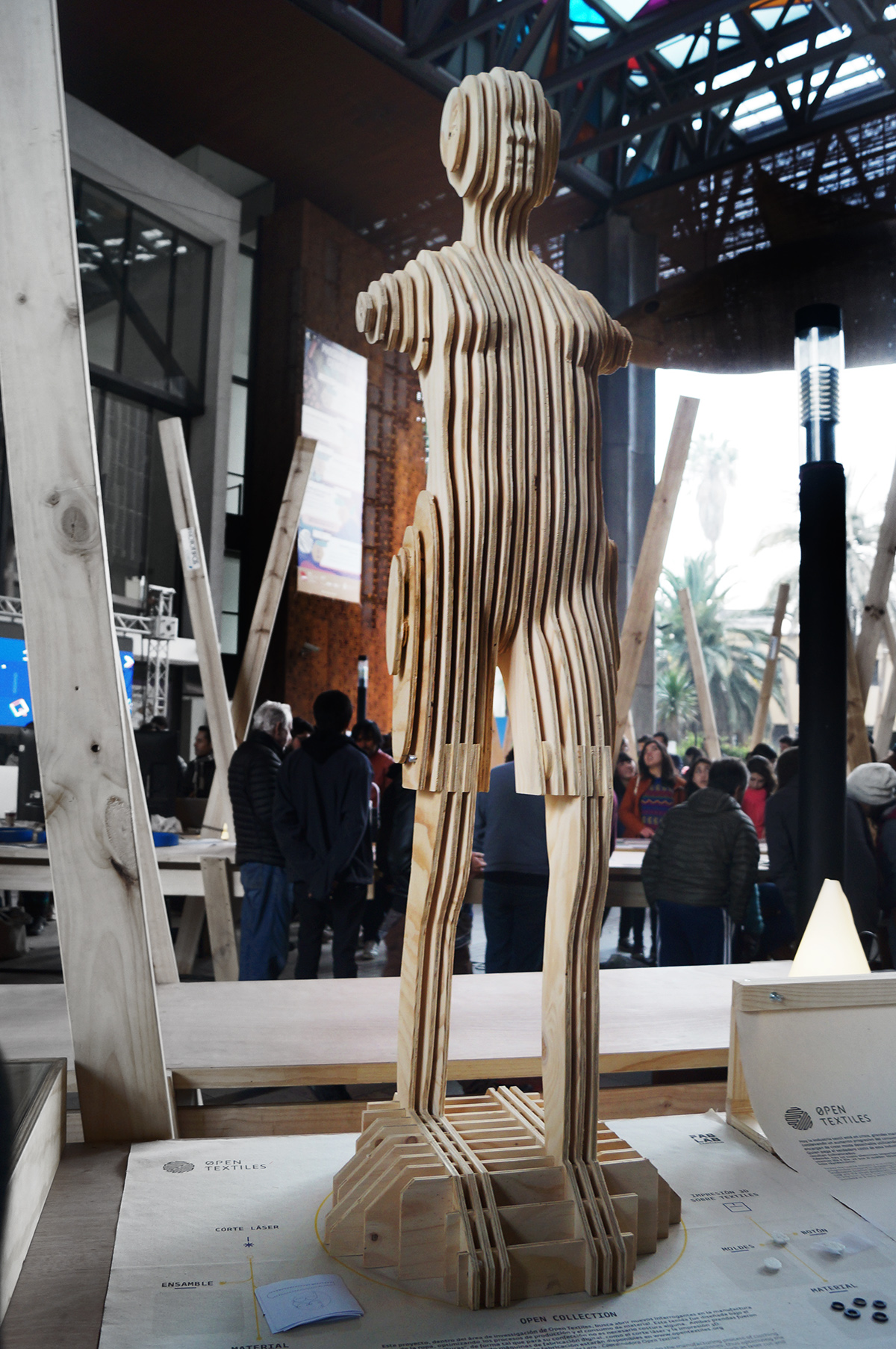

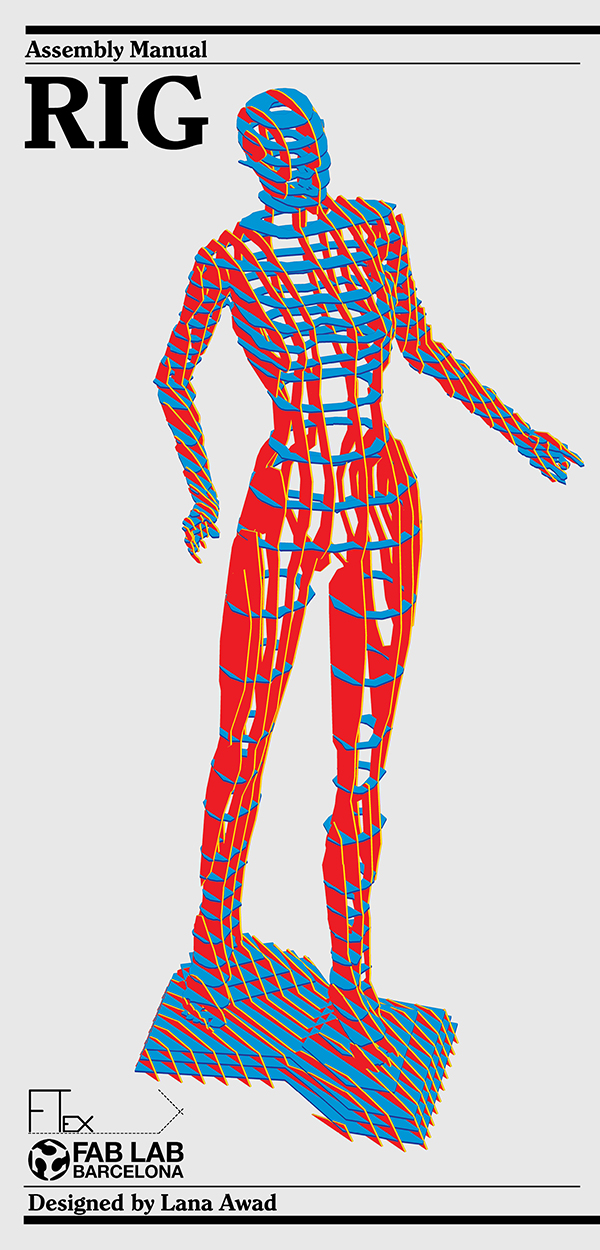

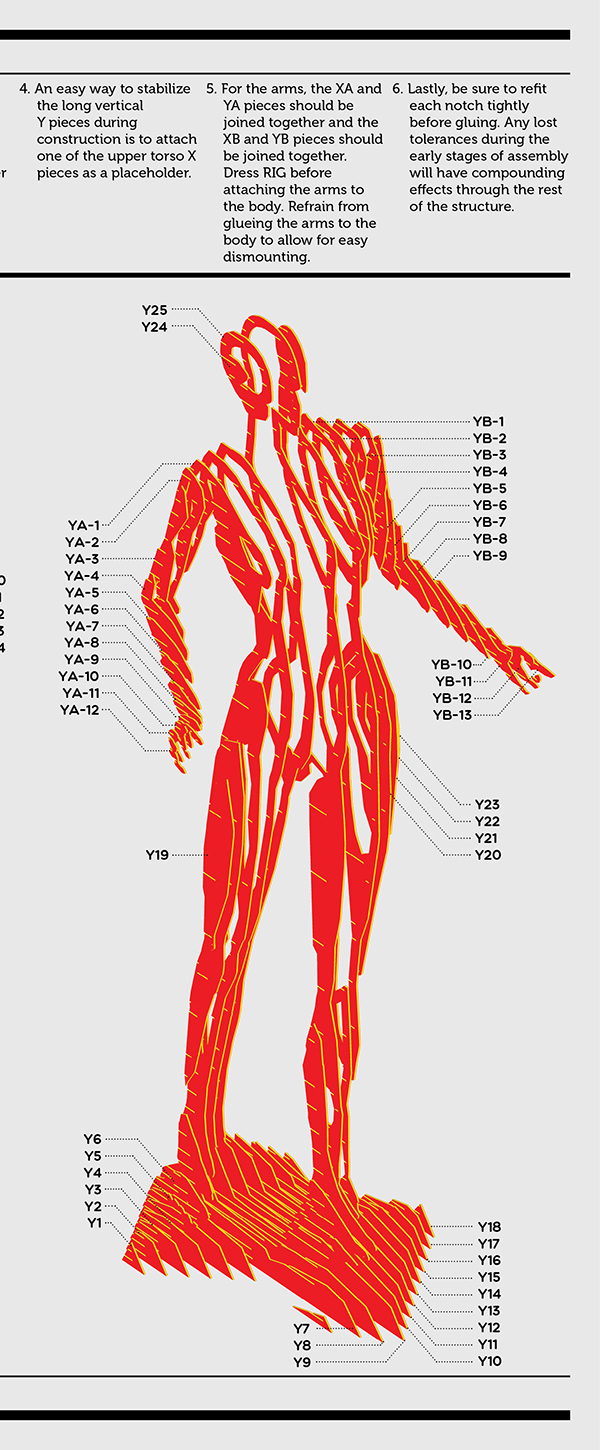

RIG is a digitally processed and fabricated mannequin designed for ¨Fab-Textiles Showcase¨ during the Fab10 international conference in Barcelona.

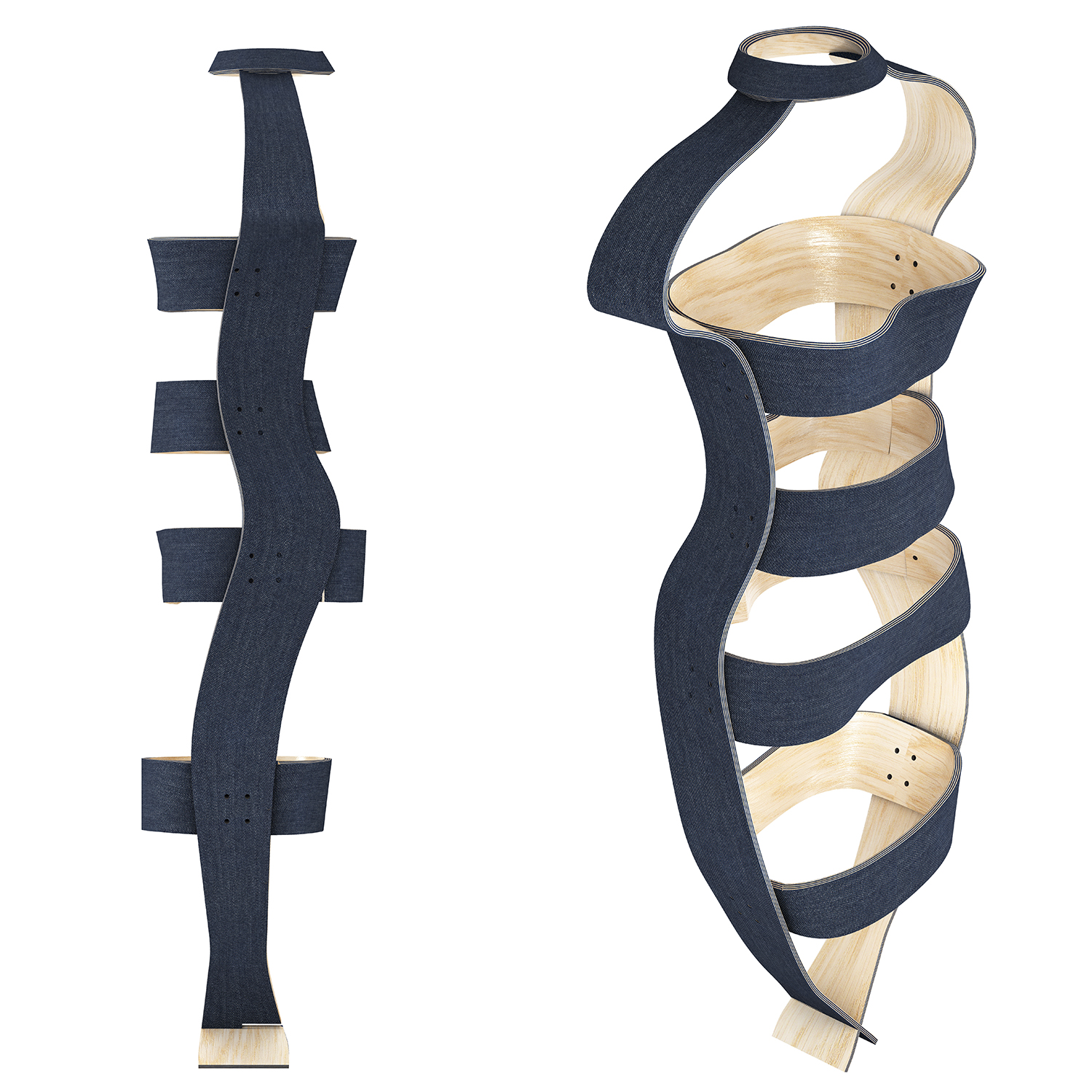

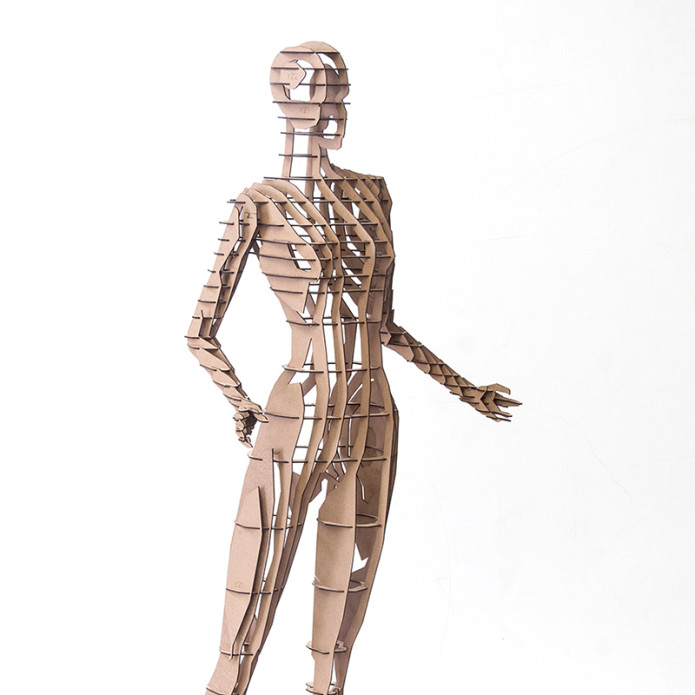

The design for RIG is an exploration into the creative potential of mannequins as tools for exhibiting and work with. RIG is a manifestation on how tools should be rethought, redesigned, and reimagined. As one walks around the waffle structure, the perspective of three-dimensionality makes the volume of the RIG appear and disappear. From the side, the physical representation of the human body is defined, yet as the visitor moves towards the front of the mannequin, the body slowly disappears, allowing the clothing to properly showcase itself.

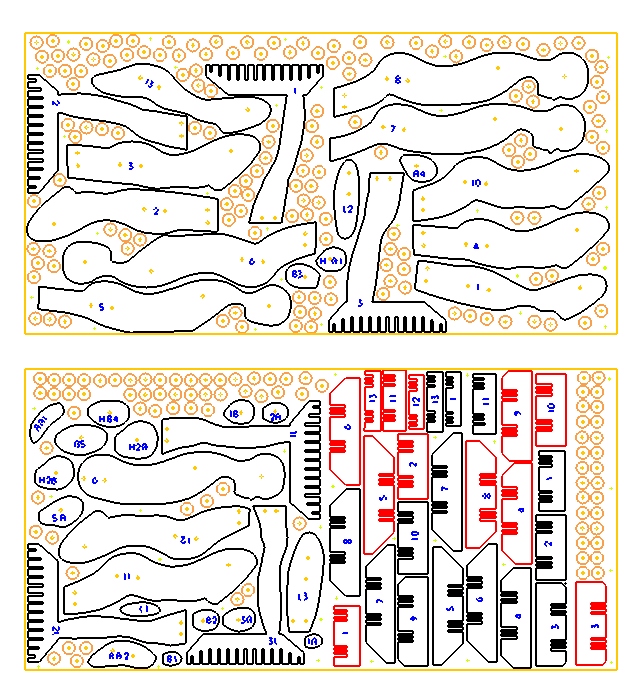

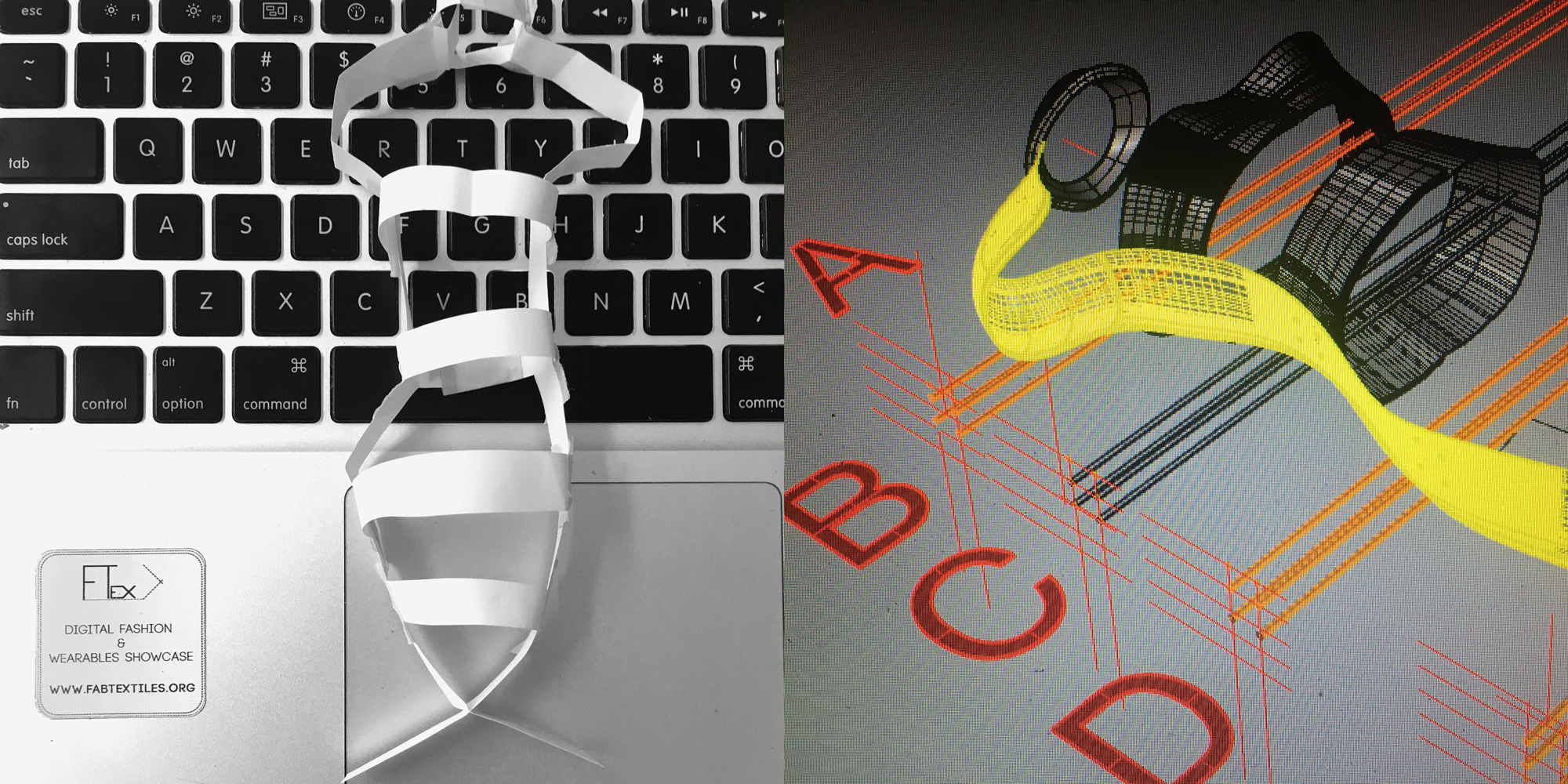

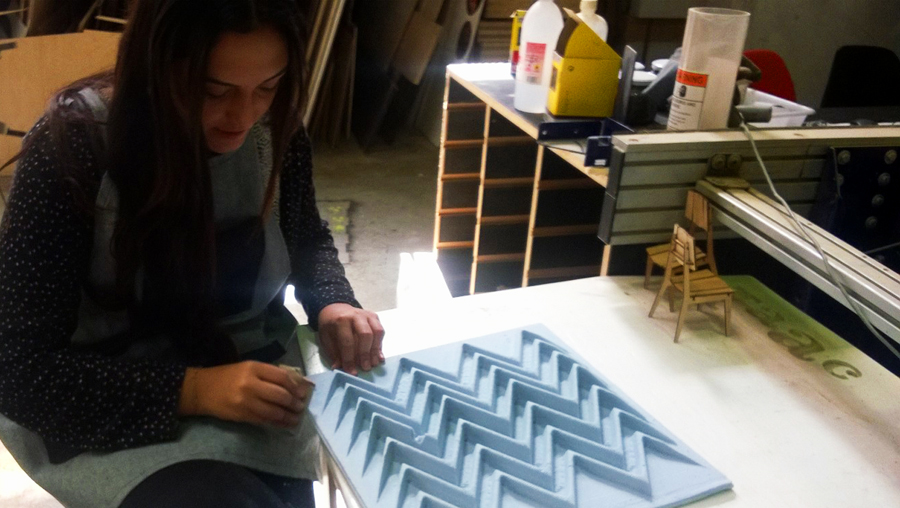

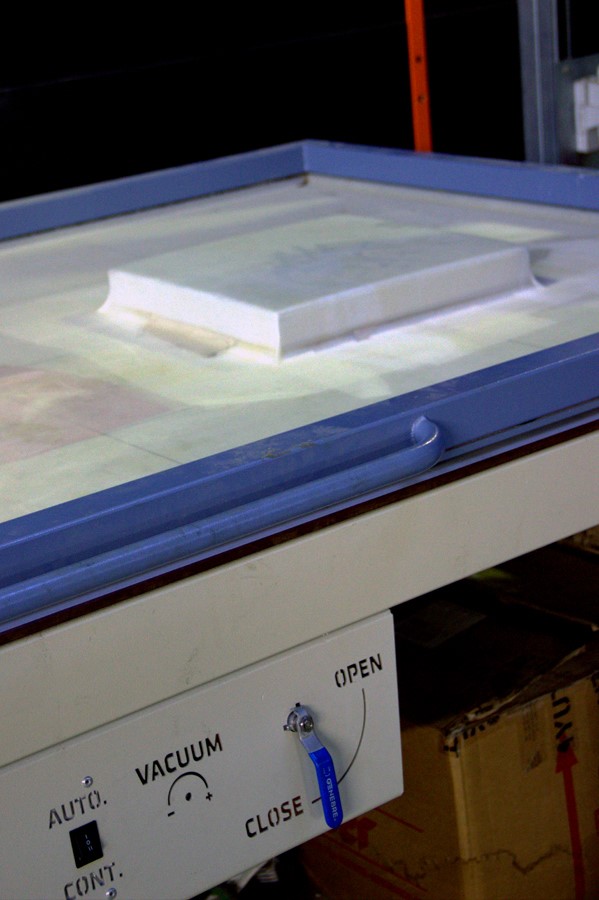

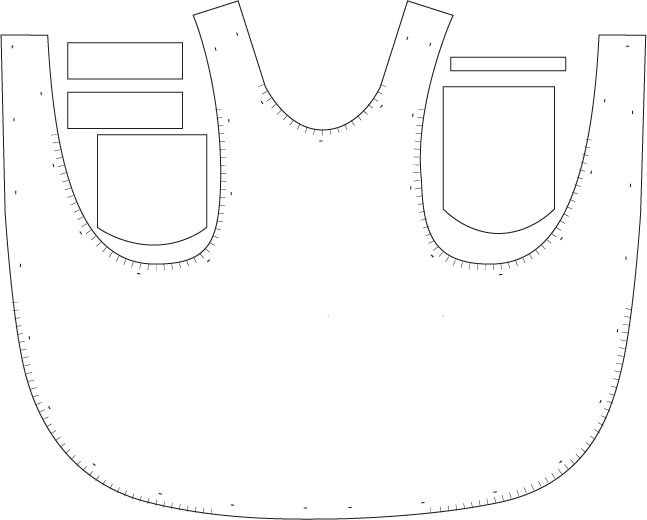

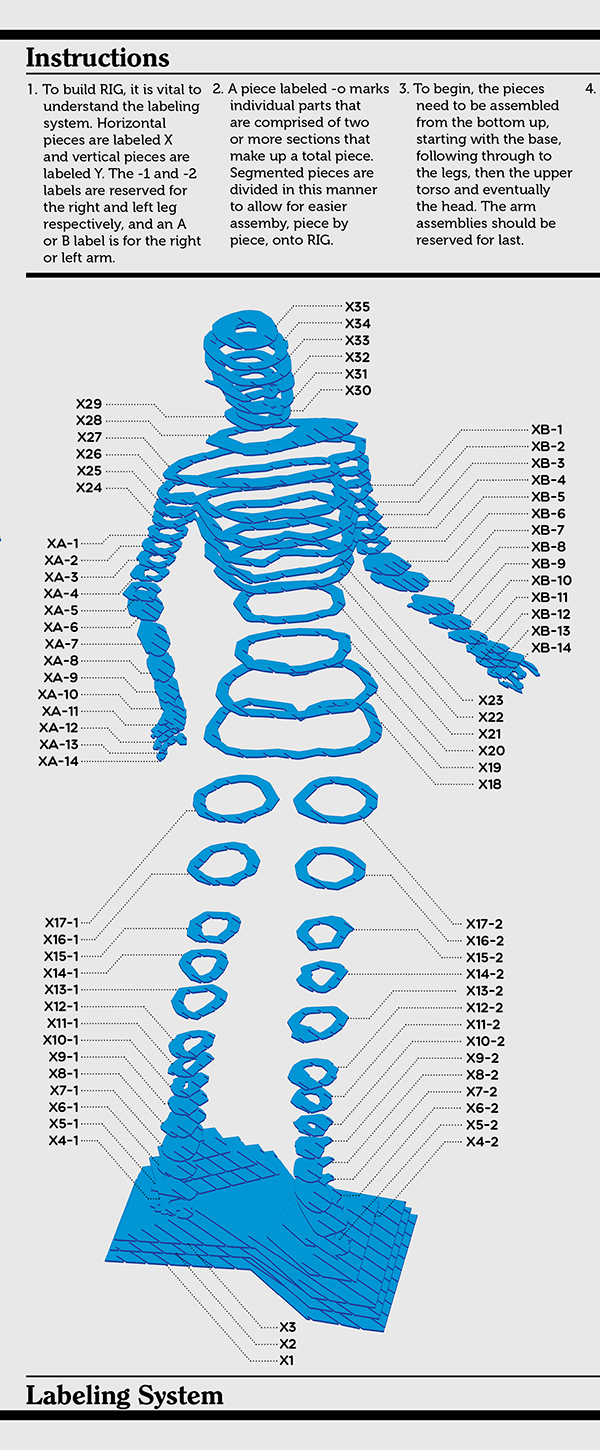

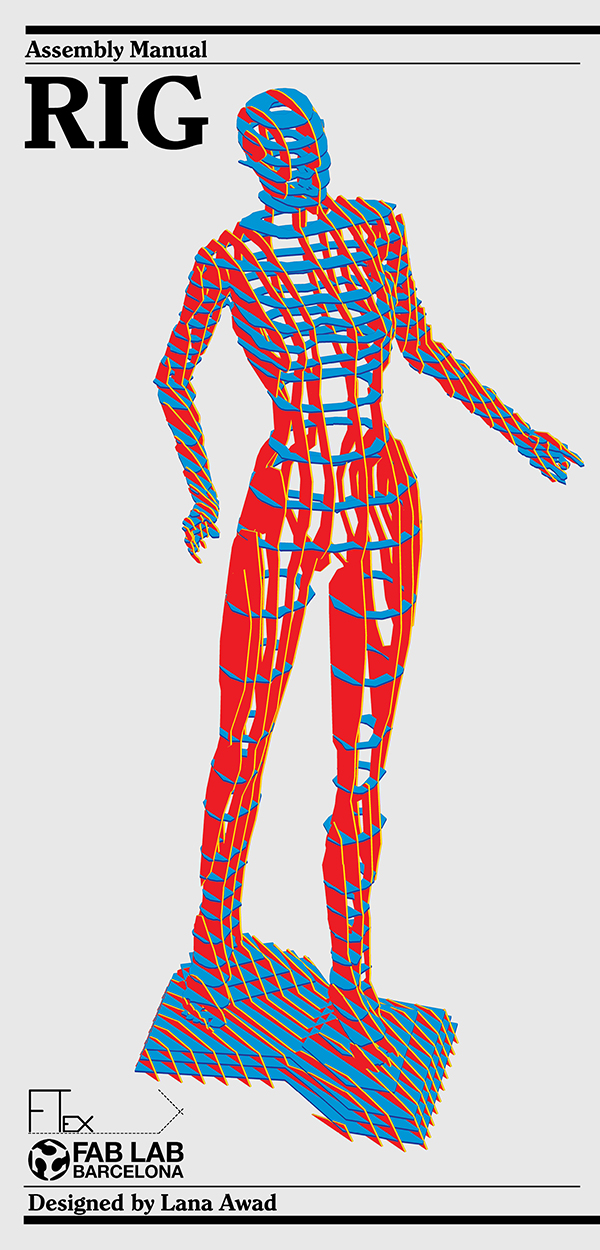

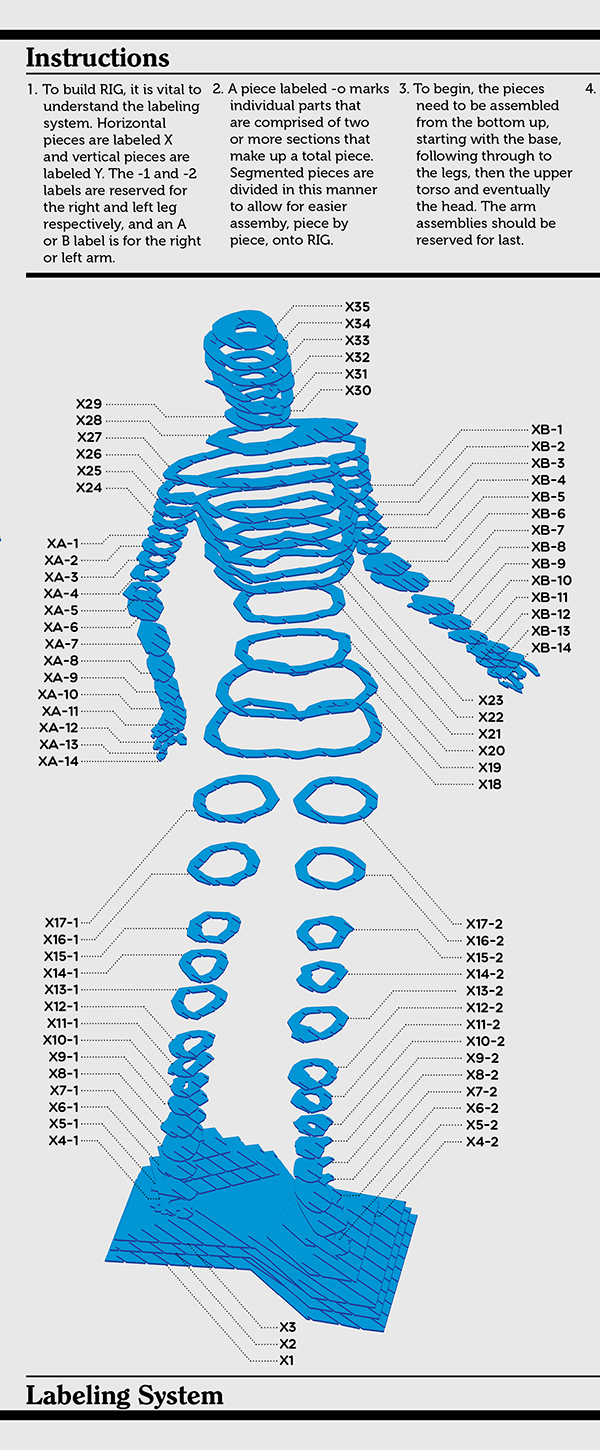

For the digital design process, the software 123d Make was used to generate the waffle structure, where you can find all the files. Each section of the mannequin required a different waffle density depending on the structural requirements and resolution of detail required. These varying strategies were applied to the right arm, the left arm, the torso and the base and then compiled into Rhino to adjust the overlapping conditions. In total, 15 mannequins were produced with each RIG consisting of 184 unique pieces lasercut out of 3mm MDF.

Credits: Fab Lab Barcelona

Design: Lana Awad

Fabrication: Lana Awad, Drew Carson, Anastasia Pistofidou

Special thanks to: Carmen/Ece/Andrea/Sebastian/Thiago/Andre/Efilena/

Photography credits: Thiago Kunz