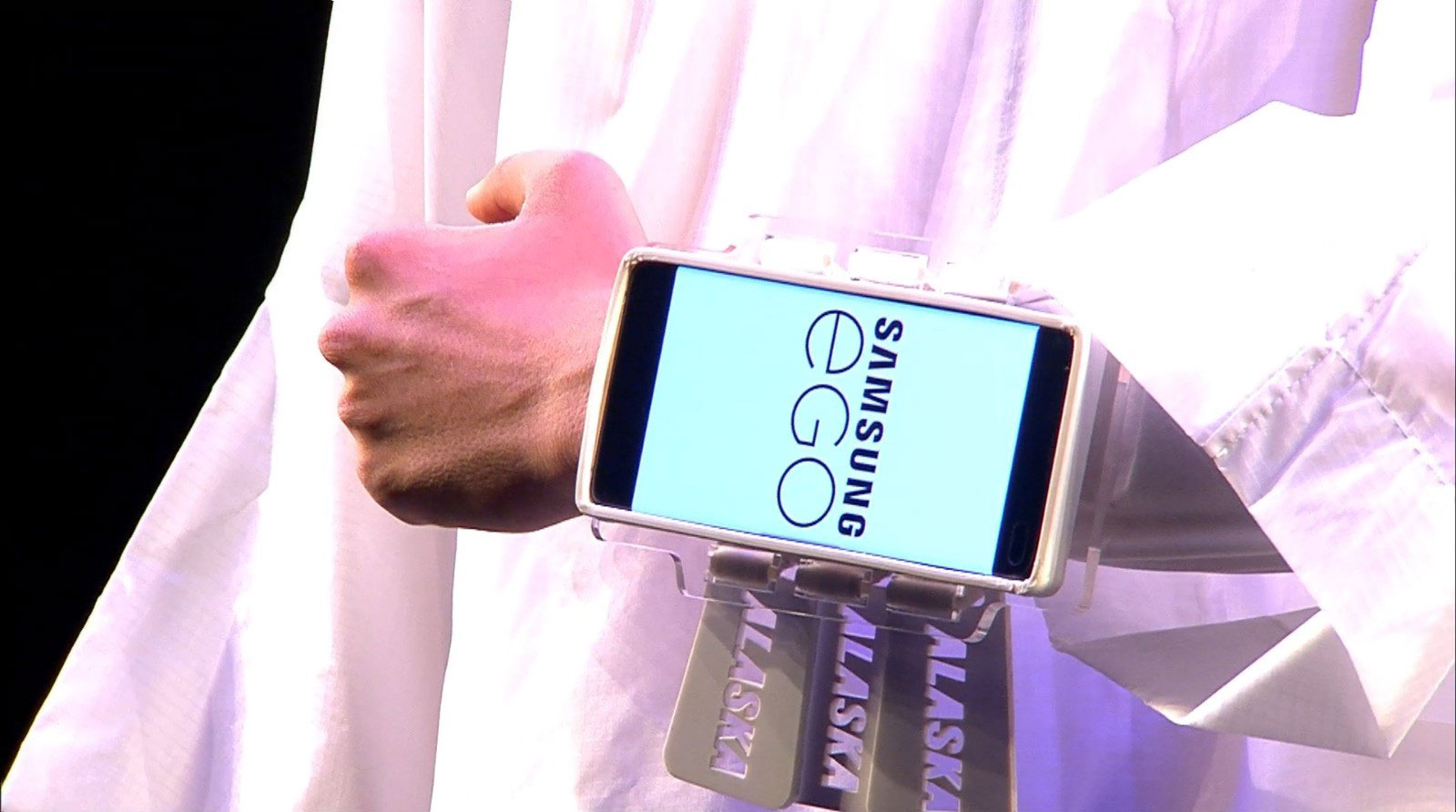

DECONSTRUCTIVE HEADS collection / ALASKA ACCESORIOS

Winner of the contest SAMSUNG EGO Innovation Project /

Mercedes Benz Fashion Week Madrid

Project by Betiana Pavón / FabTextiles / Fabricademy BCN Student

Betiana Pavon, an Argentinian Accessories designer with her brand ¨ALASKA Accesorios¨ studied at Fabricademy Barcelona in 2018-19.

With her final project she applied to the Samsung Ego Innovation Prize and was selected to present a complete collection for the edition of July 2019 with a prize for development of 10.000 euros!

The project is focused on the design, prototyping and development of "head accessories". Re-referred to as "portable objects", a perfect excuse to crown the head with a distinctive piece, a piece that can be unique, that identifies directly with its user and interacts with it, using Samsung devices as a link.

The project was developed at Fab Textiles Lab in Fab Lab Barcelona for 1,5 month where all looks and custom electronics where designed and fabricated.

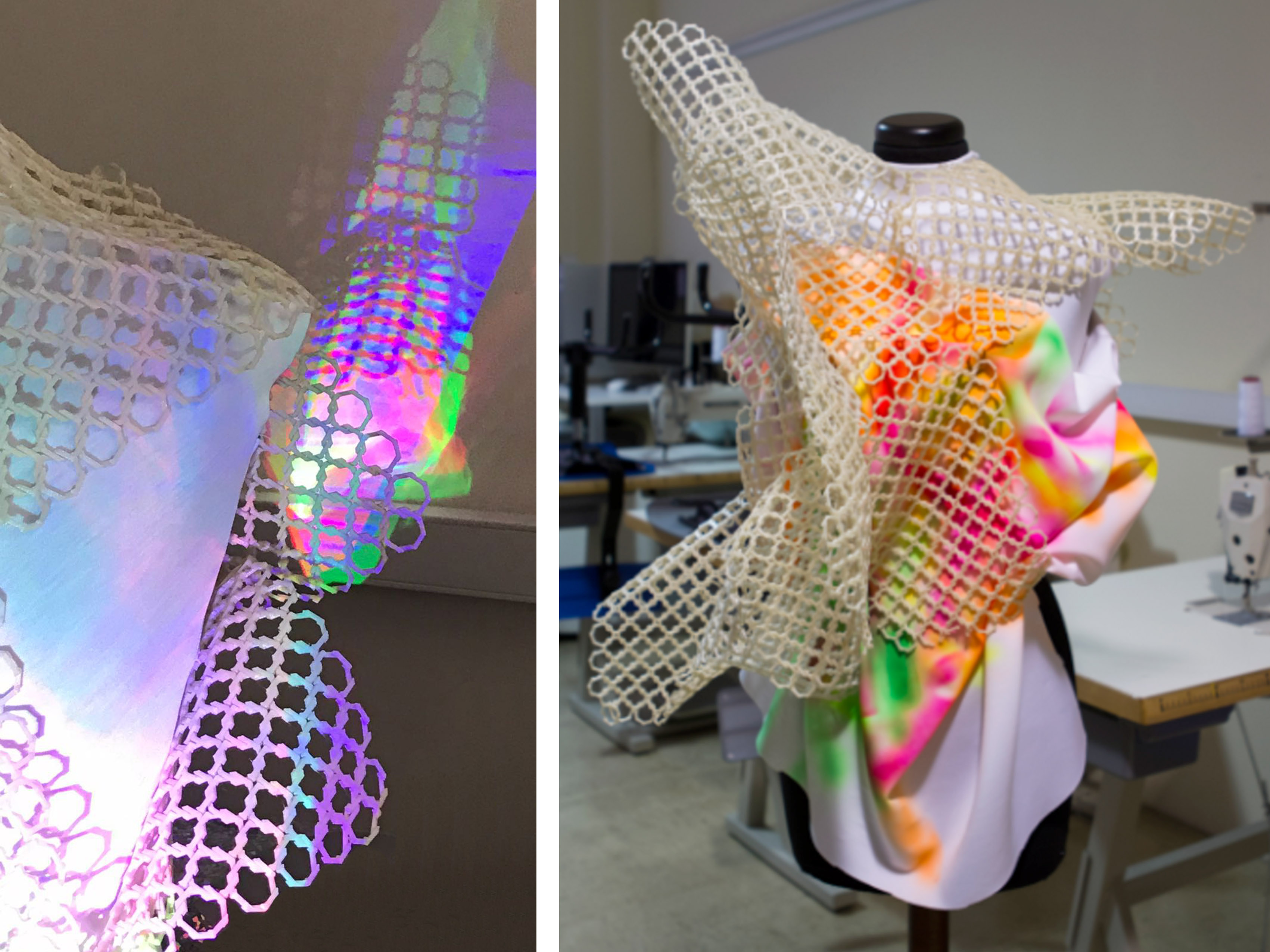

As for typologies and morphologies, the concept of “portable structures” is addressed, which can be constructed and deconstructed through modules, achieving almost abstract accessories.

The inspirational axis of this collection is the "Deconstructivist Movement" reflected in organic forms, fragmented, distorted and complex geometries ... product of the incorporation of new technologies (Hardware: machinery, electronics) and computational design tools (Software). The conception of this collection is based on the liberation of geometry and rules in general.

NEW TECHNOLOGIES / PROCESS

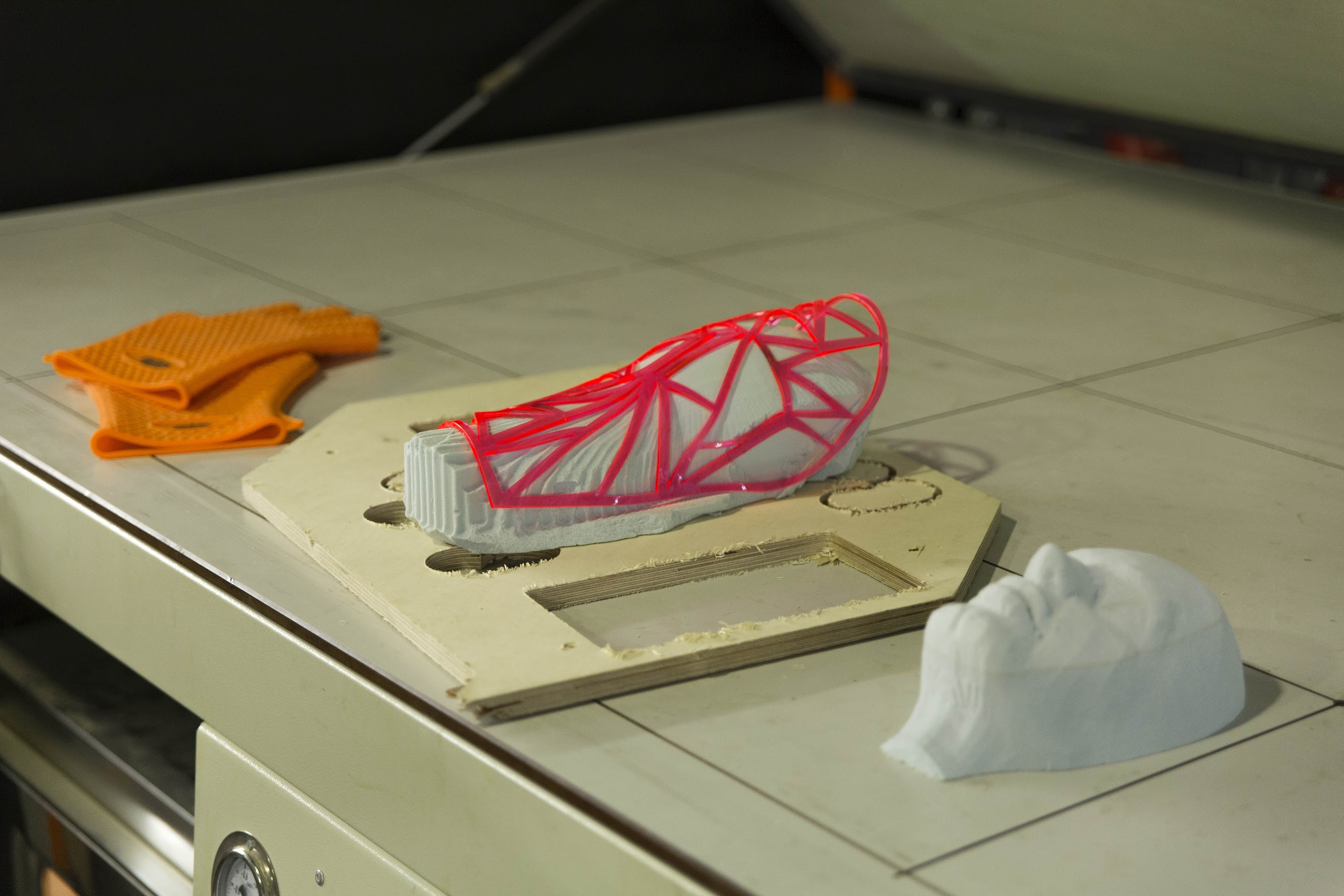

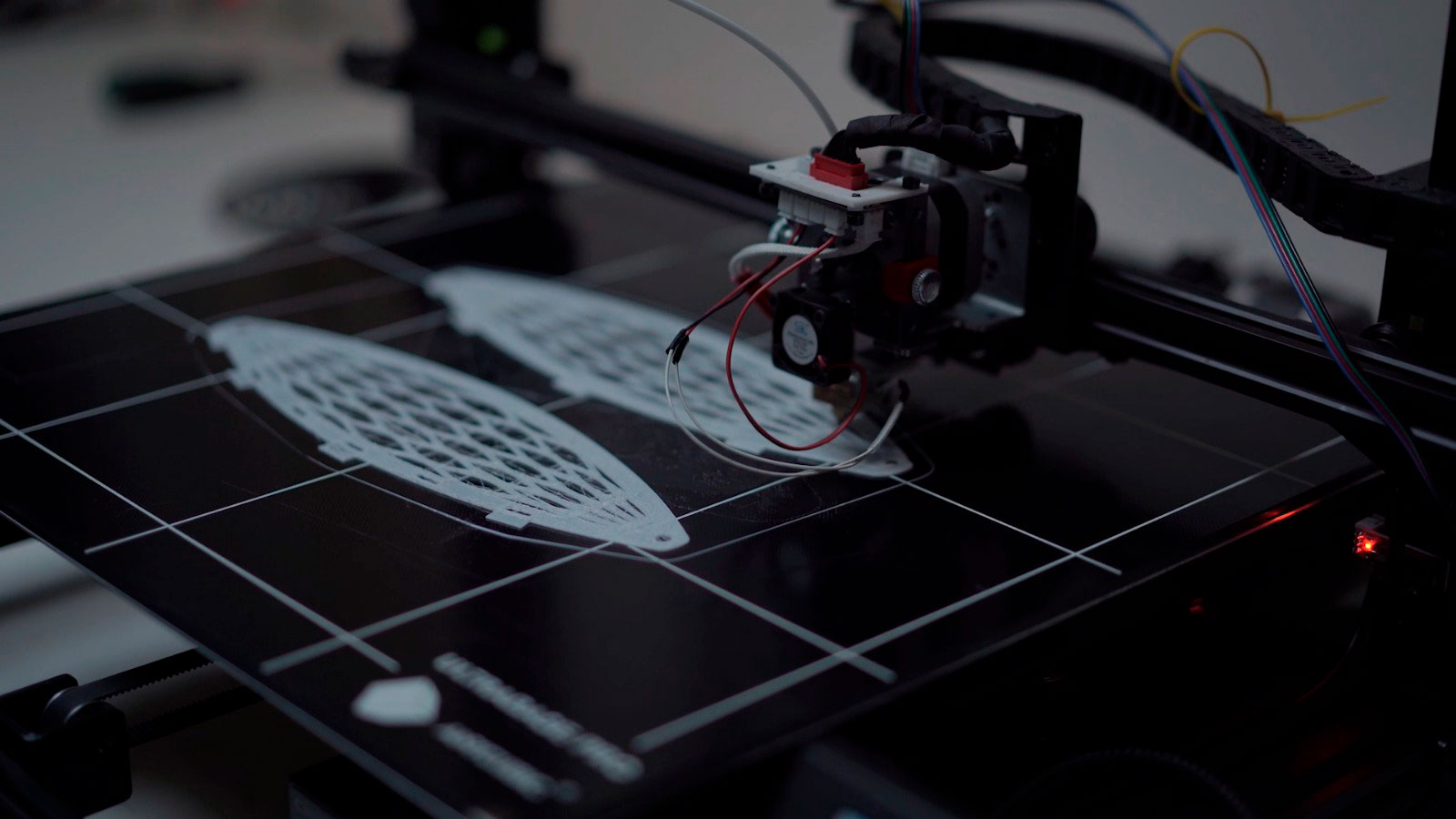

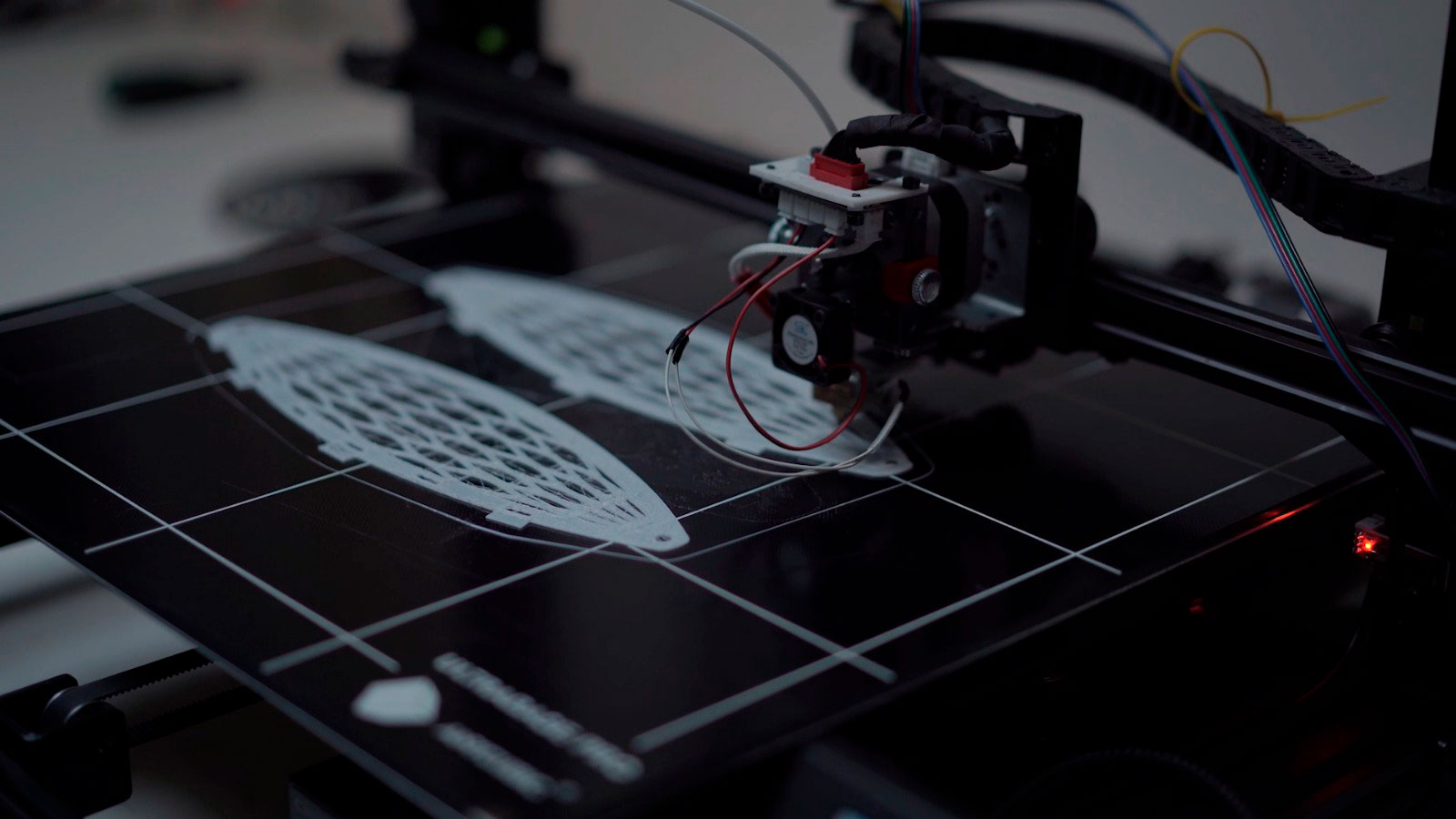

3D Print

The computational design allows a new reinterpretation of the forms, in this case applied in portable accessories. By erasing old construction limits, 3D printing allows for the realization of unique, custom-made pieces and contributing to a sustainable digital manufacturing model, where it is produced only on the basis of real demand, thus reducing the waste generated by the fashion industry.

Laser cut

The implementation of new materials (such as acrylic, technical textiles, etc.) and the inclusion of parametric digital patterns that allow the creation of fragmented geometries, distortion and complexity of shapes, require the use of new tools, such as laser cutting. The inclusion of this machinery in the manufacture of this type of parts is key, since it allows perfect finishes, pinpoint accuracy and reduces manual work. Thus achieving in a single step, fast and efficient cutting of pieces and perfect patterns in series.

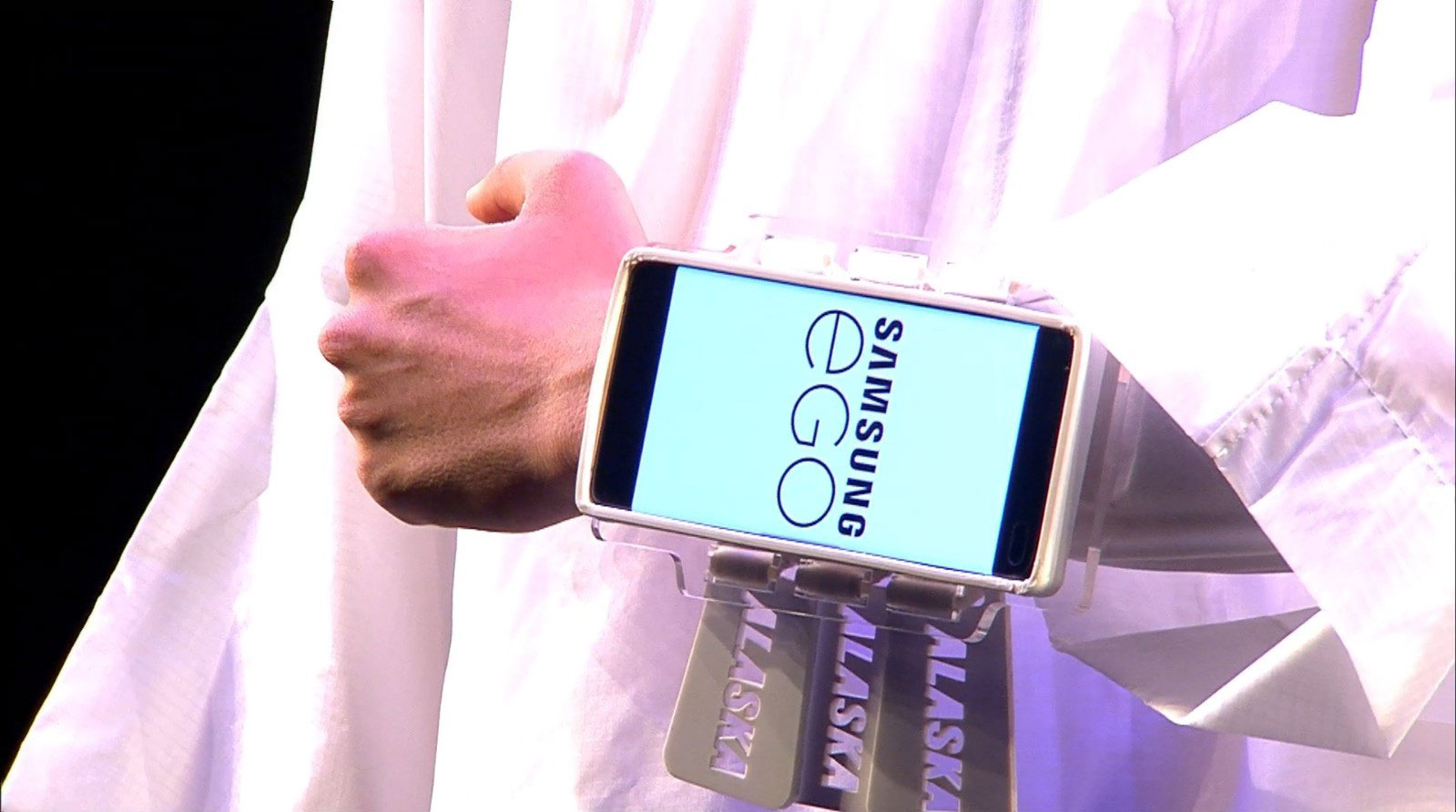

SAMSUNG DEVICES / INTERACTION INTEGRATION

The main intention of this project is that Samsung devices are not only an addition in the proposed style, but that they interact directly as a link between the carrier and accessories. That is, include technology in the entire project.

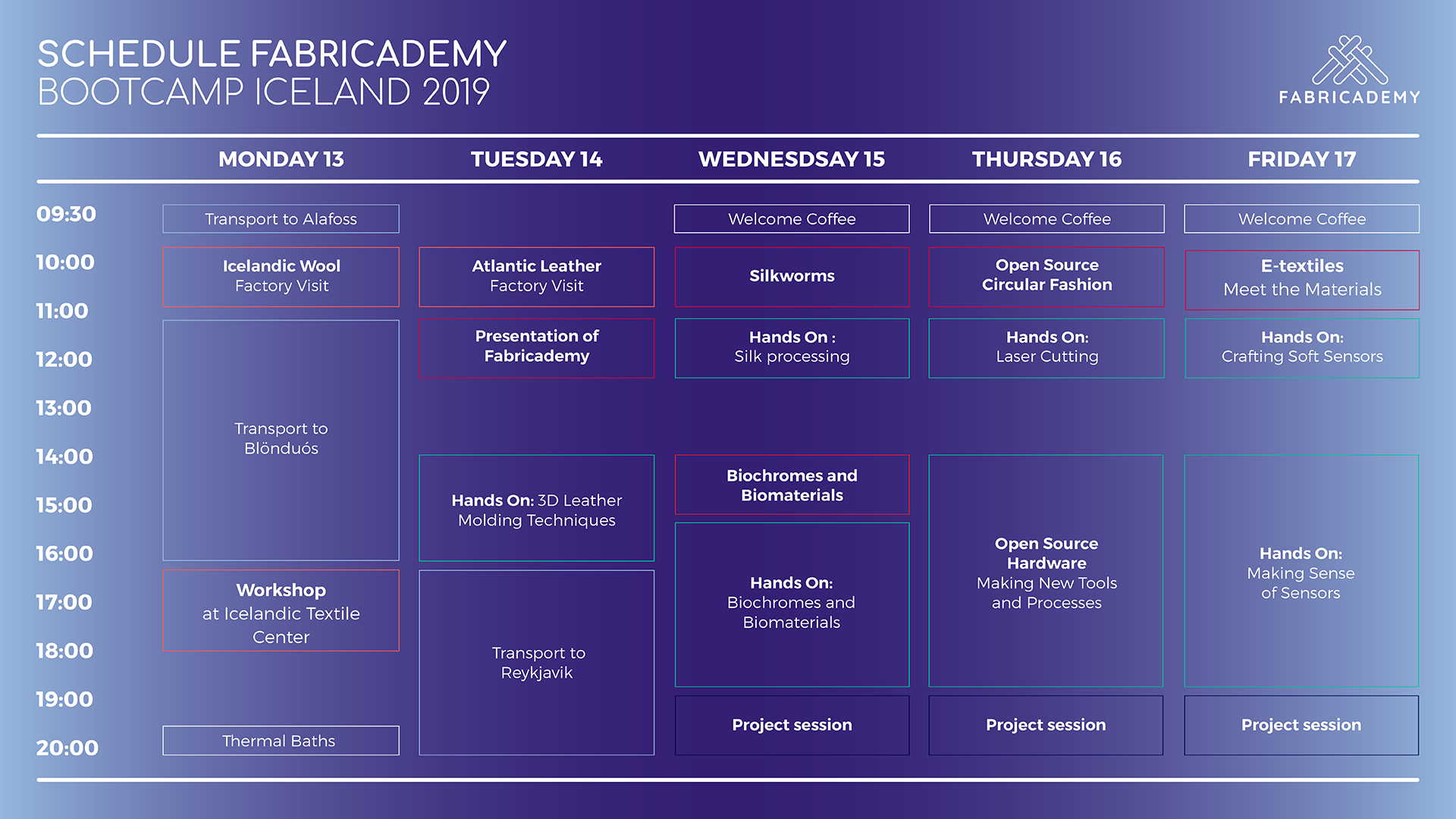

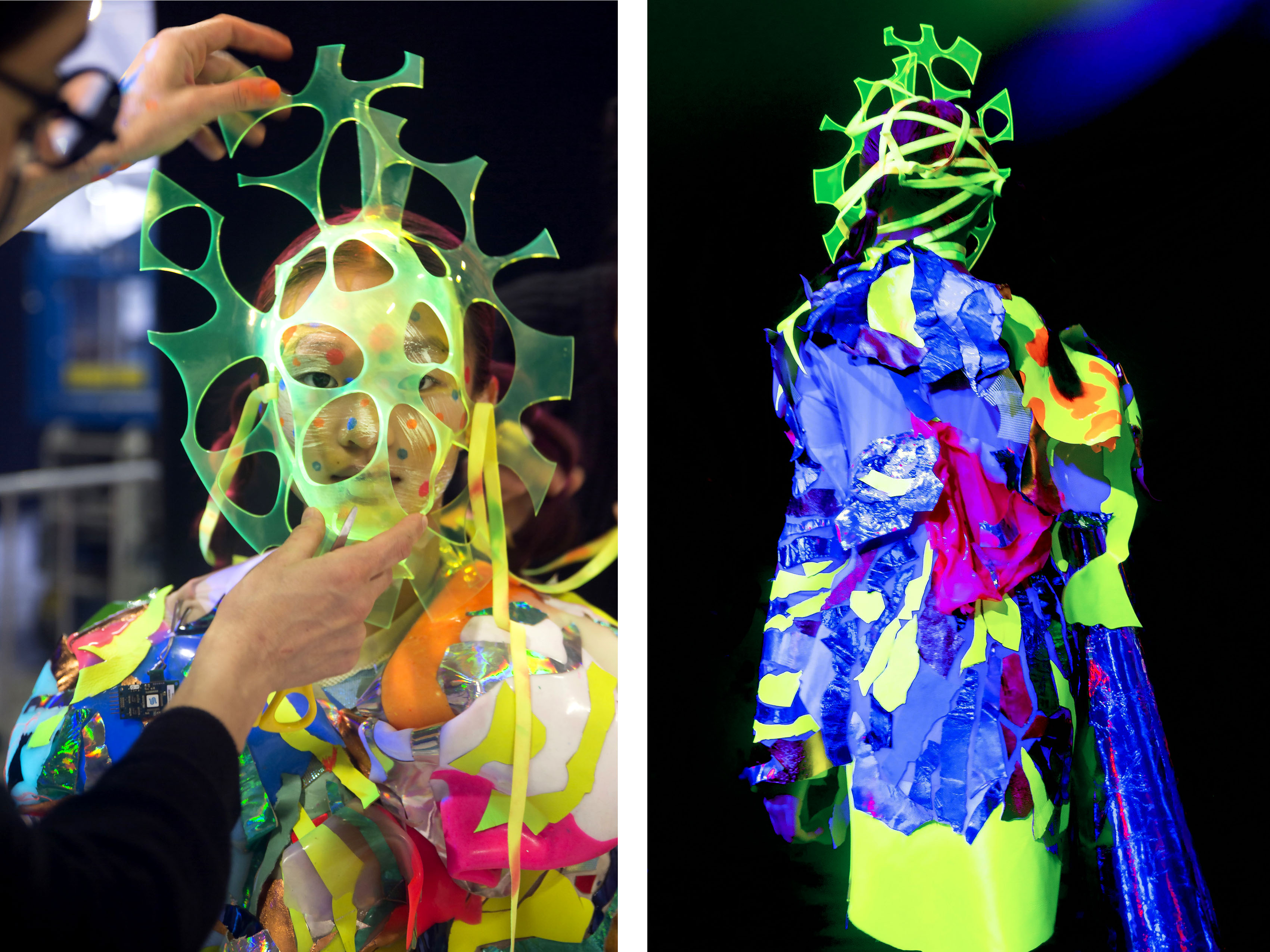

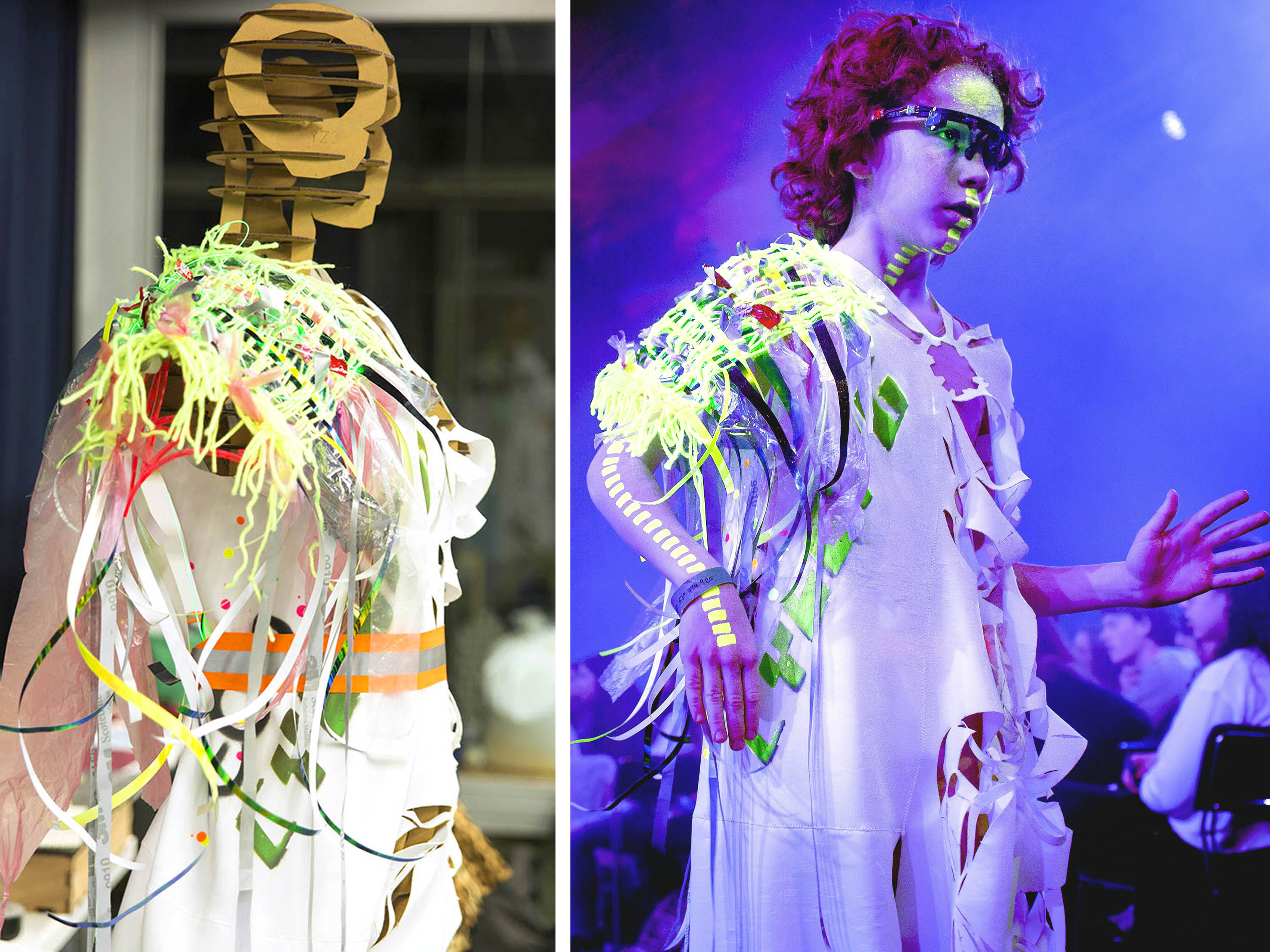

Runway Mercedes Benz Madrid Fashion Week / July 2019

Runway Mercedes Benz Madrid Fashion Week / July 2019

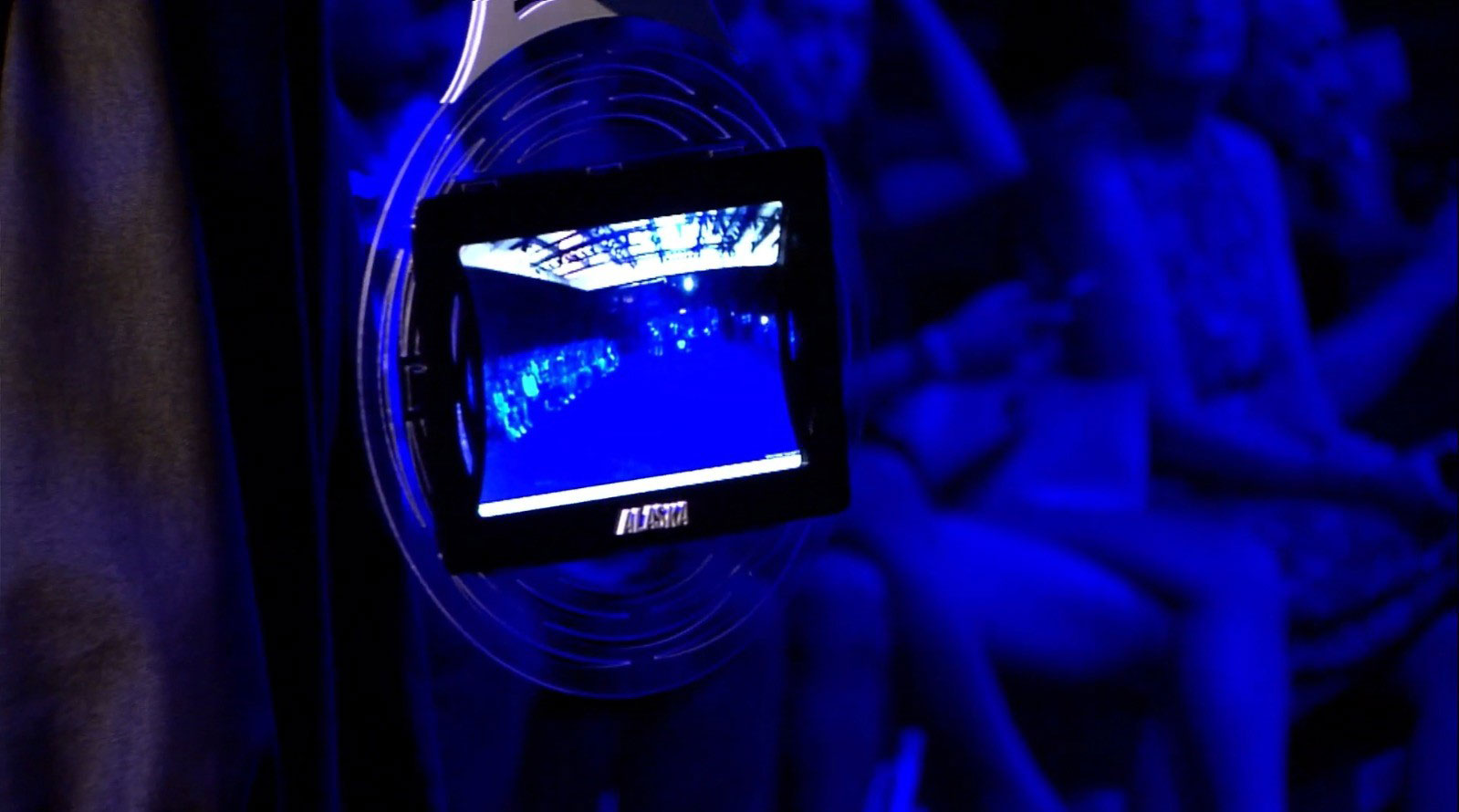

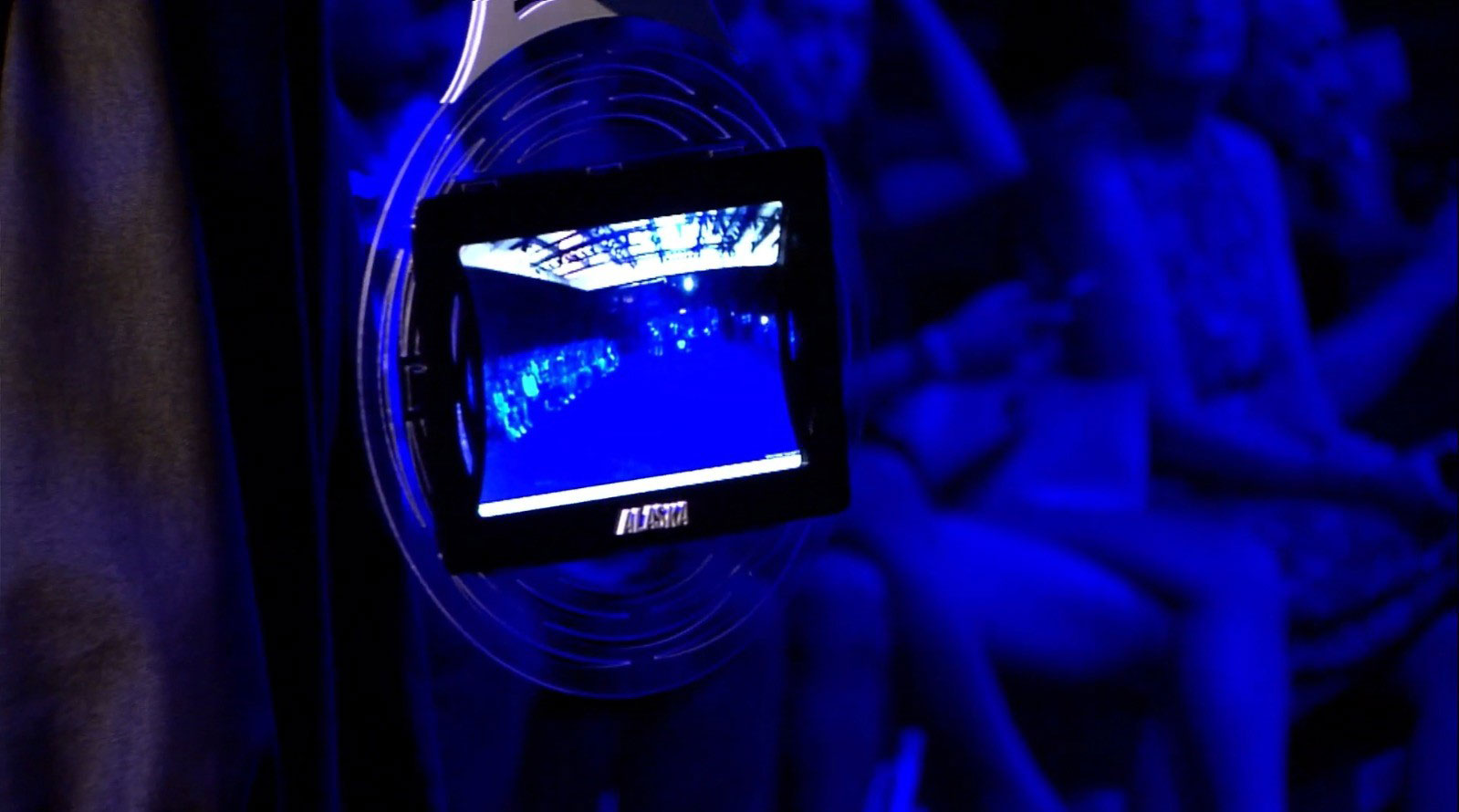

LOOK 1 / Concentric Hat -Input: Sound vibrations (microphone sensor) -Output: Rhythmic flashing of the lights (neo pixels) integrated in the prototype. Visualization of the sound vibrations received at the moment, on the tablet device.

LOOK 2 / Aurora Cap -Input: The device is connected via Bluetooth using the Android APP "Adafruit Bluefruit". -Output: This APP allows the user to select between 16 million colors, the adjustable brightness of the light source and also use this app to generate their own color light show.

LOOK 3 / Lamp Hat

-The hat contains a custom board, in which a rhythmic code of the LEDs was turned on and off, based on the song of the catwalk, which was saved in ATtiny format. The LED light is channeled and is reflected in the lateral reflectance optical fiber.

LOOK 4 / Parametric Hat

-Input: A webcam incorporated into the accessory records in real time.

-Output: the filming of the runway of the model on the catwalk is displayed on the tablet device

LOOK 5 / Reflecting Hat

-The structure hat formed by a helmet printed in 3D and wing deconstructed parametrically achieved through laser cutting in methacrylate, is assembled and joined through ribbons of reflective material, which reacts to the light of the flashes.

LOOK 6 / Geological Hat

-Input: The device is connected via Bluetooth using the Android APP "Adafruit Bluefruit".

-Output: The user can select the color, but in this case of the neo pixels incorporated in the hat, which in turn are programmed to generate a loop circulation effect pattern around the helmet.

LOOK 7 / Vader Cap

-The user can change the light effects of the built-in LEDs through a button (custom circuit and board). In turn, the light is reflected in the "hair" of fiber optic embroidered by hand in the translucent layer.

PROJECT TEAM:

Project by Betiana Pavón

Mentoring by Anastasia Pistofidou

Design and production assistant Ana Correa

Electronics consulting and development Angel Muñoz and Ioannis Vogdanis

Developed in Fabtextiles, FabLab Barcelona, IAAC Institute of Advanced Architecture of Catalonia.

.

ZAGV clothes

Silvia Fado shoes

http:// Samsung EGO / INNOVATION PROJECT 2019 from ALASKA Accesorios on Vimeo.

http:// ALASKA Accesorios / Mercedes Benz Madrid Fashion Week / 2019 from ALASKA Accesorios on Vimeo.

ELECTRONIC COMPONENTS USED

Adafruit Feather M0 Bluefruit LE

Attiny85

Adafruit Microphone / Breakout Boards

Programmable RGB LEDs

BTF-LIGHTING pixels

MakerHawk 3.7V rechargeable lithium battery

Optical Fiber / Slide Glow

Runway Mercedes Benz Madrid Fashion Week / July 2019

Runway Mercedes Benz Madrid Fashion Week / July 2019