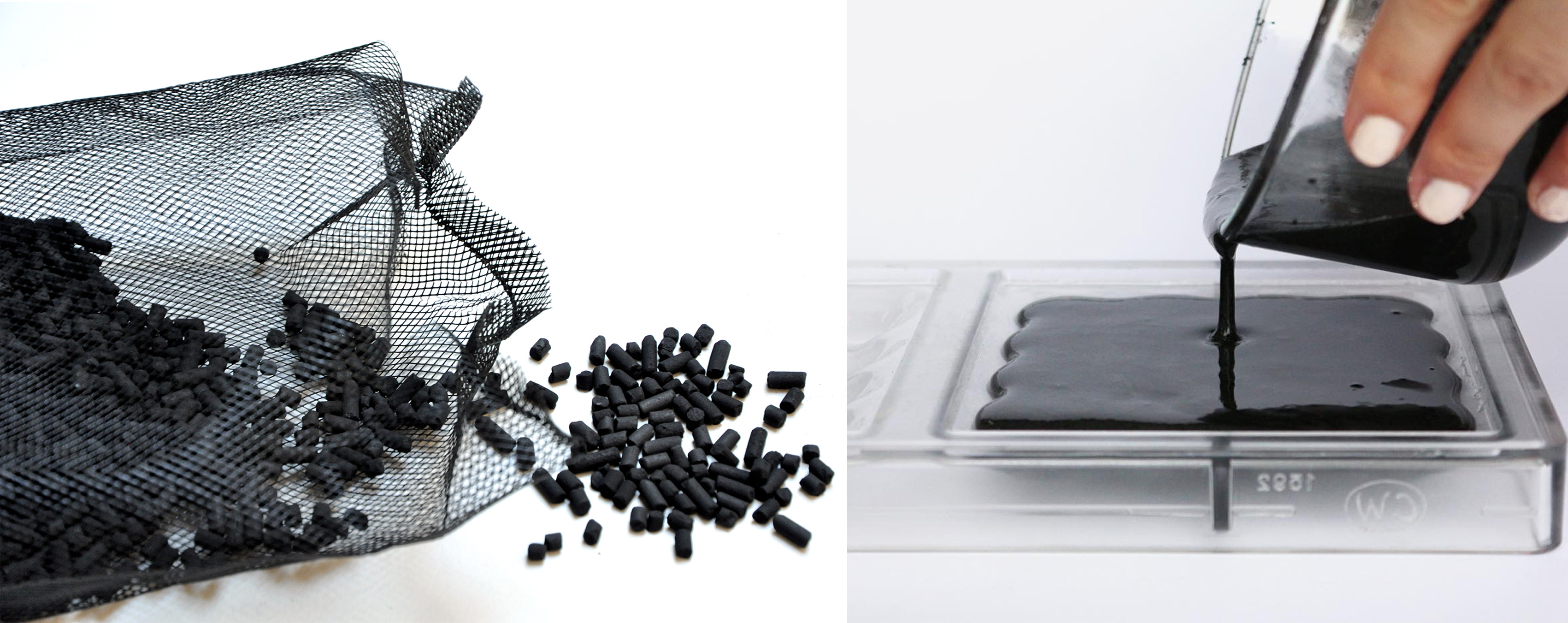

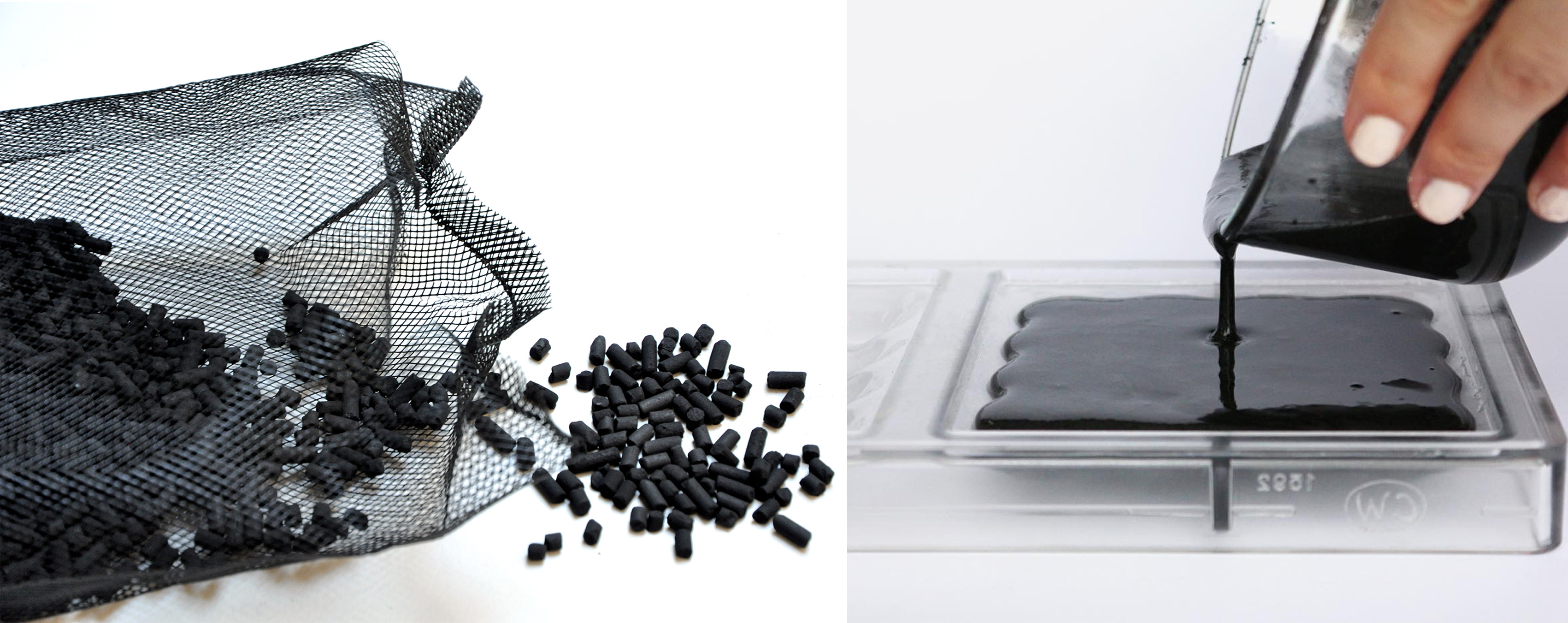

Grains of activated charcoal, Fab Textiles, Fab Lab Barcelona, 2017

Liquid mixture of bioplastic and activated charcoal, CEDIM Lab by Restology project, 2017

Activated charcoal is one material that seems especially applicable to Fab Lab makers, because of its ecologically sound and purifying properties. It is essentially a form of incredibly microporous carbon, processed from natural carbon-rich materials by applying various gases or chemicals to ‘burn’ in tiny holes and thus exponentially increasing its surface area. The result ? A material that can efficiently filter out all manner of impurities and toxins. A super-sponge, if you will. Bioplastics present themselves as an excellent and similarly sustainable substrate for activated charcoal with a wide range of uses.

.

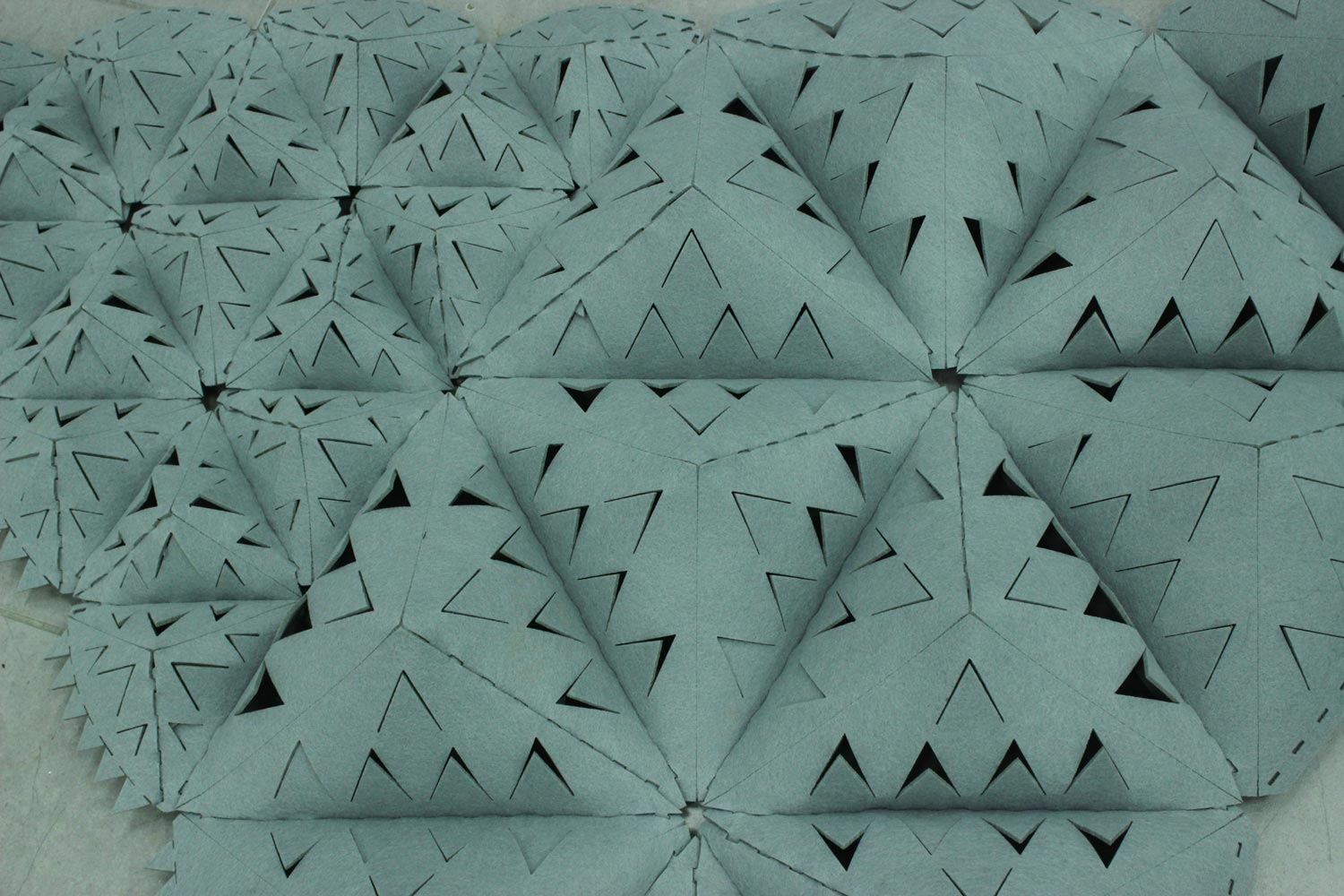

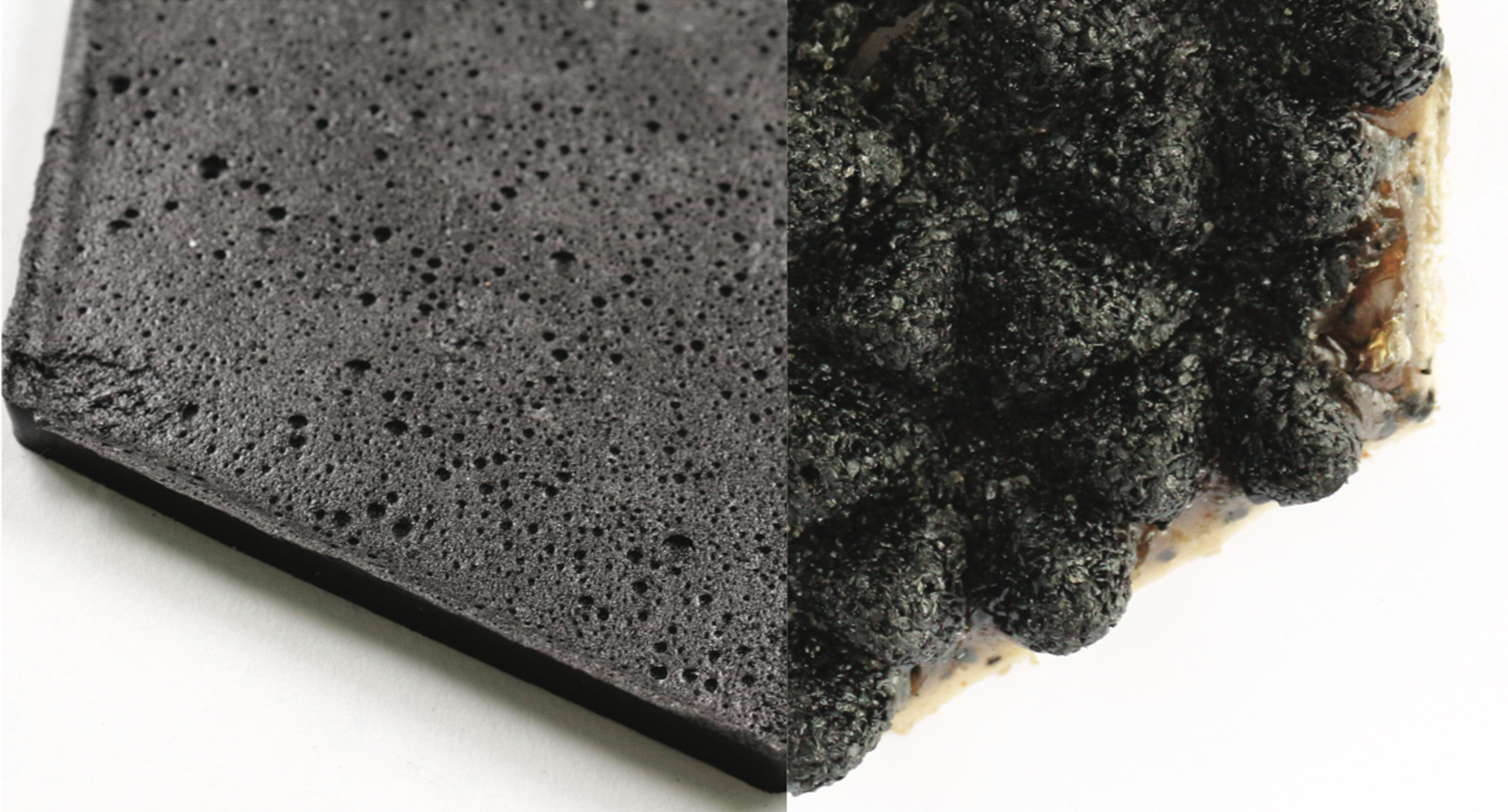

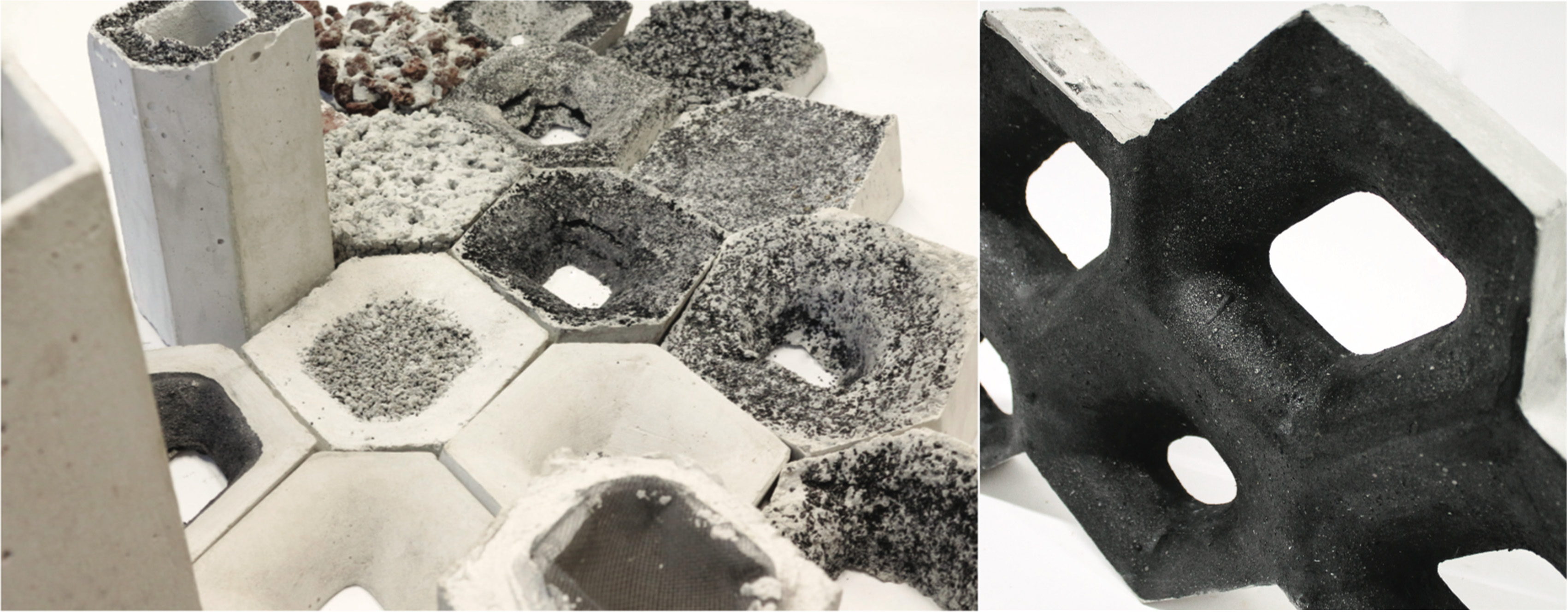

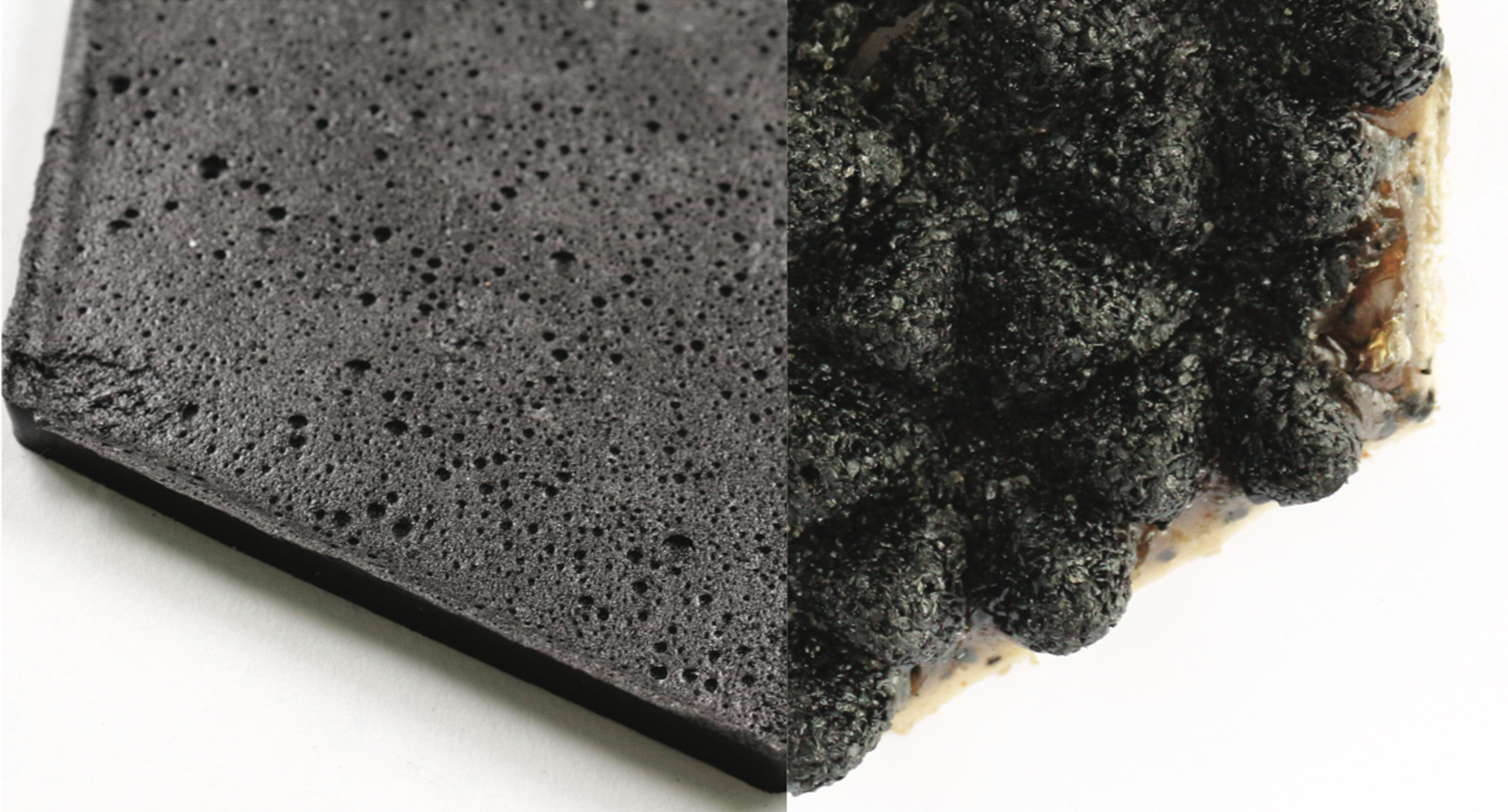

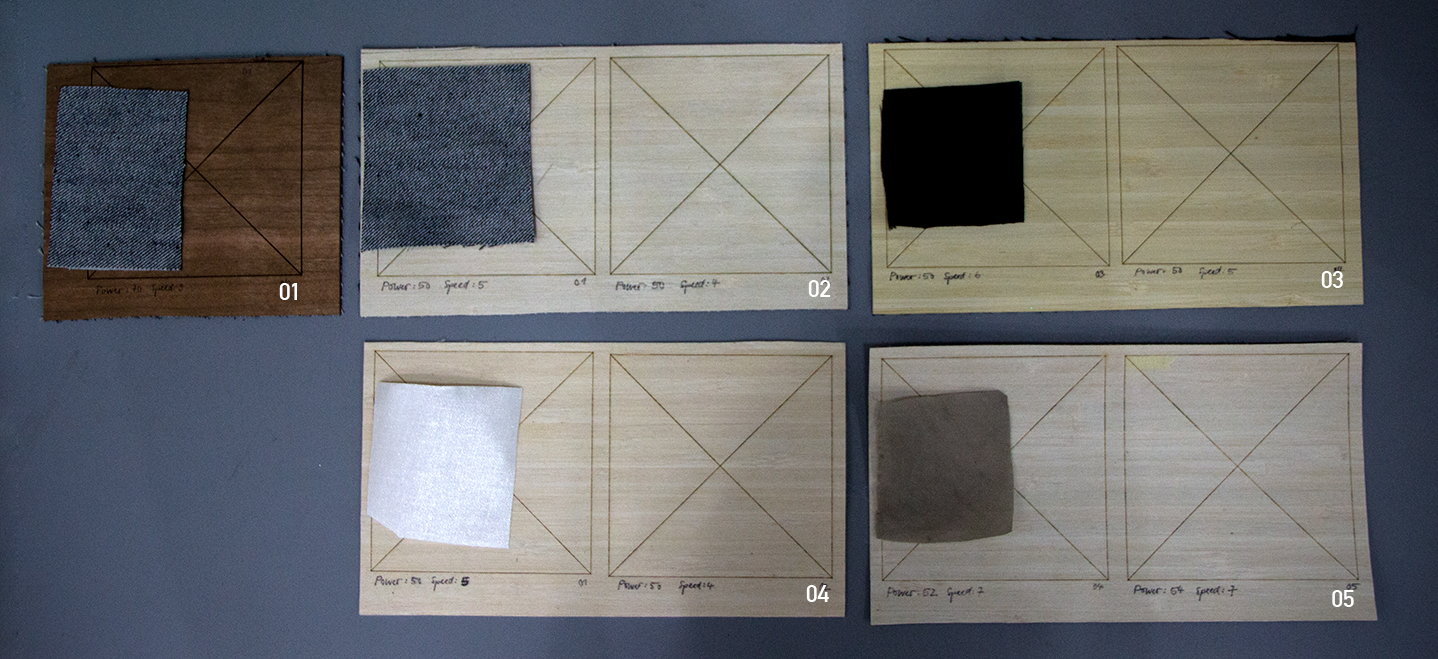

Bio-composite module tests, CEDIM Lab by Restology project, 2017

.

During the material research, Maria Luisa and I tried out 10 different recipes to discover the correct ratio of ingredients that provided the most appropriate amount of flexibility for using activated charcoal as a filter. For this research, we decided to use gelatin as our biopolymer and glycerol as our plasticizer. By experimenting with the quantities of glycerol relative to activated charcoal, one can influence the degree of flexibility of the mixture. Maria Luisa told me that in the previous experiments with her team, the issue was that the samples were cracking after the drying process. Probably because the bioplastic mixture was containing too much activated charcoal according to the glycerol ratio.

.

Bio-composite recipe experimentations, Fab Textiles, Fab Lab Barcelona, 2017

.

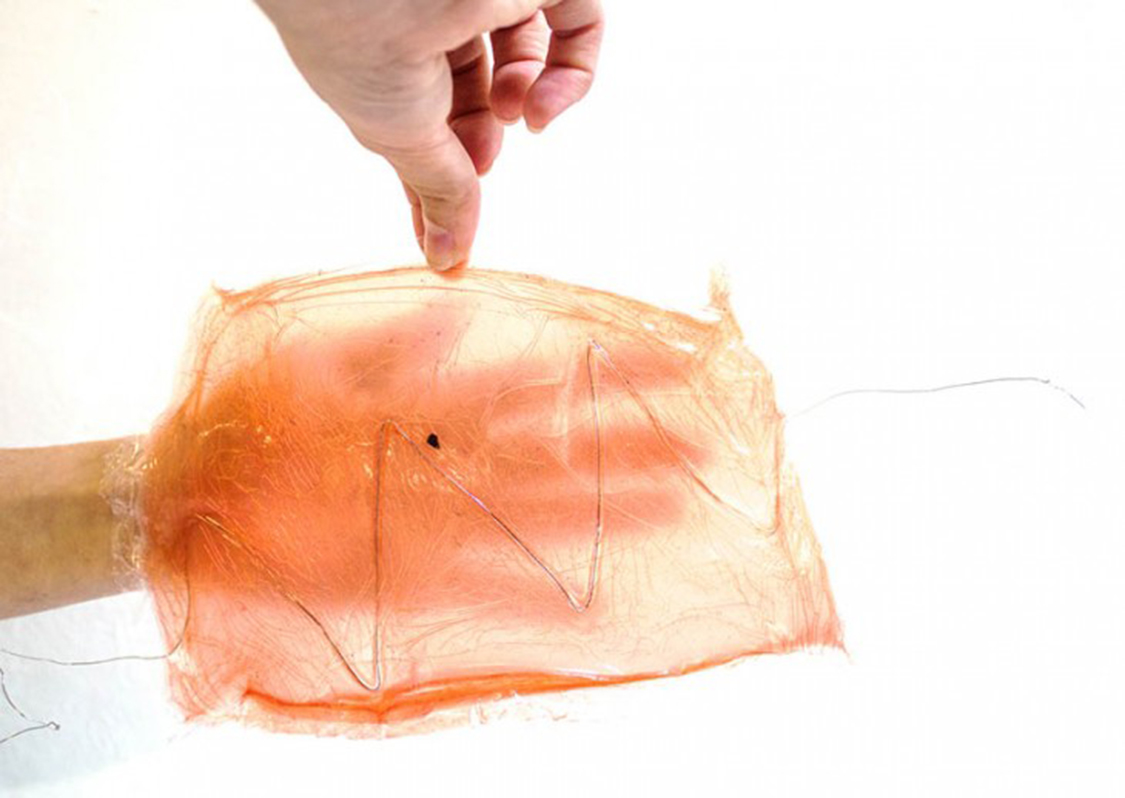

At the end of the experiments, we succeeded to have good results, with samples with different flexibility (hard like a rock to flexible like rubber) and textures (Rough to Smooth and Matte to Shiny). I noticed that some of the samples were conductive, an interesting fact that we could use for future e-textiles and wearables.

.

Bio-composite recipe experimentations, Fab Textiles, Fab Lab Barcelona, 2017

.

|

Samples

|

Water

|

Gelatin

|

Activated Charcoal

|

Glycerol

|

Flexibility

|

Texture

|

Conductivity

|

Resistance

10 cm

|

|

#1

|

100 ml

|

25 g

|

15 g

|

No

|

Hard

|

Smooth & Matte

|

Conductive

|

80 – 200 Ohm

|

|

#2

|

100 ml

|

25 g

|

15 g

|

10 g

|

Hard

|

Smooth & Matte

|

Conductive

|

100 – 200 Ohm

|

|

#3

|

100 ml

|

25 g

|

15 g

|

25 g

|

Very Flexible

|

Smooth & Shiny

|

Conductive

|

150 – 200 Ohm

|

|

#4

|

100 ml

|

25 g

|

15 g

|

35 g

|

Very Flexible

|

Smooth & Shiny

|

Non conductive

|

—

|

|

#5

|

100 ml

|

25 g

|

5 g

|

10 g

|

Flexible

|

Rough & Shiny

|

Non conductive

|

—

|

|

#6

|

100 ml

|

26 g

|

16 g

|

10 g

|

Shapeable

|

Rough & Shiny

|

Conductive

|

100 – 200 Ohm

|

|

#7

|

100 ml

|

16 g

|

16 g

|

10 g

|

Flexible

|

Smooth & Matte

|

Conductive

|

150 – 200 Ohm

|

|

#8

|

100 ml

|

50 g

|

16 g

|

10 g

|

Bendable

|

Rough & Matte

|

Non conductive

|

—

|

|

#9

|

70 ml

|

26 g

|

16 g

|

10 g

|

Flexible

|

Rough & Matte

|

Non conductive

|

—

|

|

#10

|

130 ml

|

26 g

|

16 g

|

20 g

|

Flexible

|

Rough & Matte

|

Non

Conductive

|

—

|

.

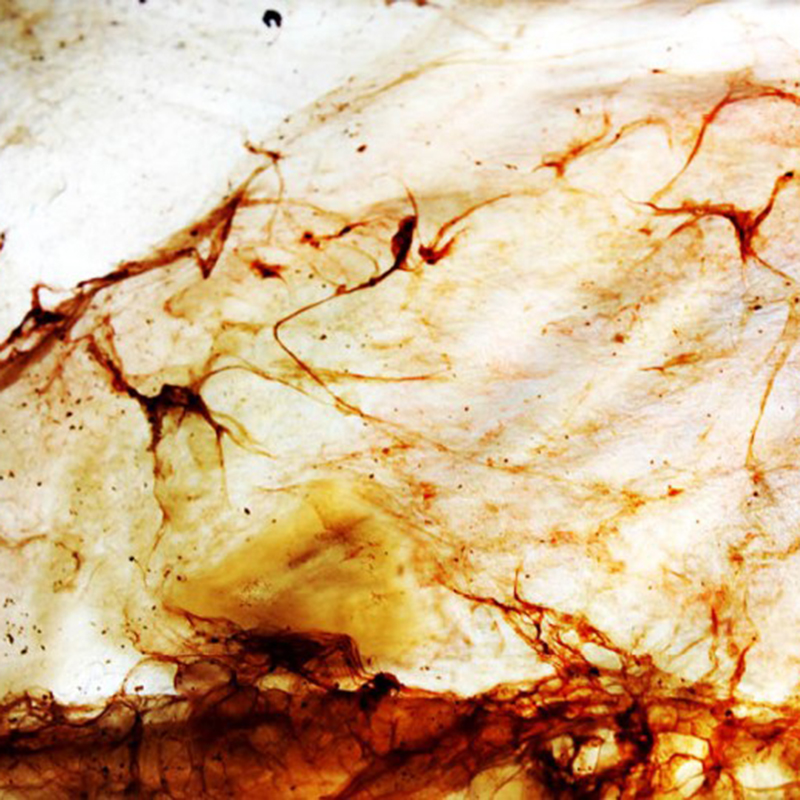

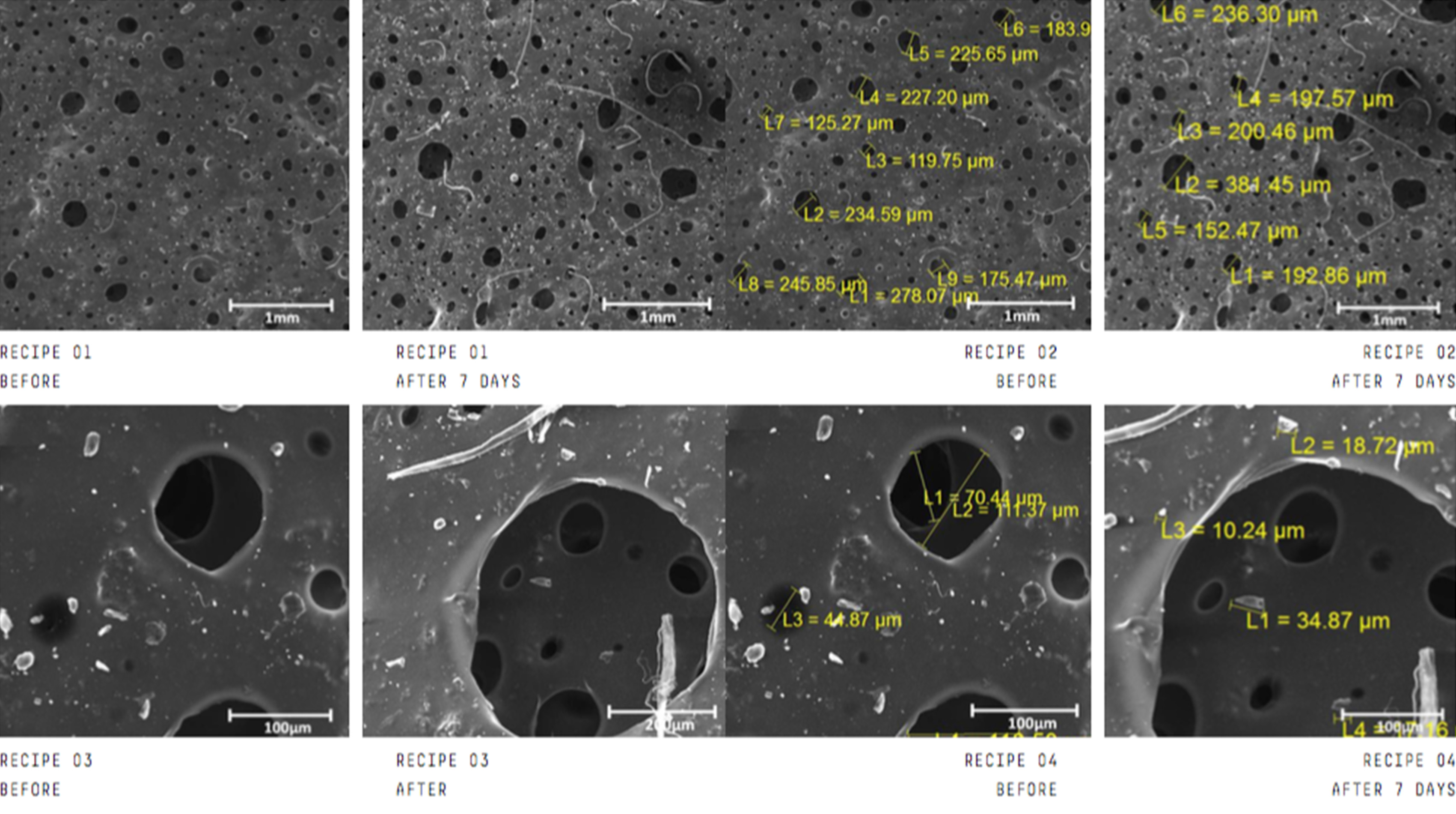

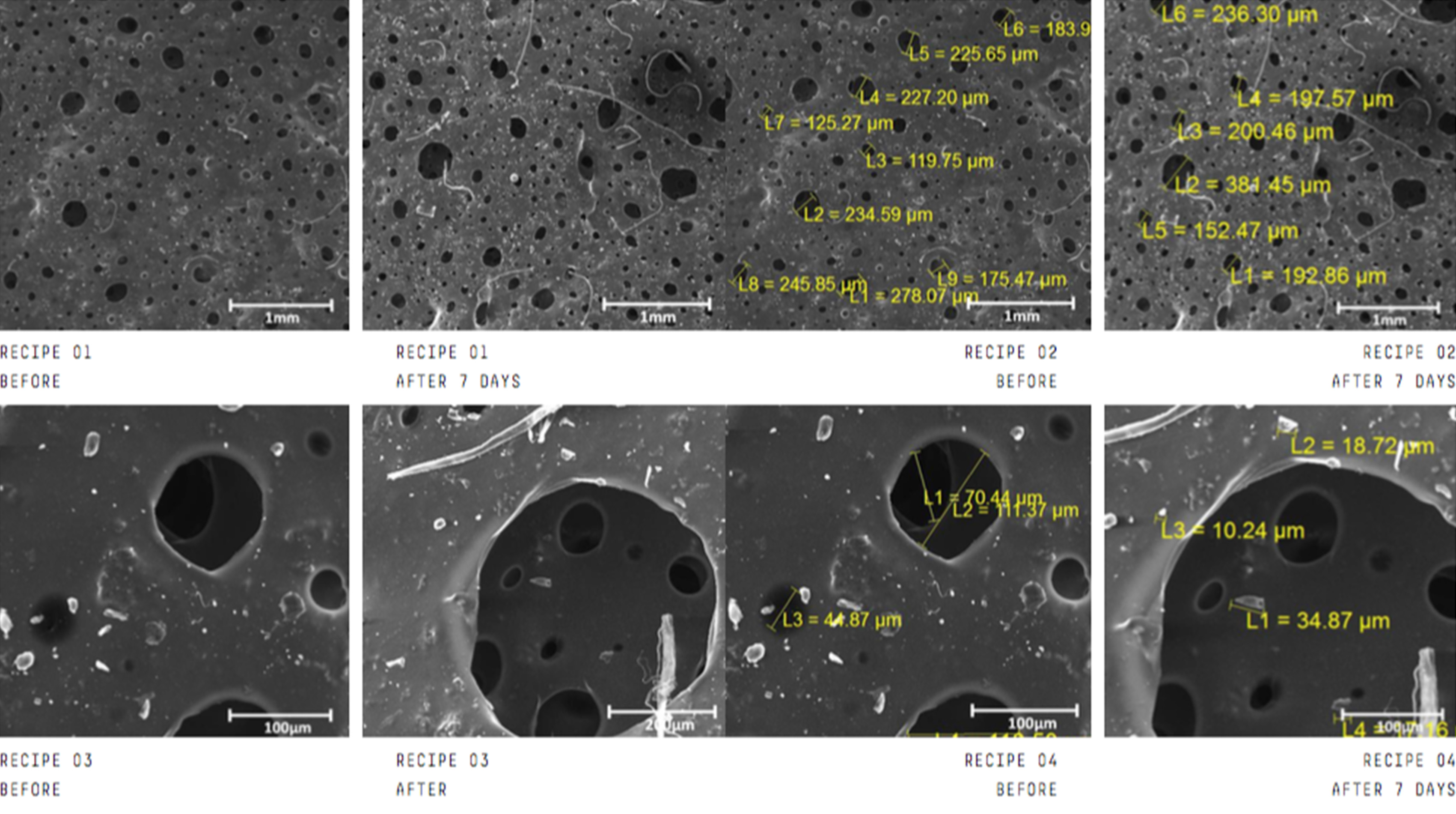

Some samples made for the Restology project were sent to the laboratory to be tested. The scan of electrons viewed in the microscope shows that the best recipe for creating a bio filter is one with the greatest amount of activated charcoal and almost as much glycerol as gelatin for better flexibility. The amount of ingredients use for this recipe is 20% glycerol , 28% gelatin, 57% activated charcoal and 14% water. Compared to the others, this recipe presented the highest average pore-size of 50μm, “creating a set of thin porous walls one behind another with inside cavities allowing the filtration of air pollutants.”**

.

Microscope scan of the bio-composite electrons, CEDIM Lab by Restology project, 2017

.

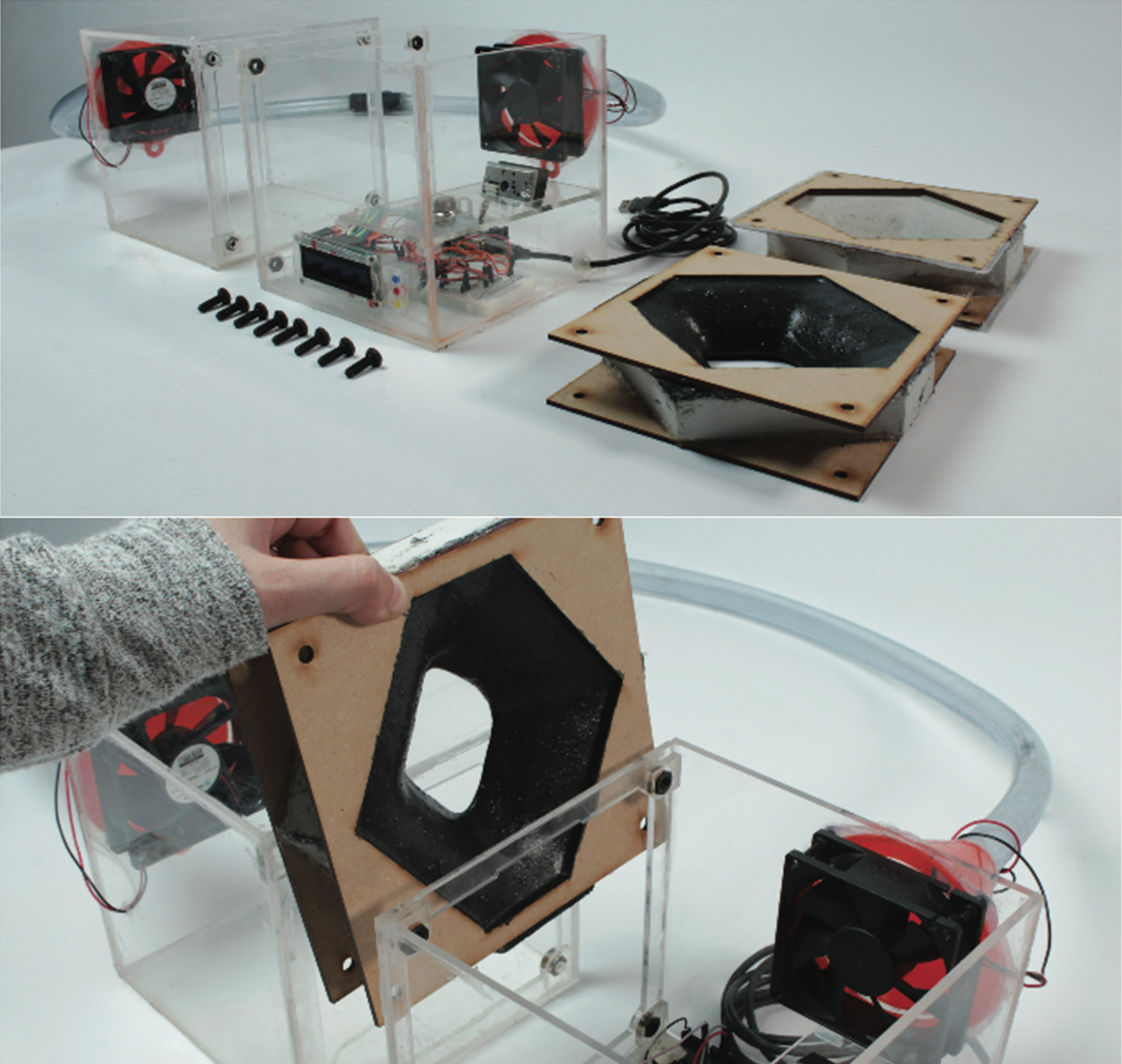

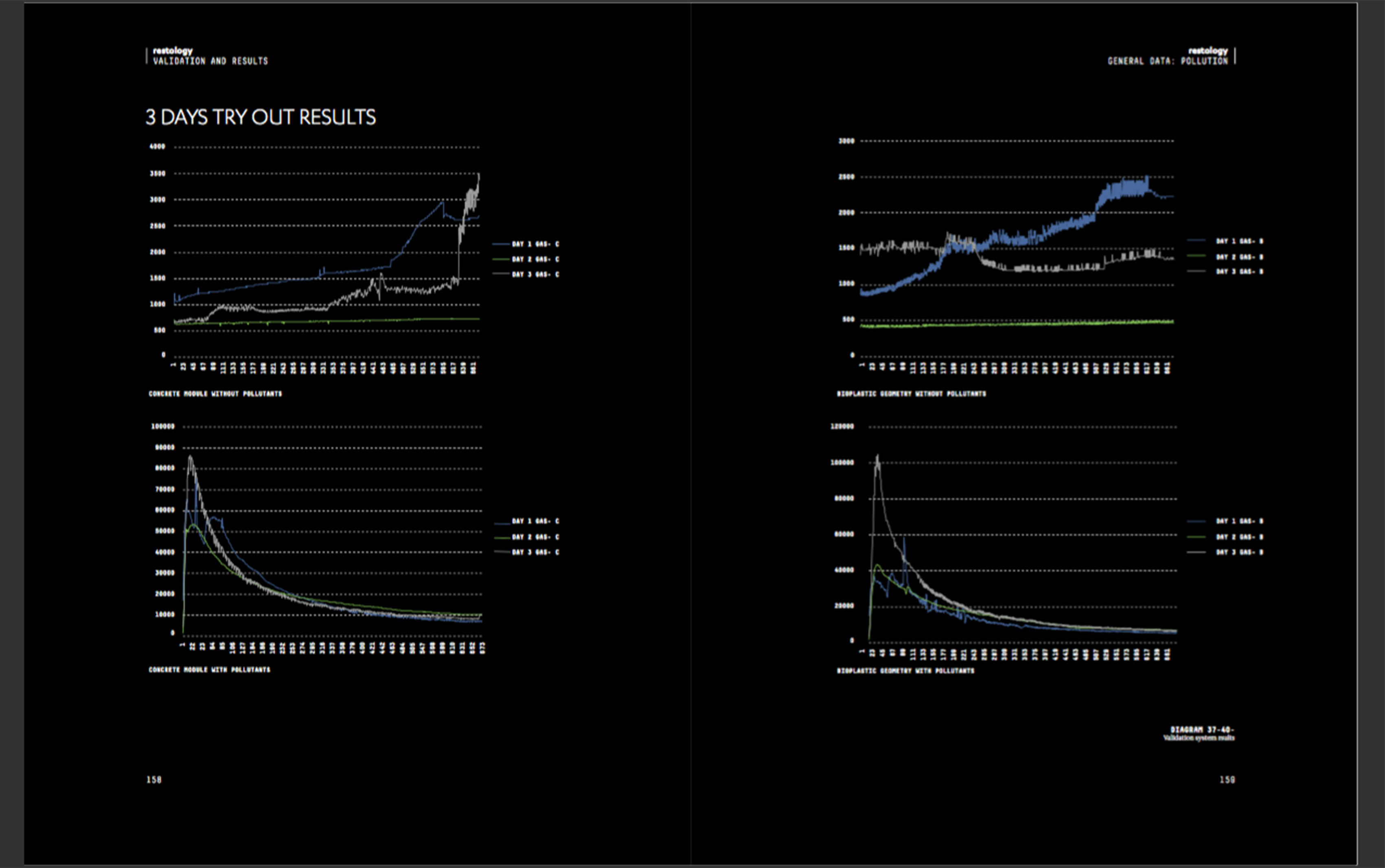

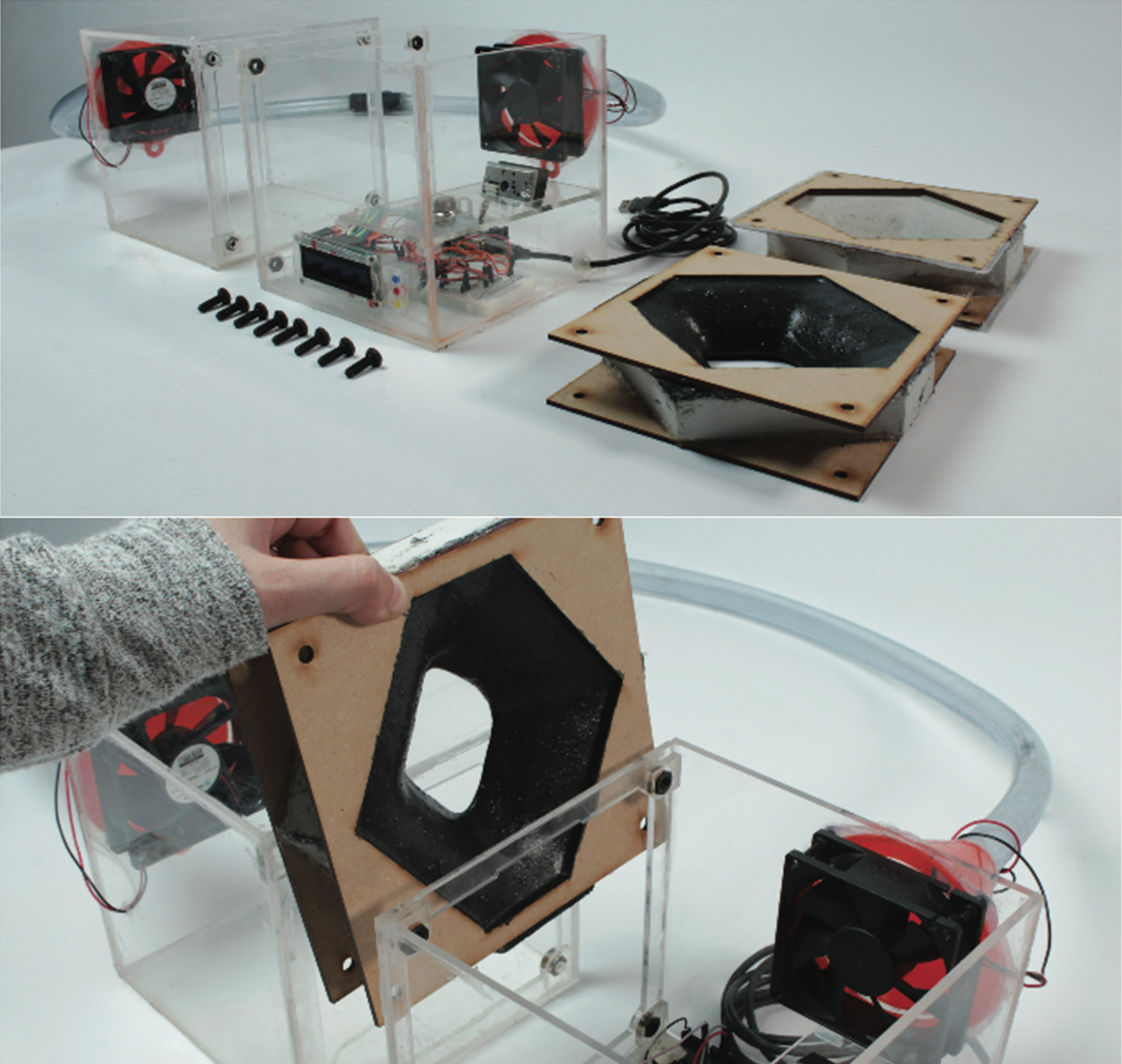

The laboratory analysis proved that one of the activated charcoal and bioplastic mixture was porous enough to fix pollutant particles. To validate the filtering potential of this bio-composite, the Restology researchers developed a machine measuring microparticles and gases such as NH3, Nox, Alcohol, Benzen, Smoke, CO2… This two-chambered device contains an Arduino system connected to two sensors : one reading dust density (GP2Y1010AU0F sensor) and one calculating air quality (MQ135 sensor). The two chambers are separated by the bio-composite filter, the polluted air is introduced in the first chamber, measured, and then remeasured in the second chamber after passing through the bio filter.

.

Data compilation machine : measuring air particles and gas, CEDIM Lab by Restology project, 2017

.

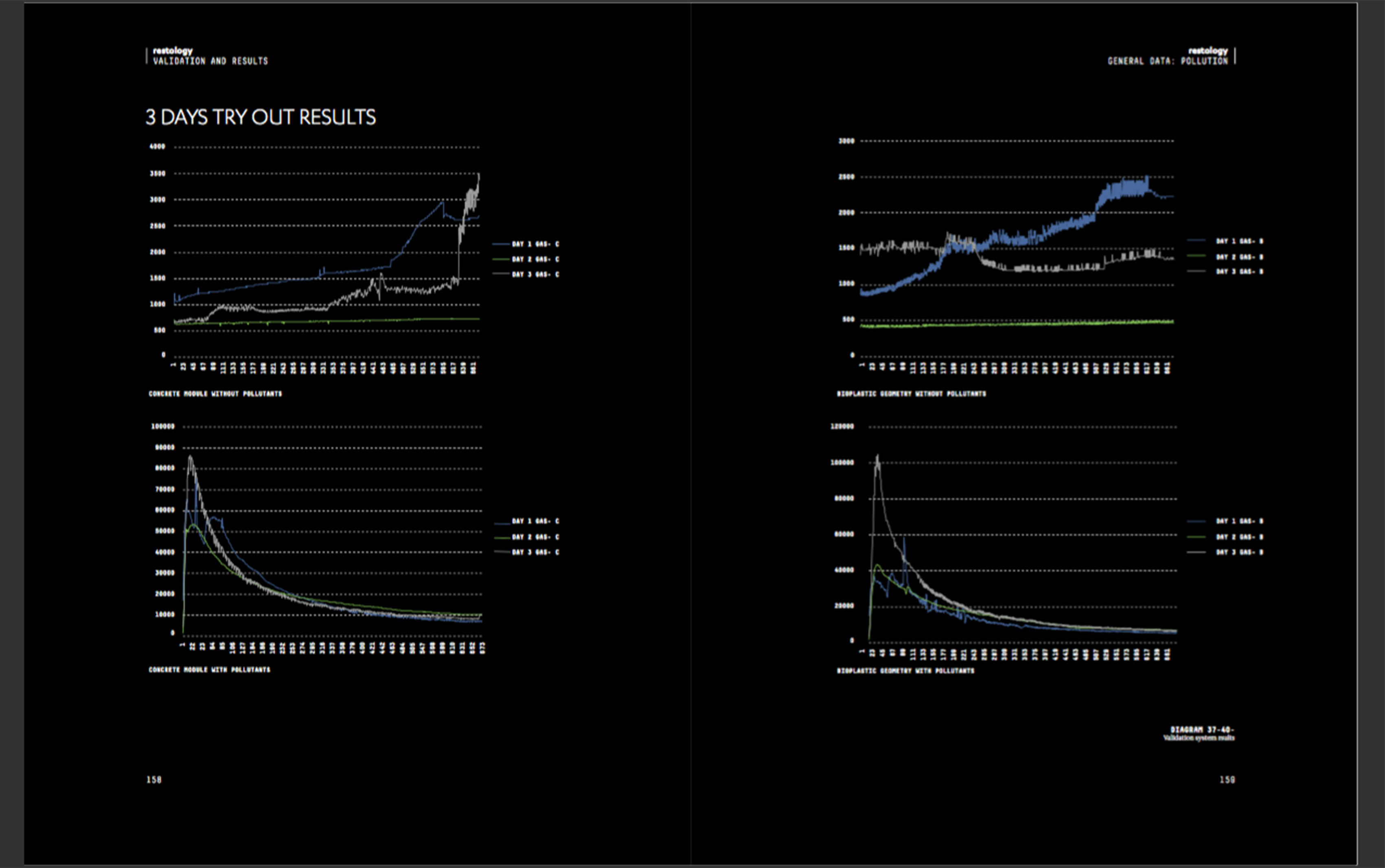

3 Days try out results, data compilation machine : measuring air particles and gas, CEDIM Lab by Restology project, 2017

.

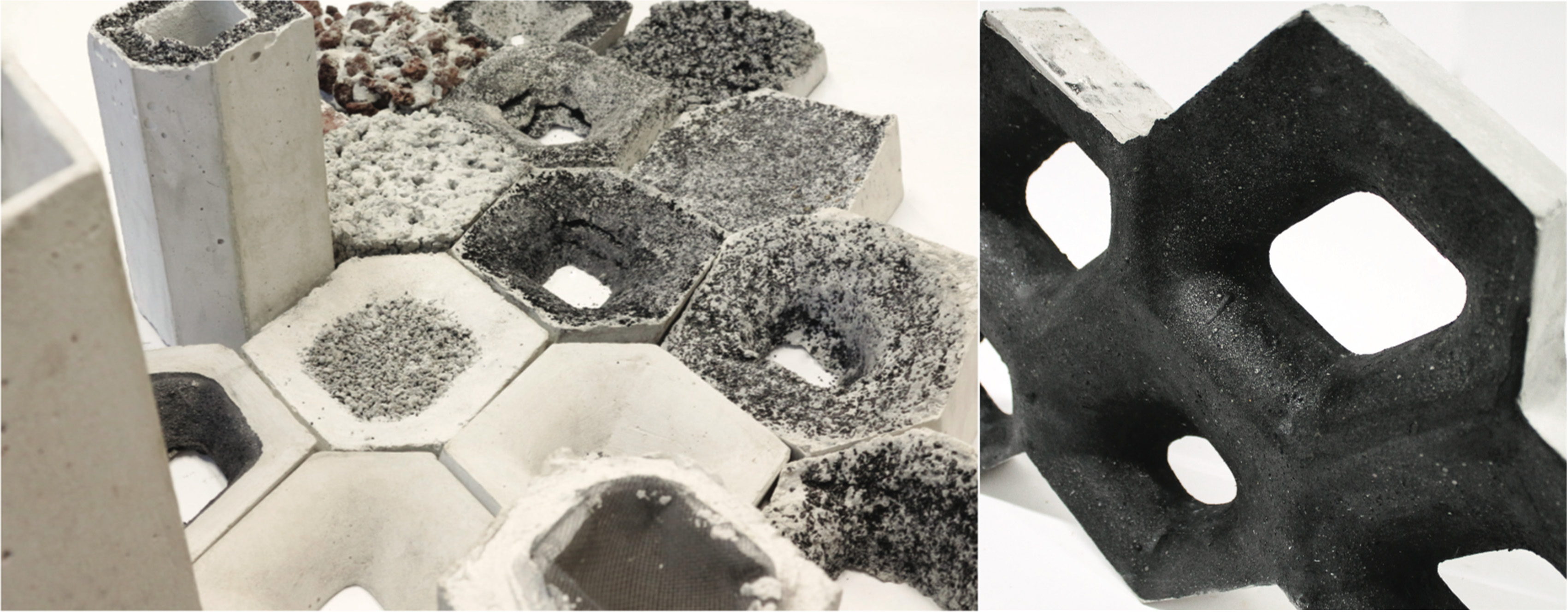

OUTDOOR & INDOOR RESTOLOGY MODULE

Outdoor filter module : concrete, bioplastic and activated charcoal, CEDIM Lab by Restology project, 2017

.

Indoor filter module : bioplastic and activated charcoal, CEDIM Lab by Restology project, 2017

.

* E-Medecine Health Article, Medical Author: John P.Cunha, DO, FACOEP and Medical Editor: Melissa Conrad Stoppler, MD, Chief Medical Editor / Medically reviewed by John A. Daller, MD; American Board of Surgery with subspecialty certification in surgical critical car.

** Restology, absorption of suspended particles through bioplastic and activated charcoal, multidisciplinary thesis, Centro de Estudios Superiores de Diseno de Monterrey S.C., 7 December 2017.

Restology project by Monterrey Center for Higher Learning of Design (CEDIM University), Monterrey Mexico, Architecture Department Direction :

– Project Leader : Yessica Mendez Sierra

– Students : Ada Gloria Gonzalez Mireles, Ana Graciela Gonzalez Sanchez, Ana Maria Vargas Lasserre, Andrea Lizette Najera Rodriguez, Bárbara Garza Saldaña, Carla Ruizvelasco Garza, Cristina Adriana Briones Nuñez, Dana Mayeli Rangel Torres, Estefanía Flores Jiménez, Juana Valeria Gonzalez Ortiz, Kathia Quintanilla Garcia, Maria De Lourdes Hernández Lima, Maria Luisa Becerril Garcia, Mayra Valeria Moreira Balderas, Melissa Chapa Gil, Oscar Javier Alvarado Contreras, Priscila Luna Ramos, Roberto Luis Valenzuela Cortazar, Sara Eugenia Gonzalez Mascareñas, Veronica Saldaña Garza

-> About Restology project : https://www.trendhunter.com/trends/reduce-air-pollution

Article written by Clara Davis

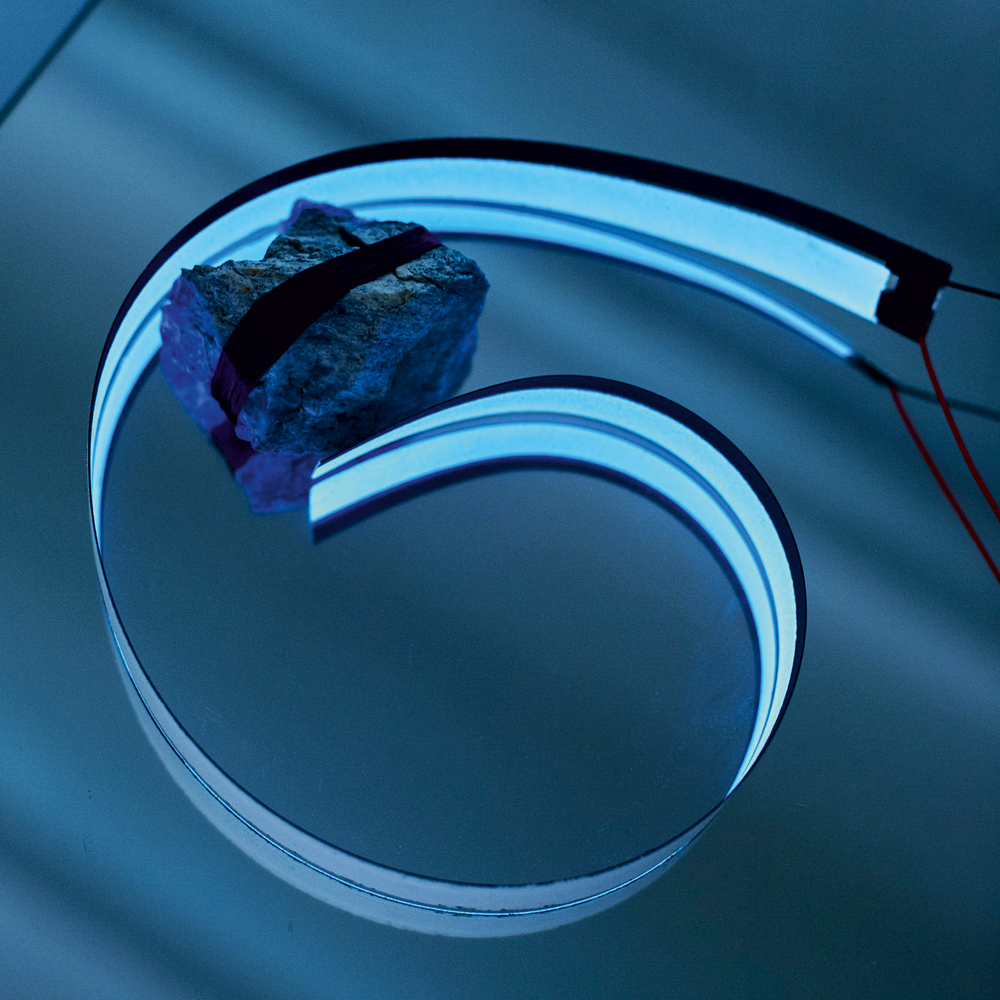

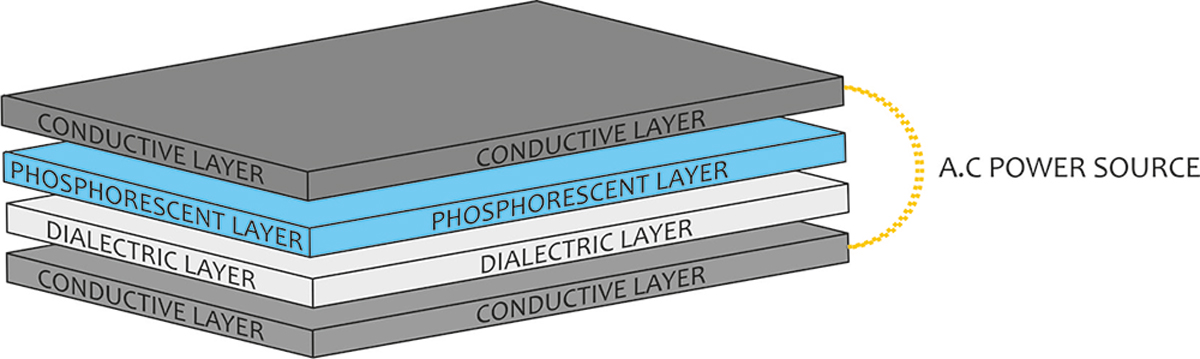

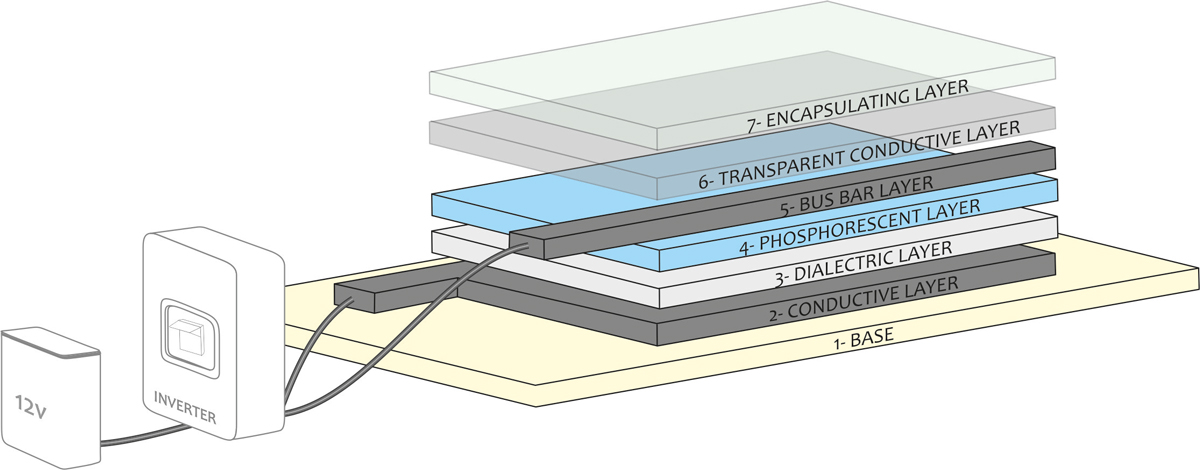

Electroluminescent

Electroluminescent

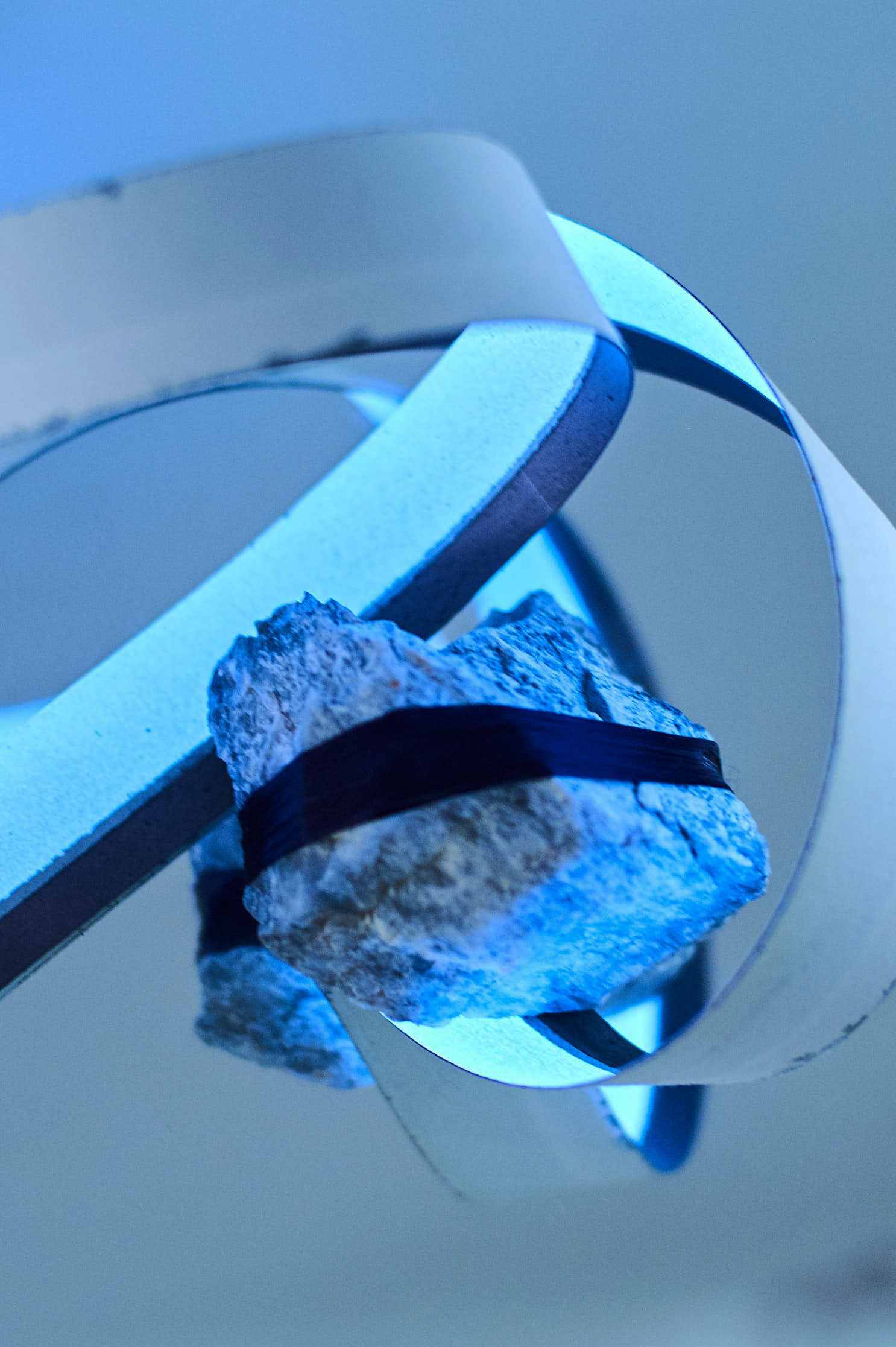

Pictures from Refraccions Exhibition, Cristina Noguer

Pictures from Refraccions Exhibition, Cristina Noguer

![5_BIO[lum]SKIN](http://fabtextiles.org/wp-content/uploads/2016/05/5_BIOlumSKIN.jpg)