This tutorial gives an insight into the correct choice for fabric and appropriate 3D geometries that give properties to the soft structure.

textiles

Fab Textiles Bootcamp

This tutorial gives an insight into the correct choice for fabric and appropriate 3D geometries that give properties to the soft structure.

Skin2 Elective Seminar // Biocouture// Bioplastics

What will the human of the future be like? Focusing on the human skin, as a means for protection but also a mediator of our senses and the environment, the Master in Advanced Architecture seminar Skin2 led by Manuel Kretzer and Anastasia Pistofidou, wanted to look into ways of creating novel interactions and bodily experiences.MAA students experimented with raw materials and recipes to create thin membranes and surfaces, which were further supplemented through embedded electronics. Besides developing advanced material systems, a crucial task for the students was been to think about the practical applications and implications of a second skin.

PROJECTS

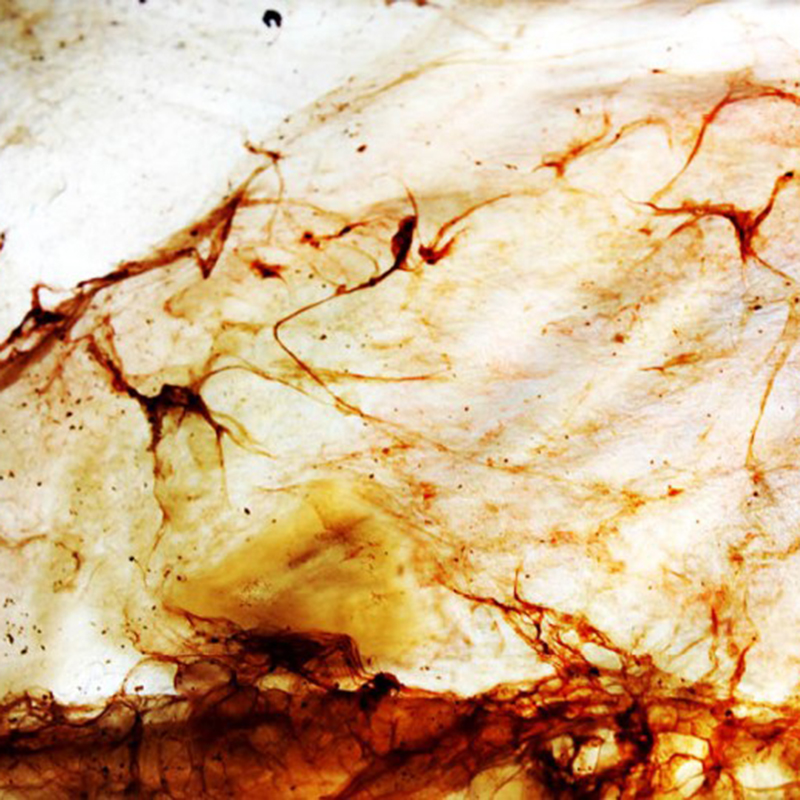

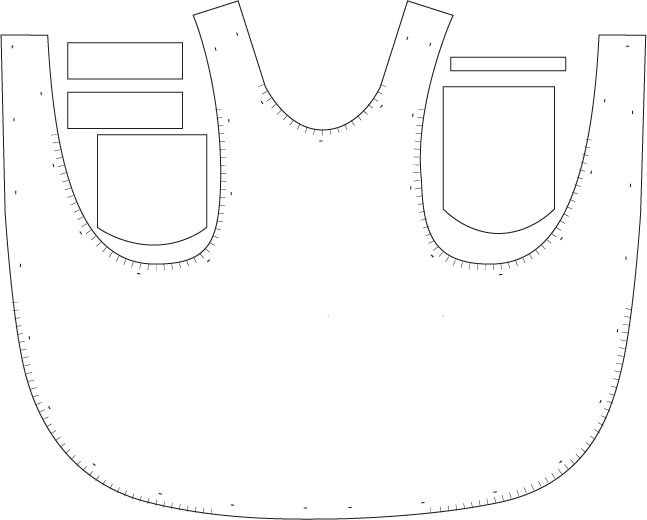

ENCRYPTED BIOMETRICS

by Jonathan Irawan, Lalin Keyvan, Jean Sebastian Munera and Connor Stevens What we envision as a result of the new skin, is that the world will no longer be defined by political or geographical boundaries, but rather territories of health zones to maintain certain liveability aspects. Whether this is a good outcome or not we shall tell. Another result of the skin is the development of a new sense, a sixth sense.As a design, pockets to analyse blood and a vein network were to combined as the encrypted biometric skin.

What we envision as a result of the new skin, is that the world will no longer be defined by political or geographical boundaries, but rather territories of health zones to maintain certain liveability aspects. Whether this is a good outcome or not we shall tell. Another result of the skin is the development of a new sense, a sixth sense.As a design, pockets to analyse blood and a vein network were to combined as the encrypted biometric skin.

Video SKINS2 – Encypted Biometrics

BIO[LUM]SKIN

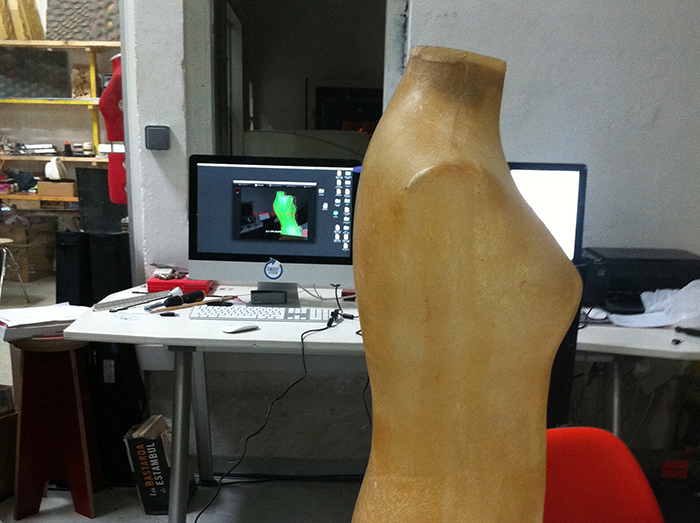

by Thora H. Arnardottir, Noor Elgewely, Jessica Dias, Ingried Ramirez We imagine a future that is completely dark. Where humans have evolved into an altered state of organisms, forming a different species interdependent on each other. Our concept for the skin was to create a new organ as an extension of the human body. We want to host living organisms on our second skin to illuminate the otherwise invisible creatures from the deep sea.We dried the bio-plastic cast on a mannequin in order for it to take the contour of the body and spine. The geometry of this wearable was developed from the hand sketches, and then translated into a 3D model using Rhino.

We imagine a future that is completely dark. Where humans have evolved into an altered state of organisms, forming a different species interdependent on each other. Our concept for the skin was to create a new organ as an extension of the human body. We want to host living organisms on our second skin to illuminate the otherwise invisible creatures from the deep sea.We dried the bio-plastic cast on a mannequin in order for it to take the contour of the body and spine. The geometry of this wearable was developed from the hand sketches, and then translated into a 3D model using Rhino.

MIURA ORI SKIN

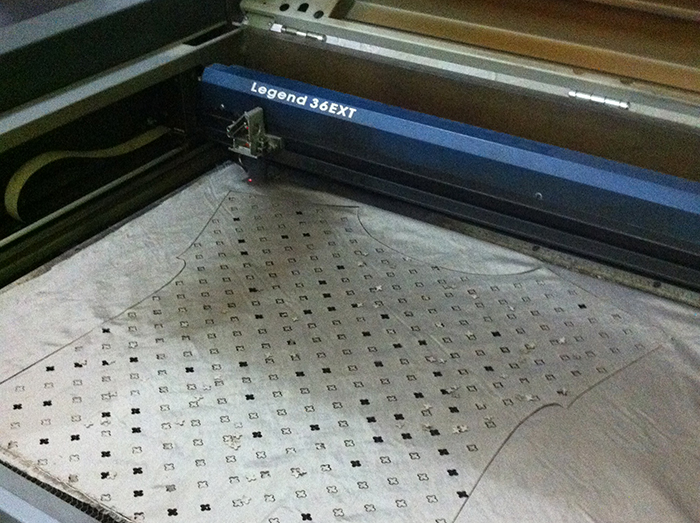

by Jengrung Hong, Sameera Chukkapalli, Hsin Li, Tanuj Thomas Based on the final system for the proposed skin design, the Material and Fabrication techniques decided are as follows: Fabric: Laser cutting / Folding, Thermochromics: Screen Printing, 3D Printing: SLS nylon / Mold casting. The Miura fold is a form of rigid origami, meaning that the fold can be carried out by a continuous motion in which, at each step, each parallelogram is completely flat.

Based on the final system for the proposed skin design, the Material and Fabrication techniques decided are as follows: Fabric: Laser cutting / Folding, Thermochromics: Screen Printing, 3D Printing: SLS nylon / Mold casting. The Miura fold is a form of rigid origami, meaning that the fold can be carried out by a continuous motion in which, at each step, each parallelogram is completely flat.

VOIDSKIN

by Robert Chacon, Khushboo Jain, Christopher Wong BanteringDynamics is pleased to introduce an innovative weapons paradigm that will revolutionize the global battle against crime and disorder. VOIDSKIN (Variable Organic/Inorganic Differentiation System K_________ Inhibition N_________) transparently protects security personnel from the deleterious effects of VOID weapons technology through the thermoreaction of shielding picoparticles to the instantaneous pseudoabsolute zero generated by the discharge of a VOID weapon. VOIDSKIN’s triple layering system redundantly ensures protection against dematerialization while incorporating thermonegative resistance to plasma weapons.

BanteringDynamics is pleased to introduce an innovative weapons paradigm that will revolutionize the global battle against crime and disorder. VOIDSKIN (Variable Organic/Inorganic Differentiation System K_________ Inhibition N_________) transparently protects security personnel from the deleterious effects of VOID weapons technology through the thermoreaction of shielding picoparticles to the instantaneous pseudoabsolute zero generated by the discharge of a VOID weapon. VOIDSKIN’s triple layering system redundantly ensures protection against dematerialization while incorporating thermonegative resistance to plasma weapons.

EL AMOR EN LOS TIEMPOS DEL CÓLERA

by Justyna Brzakala, Lina Salamanca,Dirk Van Wassenaer, Pedro Levit Arroyo We will create a membrane which permits people to maintain intimacy without therisk of contamination.Intimate relationships allow a social network for people to form strong emotional attachments. These relationships involve feelings of liking or loving one or more people, romance, physil or sexual attraction, sexual relationships, or emotional and personal support between the members.

We will create a membrane which permits people to maintain intimacy without therisk of contamination.Intimate relationships allow a social network for people to form strong emotional attachments. These relationships involve feelings of liking or loving one or more people, romance, physil or sexual attraction, sexual relationships, or emotional and personal support between the members.

Video El Amor Ee Los Tiempos Del Cólera

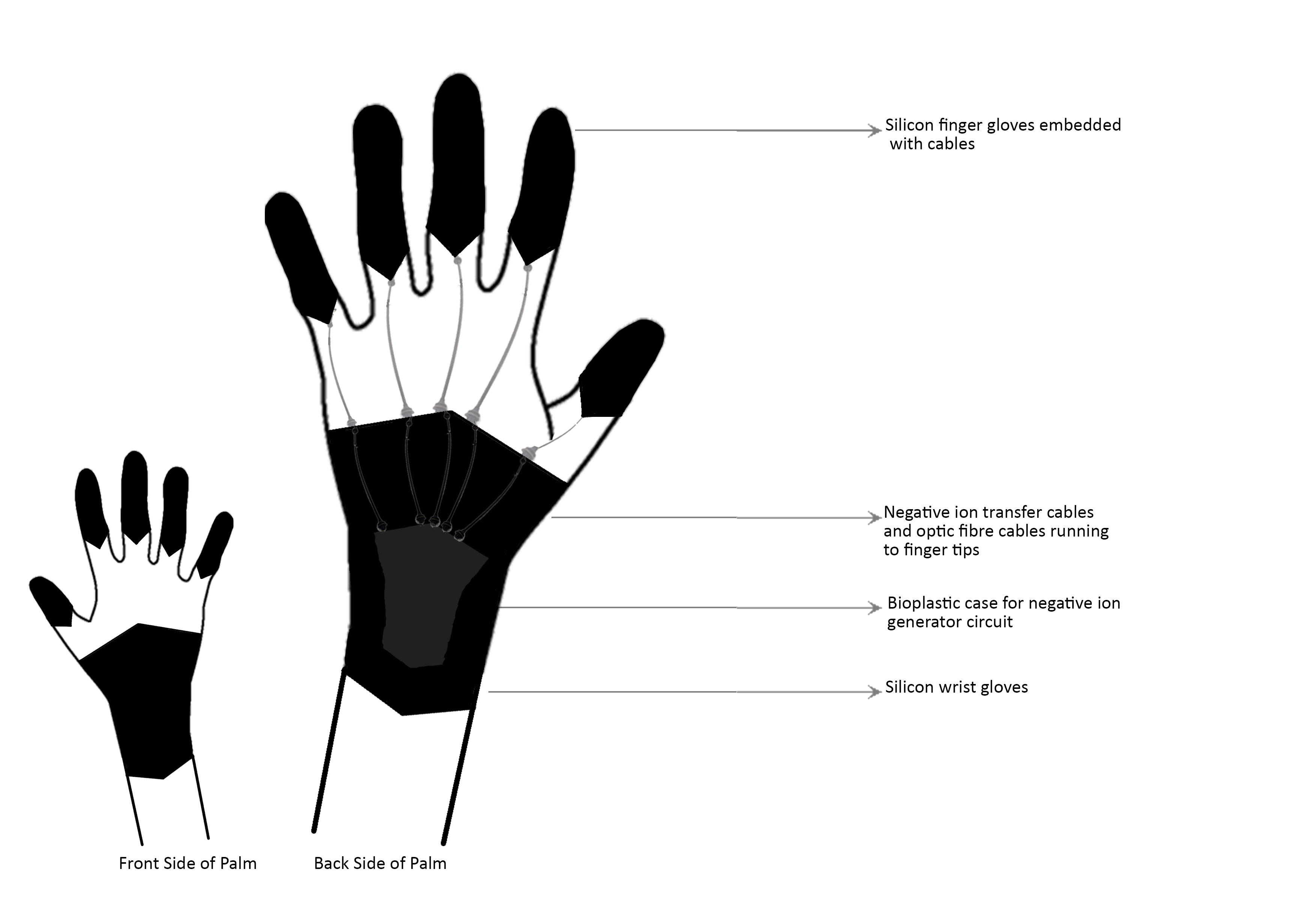

RE[SKIN]ULATE – [ION]TEX

by Sahana Sridhar, Nisarg sheth, Anastasia Stephany

What we need is a second skin that could produce or attract negative ion for our body. Therefore we try to invent a new material which we named [ION]-Tex. From all the experiment and research, it was figured that the best way to achieve our goal is to combine few steps with turpentine and graphene with the silicon mold, to make sure that the prototype could work. This material that we found could be produce as vary products such as blanket, mask, belt, etc.

What we need is a second skin that could produce or attract negative ion for our body. Therefore we try to invent a new material which we named [ION]-Tex. From all the experiment and research, it was figured that the best way to achieve our goal is to combine few steps with turpentine and graphene with the silicon mold, to make sure that the prototype could work. This material that we found could be produce as vary products such as blanket, mask, belt, etc.

Video RE[SKIN]ULATE – [ION]TEX

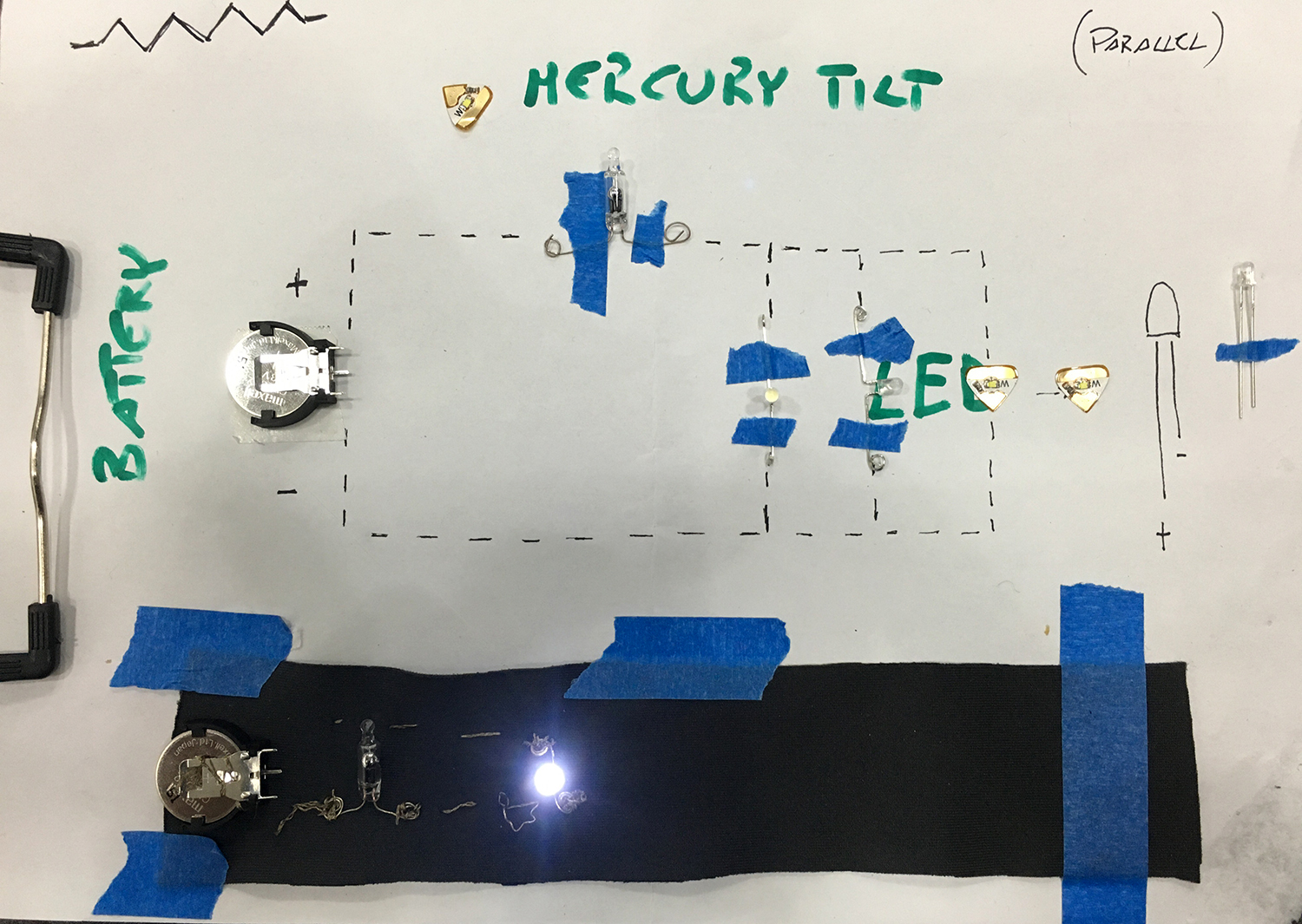

The first phase of the seminar focused on creating new materials or combining existing materials into advanced composites, with a particular focus on bioplastics and kombucha. During the second part of the course students could investigate the augmentation and actuation of the material systems through means of electronics and physical computing.

The final phase was reserved to developing a functional application, working prototype and speculative future scenario, presented through means of video and material catalogues.

SKIN2

What will the human of the future be like? Ray Kurzweil predicts the ‘Singularity’, the progressive amalgamation of the human brain and machine intelligence. Aubrey de Grey understands aging as a disease that can be cured and may lead to infinite life extension. And Zoltan Istvan, who with his ‘Transhumanist Party’ is currently running for US presidency, advocates -among other things- the technological enhancement of the mind and body through robotics and smart devices. Within the context of ‘Humanity +’ we want to explore the possibilities and potential effects of augmenting the self and extending the body. Focusing on the human skin, as a means for protection but also a mediator of our senses and the environment we want to look into ways of creating novel interactions and bodily experiences. We will work with raw materials and recipes to create thin membranes and surfaces, which will be supplemented through embedded electronics. Besides developing advanced material systems a crucial task will be to think about the practical applications and implications of a second skin.

The first phase of the seminar will focus on creating new materials or combining existing materials into advanced composites. During the second part of the course we will investigate the augmentation and actuation of our material systems through means of electronics and physical computing. The final phase is reserved to developing a functional application, working prototype and speculative future scenario.

Fab Textiles SHOWCASE @ FAB10

THE SHOWCASE

This selection of young and skilful creators that combine fashion design, technology and wearables. Different materials, crazy ideas and unique processes are realised. Sensor driven textiles, digital couture and interactive performance come into our everyday life. Architects, fashion designers, engineers and programmers in multidisciplinary synergies reinvent and establish new ways in approaching fashion, wearables, materiality and local customised production. The showcase tries to cover this rich and creative landscape with a selection of creators all over around the world that use digital technologies for Fashion, Wearables and Performative Arts.

The showcase came up as an idea to compile this tendency in fashion and present garments that come from different contexts. Brands based in Barcelona, such as Jorge & Esther, start ups that are doing hardware development inside the fab lab, such as FirstV1sion, work of students in local Fashion Schools, IED, ESDI and international creators based in other Fab Labs, such as WAAG Society in Amsterdam, Fac Lab in Paris, artists like Afroditi Psarra during their artistic residency at EASTN that work with e-textiles and performance.

FAB TEXTILES questions the way fashion industry and education have transformed our life in prototypical and excessively accelerated manner. Inside a triggering and innovative environment, the fab lab sets the ground for experimentation on new materials and processes through a technological prism that addresses innovation and entrepreneurship. New ways of manufacture are carried out, combining traditional methods and new digital tools. Under this context, you can navigate between integrating some sensors on a wristband or making a four meter long tessellated dress with wood.

The last two years inside IAAC FAB LAB BARCELONA, through projects, workshops, collaborations and curiosity, various techniques have been applied for a research in the evolution of the way we create, produce and consume our clothing. This applied research is about integrating technological advances into the textile industry and education for an evolution for the future economy. Where does out body stop, where does space begin, how can we augment our body and how we can redefine what is the border being architecture and human. Can we imagine the same product being produced in a distributed manufactured way, inside a Fab Lab , taking different form according to local materials and consumer needs? How is the paradigm of fast fashion changing into a more conscious, custom and experimental way? What are the additive values and where does innovation flourish and expand?

Cecilia Raspanti @ Fab Lab Amsterdam

Cecilia during her residency – internship at Fab Lab Amsterdam has created a collection inspired by the complexity and beauty of the forms of nature. “Natural forms, patterns, surfaces and processes that create what surround us. But even more important, because we are talking about digital fabrication, the limits and the boundaries of each machine are really what guided my project, as they are different than the ones i normally encounter as fashion and textiles designer.”

Cecilia’s work opens a dialog of design thinking where material, laser cutting and pattern co exist, one setting the parameters for the other.

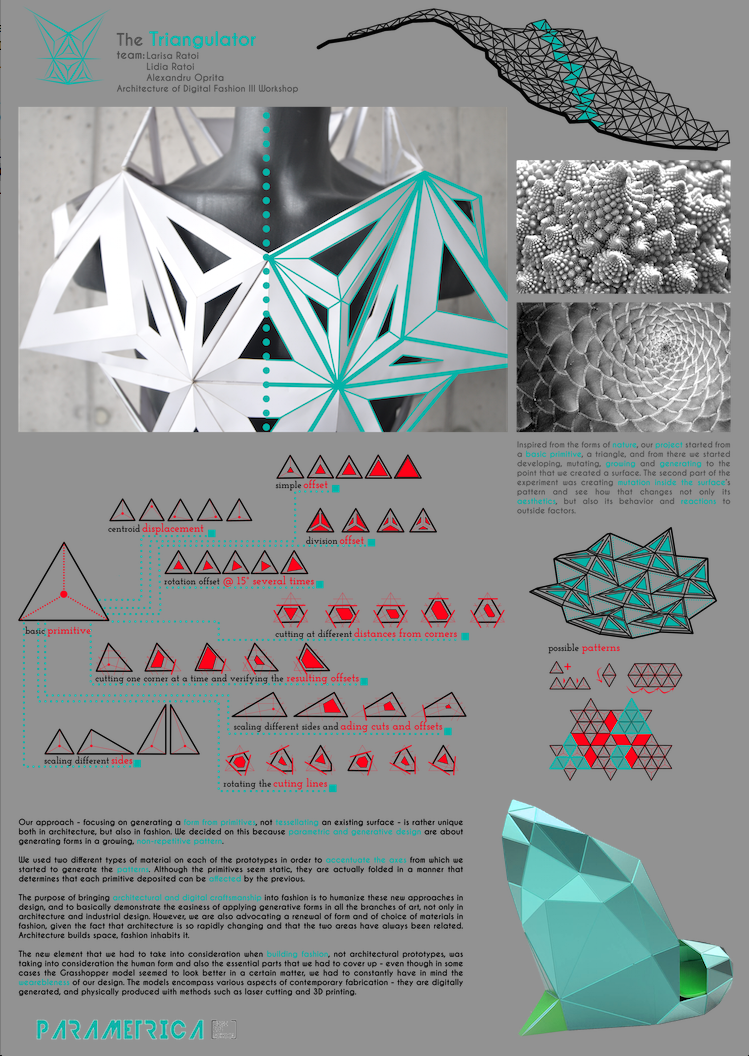

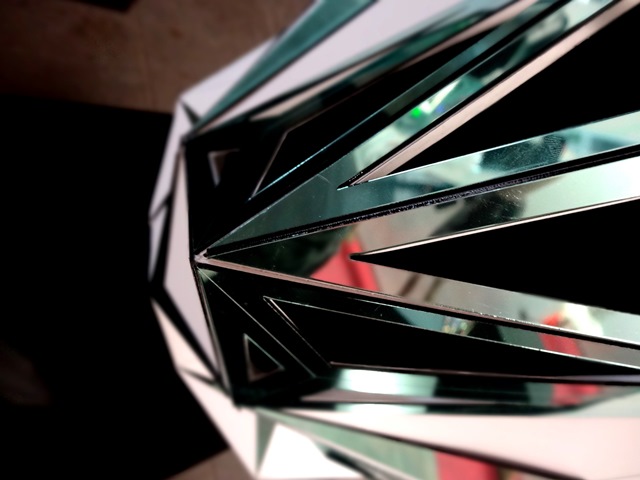

Parametrica Digi Fab School @ Romania

Diana Ditrenau leads together with young Romanian experts, designers, developers or architects, Parametrica, digi fab school. Experimental-workshops created by the school present projects like Exoskeleton Dress(designer Andrei Moldoveanu) and Hands Off Skirt (designer Diana Giurea) where architecture mixes with fashion and digital tools from other disciplines serve for fashion design.

Lume @ Barcelona

Elizabeth & Luis Fraguada

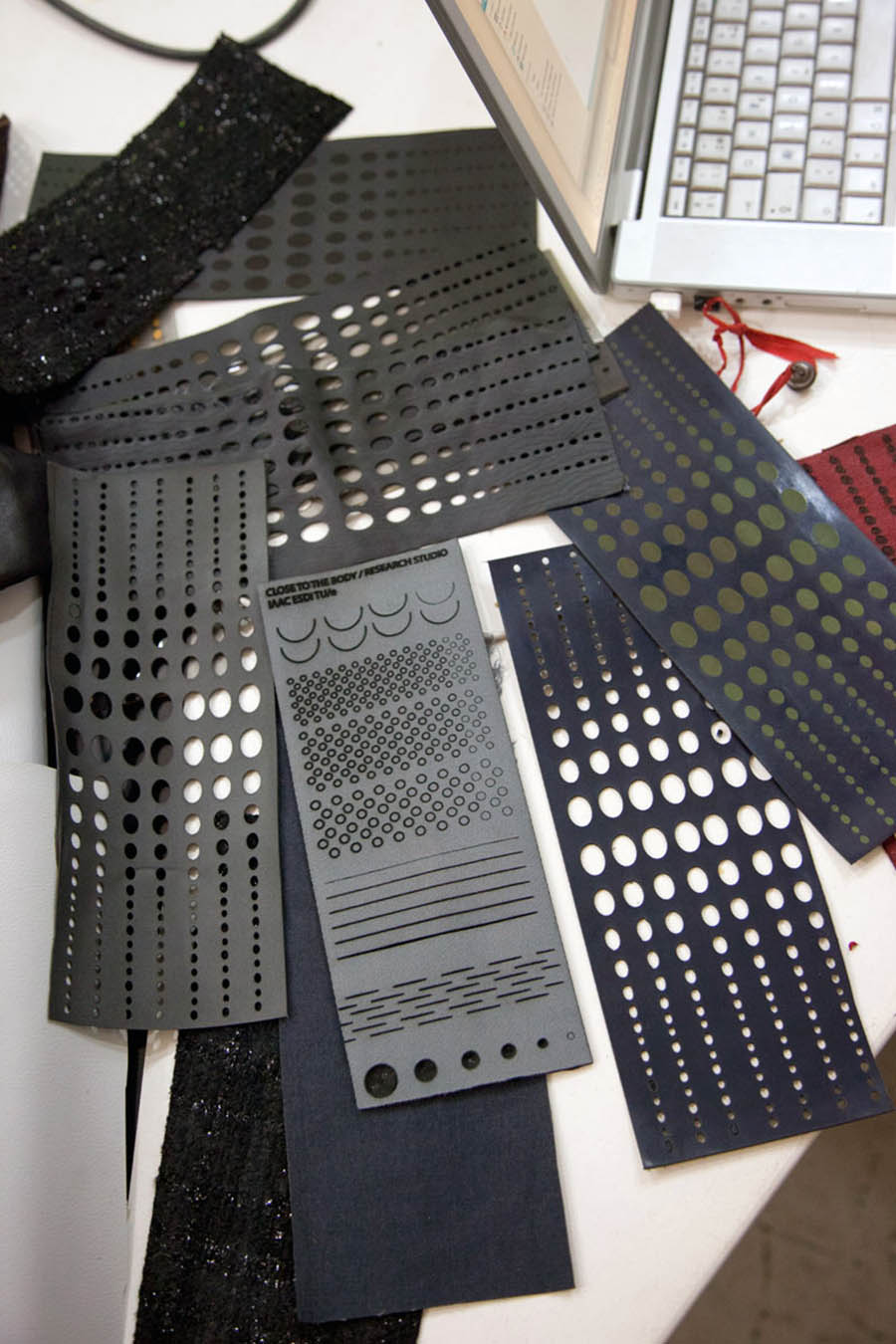

Lüme is an electronically infused clothing collection which integrates dynamic, user customisable elements driven wirelessly from a common mobile phone. The design and engineering of the collection is focused on the integration of electronics in such a way that they could be easily removed or embedded when desired, thus creating pieces that are easy to wash and care for. The initial objective for the collection was to create a series of garments that could adapt to the users daily life, changing in color depending on the event, location, mood, or even just to match another garment or accessory. The garments also can respond to sound, if the user pleases to select this option within the phone application. The laser cut piece within each garment can also be customised, to another pattern (other than damask pattern), such as polka dots, flowers, lines, etc. The entire mini collection when the electronics are not utilised, are simple black everyday garments, giving the wearer multi-use garments, for multiple looks. A true blend of fashion and technology.

Soft Articulations @EASTN

Afroditi Psarra

Soft^Articulations is a project inspired by retrofuturism and the idea of creating a soft exoskeleton that translates muscle articulations into sound. The project proposes the creation of wearable system that using handmade bend sensors on various muscle joints wishes to explore the dipole relation between the actions of relax and tense both physically and sonically. The output of the work will conclude in an interactive sound performance. The suit is inspired by the work of pioneer contemporary dance choreographer Martha Graham and her piece Lamentation, which features a stretch cylinder garment.

Afroditi works with e-textiles and performative arts not only for the development of her own projects, but also transmitting all the knowledge of making inside the context of open source culture and sharing creative commons.

Illusination

Emma Melin @IED

Illusination is a collection based on the relationship between shadow and light, the mysticism of the Arab culture and its complex geometrical patterns. How the light is shining through this patterns on the mosques and creates a reflexion of shadow as a distorted replication of form.The form of silhouette and cuts are extracted from the geometrical structure of the Arab patterns and also the drapy loose expression of Arab clothing.Colours come from the colourful Arab mosaic. Fabrics are mostly silk, a combination of flowy silk and shantung as a contrast to create complexity.

Emma Melin, during her studies at IED fashion school she discovered the Fab Lab Barcelona and the possibility of creating patterns on textiles by designing with illustrator and sending directly to the laser cutter.During her tesis presentation she made a collection that showed her designs form the first day she got introduced to this new technology until the moment she became an expert and dominated the tool.

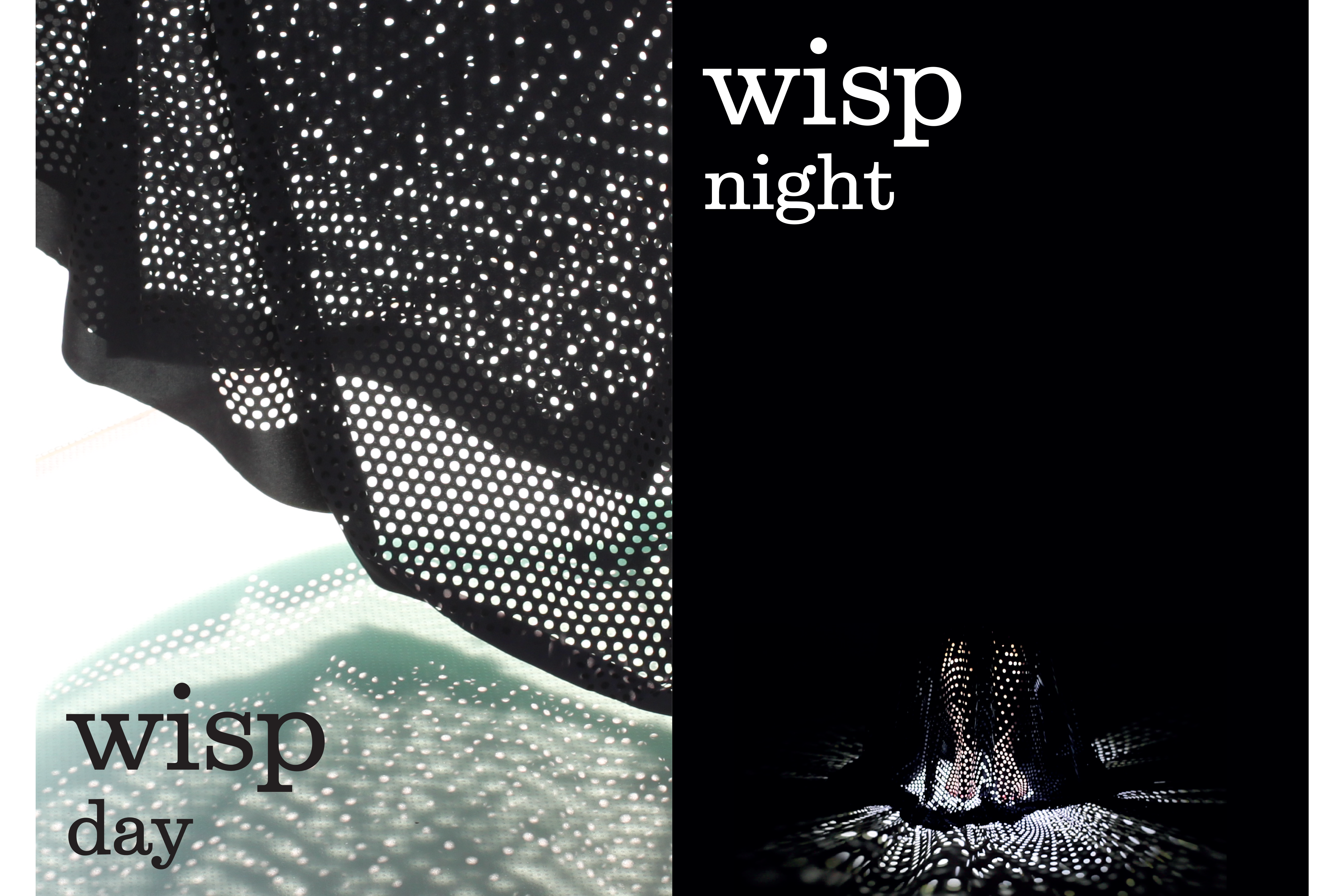

WISP

Marina Pujadas Carmen Aguilar

Wisp is traditionally defined as a floating ball of light. .The dress transforms at night. Light patterns are projected outward as its wearer turns into a beautiful and abstract light. At night, directional LEDs are worn on the legs generating an aura of organic geometry in permanent transformation alerting passerby’s of her presence as well as lighting the way through the dark. Light visualises and amplifies all movements transforming the space, creating confusion between light/shadow as well as fabric/space.

The wearable Fashion Orchestra@ESDI

Marina Castan- Gerard Rubio

The Wearable Fashion Orchestra is a live show that merges fashion and technology to establish an intimate interaction between the wearable/instrument and the dancer/performer, a textile orchestra that creates a musical composition through a contemporary dance choreography, a fashion collection that becomes a synesthetic experience.

Each garment is connected with a WiFi mesh to a computer where sounds are generated in realtime..

Blink Blink @ Milan

Mery Glez Alex Reche

Blink Blink is a T-shirt for performers that work with sound. Blink Blink reacts to the music and animates LED stripes to augment DJ performances.

Firstv1sion @ WAYRA

First V1sion is developing a new broadcasting system allowing the players’ point of view to be shown in sports such as basketball, football, tennis,athletics and many more. A jersey with embedded electronics that gives the value of integration in wearable technology that is imperceptible to the player.The system is compiled of a HD camera, zero delay transmitter, a flexible circuit board) in a well ventilated, soft, but safe material. FirstV1sion is part of the 10 finalists of Intel Make it wearable competition and is currently transmitting Euroleague games.

Fab Textiles showcase took place on 2-8 July 2014 at Fab10, the 10th international conference of the FabLabs, hosted in Barcelona by Fab Lab Bcn.The showcase wants to expand and cover the Fab Labs of the global network.

All the conventional mannequins where a kind contribution of the Superior School of Art and Design,La Llotja, by Roser Vallès.

A great thanks to all the people involved to make this exhibition happen>

Thiago Mundim, Lana Awad, Drew Carson, Efilena Baseta, Ece Tankal, Carmen Aguilar, Lucas Capelli and many many more!

Fab Textiles V5

Fab Textiles V5: Redefining pattern making and traditional seam joinery

Participants to this edition of the Fab textiles workshop were introduced to digital modelling techniques that allowed them to develop designs in Rhino and fabricate personally customised clothing using the technology provided at the lab.

The first assignment was to transform an image using Grasshopper into complex geometry using a series of data manipulations based on colour information.

Once participants had a basic understanding of digital model and manipulation techniques, they learned methods to digitally design and produce individually designed clothing. First, a mannequin was scanned using Kinect and imported into Rhino. Participants then collectively decided on the design of the garment by physically projecting lines onto the body. These lines were then imported into rhino and digitally projected onto the mannequin. These lines delineated the components that would then be laser cut from textiles and assembled as a kit of parts.

Using this process, participants have learned how to fully develop their textile based projects digitally from the design project, all the way through to development and fabrication.

Introduction to the Fab Lab Machinery

Fabrication of Textile Patterns

Rastered Textiles with Patterns

Kinect scanning of the Mannequin

Video of Digital Production:

Fab Textiles V5 from Fab Lab Barcelona on Vimeo.

Fashion design exploration with Natural hemp fibers

The Barcelona Fab textiles based in the Stigmergic Fibers (A new approach to material behaviour) designed by Jean Akanish, Jin Shihui , Alexander Dolan and Ali Yerdel in the Master for Advanced Architecture (IAAC 2012-2013_ Digital Tectonics – Fabrication Ecologies) is working in a new technology for fashion design related with natural hemp fibers.

This material is a non-woven material that allows applications without sewing on structures allowing continuity and multiple densities.

This material is a non-woven material that allows applications without sewing on structures allowing continuity and multiple densities.

Using natural hemp fibers and white glue, the application on wearables opens new concepts in fashion design based on ecological concepts.

______________________________________________________________________

Watch the video about the process in the next link:

Video of the exploration process.

Summer workshop with Fashion students of BAU, School of Design

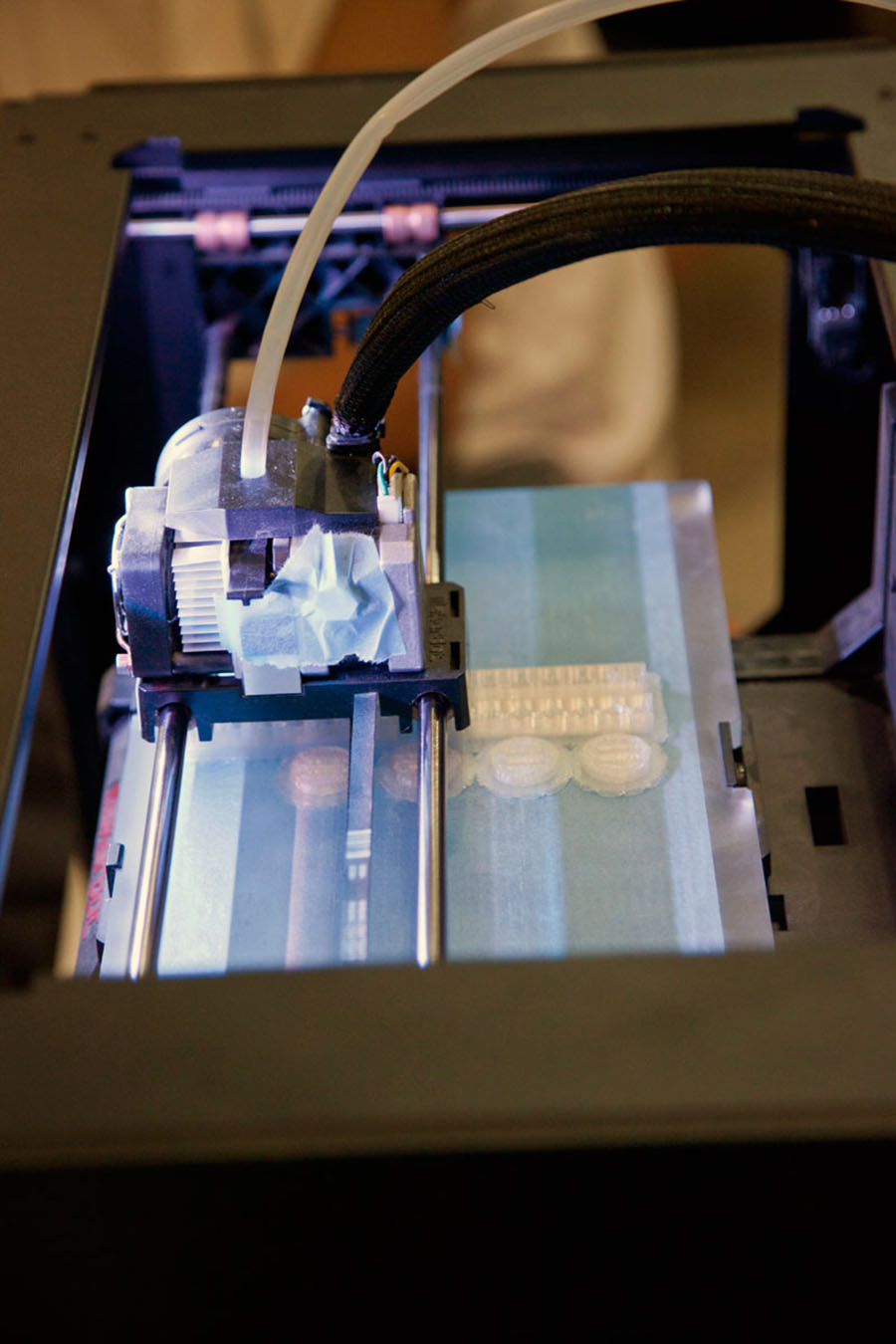

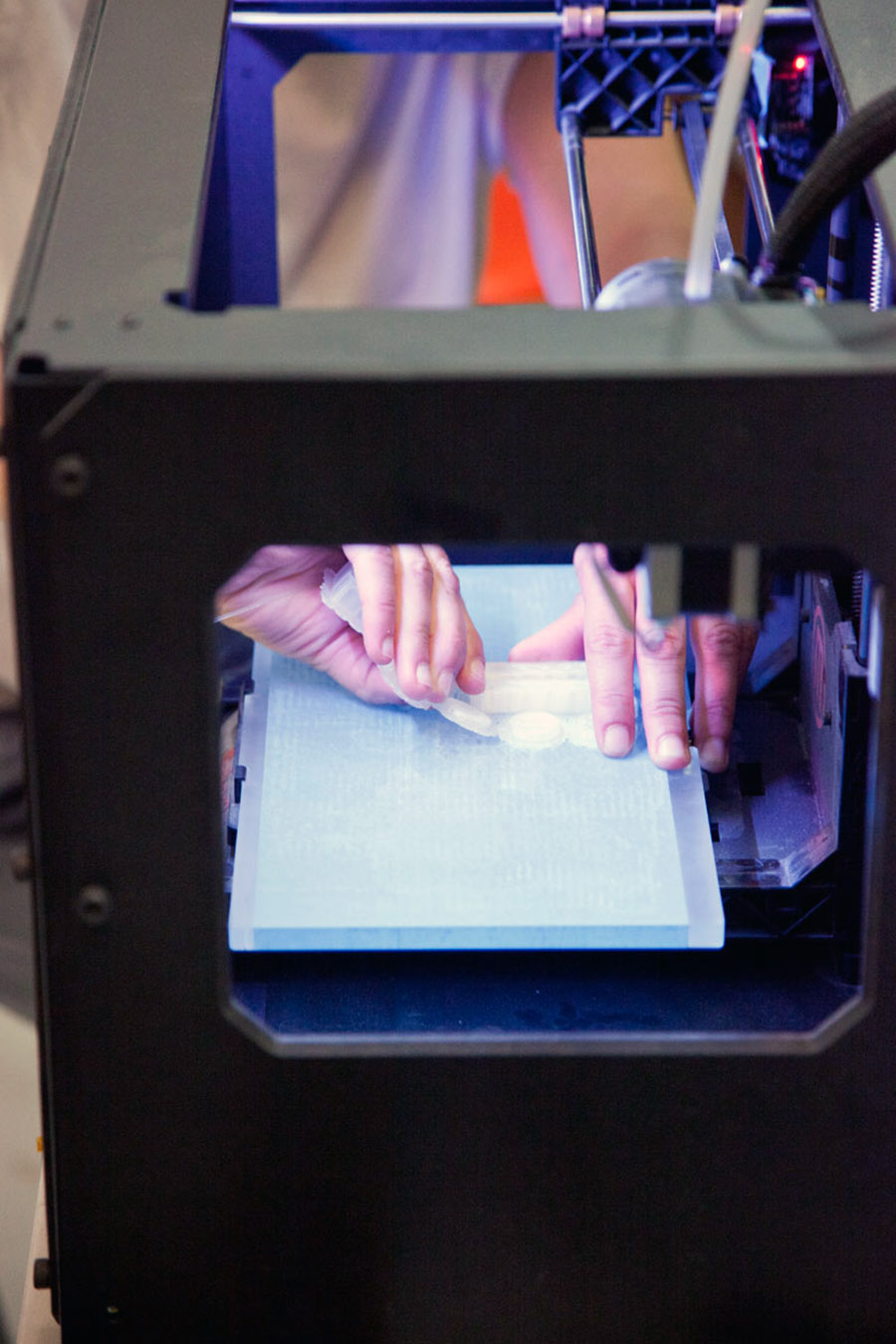

During the summer workshops, fashion students of BAU, School of Design made a workshop of digital fabrication technologies applied in fashion.Students were introduced to laser cutting patterns, laser cutting existing clothes, 3D printing and digital embroidery.Digital fabrication opens different possibilities in Fashion education, production and consumption.

The students during the workshop were introduced to the maker culture and technologies available in the context of the Fab Lab Barcelona in order to understand the possibilities of digital creation and learning by doing methods in fashion.